Method for preparing CHA molecular sieve membrane in clean liquid

A technology of molecular sieve and clear liquid, which is applied in the direction of chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of unsuitable scale preparation, film thickness flux, environmental pollution, etc., to improve nucleation efficiency and reduce Generation of large particles, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

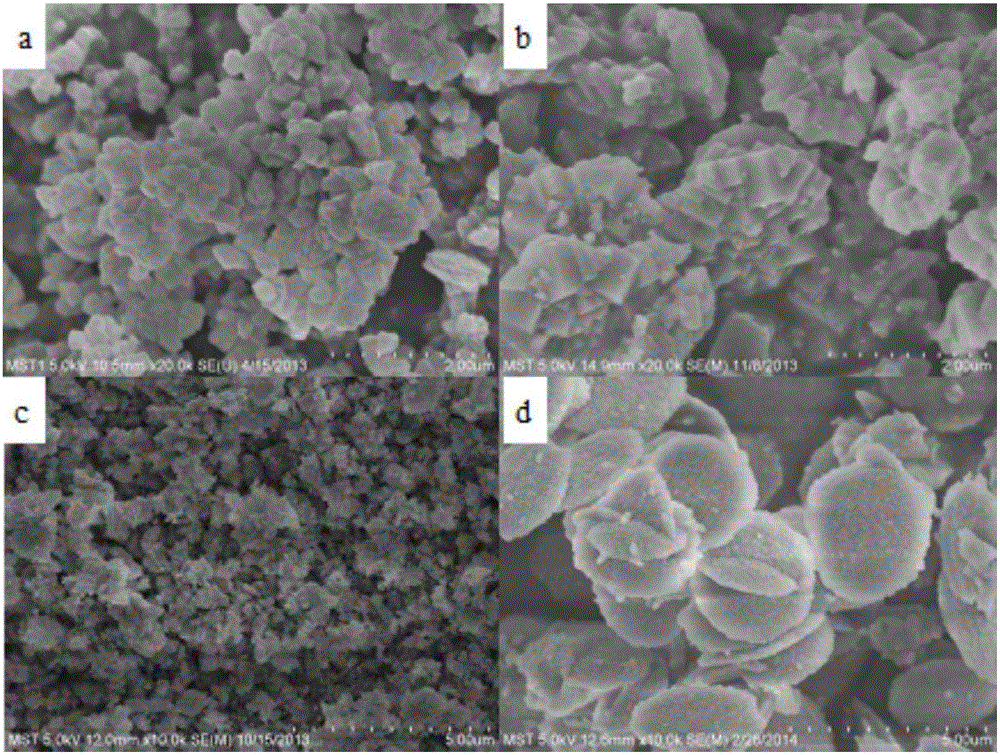

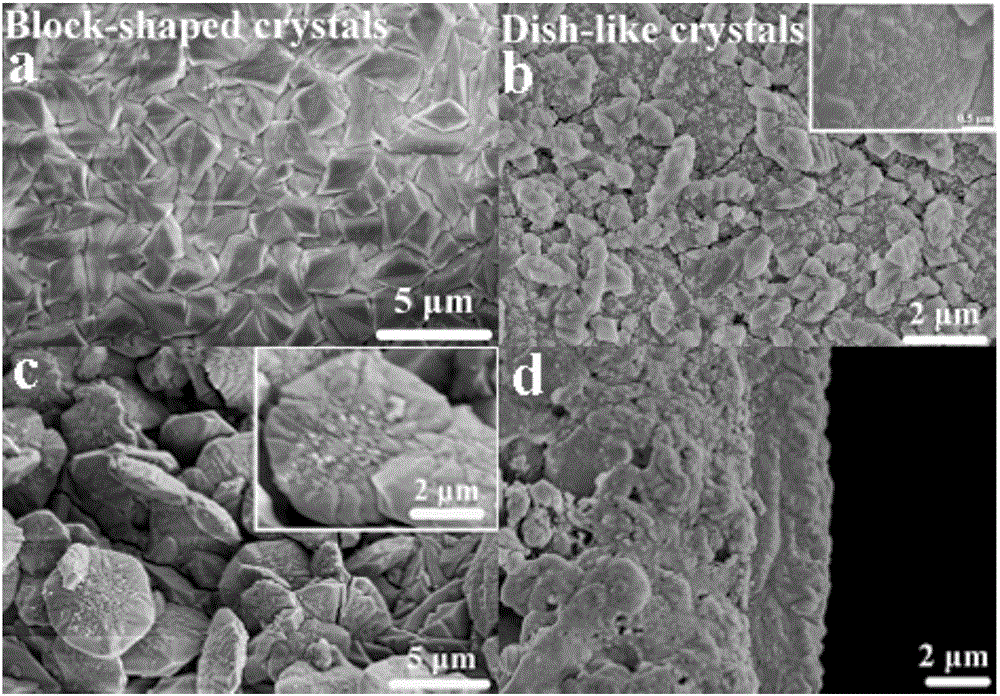

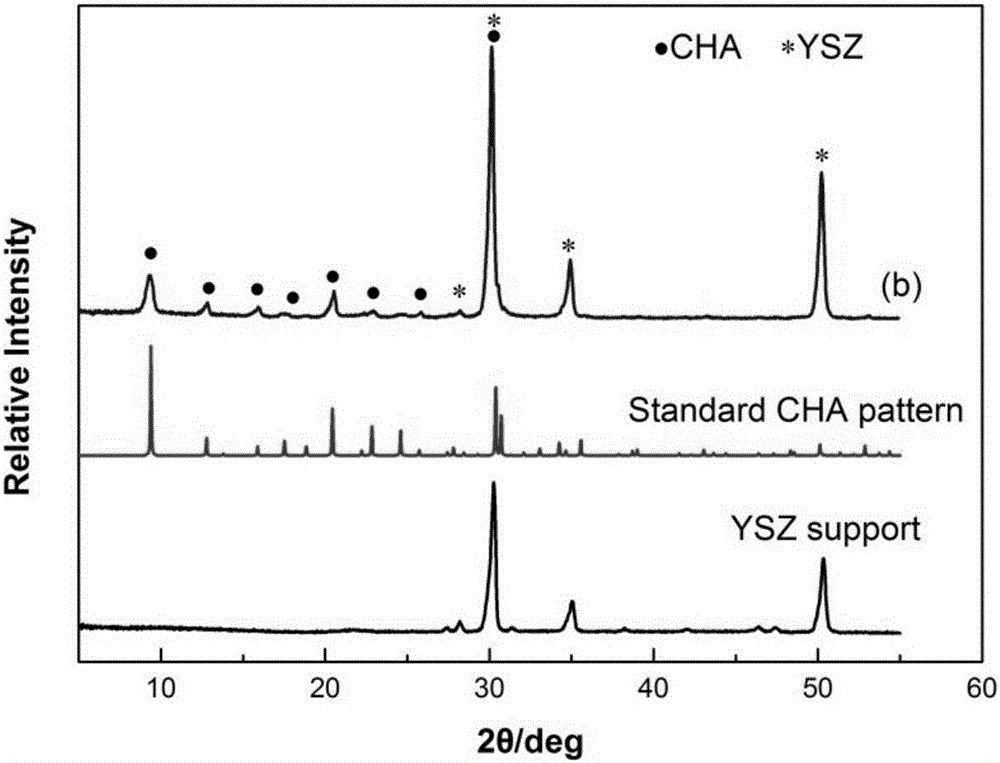

[0035] Add 1 g of ball-milled CHA molecular sieve seed crystals with a particle size of 0.10 μm into 1 L of deionized water, and sonicate for one hour to obtain a CHA seed crystal suspension, and immerse the polished mullite tubular support in the seed crystal suspension Take it out after 1 s, and dry it at 65°C for 2 h for later use. Use potassium hydroxide, aluminum hydroxide, silica sol and deionized water to configure the synthesis solution, and the molar ratio of the synthesis solution is: Al 2 o 3 :SiO2 2 :K 2 O:Na 2 O:H 2 O= 1 : 60 : 15 : 0 : 20000, pour the aged (ageing 0 h) synthetic solution into a PTFE-lined synthesis kettle, and put the seeded base film vertically into the synthetic solution, at 150 The hydrothermal synthesis was carried out at ℃ for 12 hours, and then the surface of the membrane was cleaned with absorbent cotton and deionized water, and the membrane was soaked in deionized water until the pH was 7. After drying, a tubular CHA molecular sieve ...

Embodiment 2

