Monodispersity polystyrene nanosphere and preparation method thereof

A technology of polystyrene nano and polystyrene spheres, which is applied in the field of monodisperse polystyrene nanospheres and its preparation, can solve the problems of uncontrollable particle size, cumbersome and complicated synthesis methods, etc., and enhance the ability to capture free radicals , Accelerate the polymerization rate and increase the effect of nucleation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] Step 1, first mix styrene monomer, polystyrene microbeads, cetyl alcohol and octylphenol polyoxyethylene (10) ether according to the ratio of 98: 1.2: 1.98: 2.2 by weight and stir for 20 minutes, then add After adding water, continue to stir for 30 minutes to obtain a mixed solution; wherein, the polystyrene microbeads have a bead diameter of 3 mm, the water is distilled water (or deionized water), and the weight ratio between water and styrene monomer is 10.8:1.

[0022] In step 2, the mixed liquid is first placed under ultrasonic waves for 5 minutes, wherein the power of the ultrasonic waves is 120W, to obtain a fine emulsion. After passing nitrogen into the miniemulsion for 10 minutes, potassium persulfate was added thereto for 4 hours of polymerization reaction, wherein the flow rate of nitrogen gas was 100 ml / min, and the weight ratio between potassium persulfate and styrene monomer was 0.3:98. made approximately fi...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] Step 1, first mix styrene monomer, polystyrene microbeads, cetyl alcohol and octylphenol polyoxyethylene (10) ether according to the ratio of 99: 1.1: 1.99: 2.1 by weight and stir for 23 minutes, then add After adding water, continue to stir for 33 minutes to obtain a mixed solution; wherein, the polystyrene microbeads have a bead diameter of 4 mm, the water is distilled water (or deionized water), and the weight ratio between water and styrene monomer is 10.5:1.

