Self-nucleation method for high-polymer materials

A polymer material and self-nucleation technology, applied in the direction of single-component polyester rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of narrowing the use range of polymer matrix materials and reducing the nucleation effect of compatibility To achieve significant economic and social benefits, improve material crystallization and performance, and achieve good material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the method for polybutylene succinate self-nucleation

[0025] The clathrate of polybutylene succinate and urea (mass ratio: 1:2) was electrospun and heat-treated to obtain the clathrate; the urea was removed to obtain the extended chain crystal of polybutylene succinate (referred to as self-nucleating agent). The melting point of polybutylene succinate linear crystals measured by DSC test is 136.8°C. Add the self-nucleating agent into the polybutylene succinate raw material matrix at a mass ratio of 1:99, and use a twin-screw extruder to blend for 10 minutes (blending temperature is 130°C) to obtain Crystalline polybutylene succinate material.

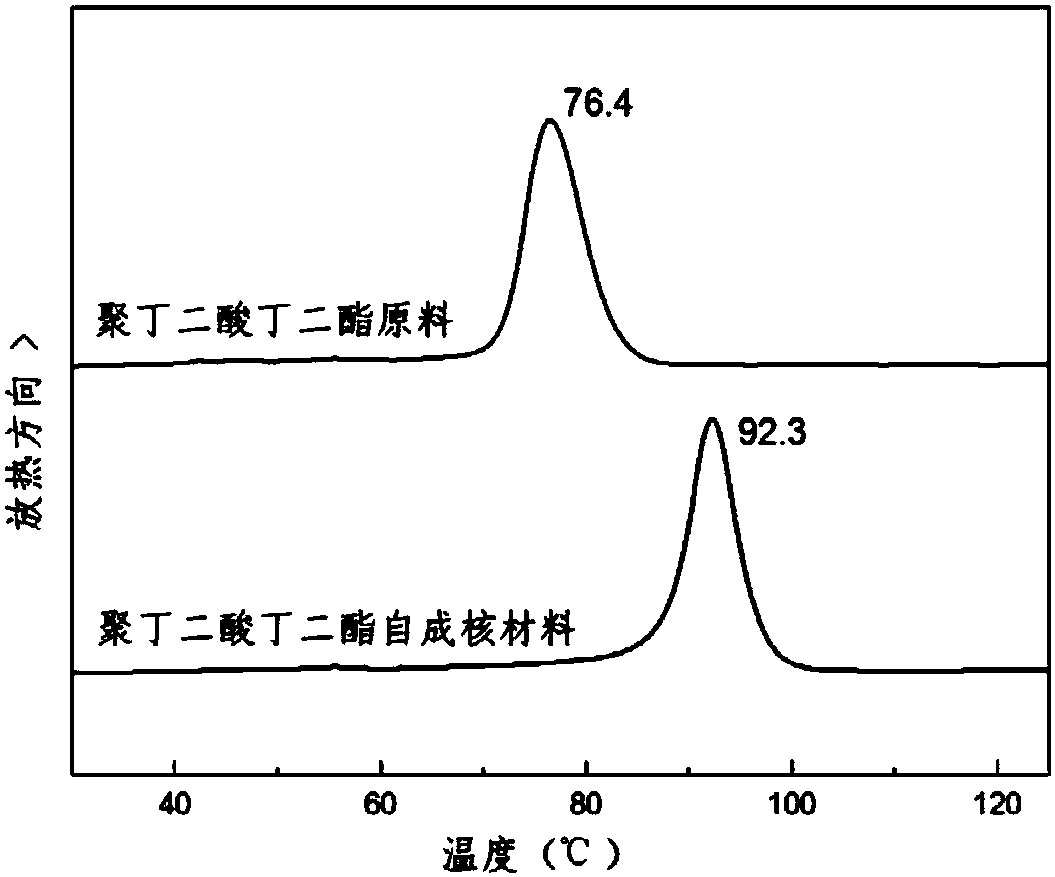

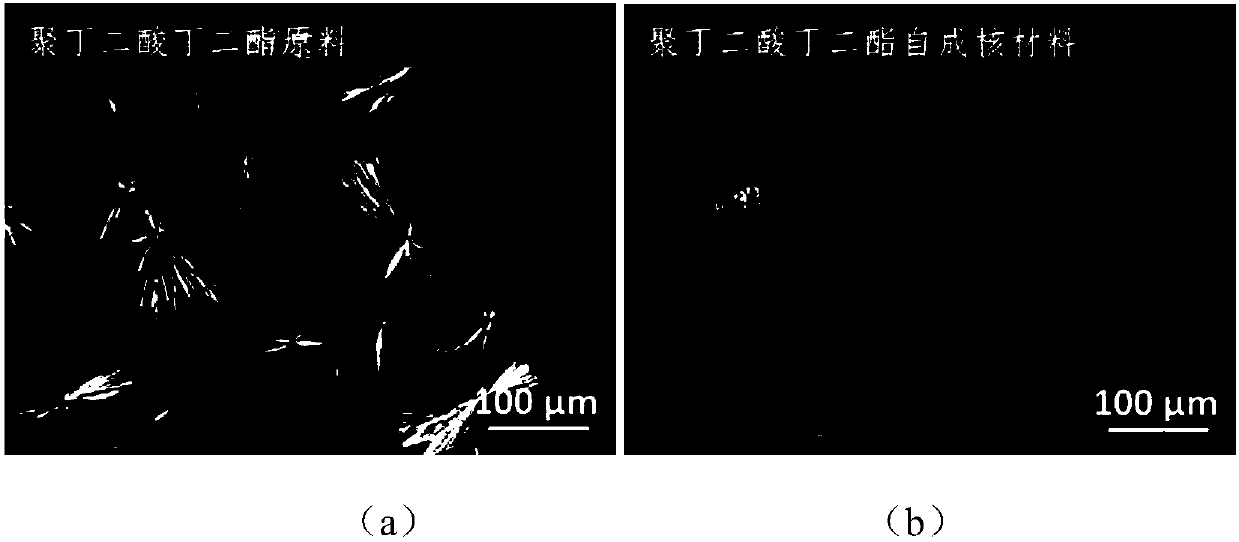

[0026] Using DSC tests (such as figure 1 As shown), the temperature was increased from room temperature to 130 °C at a heating rate of 10 °C / min, and after a constant temperature of 5 minutes, it was lowered to room temperature at 10 °C / min, and the obtained polybutylene succinate containing extended chain crys...

Embodiment 2

[0027] Embodiment 2, the method for polybutylene succinate self-nucleation

