Method for preparing polypropylene composite

A technology for composite materials and polypropylene, which is applied in the field of preparation of polypropylene composite materials, can solve problems such as the inability of nucleating agents to function effectively, and achieve the effects of easy realization of reaction conditions, high thermal stability, and increased heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

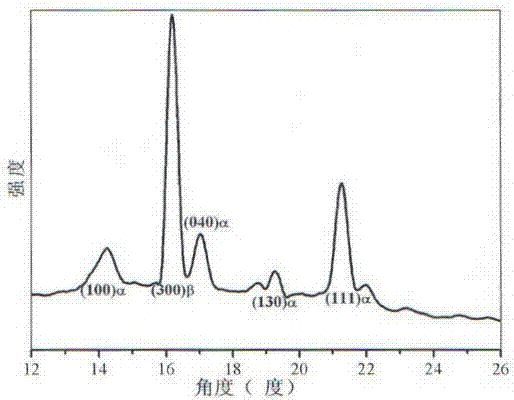

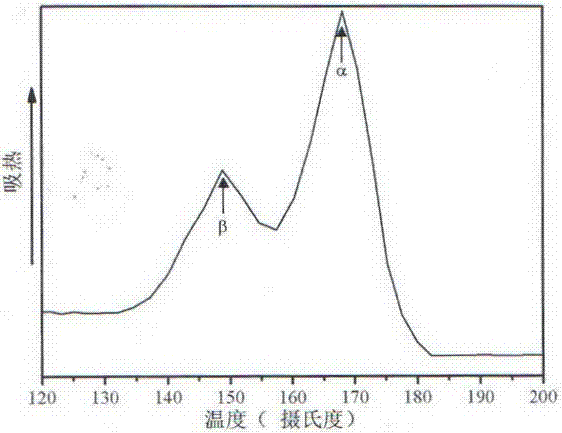

Embodiment 1

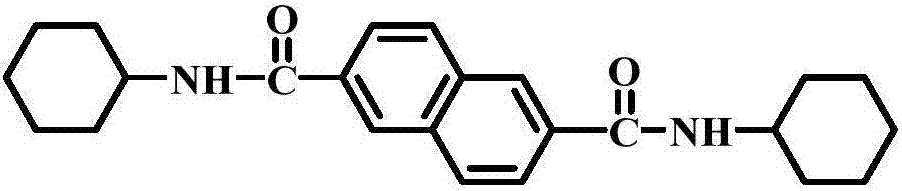

[0080] a. Weigh polypropylene 79.3%, antioxidant 0.2%, β-nucleating agent N,N′-dicyclohexyl-2,6-naphthalamide 0.3%, and dry in an oven at 80℃ for 12h , And then put it into a high-speed mixer to mix, and then add it to a twin-screw extruder to extrude and granulate. The twin-screw parameters are: the temperature in the first zone is 160℃, the temperature in the second zone is 180℃, and the temperature in the third zone is 210 ℃, four zone temperature is 220℃, five zone temperature is 220℃, head temperature is 210℃, twin screw speed is 70r / min, feeder speed is 4r / min, pelletizer speed is 200r / min, among which Antioxidant is compounded by pentaerythritol tetrapropionate and tris(2,4-di-tert-butylphenyl) phosphite in a mass ratio of 1:1;

[0081] b. Dry the granulation in step a in an oven at a temperature of 60°C overnight, mix it with 20% of the dried glass fiber and 0.2% of the compatibilizer, and then extrude it in a twin-screw extruder for granulation. The screw parameters are...

Embodiment 2

[0087] a. Weigh polypropylene 69.3%, antioxidant 0.2%, β-nucleating agent (N,N'-dicyclohexylterephthalamide) 0.3% according to the mass fraction, and place them in an oven at 80°C for 12 hours. Put it into a high-speed mixer for mixing, place it in an oven at a temperature of 80℃ for 12h, then mix it, add it to a twin-screw extruder for extrusion and granulation. The twin-screw parameters are: the temperature in the first zone is 165℃, and the temperature in the second zone is 185℃, temperature in three zones is 215℃, temperature in four zones is 225℃, temperature in five zones is 225℃, head temperature is 215℃, twin screw speed is 60r / min, feeder speed is 8r / min, pelletizing The machine speed is 300r / min, and the antioxidant is compounded by pentaerythritol tetrapropionate and tris(2,4-di-tert-butylphenyl) phosphite at a mass ratio of 1:1;

[0088] b. Dry the granulation in step a in an oven at a temperature of 60°C overnight, mix it with 30% of the dried glass fiber and 0.2% of...

Embodiment 3

[0091] a. Weigh 75% polypropylene, 0.2% antioxidant, and 0.2% α-nucleating agent 2,2'-methylene-bis(4,6-di-tert-butylphenyl) sodium phosphate according to mass fraction, Placed in an oven at a temperature of 80℃ for 12h, put it in a high-speed mixer, mix it, and then add it to a twin-screw extruder for extrusion and granulation. The twin-screw parameters are: the temperature in the first zone is 150℃, and the temperature in the second zone is 170℃, three zone temperature is 200℃, four zone temperature is 210℃, five zone temperature is 210℃, head temperature is 200℃, twin screw speed is 80r / min, feeder speed is 5r / min, pelletizing The machine speed is 350r / min. The antioxidant is compounded by pentaerythritol tetrapropionate and tris(2,4-di-tert-butylphenyl) phosphite at a mass ratio of 1:1;

[0092] b. Dry the granulation in step a in an oven at a temperature of 60°C overnight, mix it with 24.5% of the dried glass fiber and 0.1% of the compatibilizer, and then extrude it in a twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com