Patents

Literature

89 results about "Core formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Core formation. The core formed during accretion, as metal from impactors sank through a magma ocean to the center of the Earth. Liquid metal in contact with liquid silicate equilibrated at high pressures and temperatures, resulting in the core and mantle compositions that we see in the Earth today.

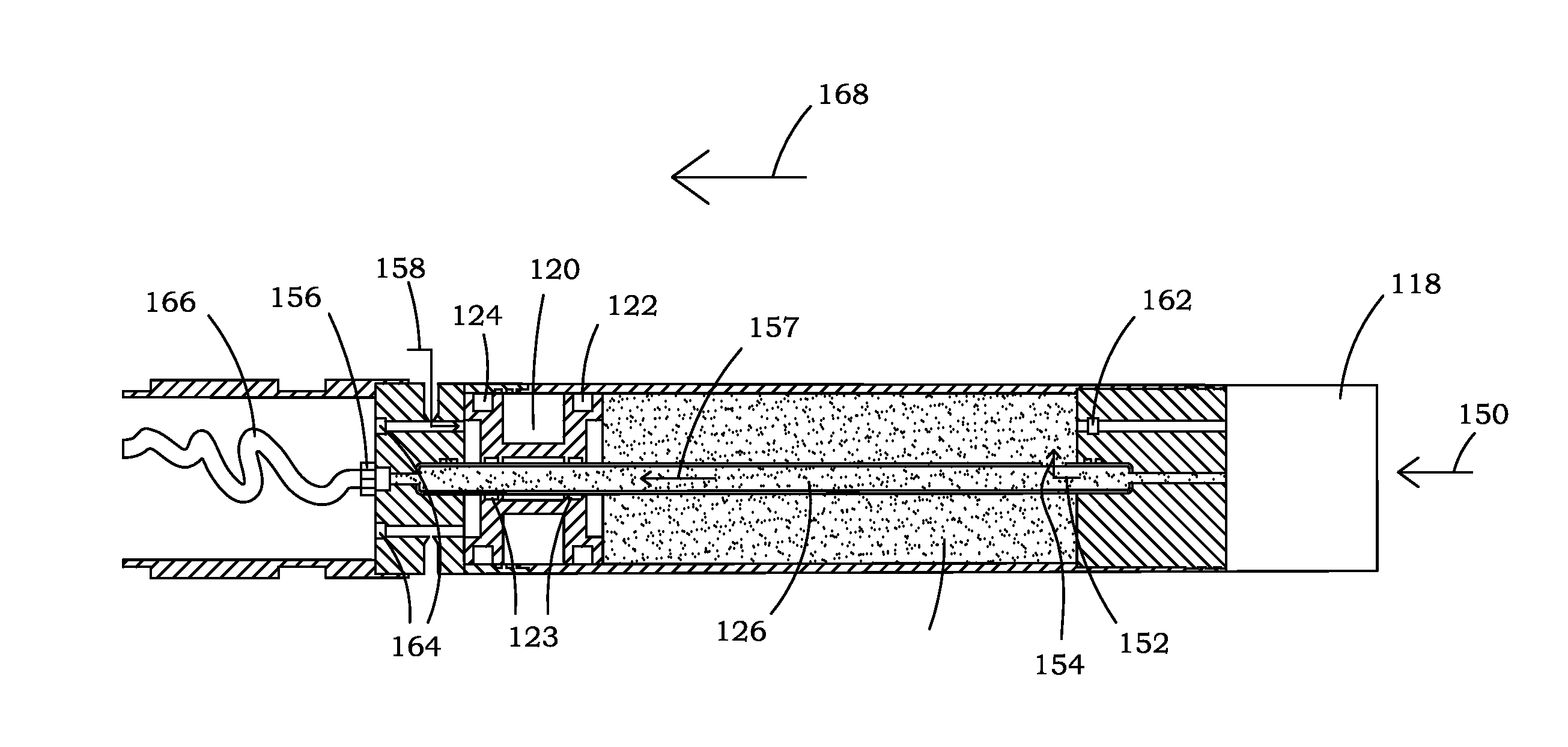

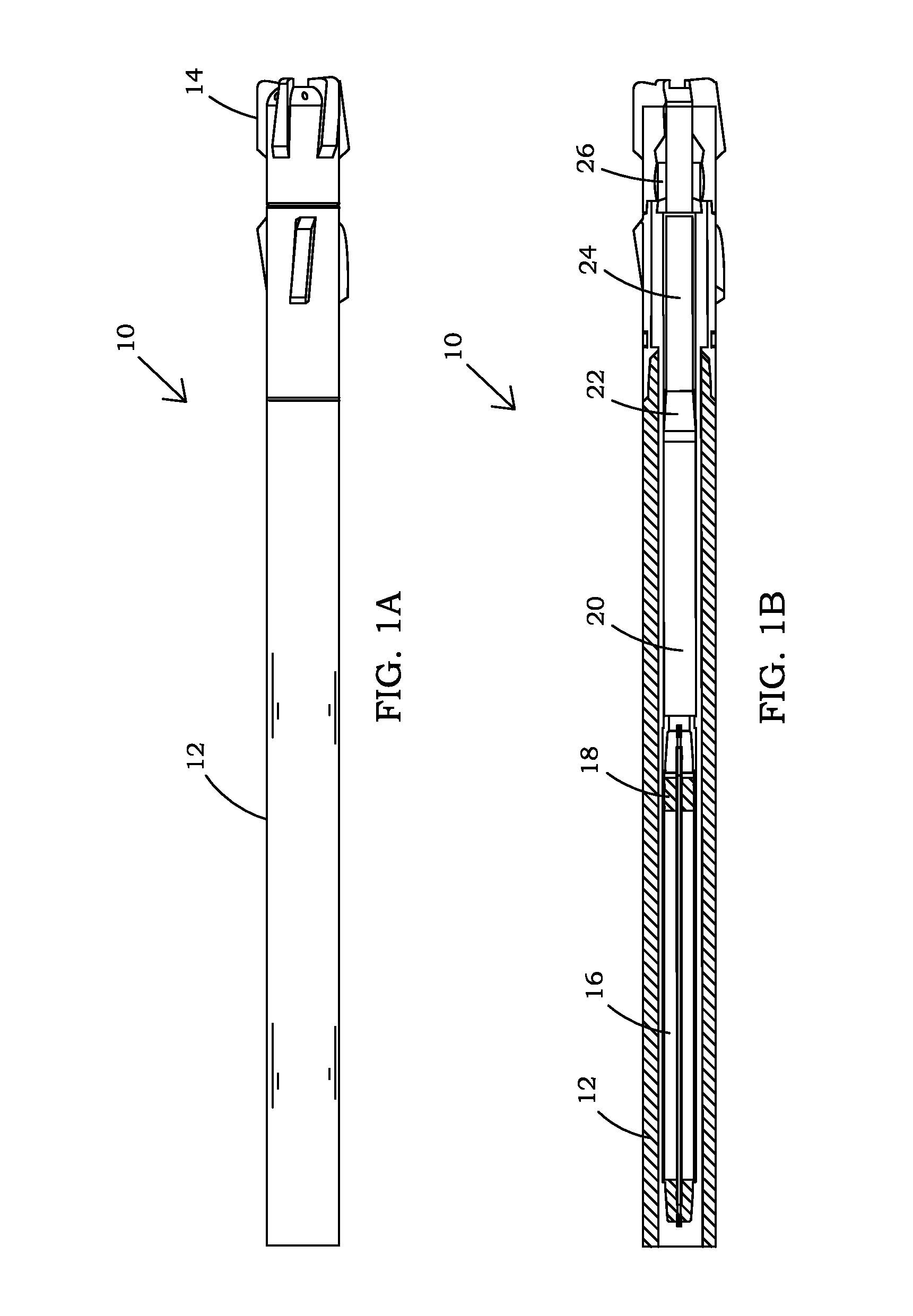

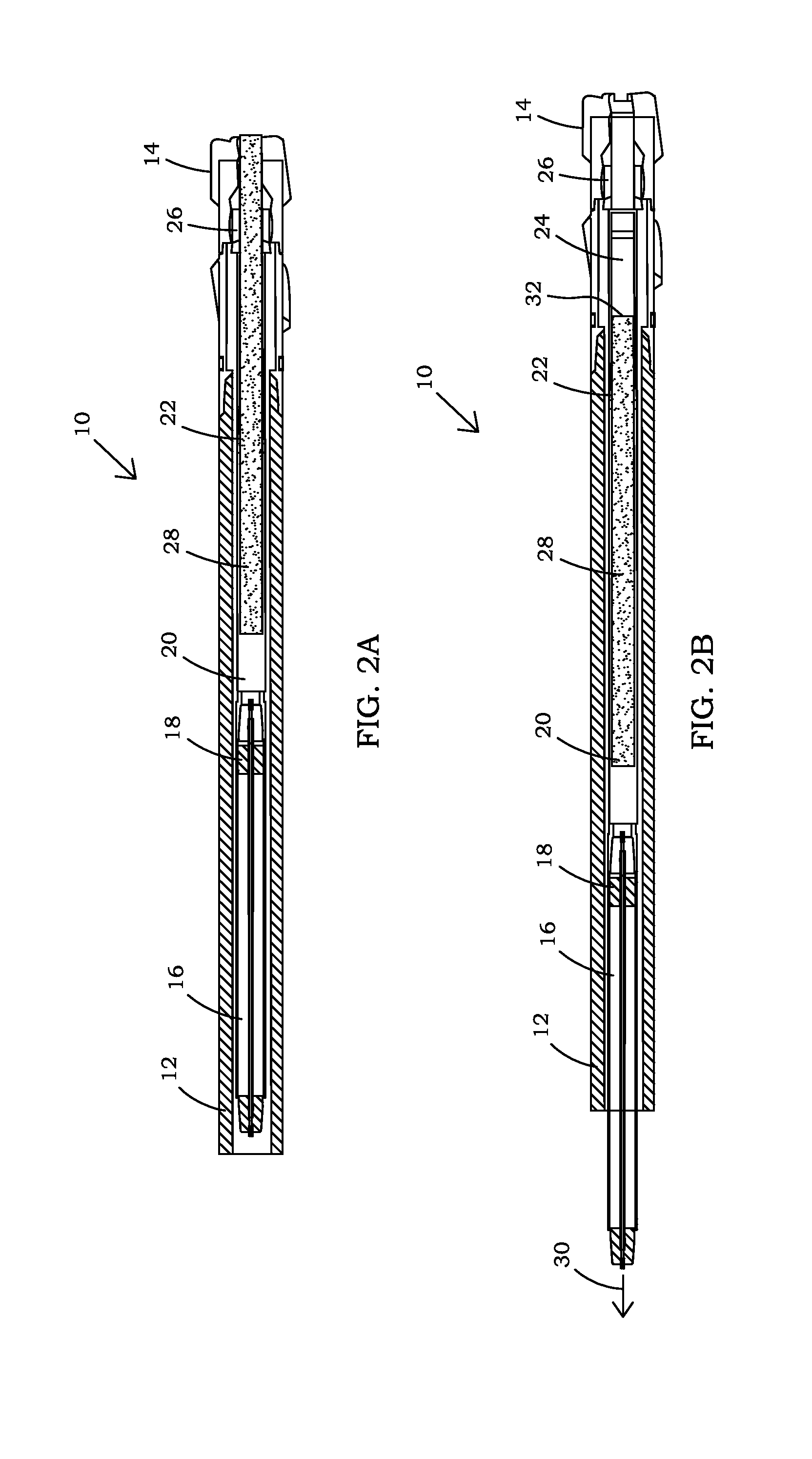

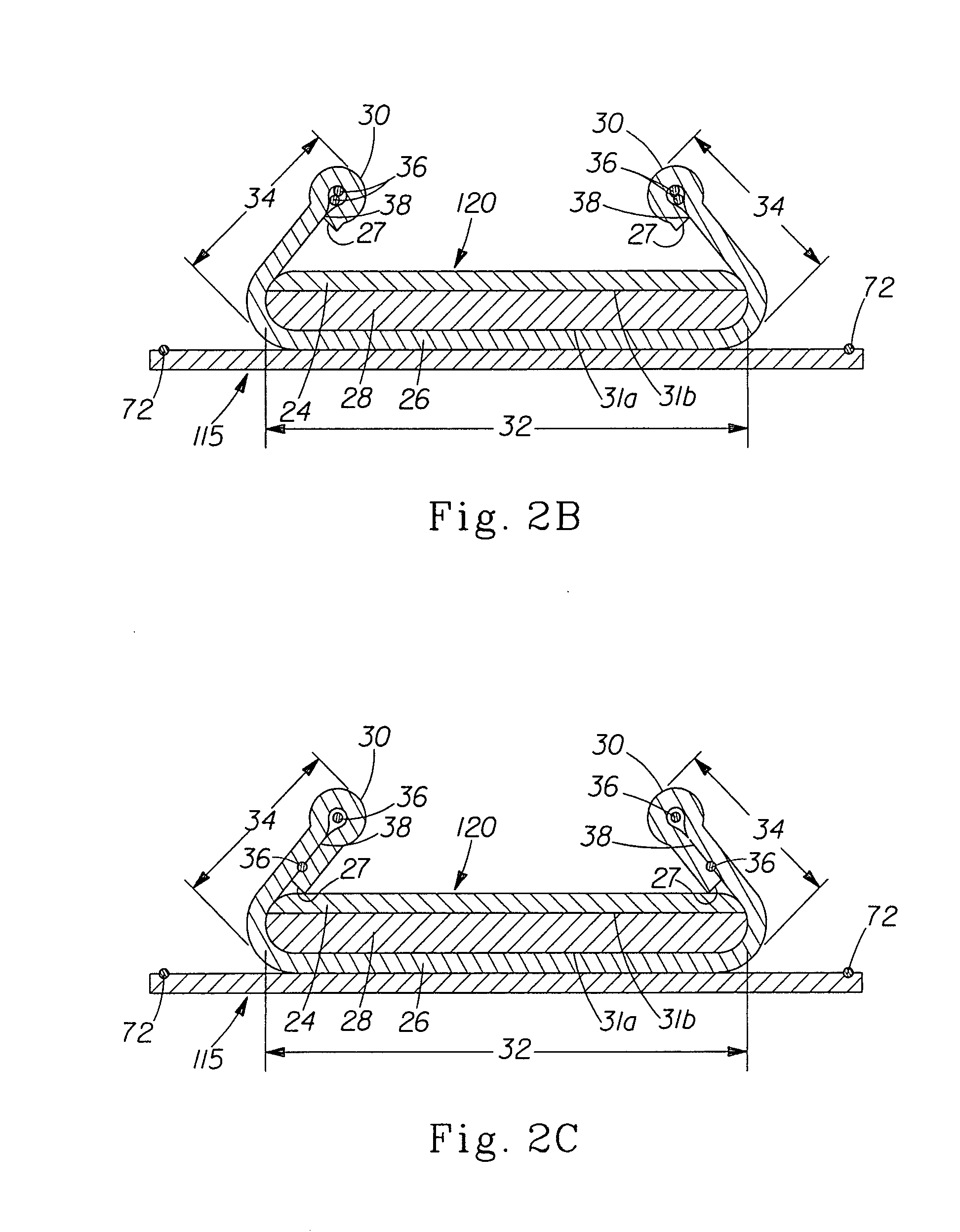

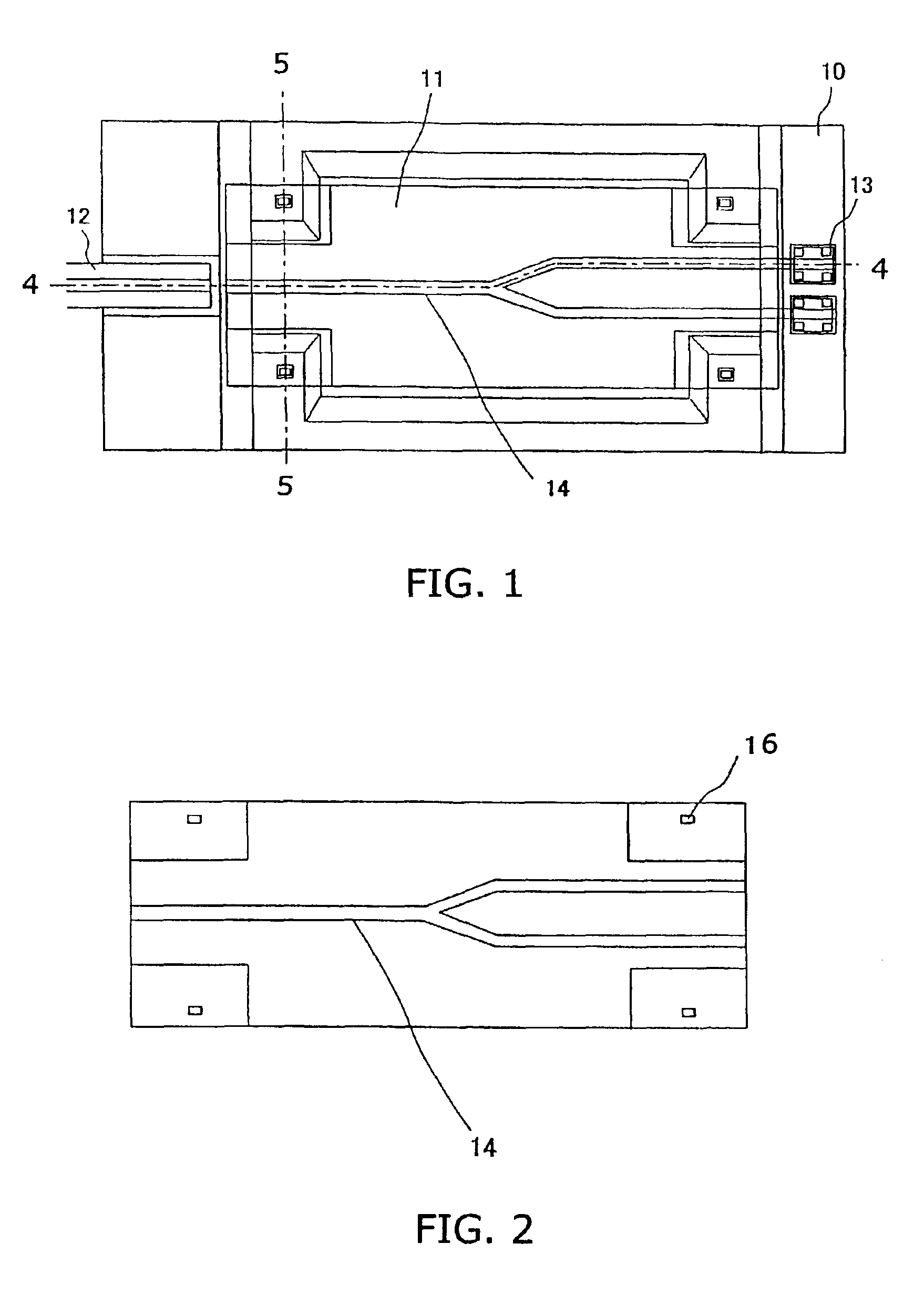

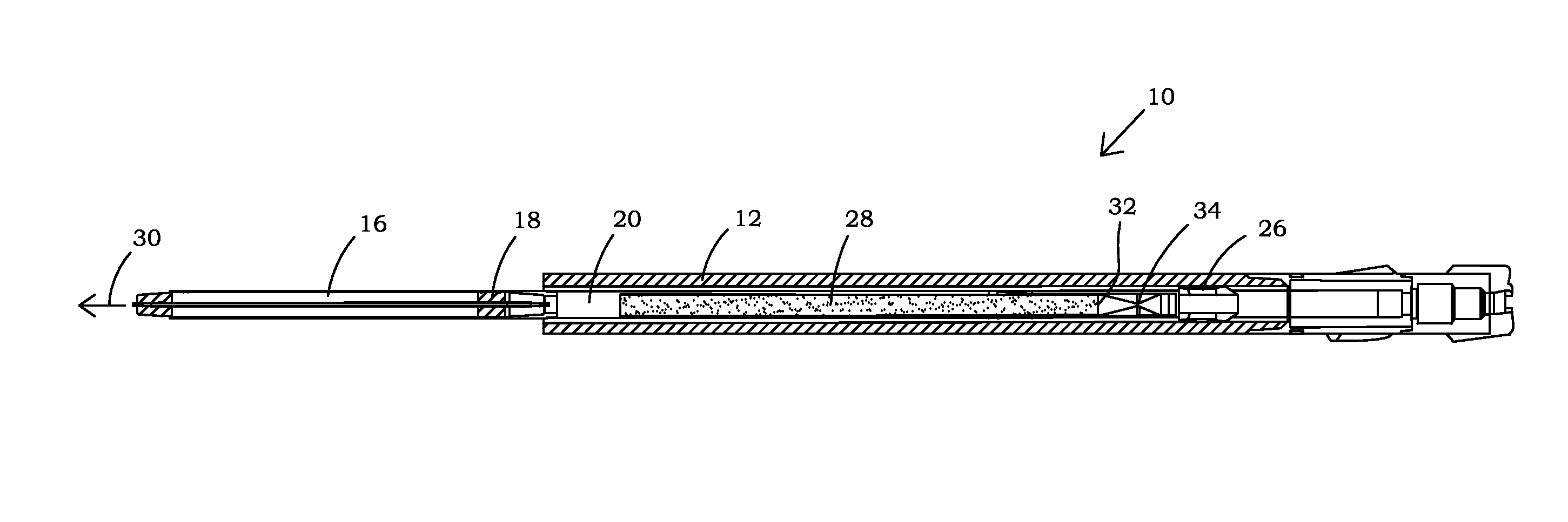

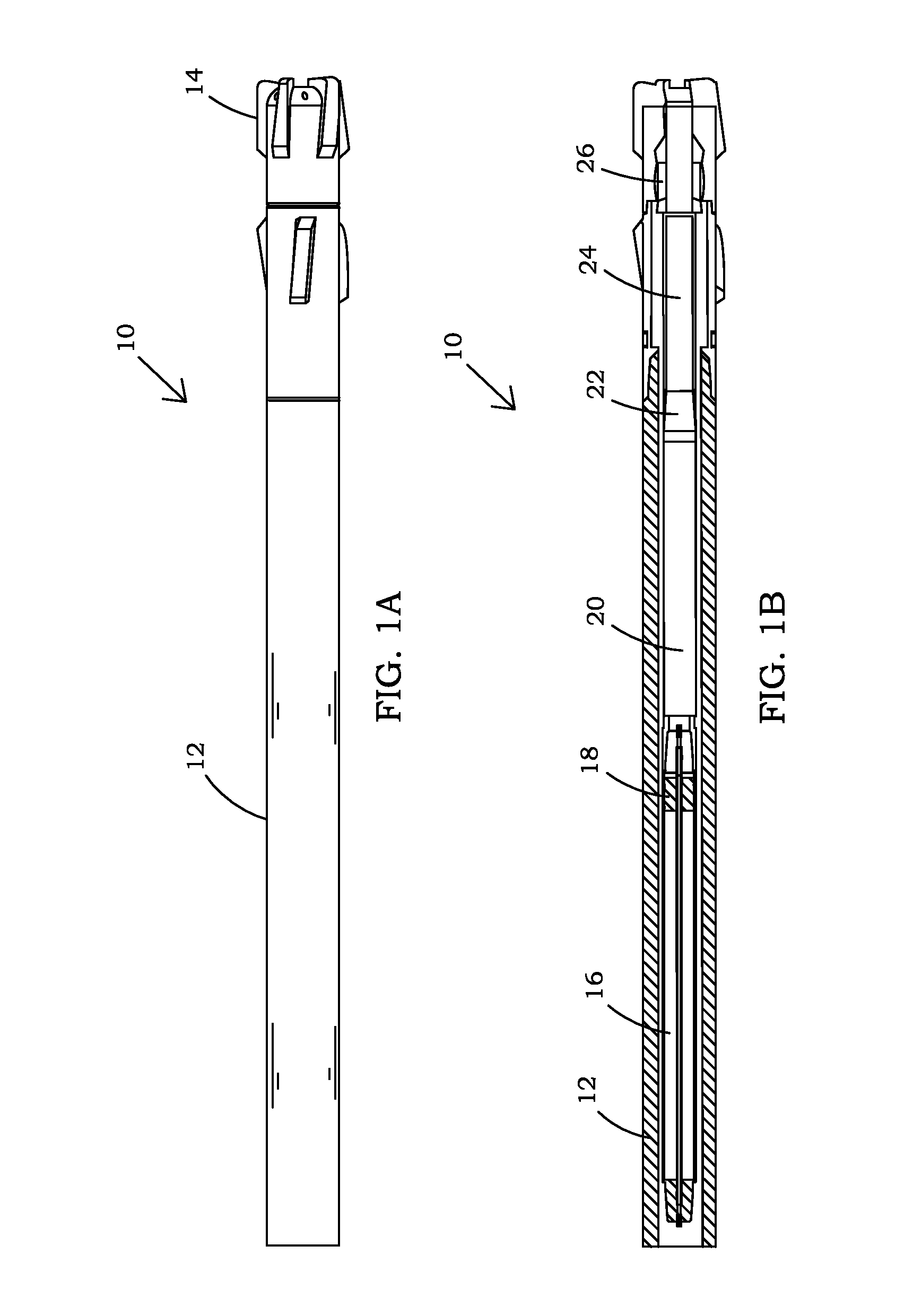

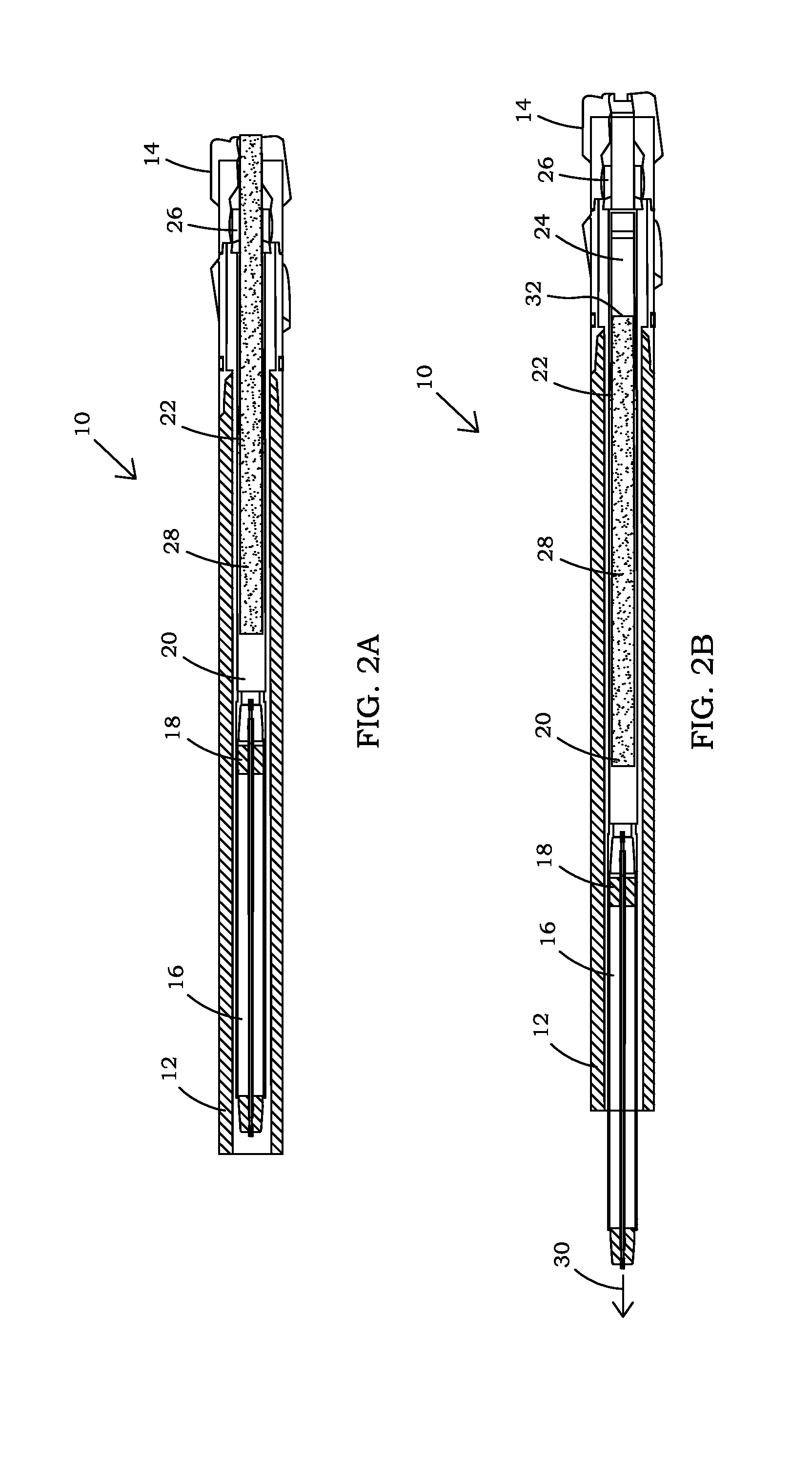

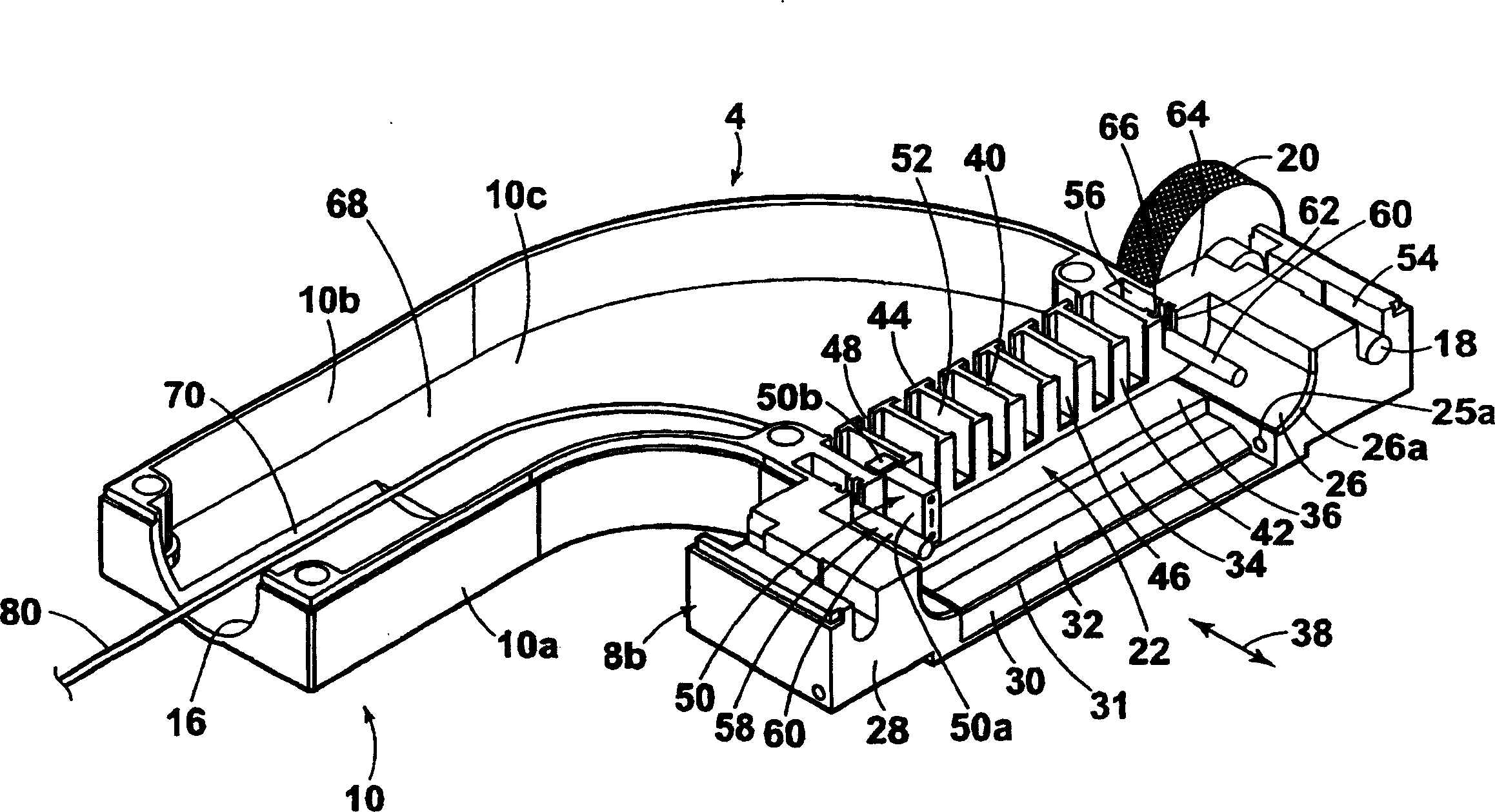

