Polypropylene composition for chemical pipelines and preparation method thereof

A polypropylene composition and chemical pipeline technology, applied in the field of polypropylene composition, can solve the problems of high brittleness, corrosion resistance of the composition, easy brittle cracking and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

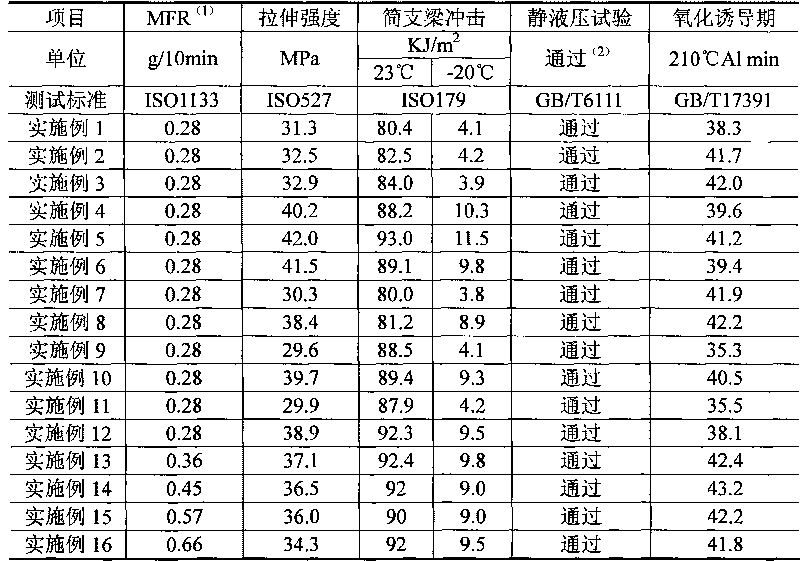

Examples

preparation example Construction

[0027] The composition preparation method of the present invention comprises following two kinds:

[0028] (1) It is prepared by a two-step method. The first step is to prepare the auxiliary masterbatch first, that is, to mix and granulate the antioxidant, β-nucleating agent and polypropylene carrier to make a masterbatch. The weight of the polypropylene carrier in the masterbatch The number of parts is 80-90, and the parts by weight of other additives are 10-20; the second step is to blend and granulate the additive masterbatch with the remaining PP-H powder or pellets and gray β-crystal accelerator masterbatch .

[0029] (2) It is prepared by one-step method. After mixing PP-H powder or pellets, β-nucleating agent, antioxidant and gray β-crystal promoting masterbatch, it is directly granulated.

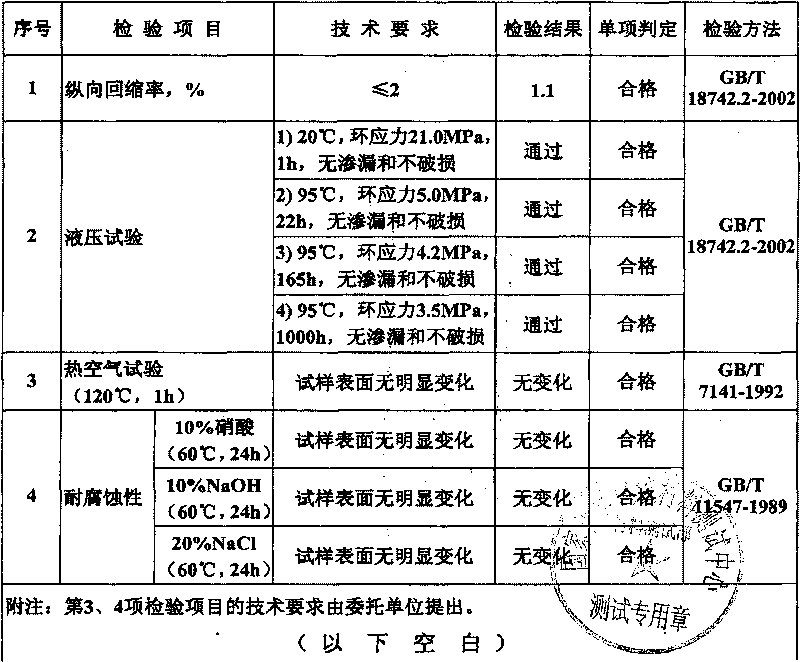

[0030] The PP-H composition prepared by the above method has good aging resistance, heat resistance, chemical corrosion resistance and creep resistance.

[0031] The composition o...

Embodiment 1

[0033] Embodiment 1 (all parts by weight, hereinafter the same):

[0034] PP-H resin (MFR=0.26g / 10min) 100 parts

[0035] Rare earth nucleating agent WBG 0.1 parts

[0036] [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.3 parts

[0037] Tris(2,4-di-tert-butylphenyl)phosphite 0.25 part

[0038] Bis(stearyl alcohol) thiodipropionate 0.2 parts

Embodiment 2

[0040] PP-H resin (MFR=0.26g / 10min) 100 parts

[0041] Rare earth nucleating agent WBG 0.12 parts

[0042] [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.3 parts

[0043] Tris(2,4-di-tert-butylphenyl)phosphite 0.25 part

[0044] Bis(stearyl alcohol) thiodipropionate 0.2 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com