Preparation method of ultrafine organic phosphate nucleating agent

An organic phosphate and nucleating agent technology, applied in the petrochemical field, can solve the problem of inability to obtain ultra-fine organic phosphate nucleating agent, etc., and achieve the effects of improving rigidity, uniform particle size and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of ultrafine preparation method of organophosphate nucleating agent, comprises the following steps:

[0030] The first step is to dissolve the raw materials:

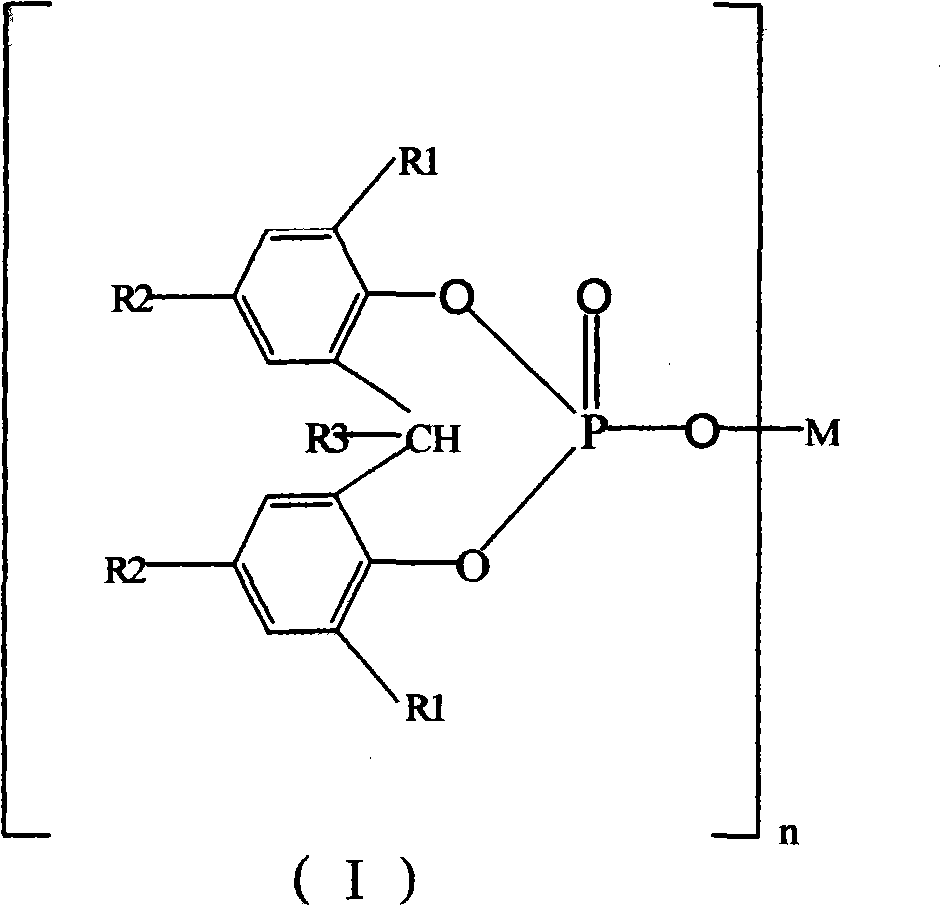

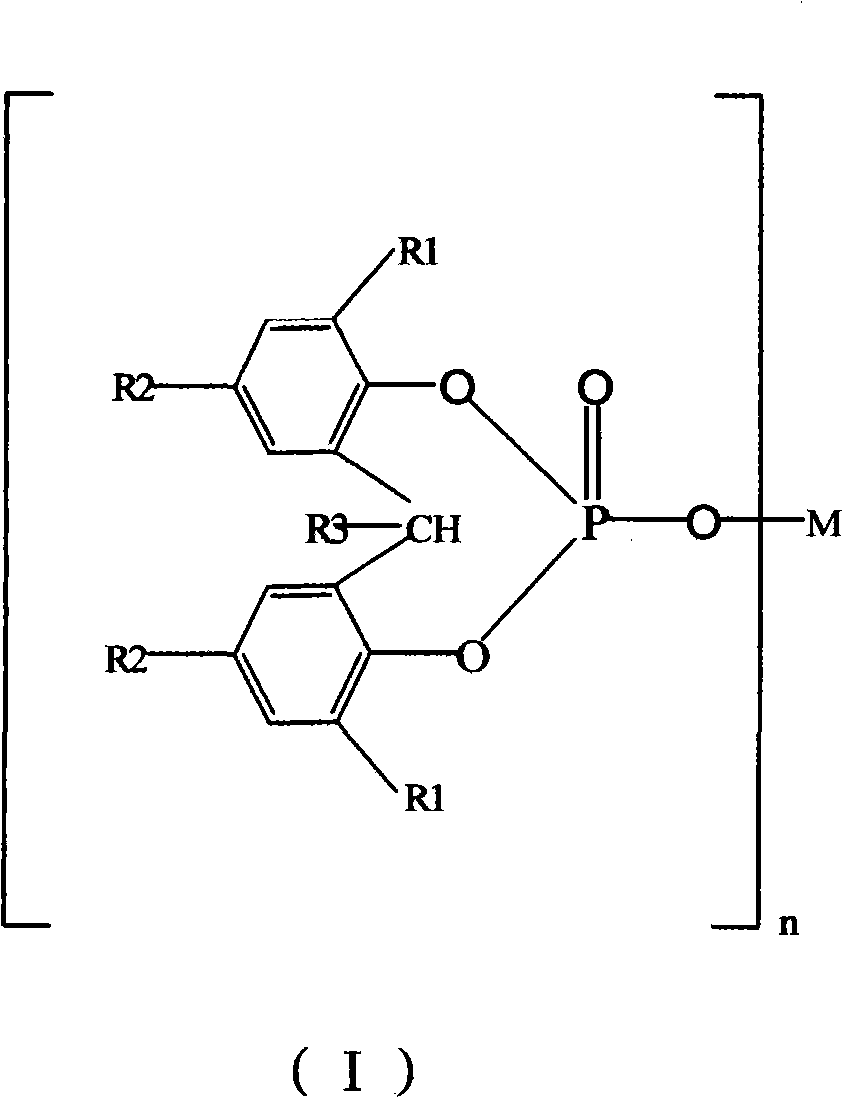

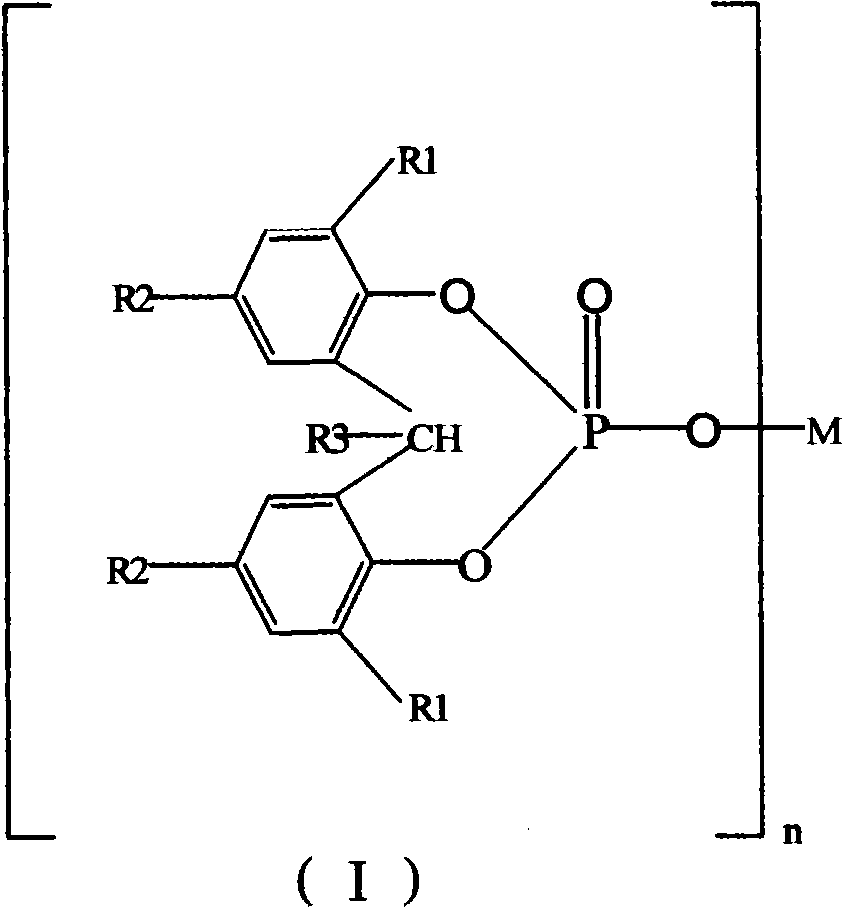

[0031] Be that the crude product of the substituted diaryl organic phosphate nucleating agent of formula (I) is a raw material with the general structure formula,

[0032]

[0033] (I) In the formula: R1 is the alkyl group of C1~C6, R2 is the alkyl group of C1~C6, R3 is the alkyl group of hydrogen atom or C1~C4, M is one of following metal atom or group: sodium, potassium , lithium, calcium, magnesium, aluminum, zinc, barium, copper, tin, zirconium, aluminum hydroxy, ammonium; n is 1 or 2;

