Integrated broadband high-wave-transmissivity tough polyolefin microporous foam material and preparation method thereof

A technology of microcellular foam and polyolefin, applied in the field of communication equipment materials, can solve the problems of limited application, relatively high brittleness, poor tear resistance, etc., and achieve the effect of improving mechanical properties, increasing melt strength, and uniform cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation process of the above-mentioned wave-transparent material can be divided into two steps: the preparation of raw materials and the foaming process.

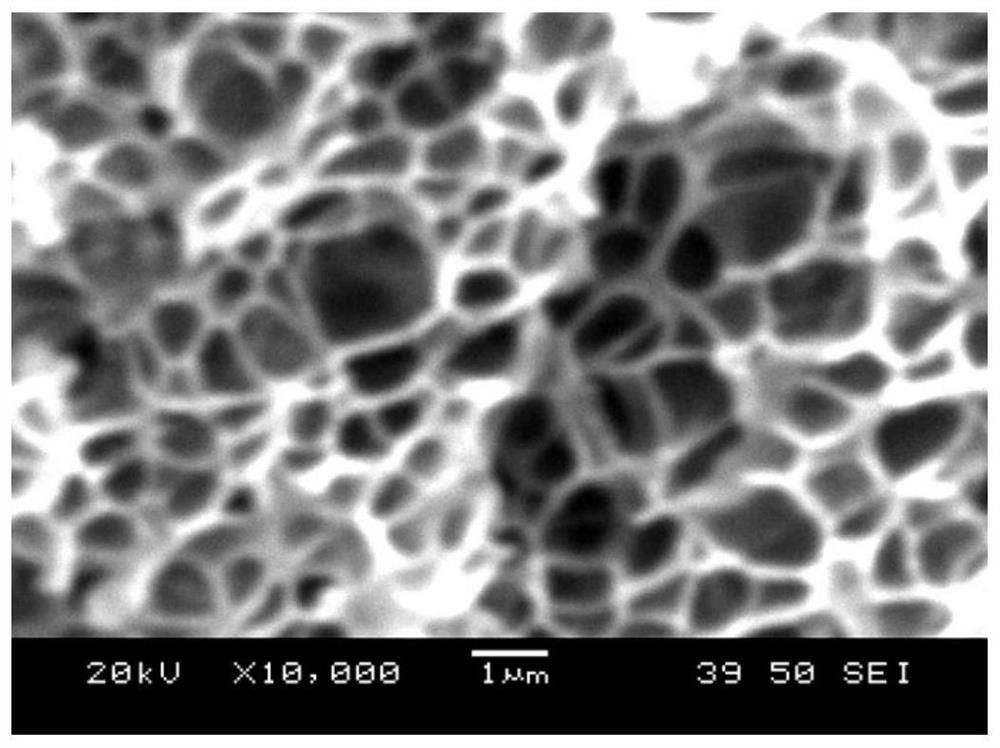

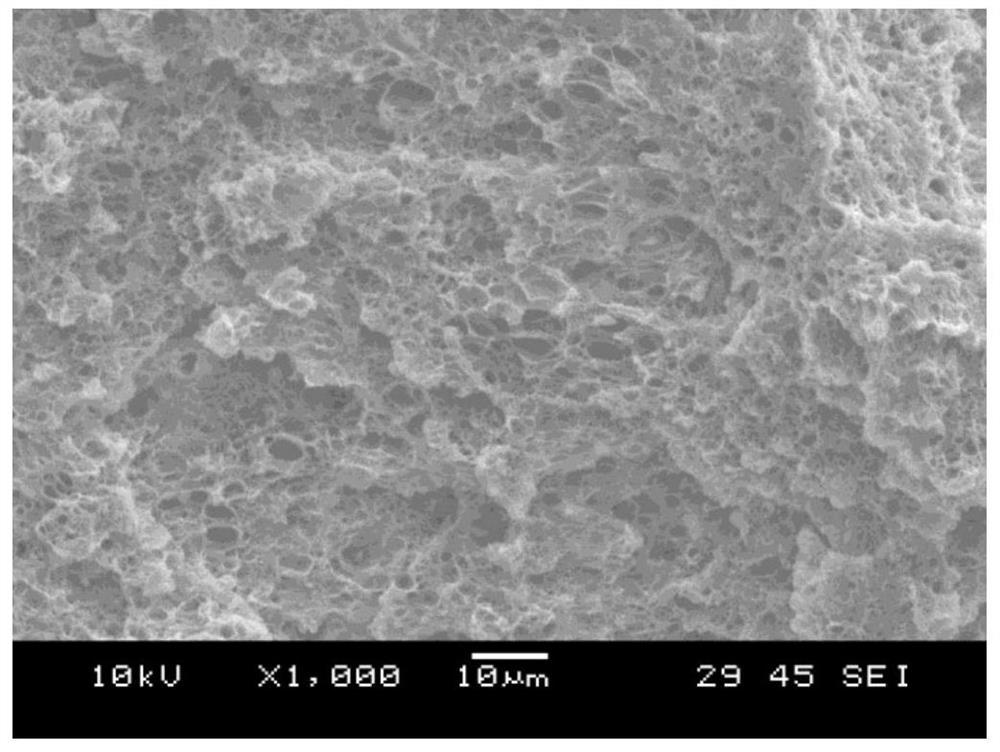

[0036] For the preparation process of raw materials, fully mix polyolefin pellets (melt index ≤ 5g / 10min), β-cyclodextrin urethanization modifier, flame retardant, anti-aging agent and use three-layer co-extrusion screw The extruder thickness is 10-15mm thick polyolefin sheet, the thickness of the upper and lower layers is 0.5mm-2mm thick, the content of β-cyclodextrin urethanization modifier is 1%-5%, and the middle layer is 6- The thickness is 14mm, and the content of β-cyclodextrin urethane modification agent is 3%-10%. The upper and lower cortex are more modified, which promotes CO 2 The solubility improves the nucleation efficiency and effectively reduces the cell size; at low expansion ratios, the hardness increases, and the toughening modification can also effectively improve the toughness of the hard...

Embodiment 1

