Method for preparing high-crystallinity polylactic acid material or article with high crystallization rate

A technology of polylactic acid materials and high crystallinity, which is applied in the field of polymer materials, can solve the problems of limited promotion of polylactic acid crystallization, and achieve the effects of promoting crystallization rate, increasing crystallinity, and high nucleation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

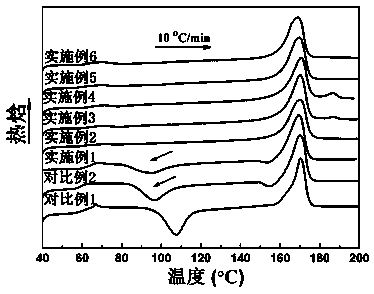

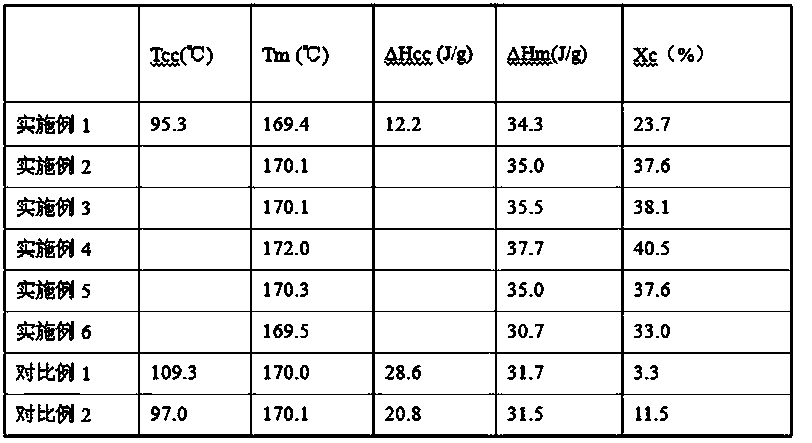

Embodiment 1

[0020] (1) Anneal the lactic acid polymer with a higher melting point at 60°C to 200°C for later use;

[0021] (2) Pulverize the lactic acid polymer resin with a higher melting point in step (1) into powder at room temperature for later use; dry poly-L-lactic acid with a melting point lower than that of the nucleating agent in a vacuum oven at 60°C for 12 h spare;

[0022] (3) The lactic acid polymer resin with higher melting point and polylactic acid with low melting point in step (2) are blended and granulated at 170°C by Haake rheometer at a mass ratio of 0.1:99.9.

Embodiment 2

[0024] (1) Anneal the lactic acid polymer with a higher melting point at 60°C to 200°C for later use;

[0025] (2) Pulverize the lactic acid polymer resin with a higher melting point in step (1) into powder at room temperature for later use; dry poly-L-lactic acid with a melting point lower than that of the nucleating agent in a vacuum oven at 60°C for 12 h spare;

[0026] (3) The lactic acid polymer resin with higher melting point and polylactic acid with low melting point in step (2) are blended and granulated at 170°C by Haake rheometer at a mass ratio of 1:99.

Embodiment 3

[0028] ((1) Anneal the lactic acid polymer with a higher melting point at 60°C to 200°C for later use;

[0029] (2) Pulverize the lactic acid polymer resin with a higher melting point in step (1) into powder at room temperature for later use; dry poly-L-lactic acid with a melting point lower than that of the nucleating agent in a vacuum oven at 60°C for 12 h spare;

[0030] (3) The lactic acid polymer resin with higher melting point and polylactic acid with low melting point in step (2) are blended and granulated at 170°C by Haake rheometer at a mass ratio of 5:95.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com