Shell powder filler having high beta-nucleation effect on polypropylene and preparation method for filler

A technology of nucleation and shell powder, which is applied in the field of preparation of fillers for polymer materials, can solve the problems of polypropylene with high β-crystal content, reduced β-nucleation efficiency, and decreased impact properties of polypropylene and its copolymers. , to achieve high impact strength, avoid the increase of yield strength and modulus, and maintain the effect of tensile and bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of mussel shell powder filler with β-nucleation function: wash the mussel shells, coarsely crush them, remove residual meat, attachments, etc., soak them in the cleaning solution, remove the cuticle, and then use the shells obtained above to remove the cuticle Drying and grinding to obtain micronized shell powder, uniformly mixing pimelic acid and shell at a mass ratio of 1:50, to obtain mussel shell powder filler with β-nucleation function.

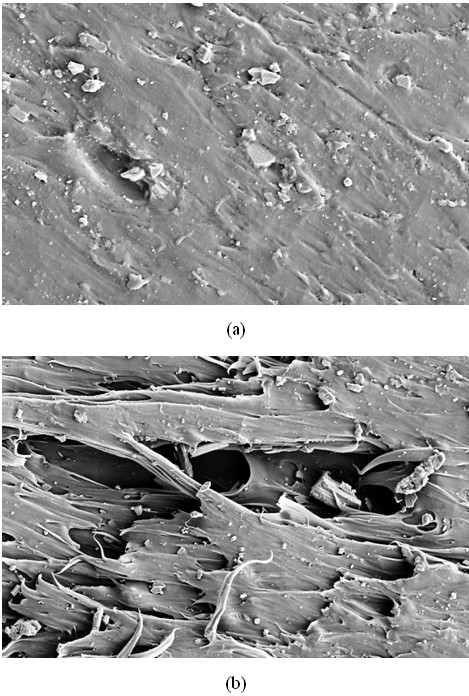

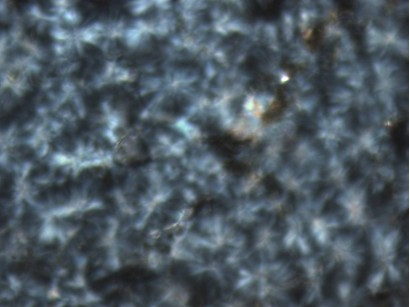

[0033] Preparation of β-crystalline polypropylene: mixing polypropylene and the above-mentioned shell powder filler at room temperature, melting and extruding at 220°C to obtain shell powder-filled polypropylene or its copolymer with high β-crystal content. The polypropylene / shell powder filler (mass ratio), that is, the prepared high β-crystal content and crystallization temperature are shown in Table 1. Electron microscopy scanning of mussel shell powder filler with β-nucleation as figure 1 shown. The scanning elec...

Embodiment 2

[0037] Preparation of polypropylene filled with mussel shell powder: use mussel shell powder as filler, and the others are the same as in Example 1. Table 2 shows the β-crystal content and crystallization temperature of polypropylene / mussel shell powder (mass ratio) and the prepared mussel shell powder filled polypropylene.

[0038] Table 2. β-crystal content of mussel shell powder-filled polypropylene

[0039] Example number Polypropylene / shell (weight ratio) β crystal content (%) Crystallization temperature (°C) Comparative example 1 100 / 0 0 115.5 Comparative example 2 99 / 1 8.5 115.3 Comparative example 3 99 / 3 8.2 115.1 Comparative example 4 95 / 5 7.3 114.9 Comparative example 5 90 / 10 2.5 114.6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com