[0034] Use at least one of the following as a solvent: acetone, ethanol, methanol, propanol, isopropanol, butanol, petroleum ether, tetrahydrofuran, ethyl acetate, toluene, ethylbenzene, N-N dimethylformamide and 1,4 - dioxane;

[0035] The raw material is added into the solvent and stirred to form a raw material...

Embodiment 1

[0051] Weigh 2,2'-methylene-bis(4-methyl, 6-tert-butylphenoxy)potassium phosphate crude raw material, add acetone and 1,4-dioxane mixed solvent, by molar ratio , acetone: 1,4-dioxane = 80: 20, after stirring and dissolving completely, a solution with a raw material content of 30% was obtained.

[0052] Use the feed pump to inject the above solution into the spray dryer, and the gas-liquid mass ratio is M G : M L =1.6:1, the air inlet temperature of the spray dryer is 140°C-160°C, and the outlet air temperature is 40°C-60°C. After drying by spraying, the solid dry powder was collected in a cyclone.

[0053] Add the solid dry powder into the mixed organic solvent of acetone and 1,4-dioxane, by mass ratio, acetone:1,4-dioxane=3:1, then add water to prepare the raw material solution, press Mass ratio, organic solvent: water: 2,2'-methylene-bis(4-methyl, 6-tert-butylphenoxy)potassium phosphate crude product=3:0.4:1;

[0054] The above raw material solution was placed in a const...

Embodiment 2

[0056] Weigh 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate crude raw material, add it into ethanol, stir and dissolve completely, and obtain a solution with a raw material content of 20%.

[0057] Use a feed pump to inject the above solution into the spray dryer. The air inlet temperature of the spray dryer is 140°C-160°C, the outlet air temperature is 40°C-60°C, and the gas-liquid mass ratio is M G : M L =1.45:1. After drying by spraying, the solid dry powder was collected in a cyclone.

[0058] Add the solid dry powder into acetone, and then add water according to the mass ratio to obtain a raw material solution, according to the mass ratio, organic solvent: water: 2,2'-methylene-bis(4,6-di-tert-butylbenzene Oxygen)sodium phosphate crude product=2:1.8:1.

[0059] The above raw material solution was placed in a constant temperature water bath with a temperature of 25 °C. Start stirring, carry out solvent dispersion and crushing, stir for 45 minutes, collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com