[0048] The preparation process of the β-cyclodextrin urethane modification agent is as follows: In a dry three-necked flask, the toluene diisocyanate solution is dropped into the pyridine solution of the dehydrated β-cyclodextrin, wherein n(-NCO) / n(-CH 2 OH) between 1.8-2.0. Then add a small amount of catalyst (organotin such as dibutyltin dilaurate), and stir evenly. The exothermic heat of the reaction automatically rises to 80°C, and the reaction is performed at a constant temperature for about 2 hours to obtain a prepolymer. Cool down to about 60°C, add the chain extender ethylene glycol dropwise (the amount of the substance is 0.43 times the amount of the NCO group substance remaining in the prepolymer), mix quickly and evenly, and when the temperature rises to about 80°C, stop stirring and start Vacuum devolatilization. React for about 0.5-1h and cool down, add a polymerization inhibitor (organic amines such as dibutylamine) at 40°C, stir quickly and pour into a low-t...

Embodiment 2

[0052] Mix polypropylene pellets (melt index 2g / 10min), β-cyclodextrin urethanation modifier, flame retardant, anti-aging agent according to 91:7:1:1 and 97:1:1:1 Blending, and then adding to the twin-screw multi-layer sheet extruder of the outer layer and the inner layer respectively, the processing temperature is 210-290°C, and the temperature of the sheet extrusion die is between 180-240°C. A polyolefin sheet having a thickness of 10 mm was obtained by passing through a three-roll cooling rack.

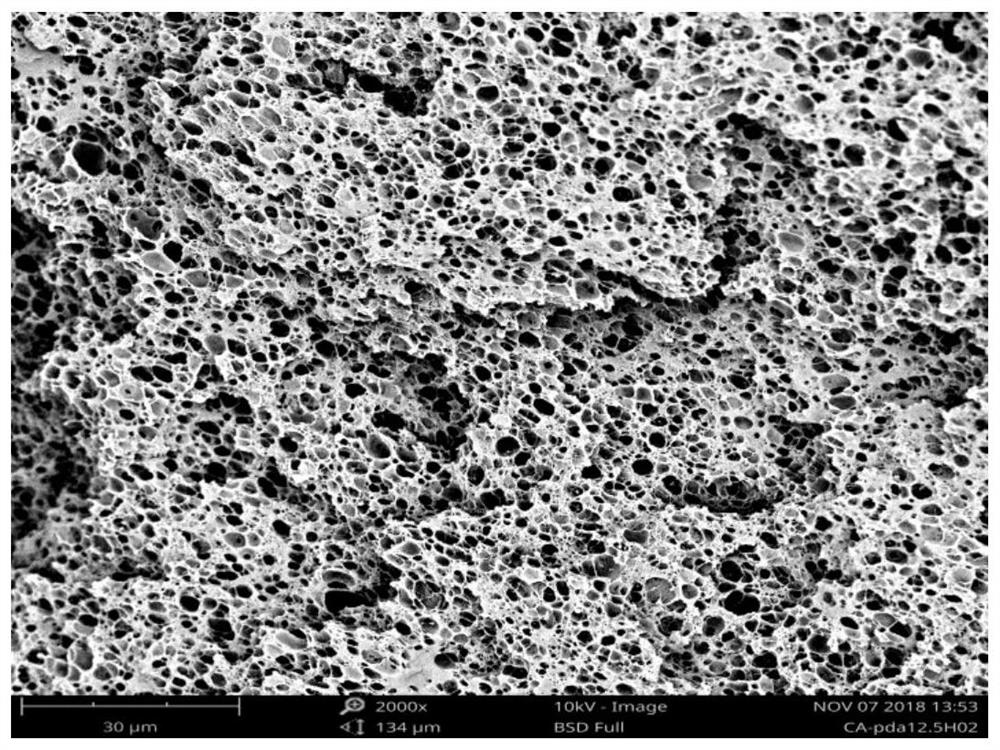

[0053] Put the obtained polypropylene sheet into the cavity of a multi-layer molded foaming machine (with a smooth release film on the upper and lower sides), fill it with supercritical fluid, the pressure is 10MPa, the temperature is 163°C, and after heat preservation and pressure holding for 30min, Quickly open the mold to release the pressure, and you can get a high-toughness one-piece polyolefin microporous high-wave-transparency material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com