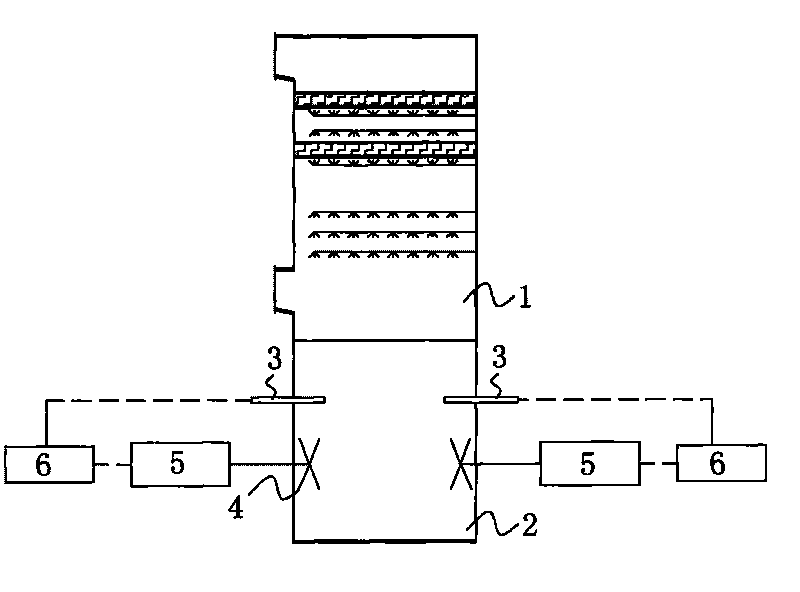

High pressure coring assembly and method

ActiveUS20120234607A1Large coreThe result is accurateDrill bitsConstructionsEngineeringHigh pressure

A wireline or drill pipe retrievable coring tool with an inner barrel to receive a core, a bottom coring tool valve operable to seal off a bottom of the inner barrel and at least one pressure canister operable to receive fluid from the core in the inner barrel. The pressure canister is operable to significantly reduce the pressure inside the inner barrel utilizing an expandable chamber to receive fluid from the core as the tool is removed from the wellbore. In one embodiment, a bottom valve mechanism moves the cored formation materials out of the way of the bottom valve before the bottom valve is closed.