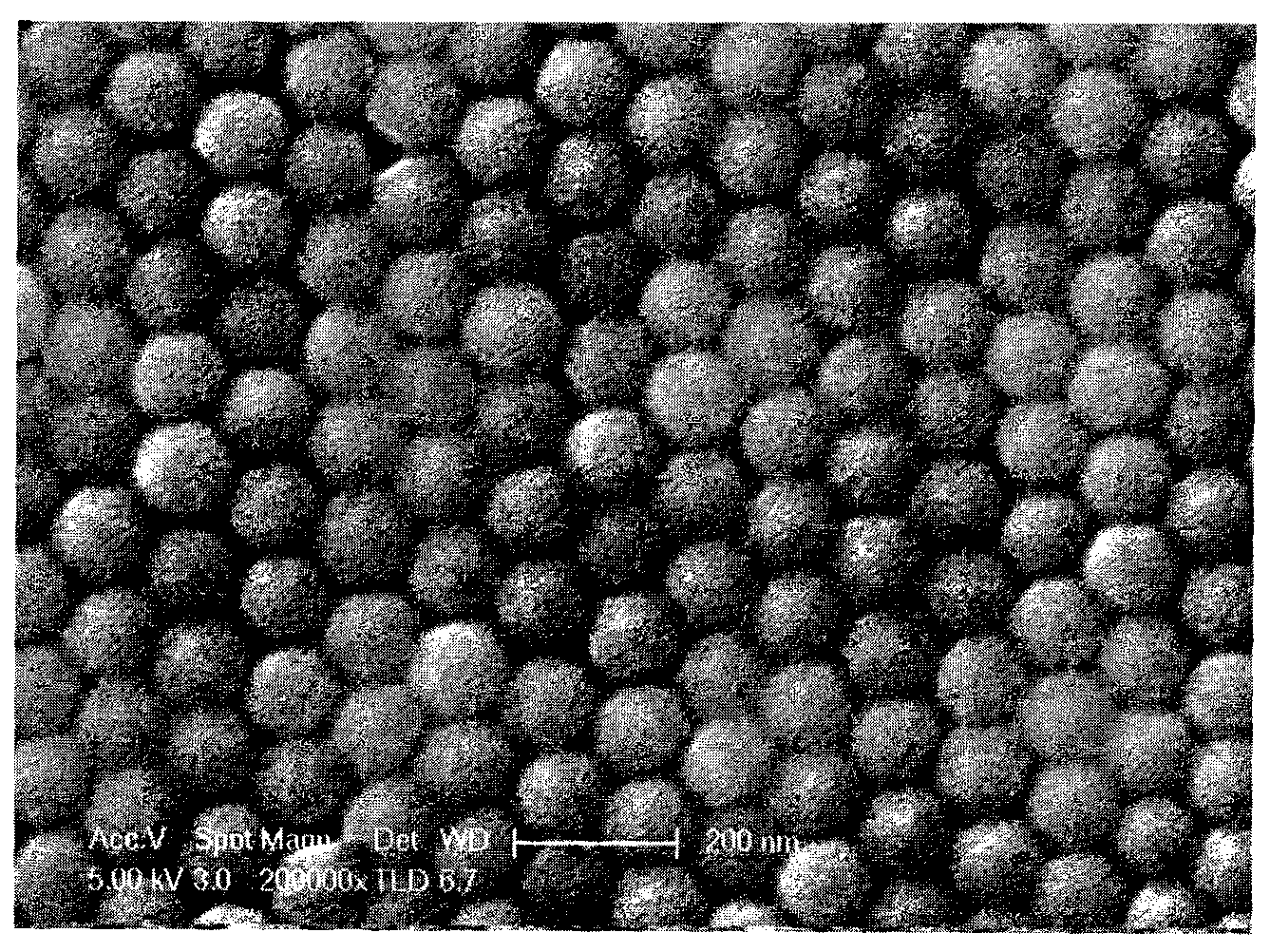

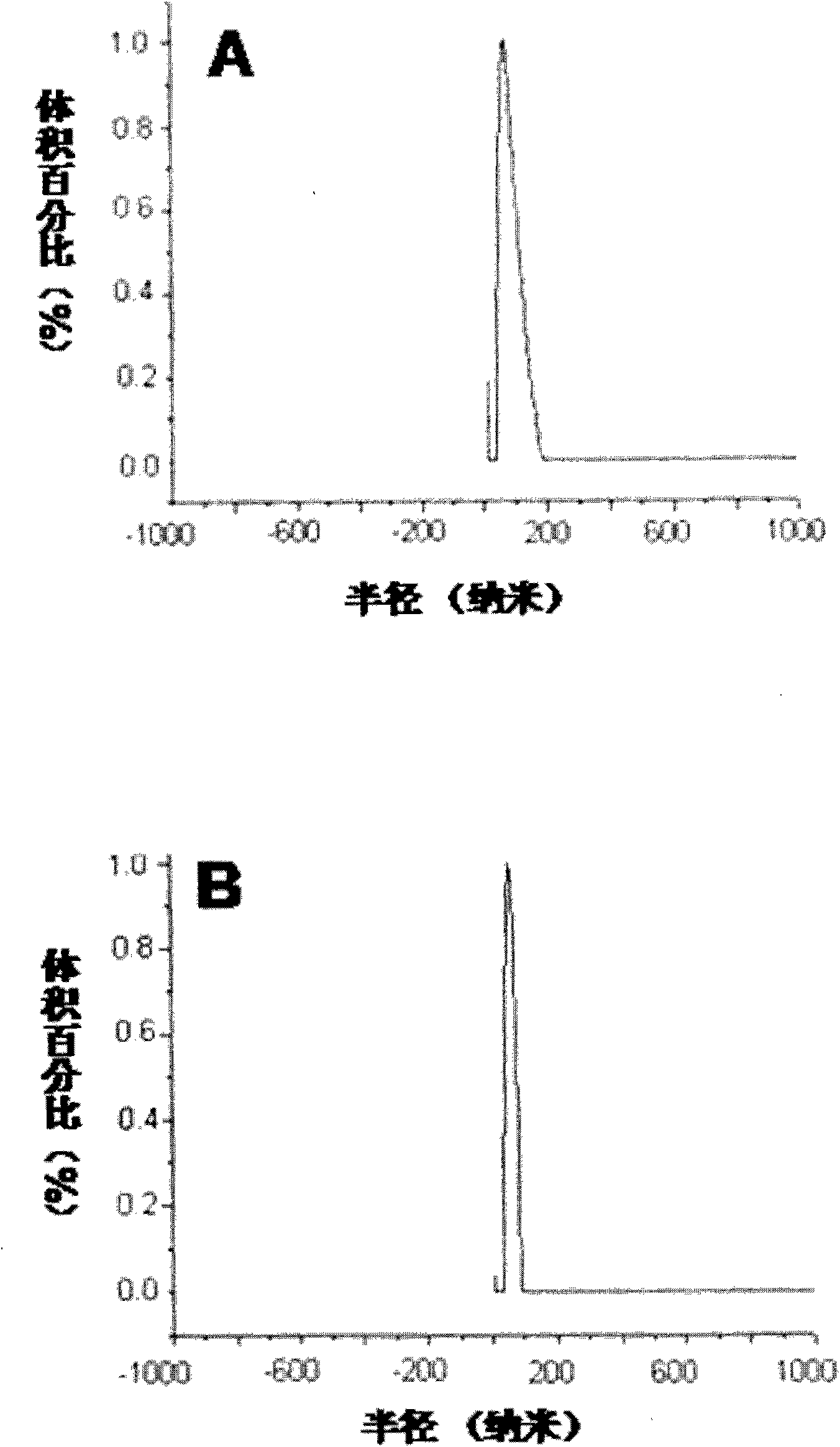

[0026] In step 2, first place the mixed solution under ultrasonic waves for 6.5 minutes, wherein the power of the ultrasonic waves is 120W, to obtain a fine emulsion. After passing nitrogen into the miniemulsion for 13 minutes, potassium persulfate was added thereto for 4.5 hours of polymerization reaction, wherein the flow rate of nitrogen gas was 88 ml / min, and the weight ratio between potassium persulfate and styrene monomer was 0.3:99. made as figure 1 wit...

Embodiment 3

[0028] The concrete steps of preparation are:

[0029] Step 1, first mix styrene monomer, polystyrene microbeads, cetyl alcohol and octylphenol polyoxyethylene (10) ether according to the ratio of 100:1:2:2 by weight and stir for 25min, and then add After adding water, continue to stir for 35 minutes to obtain a mixed solution; wherein, the polystyrene microbeads have a bead diameter of 5 mm, the water is distilled water (or deionized water), and the weight ratio between water and styrene monomer is 10.3:1.

[0030]In step 2, the mixed liquid is first placed under ultrasonic waves for 8 minutes, wherein the power of the ultrasonic waves is 120W, to obtain a fine emulsion. After passing nitrogen into the miniemulsion for 15 minutes, potassium persulfate was added therein for 5 hours of polymerization reaction, wherein the flow rate of nitrogen was 75 ml / min, and the weight ratio between potassium persulfate and styrene monomer was 0.3:100. made approximately figure 1 with f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com