Metal oxide supported beta-crystal nucleating agent and preparation method of beta-crystal nucleating agent

A technology of crystal nucleating agent and oxide, which is applied in the field of metal oxide-supported β crystal nucleating agent and its preparation, can solve the problems of poor PP compatibility, low nucleation efficiency, low heat resistance, etc., and achieve cost Reduced, simple preparation process, improved yield strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

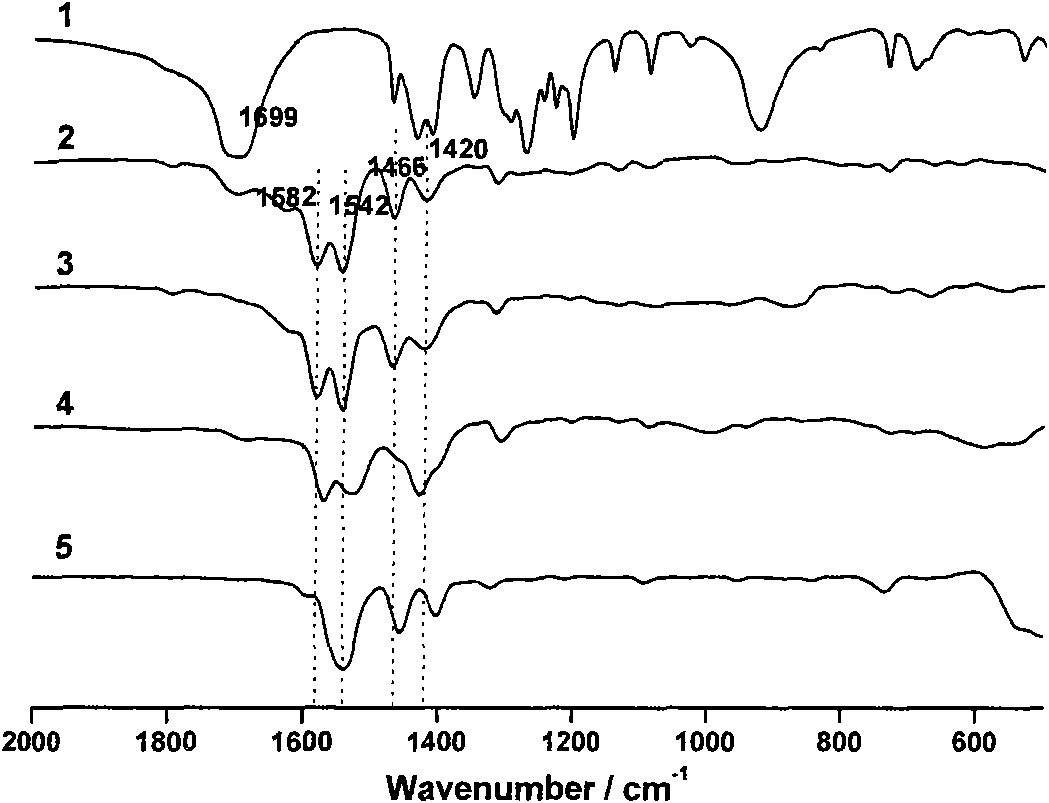

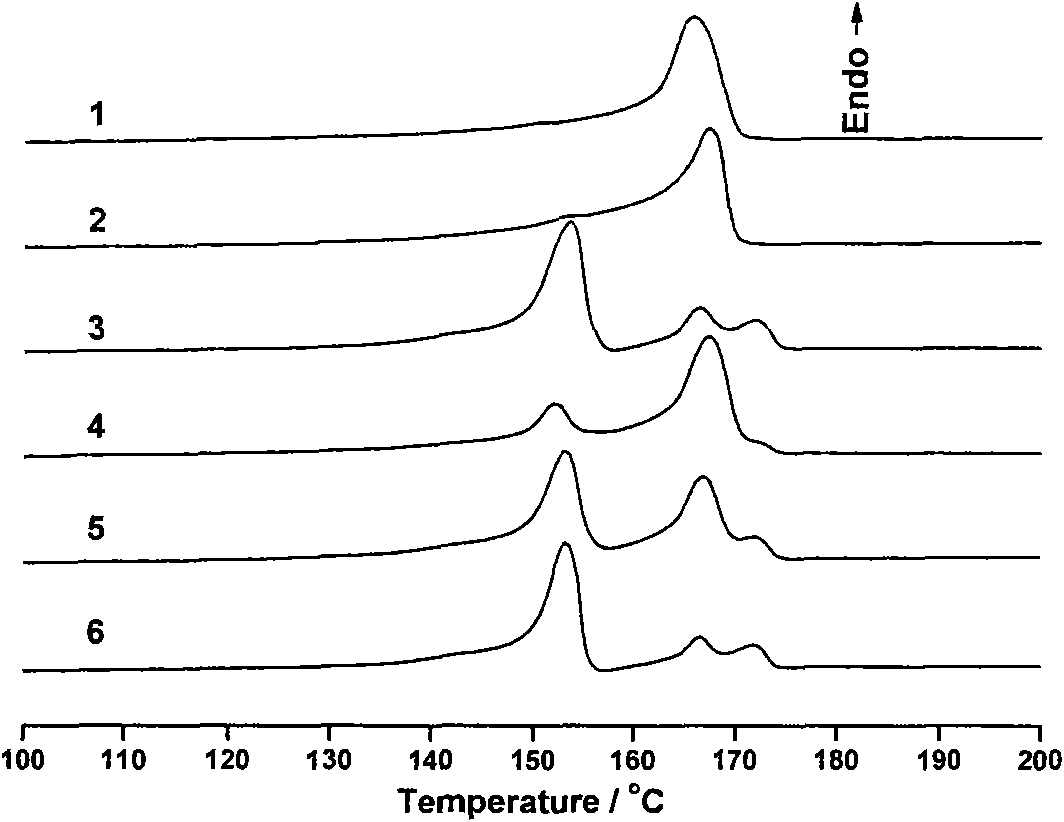

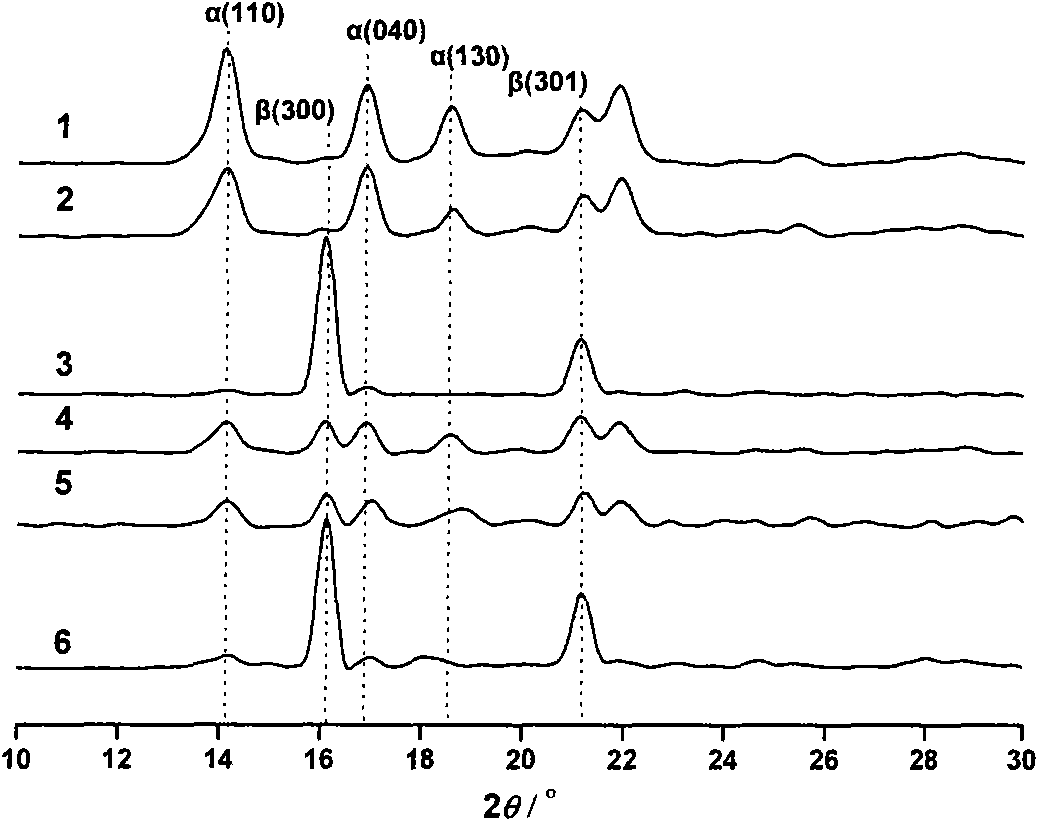

[0029] After dissolving the aliphatic dicarboxylic acid in acetone, mixing it with calcium oxide at room temperature, and volatilizing the acetone at room temperature, the supported β-crystal nucleating agent of this embodiment is prepared.

[0030] Table 1 shows the component distribution ratio and polypropylene β-crystal content of the supported β-crystal nucleating agent in this embodiment.

Embodiment 2

[0032] After dissolving the aliphatic dicarboxylic acid in acetone, mixing it with barium oxide at room temperature, and volatilizing the acetone at room temperature, the supported β-crystal nucleating agent of this embodiment is prepared.

[0033] Table 1 shows the component distribution ratio and polypropylene β-crystal content of the supported β-crystal nucleating agent in this embodiment.

Embodiment 3

[0035] After dissolving the aliphatic dicarboxylic acid in acetone, mixing it with zinc oxide at room temperature, and volatilizing the acetone at room temperature, the supported β-crystal nucleating agent of this embodiment is prepared.

[0036] Table 1 shows the component distribution ratio and polypropylene β-crystal content of the supported β-crystal nucleating agent in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com