Ultrafine organic ammonium phosphate nucleating agent and preparation method thereof

An organic ammonium salt and organic phosphate technology, applied in the field of material science, can solve the problems of high solvent use requirements, complex preparation process, wide particle size distribution, etc., and achieve short processing time, simple process and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 of the present invention: Weigh 5g of unrefined 2,2'-methylene-bis(4,6-di-tert-butylphenyl) ammonium salt nucleating agent, and add it directly to the supercritical CO 2 Inside the reactor, the reactor temperature is set to 40℃, the pressure is 20MPa, the speed is 200 rpm, supercritical CO 2 React in the medium for 2h to obtain organic phosphate supercritical CO 2 Processing product; supercritical CO 2 The processed product is added to 25ml of water, and the material B is obtained after fully stirring and dispersing; the material B is subjected to rotary evaporation and drying to obtain an ultrafine organic phosphate nucleating agent.

[0025] After testing, in Example 1, the yield of the ultrafine organic phosphate nucleating agent was more than 95%, and its shape was figure 2 Shown.

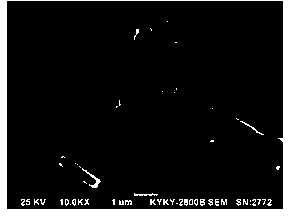

[0026] according to figure 2 It can be seen that the product of Example 1 forms a woven and fluffy structure through fine needle-like bodies. The average long diameter of the needle...

Embodiment 2

[0027] Example 2 of the present invention: Weigh 5g of unrefined 2,2'-methylene-bis(4,6-di-tert-butylphenyl) ammonium salt nucleating agent, and directly add it to the reaction kettle, 40℃, 20MPa, 200 rpm, supercritical CO 2 React in the medium for 2h to obtain organic phosphate supercritical CO 2 Processing product; supercritical CO 2 The processed product was dissolved in 56.5ml (with a mass of 45g) of absolute ethanol, and then 5ml of water was added and dispersed in a combined solvent to obtain material B; material B was dried by rotary evaporation to obtain an ultrafine organic phosphate nucleating agent.

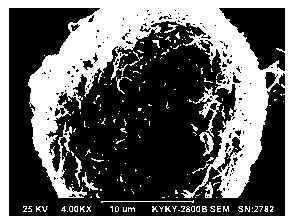

[0028] After testing, in Example 2, the yield of the ultrafine organic phosphate nucleating agent was more than 95%, the average particle size was 300 nm, and the shape was as image 3 Shown.

[0029] according to image 3 It can be seen that the product has a uniform spherical structure with an average particle size of less than 300 nm, which can be uniformly dispersed in t...

Embodiment 3

[0030] Example 3 of the present invention: Weigh 5g of unrefined 2,2'-methylene-bis(4,6-di-tert-butylphenyl) ammonium salt nucleating agent, and directly add it to the reactor, 40℃, 20MPa, 200 rpm, co-solvent 25ml absolute ethanol (mass 20g), supercritical CO 2 React in the medium for 2h to obtain organic phosphate supercritical CO 2 Processing product; supercritical CO 2 The processed product was dissolved in 50ml (40g in mass) of absolute ethanol and dispersed in a combined solvent to obtain material B; material B was dried by rotary evaporation to obtain an ultrafine organic phosphate nucleating agent.

[0031] After testing, in Example 2, the yield of the ultrafine organic phosphate nucleating agent was more than 95%, and the shape was as Figure 4 Shown.

[0032] according to Figure 4 It can be seen that the edge of the product is an aggregated structure of needle-like bodies. The average long diameter of the needle-like bodies is 300 nm, which fall off during processing and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com