[0037] 5 g of ball-milled CHA molecular sieve seeds with a particle size of 0.5 μm were added to 1 L of deionized water, and the CHA seed crystals were suspended after ultrasonication for two hours. The crystal was coated on the surface of the hollow fiber carrier by vacuum suction method, where the vacuum degree was 10 kPa, the suction time was 1 s, and then dried at 65 °C for 2 h. Use potassium hydroxide, aluminum powder, silica sol and deionized water to configure the synthesis solution, and the molar ratio of the synthesis solution is: Al 2 o 3 :SiO2 2 :K 2 O:Na 2 O:H 2 O= 1 : 10 : 60 : 0 : 1000, pour the aged (aged 1 h) synthetic solution into a PTFE-lined synthesis kettle, and put the seeded base film vertically into the synthetic solution, at 160 The hydrothermal synthesis was carried out at ℃ for 6 h, the surface of the membrane was cleaned with absorbent cotton and deionized water, and then the membrane was soaked in deionized water until the pH was 7. After dryi...

Embodiment 3

[0039] 10 g of CHA molecular sieve seeds prepared by ball milling HY with a particle size of 0.50 μm were added to 1 L of deionized water, and a suspension of CHA seed crystals was obtained after ultrasonication for two hours. The crystal was coated on the surface of the hollow fiber carrier by vacuum suction method, where the vacuum degree was 5 kPa, the suction time was 20 s, and then dried at 65 °C for 2 h. Potassium hydroxide, sodium metaaluminate, sodium silicate and deionized water are used to prepare the synthetic liquid, and the molar ratio of the synthetic liquid is: Al 2 o 3 :SiO2 2 :K 2 O:Na 2 O:H 2 O= 1 : 30 : 20 : 1 : 4400, pour the aged (ageing for 10 h) synthetic liquid into a polytetrafluoro-lined synthetic kettle, and put the seeded base film vertically into the synthetic liquid, at 180 The hydrothermal synthesis was carried out at ℃ for 2 h, the surface of the membrane was cleaned with absorbent cotton and deionized water, the membrane was soaked in deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com