Supported beta crystal core formation agent and preparation method thereof

A crystal nucleating agent and a supported technology, applied in the field of beta crystal nucleating agent and its preparation, can solve the problems of poor compatibility with PP, low nucleation efficiency, coloring of products, etc., so as to improve the nucleation efficiency and solve the problem of yielding Effects of low strength and modulus, increased nucleation points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Aliphatic dicarboxylic acid is dissolved in acetone, mixed with nano-calcium carbonate at room temperature, and the acetone solvent is volatilized at 15°C to obtain a supported β-crystal nucleating agent. Then add β-crystal nucleating agent to polypropylene to prepare high-content β-crystal polypropylene.

[0019] Table 1 shows the ingredient distribution ratio and polypropylene β-crystal content of the supported β-crystal nucleating agent in each embodiment of the present invention.

[0020] Table 1. β crystal content of polypropylene with supported β crystal nucleating agent

[0021]

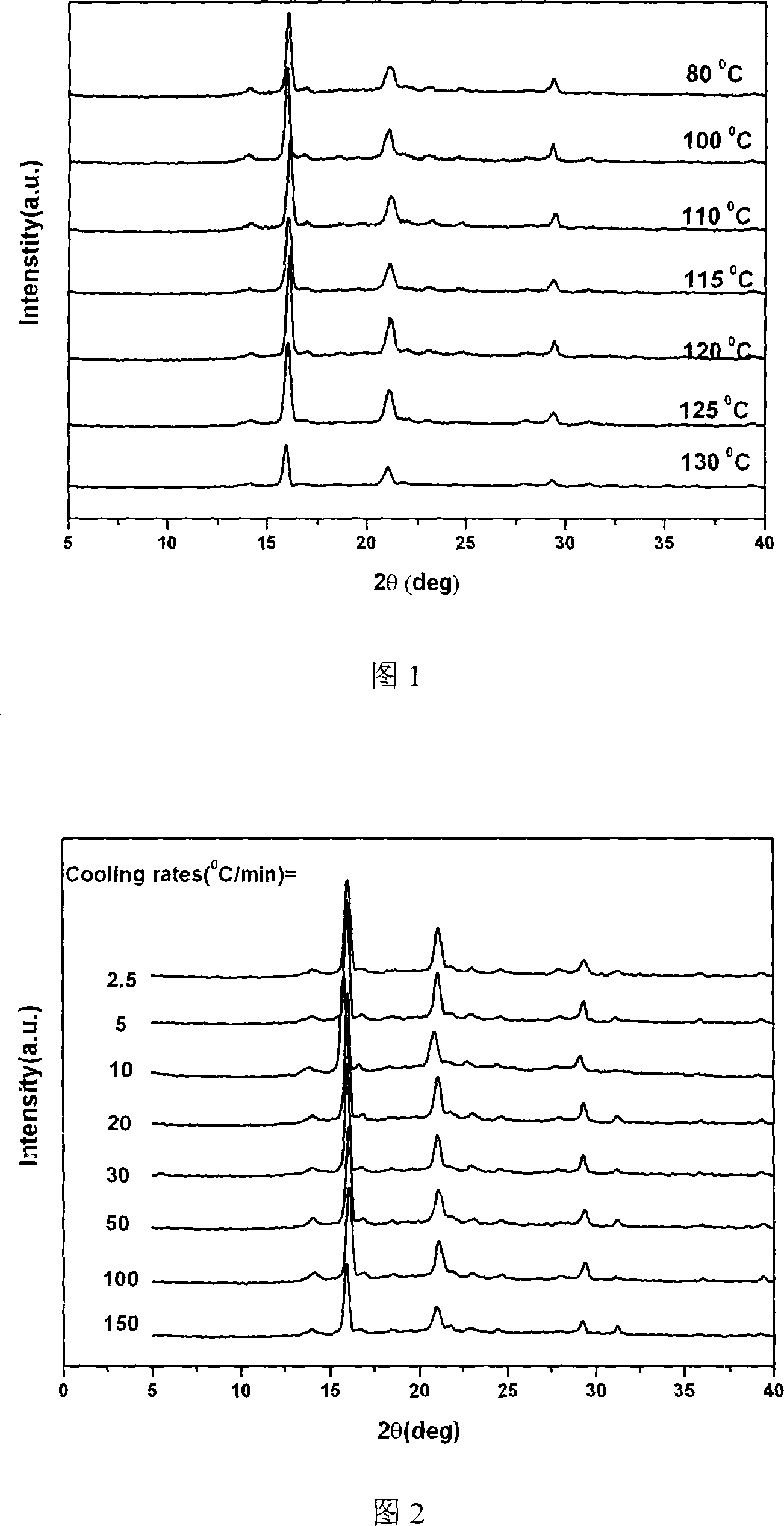

[0022] The WAXD curves of the embodiments of the present invention are shown in Figures 1 and 2. The WAXD curves in Figures 1 and 2 show that the polypropylene added with a supported β-crystal nucleating agent has only the diffraction peaks of β-crystal polypropylene, and basically no diffraction peaks of α-crystal polypropylene. See Table 1 for the content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com