Coating of light-water reactor

A technology of light water reactors and zirconium tubes, applied in coatings, metal material coating processes, ion implantation plating, etc., can solve the problems of no reliable and effective technical process methods and routes, and improve and guarantee high-quality, atomic High ionization rate and effect of improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

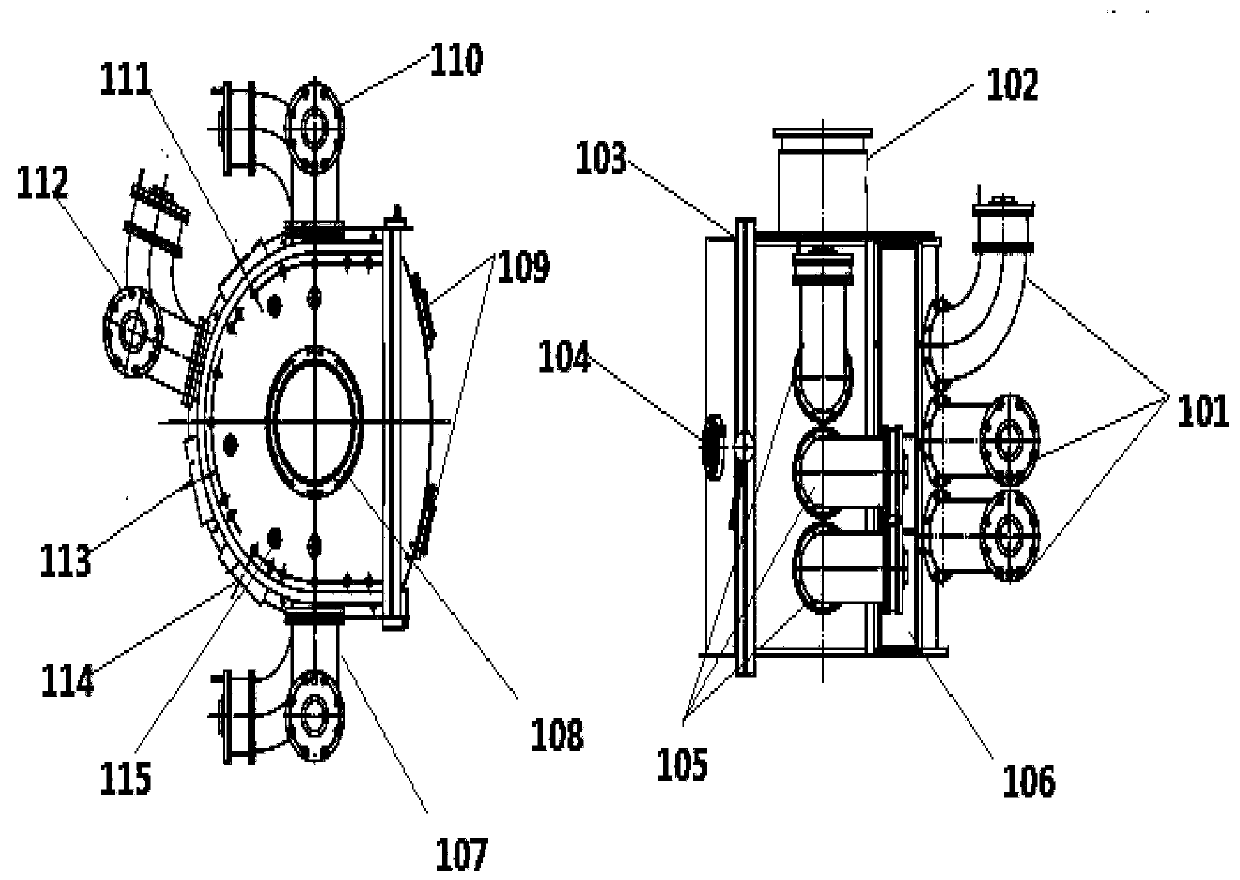

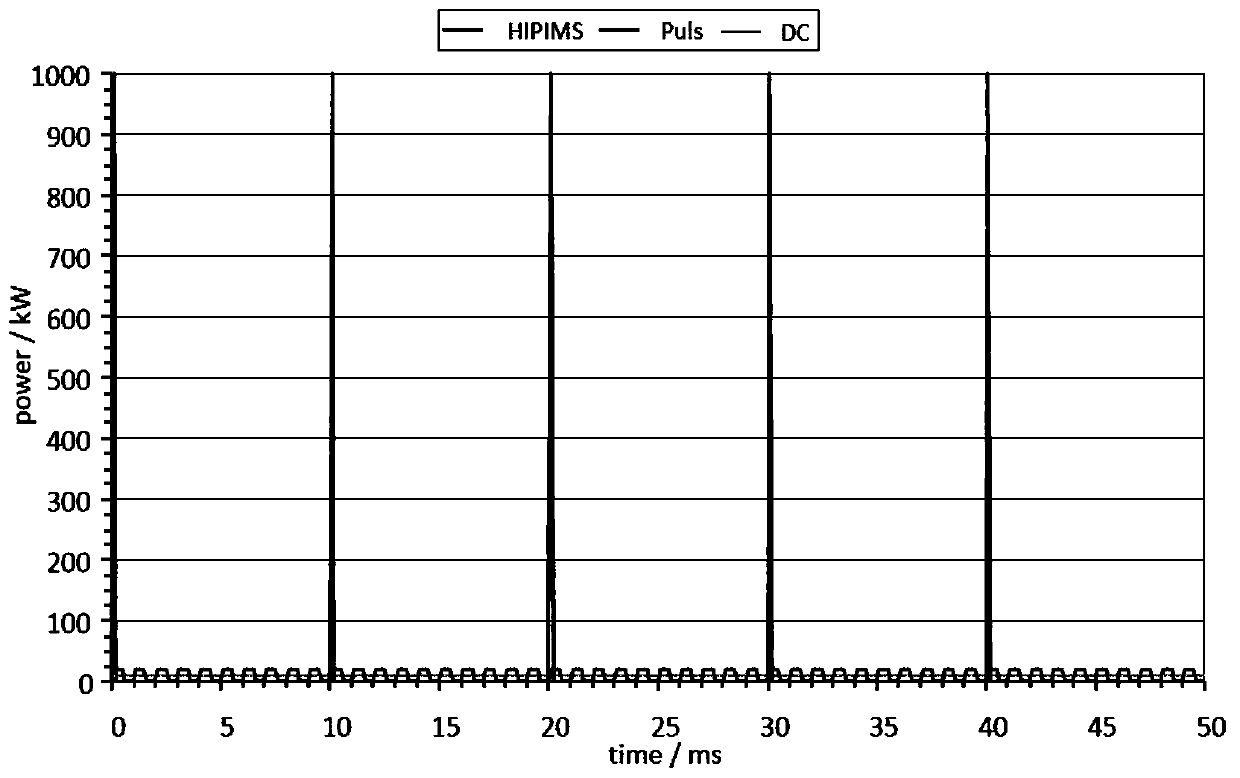

[0055] 1. Turn on the high-power pulse magnetron deposition system to clean the surface of the zirconium tube with metal ions. During cleaning, the total beam current is 2-6A, the negative pressure is 500-1000V, the high-power pulse power is 30KW, the temperature is 300-550°C, and the air pressure is 1× 10 -1 -1Pa, the incoming gas is Ar, and the bombardment time is 30-120min.

[0056] 2. Turn on the magnetic filtration technology and high-power pulse magnetron deposition technology to deposit the metal film layer on the surface of the zirconium tube. -3 -1×10 -1 Pa, the rotation mode is revolution + rotation, and the revolution speed is 10r / min; the cathode target material of magnetic filtration technology is CrAlSi, the arcing current is 80A, and the beam current is 800mA; the cathode target material of high-power pulse technology is MoNbZr, pulse power 30KW, pulse The width is 0-30ms, the beam intensity is 0-3A; the zirconium tube coating is an alternating nano-cycle comp...

Embodiment 2

[0058] 1. Turn on the high-power pulse magnetron deposition system to clean the surface of the zirconium tube with metal ions. During cleaning, the total beam current is 2-6A, the negative pressure is 500-1000V, the high-power pulse power is 100KW, the temperature is 300-550°C, and the air pressure is 1× 10 -1 -1Pa, the incoming gas is Ar, and the bombardment time is 30-120min.

