Device and method for removing fine particles from gas

A technology for removing gases and fine particles, which is applied in chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., can solve the problem of unsatisfactory effects of small particles such as PM2. Particles and other problems, to achieve the effect of simple structure, low processing cost, and increased heterogeneous nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

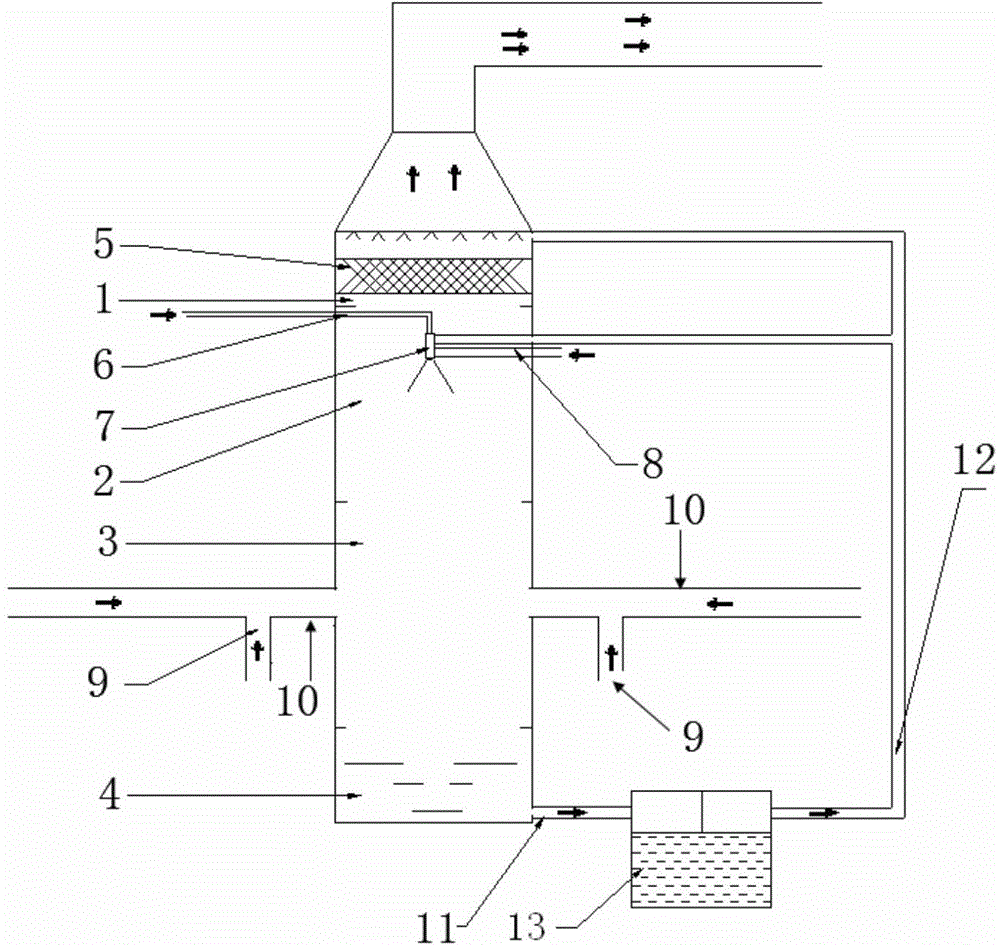

[0019] A device for removing fine particles in gas, which is divided into dusty wastewater area 4, steam preliminary phase change area 3, multiphase spray phase change and disturbance mass transfer dust removal area 2 and demisting area 1 from bottom to top ;

[0020] A mist eliminator 5 is set in the demister area 1; a multi-phase nozzle 7 is set in the multi-phase spray phase change and disturbance mass transfer dust removal area 2; the air inlet end of the multi-phase nozzle 7 is connected with the high-pressure air pipeline 6, The water inlet end of the multiphase nozzle 7 is connected to the water pipe 12, and the steam inlet end of the multiphase nozzle 7 is connected to the first steam pipeline 8; a gas inlet is provided in the steam preliminary phase change zone 3, and the gas inlet is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com