Polydopamine for β-nucleation of polypropylene and polydopamine/polypropylene composites

A technology of polydopamine and composite materials, which is applied in the field of preparation of additives for polymer materials, can solve the problems of poor interaction between polypropylene matrix, decreased β nucleation efficiency, and single function, so as to improve thermo-oxidative stability and reduce Free radical concentration, effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0041] Preparation of β crystal nucleating agent polydopamine:

[0042] Dissolve 9.086g of Tris in 1500ml of deionized water and stir evenly for 10min. The pH of the solution was then adjusted to 8.5 with concentrated hydrochloric acid. After the pH of the above solution was stabilized at 8.5, 6.750 g of dopamine powder was added and stirred evenly for 10 min. The reaction system was moved to an oil bath at 60° C. and stirred for 24 hours. After the reaction, the reaction system was subjected to suction filtration and washed with deionized water, and the washing process was repeated three times. Finally, the washed polydopamine was dried in a vacuum oven at 40° C. to finally obtain a dark brown polydopamine powder.

[0043] Preparation of polypropylene / polydopamine composites:

[0044] In the first step, prepare materials by corresponding components (see Table 2);

[0045] In the second step, the polypropylene and polydopamine powders were dried in a vacuum oven at 40°C f...

Embodiment 5-8

[0065] The raw materials and their weight proportions of Examples 5-8 are shown in Table 1, and the preparation method of the polypropylene / polydopamine composite material is the same as that of Example 1.

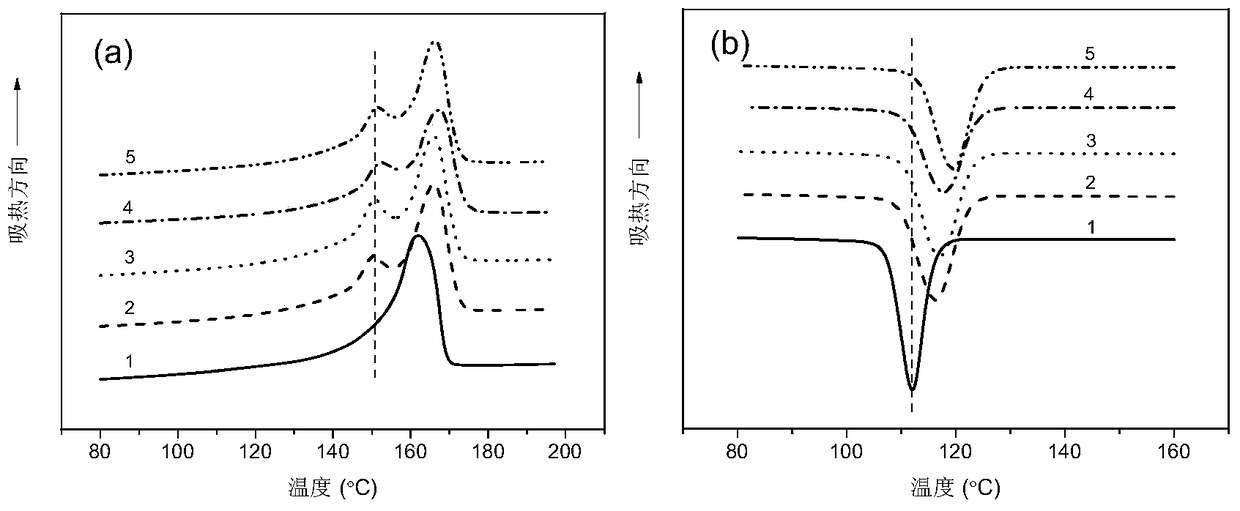

[0066] The experimental results all show that: the polydopamine particles prepared by method 2 can be well dispersed in the polypropylene matrix. After DSC and XRD characterization results, it is found that a lower content of particles can significantly induce the formation of β crystals in polypropylene, which is a An efficient β-nucleating agent. According to the results of oxidation induction test, it is found that polydopamine particles with different particle sizes prepared by different methods can significantly improve the thermo-oxidative stability of polypropylene materials, which shows that polydopamine particles are a multifunctional and efficient β-nucleating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com