Owner:CORPRO TECH CANADA LTD

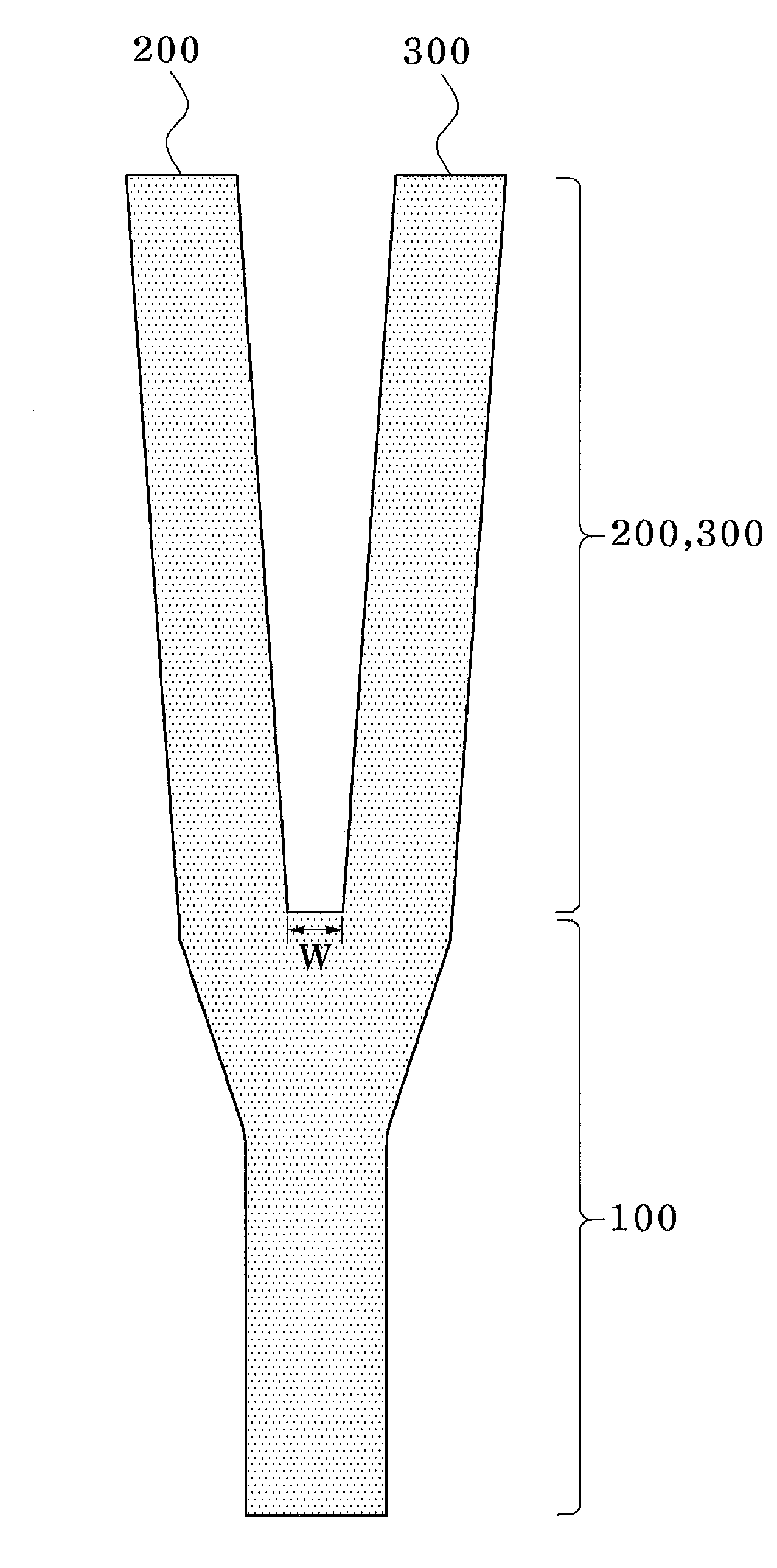

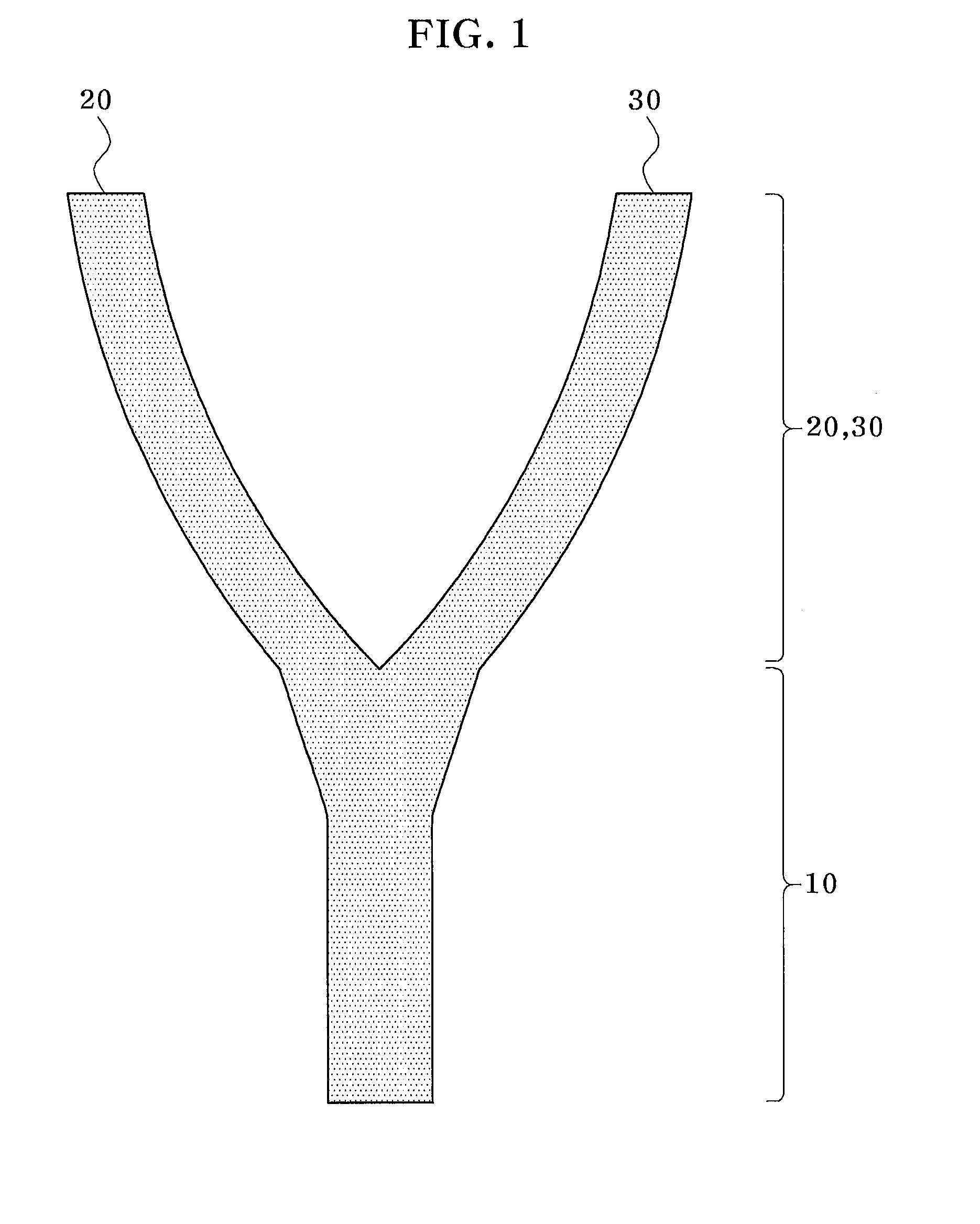

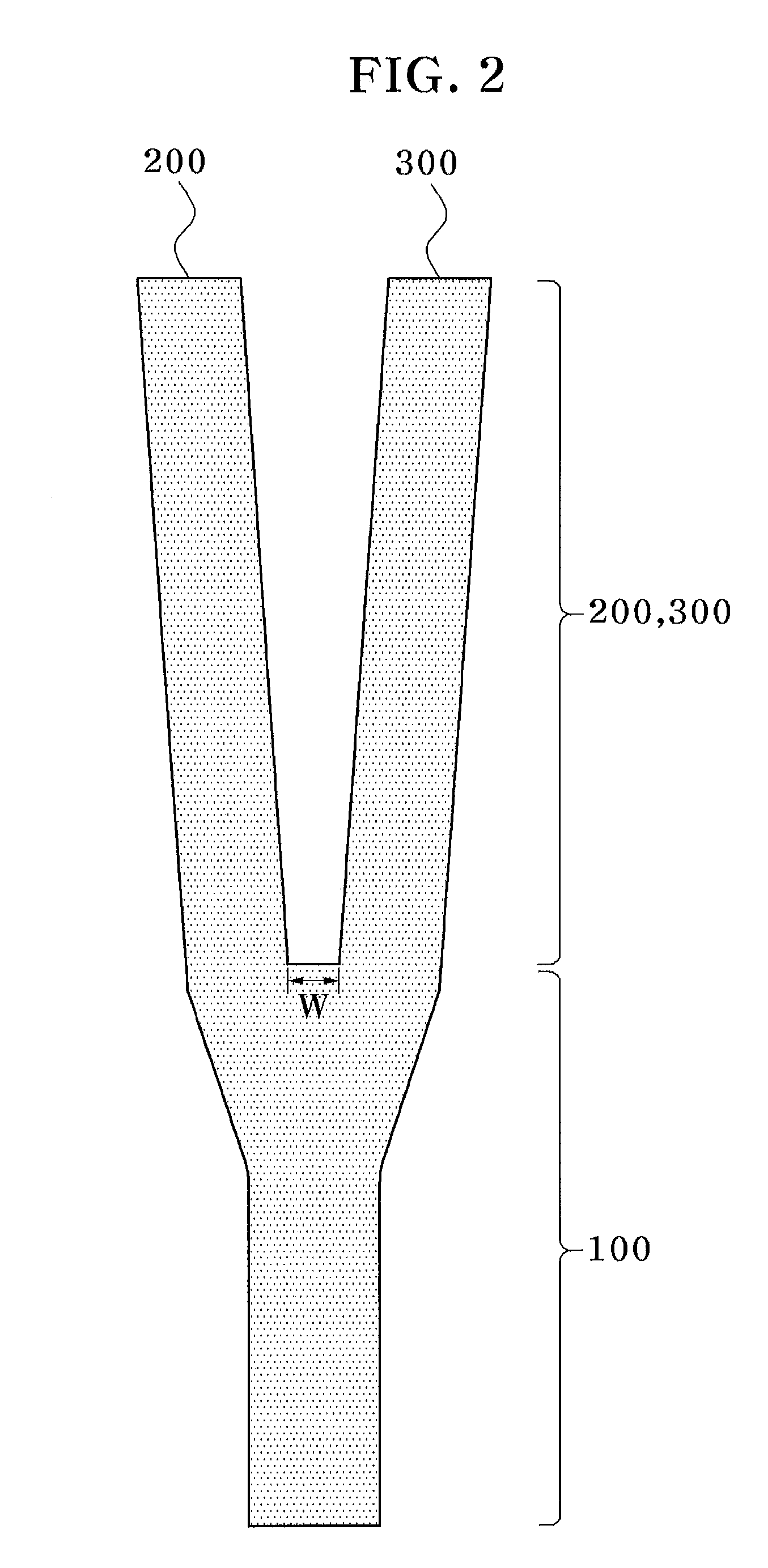

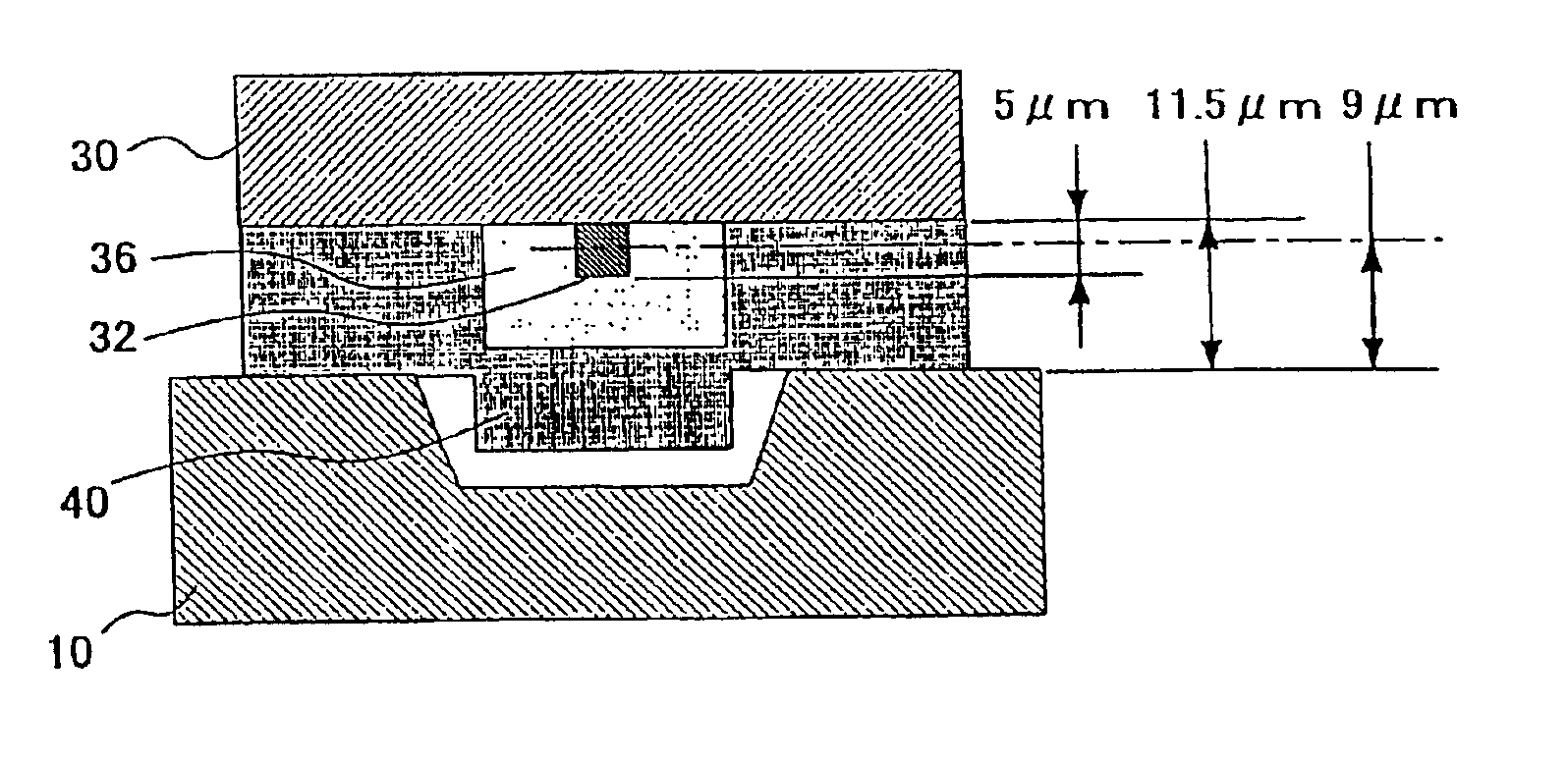

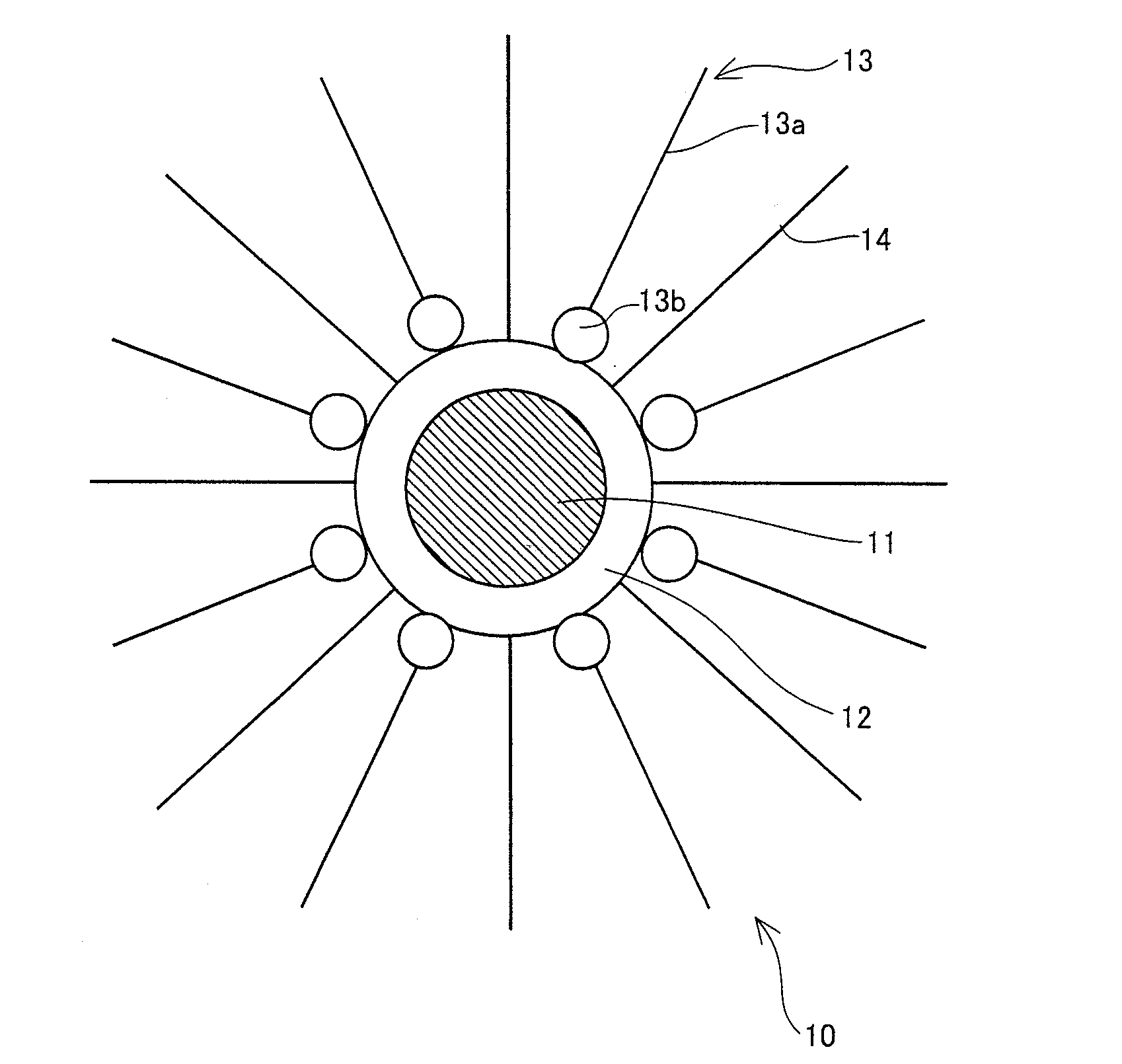

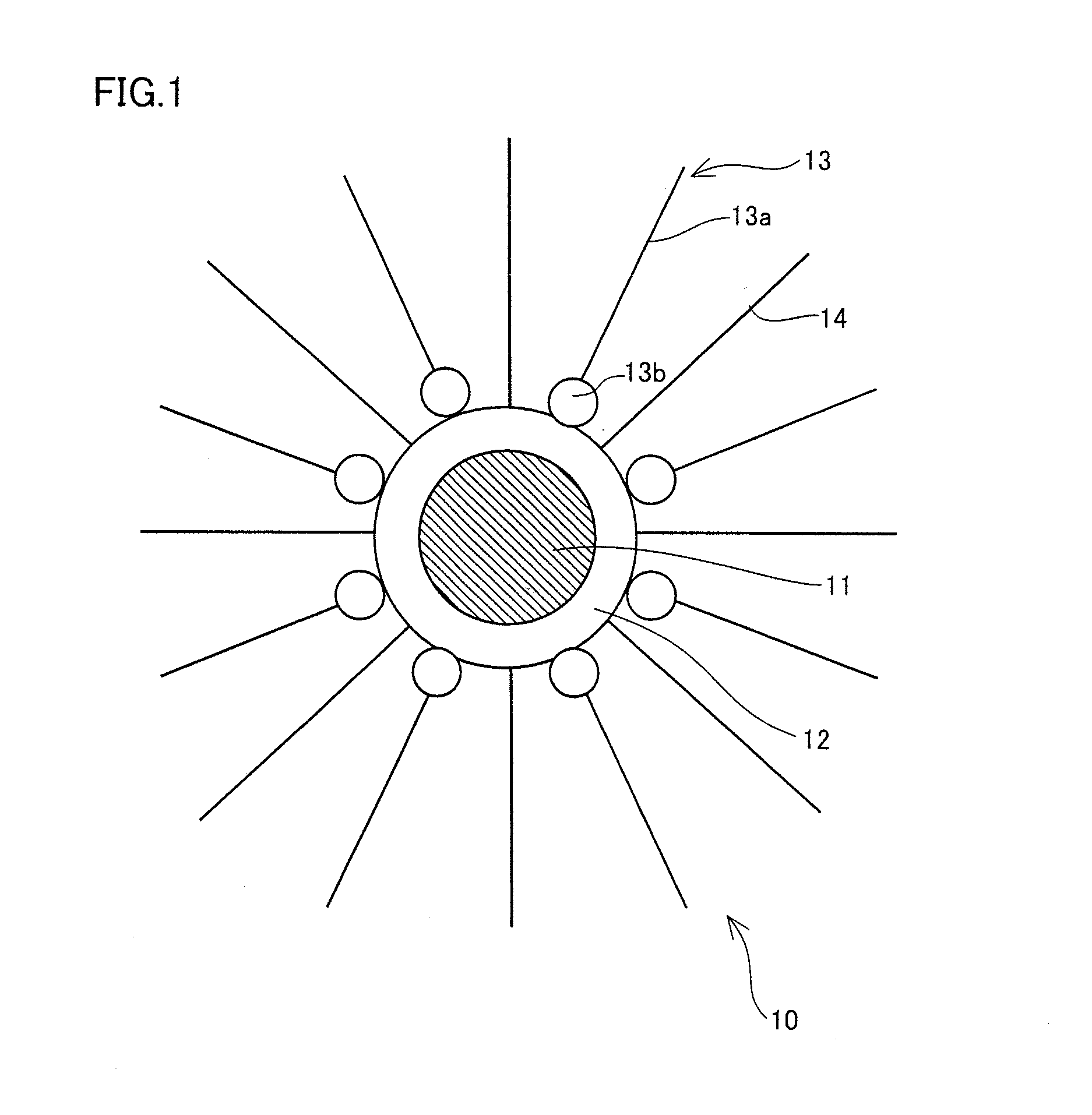

Lightwave Circuit and Method for Manufacturing Same

InactiveUS20140023320A1Minimizing optical power lossQuality improvementOptical articlesCoupling light guidesEngineeringCore formation

Provided are a lightwave circuit and a method of manufacturing the same. The lightwave circuit includes a first substrate having an engraved core formation groove which is formed on an upper portion of the first substrate, a core layer which is formed inside the engraved core formation groove, a BPSG bonding layer which is formed on the first substrate including the core layer, and a second substrate which is formed on the BPSG bonding layer. Accordingly, light loss and branching uniformity of the lightwave circuit are effectively improved, and the lightwave circuit is manufactured simply and inexpensively while also further improving light loss and branching uniformity of the lightwave circuit.

