Polymer supercritical carbon dioxide foaming nucleating agent and preparation method and application thereof

A technology of foaming nucleating agent and carbon dioxide, which is applied in the field of polymer supercritical carbon dioxide foaming nucleating agent and its preparation and application, can solve the problems of low nucleation efficiency and poor fluid solubility, and achieve high nucleation efficiency , small cell size and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

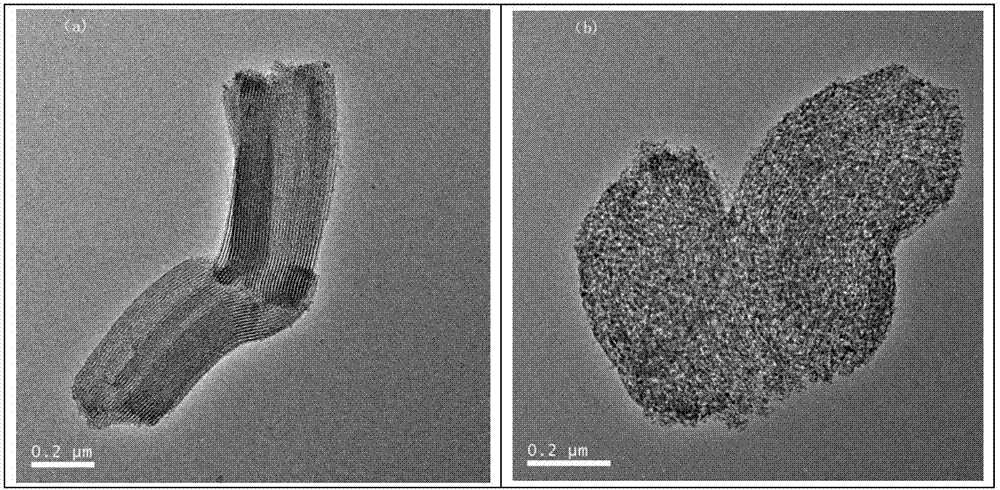

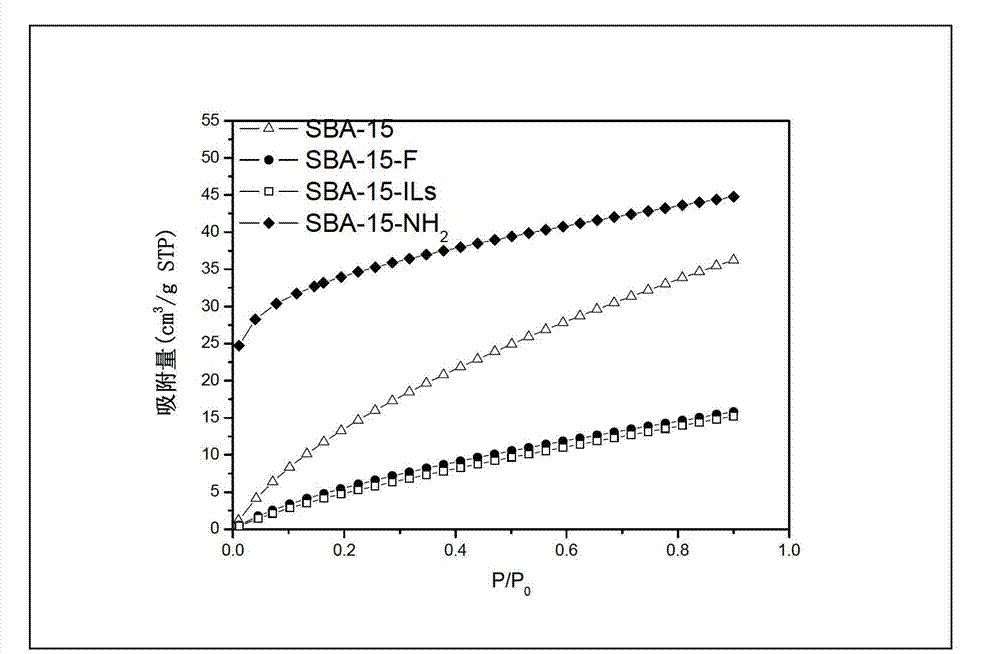

[0036] Synthesize SBA-15 with P123 as template: take 7.8g P123 and 200mL distilled water, stir well; weigh 48.8g concentrated HCl (37%) to adjust the pH value to 1.5, and gradually raise the temperature to 60°C; Ethyl ester was added to the system as a silicon source, stirred and hydrolyzed for 1 hour, then incubated for 3 hours, and the resulting suspension was centrifuged and washed and then dried to obtain mesoporous silica containing a template agent, which was calcined at 550°C for 5 hours to remove the template agent to obtain mesoporous silica. Silica (SBA-15) 4g, its morphology was observed by transmission electron microscope (such as figure 1 As shown in (a), the CO at 0°C was measured with a specific surface area tester 2 Adsorption properties, the results obtained see figure 2 .

[0037] Take more than 0.5g of SBA-15 synthesized under 0.01MPa vacuum condition, add 5ml of [C12MIM][PF6] / ethanol solution with a mass concentration of 1%, magnetically stir for 50min, ...

Embodiment 2

[0039] Take 0.5 g of SBA-15 synthesized according to the method of Example 1, under the vacuum condition of 0.01 MPa, add 5 ml of KH550 / ethanol solution with a mass concentration of 1%, stir it magnetically for 50 min, dry it in vacuum at 40 ° C for 6 h, and then dry it in vacuum at 80 ° C for 15 h to obtain Modified mesoporous silica particles SBA-15-NH 2 , which is a polymer supercritical carbon dioxide foaming nucleating agent, its CO at 0°C is measured with a specific surface area tester 2 Adsorption properties, the results obtained see figure 2 .

Embodiment 3

[0041] Take 0.5g of SBA-15 synthesized according to the method in Example 1, add 5ml of heptadecafluorodecyltriethoxysilane / ethanol solution with a mass concentration of 1% under the vacuum condition of 0.01MPa, stir magnetically for 50min, and dry under vacuum at 40°C After 5 hours, vacuum-dry at 80°C for 12 hours to obtain the modified mesoporous silica particles SBA-15-F, which is a polymer supercritical carbon dioxide foaming nucleating agent, and measure its CO at 0°C with a specific surface area tester. 2 Adsorption properties, the results obtained see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com