[0059] 2. Turn on the magnetic filtration technology and high-power pulse magnetron deposition technology to deposit the metal film layer on the surface of the zirconium tube. -3 -1×10 -1 Pa, the rotation mode is revolution + rotation, and the revolution speed is 10r / min; the cathode target material of magnetic filtration technology is CrAlSi, the arcing current is 75A, and the beam current is 750mA; the cathode target material of high-power pulse technology is MoNbZr, pulse power 100KW, pulse The width is 0-30ms, the beam intensity is 0-3A; the zirconium tube coating is an alternating nano-cycle co...

Embodiment 3

[0061] 1. Turn on the high-power pulse magnetron deposition system to clean the surface of the zirconium tube with metal ions. During cleaning, the total beam current is 2-6A, the negative pressure is 500-1000V, the high-power pulse power is 300KW, the temperature is 300-550°C, and the air pressure is 1× 10 -1 -1Pa, the incoming gas is Ar, and the bombardment time is 30-120min.

[0062] 2. Turn on the magnetic filtration technology and high-power pulse magnetron deposition technology to deposit the metal film layer on the surface of the zirconium tube. -3 -1×10 -1 Pa, the rotation method is revolution + rotation, and the revolution speed is 10r / min; the cathode target material of the magnetic filter technology is CrAlSi, the arcing current is 70A, and the beam current is 700mA; the cathode target material of the high-power pulse technology is MoNbZr, the pulse power is 300KW, the pulse The width is 0-30ms, the beam intensity is 0-3A; the zirconium tube coating is an alternat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com