Owner:LEE SEO YOUNG

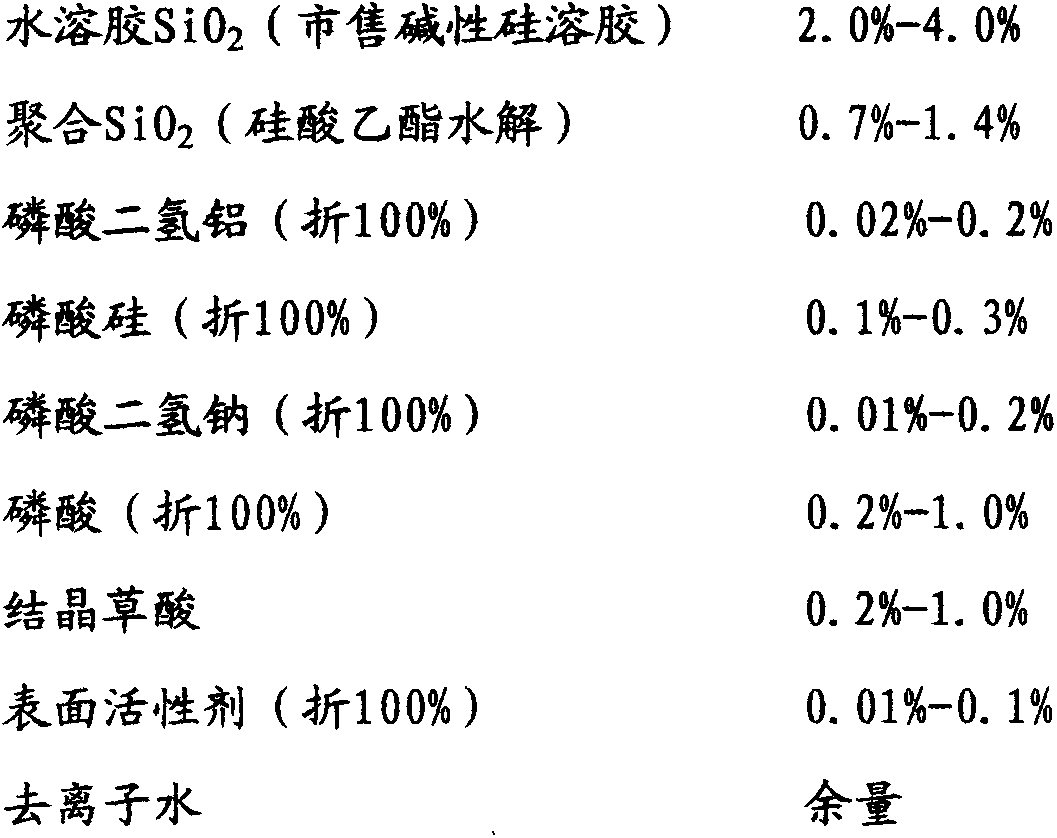

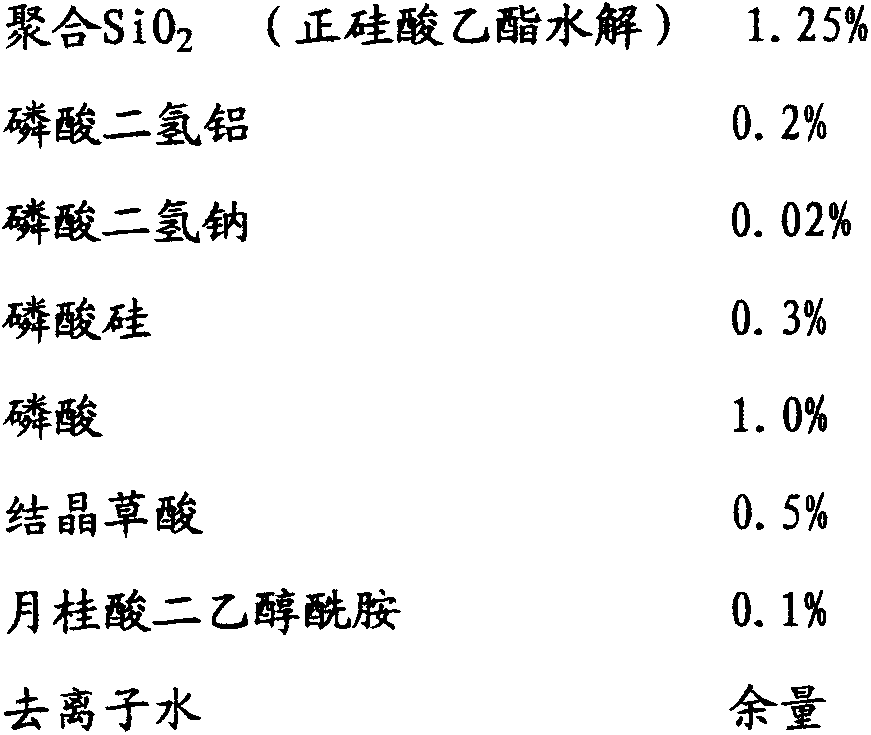

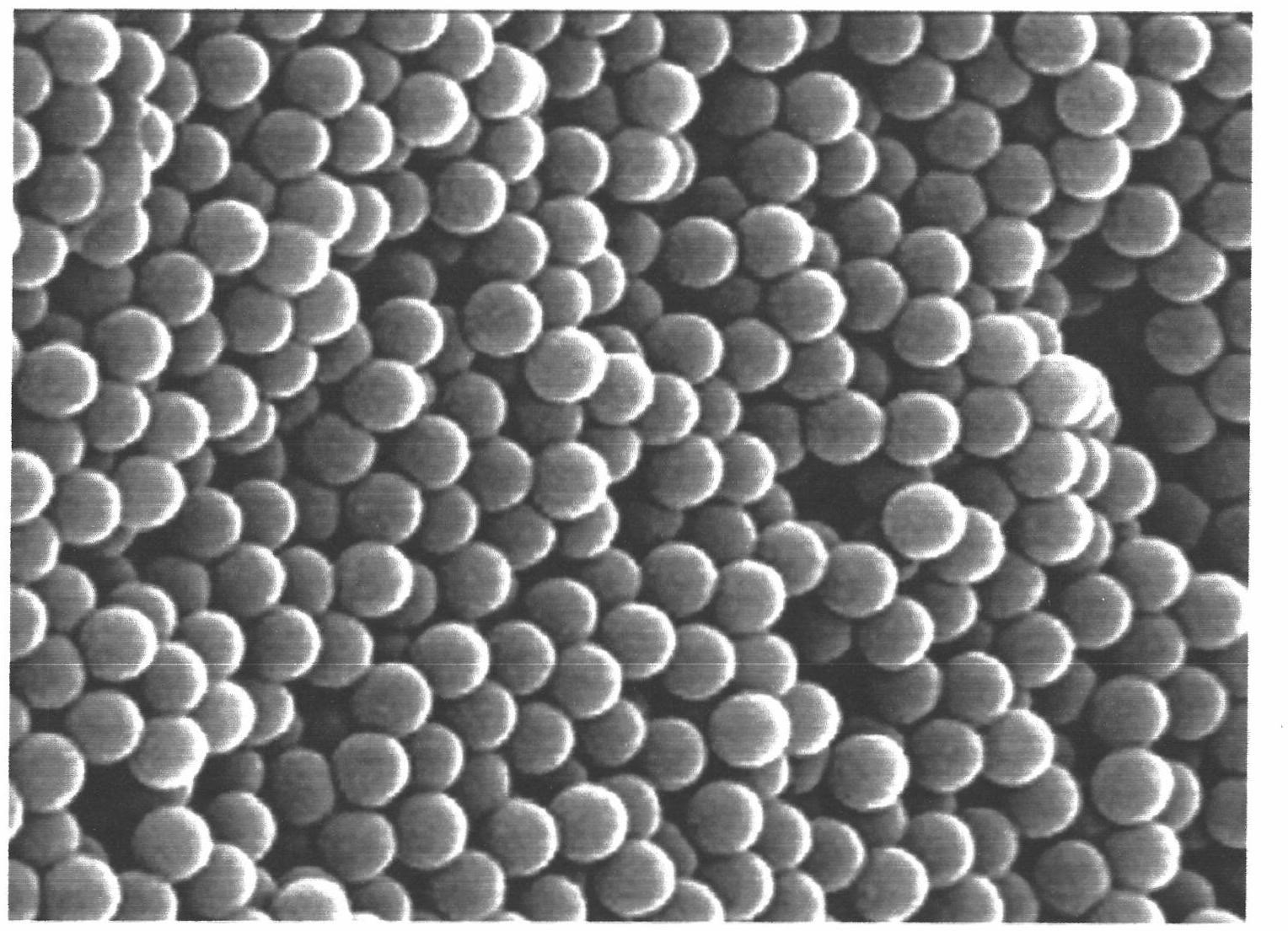

Solar glass antireflection antifouling paint and production method thereof

InactiveCN103627226AOvercome the defect of poor weather resistanceImprove anti-reflection effectCoatingsPhosphatePhosphoric acid

The invention discloses solar glass antireflection antifouling paint with high antireflection performance and high weather resistance and a production method of the solar glass antireflection antifouling paint. The solar glass antireflection antifouling paint is prepared from alkaline silica gel, poly SiO2, aluminium dihydrogen phosphate, silicon phosphate, phosphoric acid, a surfactant and deionized water. The production method comprises the following steps: a porous silicon dioxide core generated in ethyl silicate hydrolysis is covered with another hard silicon dioxide shell, silicon dioxide particles in the paint have a core-shell structure, the silicon dioxide core formation and the silicon dioxide shell covering are carried out at the same time, aluminium dihydrogen phosphate and silicate phosphate are used as a silicon dioxide curing agent to enhance the weather resistance of an antireflection membrane. The problem that antireflection performance and the weather resisting performance of conventional solar glass self-cleaning antireflection paint can offset each other is solved, the power generating efficiency of a solar cell can be improved and stabilized greatly, and the maintenance management cost of the solar cell can be reduced.