[0028] The clathrate of polybutylene succinate and urea (mass ratio: 1:2) was electrospun and heat-treated to obtain the clathrate; the urea was removed to obtain the extended chain crystal of polybutylene succinate (referred to as self-nucleating agent). The melting point of polybutylene succinate linear crystals measured by DSC test is 136.8°C. The self-nucleating agent was added to the polybutylene succinate raw material matrix at a mass ratio of 5:95, and blended for 15 minutes using a Brabender internal mixer (blending temperature was 130° C.) to obtain Core polybutylene succinate material.

[0029] Using DSC test, increase the temperature from room temperature to 130 °C at a rate of 10 °C / min, keep the temperature for 5 minutes, and then lower it to room temperature at 10 °C / min, the obtained polybutylene succinate containing extended chain crystal nuclei The crystallization temperature of th...

Embodiment 3

[0030] Embodiment 3, the method for self-nucleation of polybutylene succinate

[0031] Blend polybutylene succinate and urea (mass ratio: 1:2) at 125°C with a Brabender for 15 minutes to obtain an inclusion compound of polybutylene succinate and urea; remove urea to obtain polybutylene succinate Extended chain crystals of butylene glycolate (referred to as self-nucleating agent). The melting point of the extended chain crystals measured by DSC test is 137.2°C. Add the self-nucleating agent into the polybutylene succinate raw material matrix with a mass ratio of 10:90, and use a twin-screw extruder to blend for 20 minutes (blending temperature is 130°C) to obtain Crystalline polybutylene succinate material.

[0032] Using DSC test, increase the temperature from room temperature to 130 °C at a rate of 10 °C / min, keep the temperature for 5 minutes, and then lower it to room temperature at 10 °C / min, the obtained polybutylene succinate containing extended chain crystal nuclei T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com