Owner:TIANJIN ZHONGKE CHEM

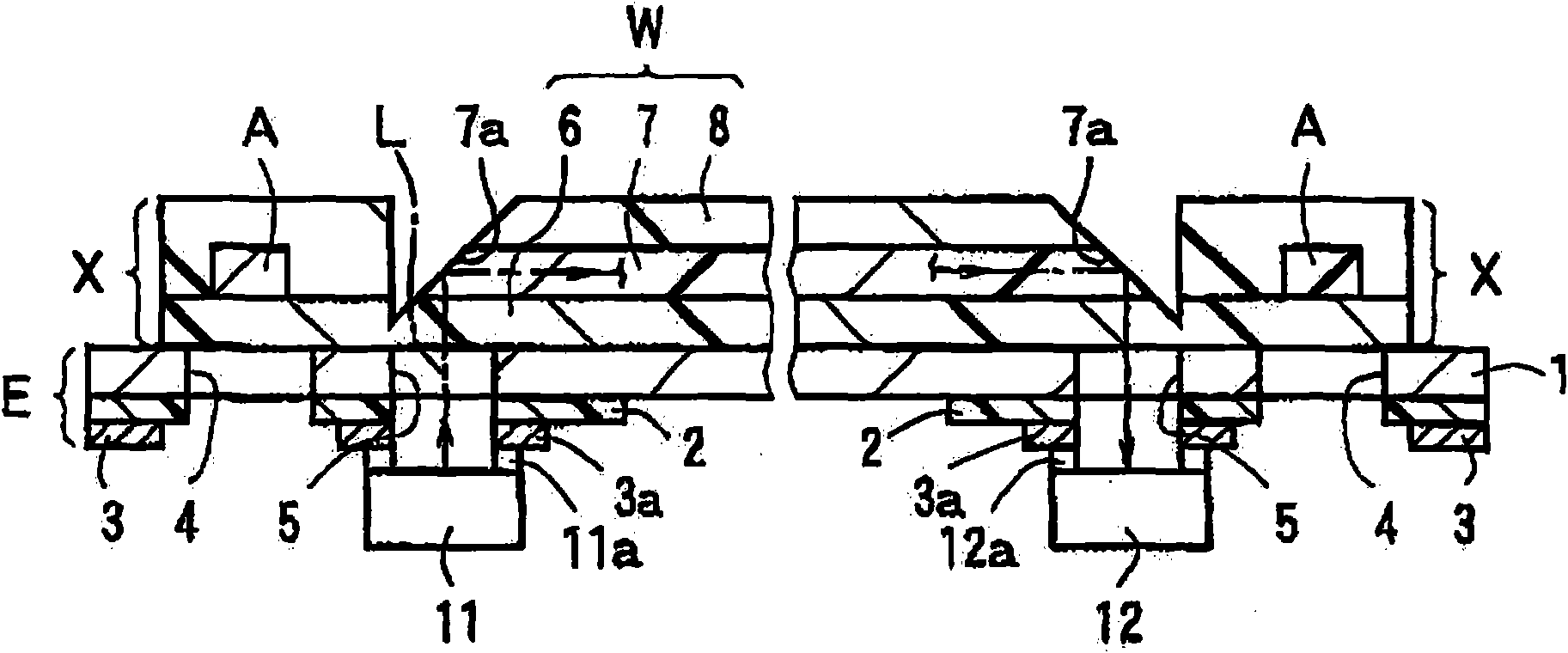

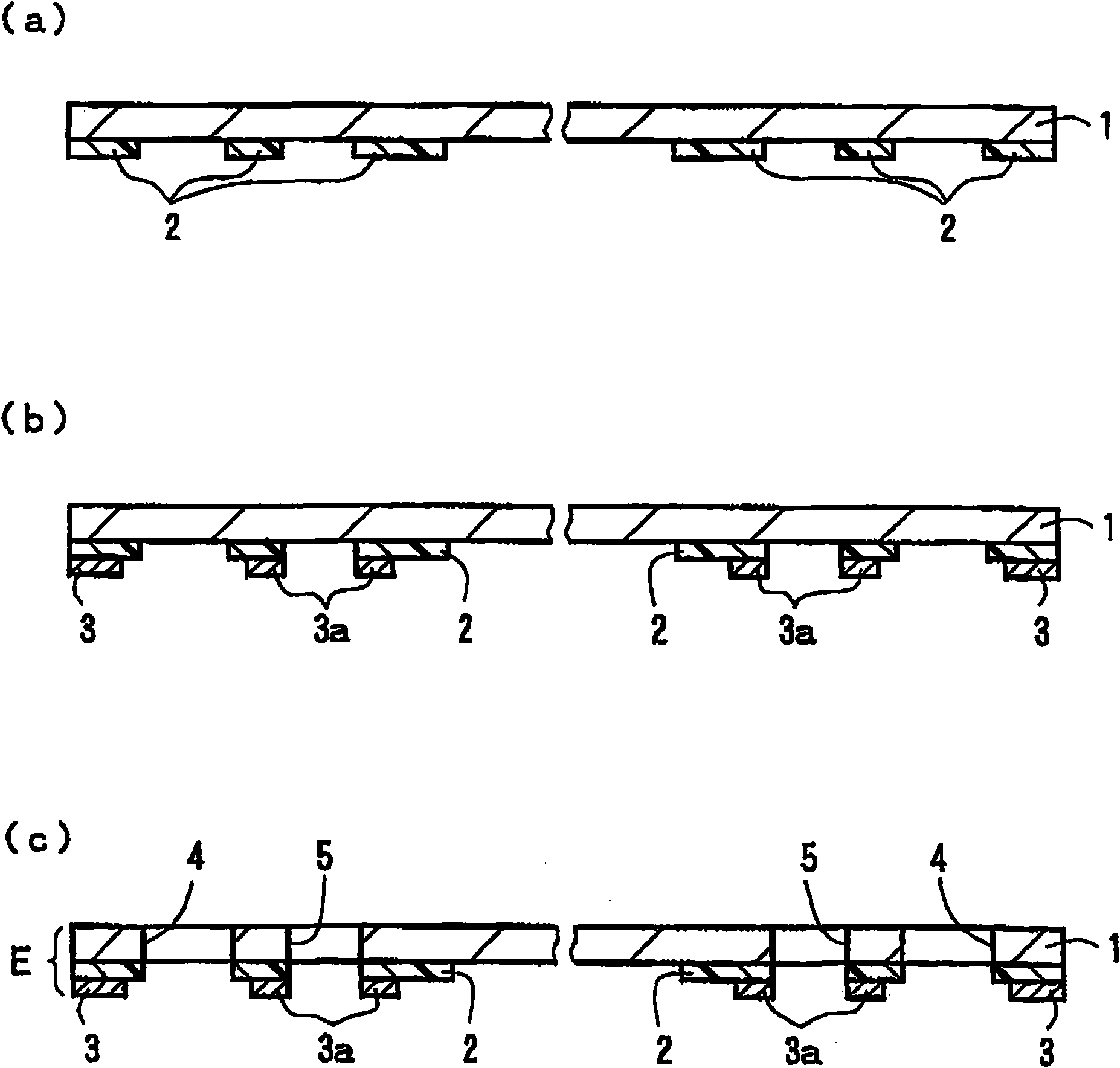

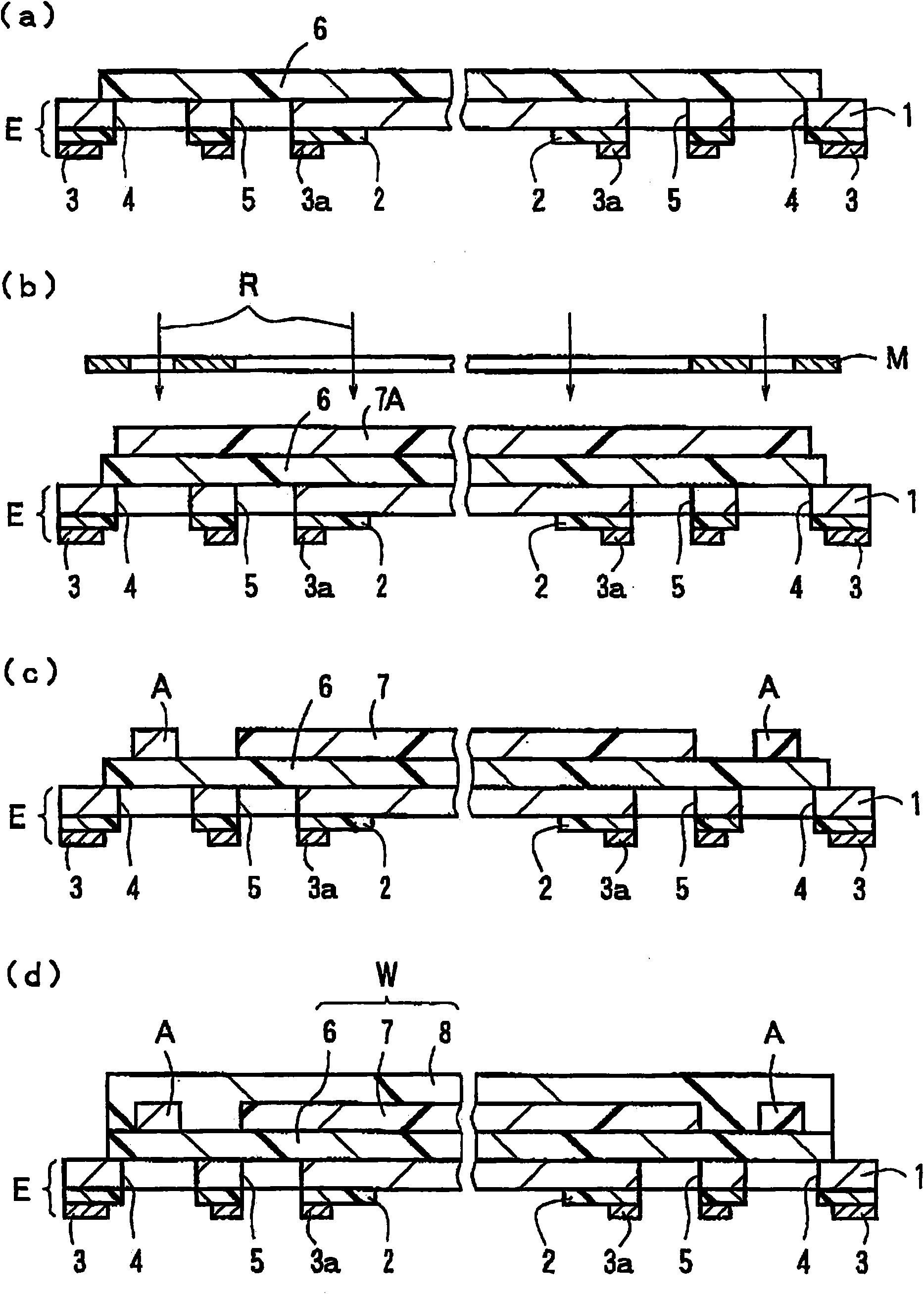

Manufacturing method of opto-electric hybrid board

ActiveCN101566706ACoupling loss is smallCircuit optical detailsPrinted circuit aspectsEngineeringOpto electronic

An opto-electric hybrid board manufacturing method improves the alignment accuracy of an optical element with respect to a core of an optical waveguide. When a core (7) of an optical waveguide (W) is formed on a surface of an electric circuit board (E), the core (7) and optical element positioning alignment marks (A) are simultaneously formed from a photosensitive resin layer including a core formation region and an alignment mark formation region by a single photolithography process. In an optical element mounting step, a light emitting element (11) and a light receiving element (12) are mounted at proper positions with respect to the core (7) of the optical waveguide (W) with reference to the alignment marks (A).

Owner:NITTO DENKO CORP

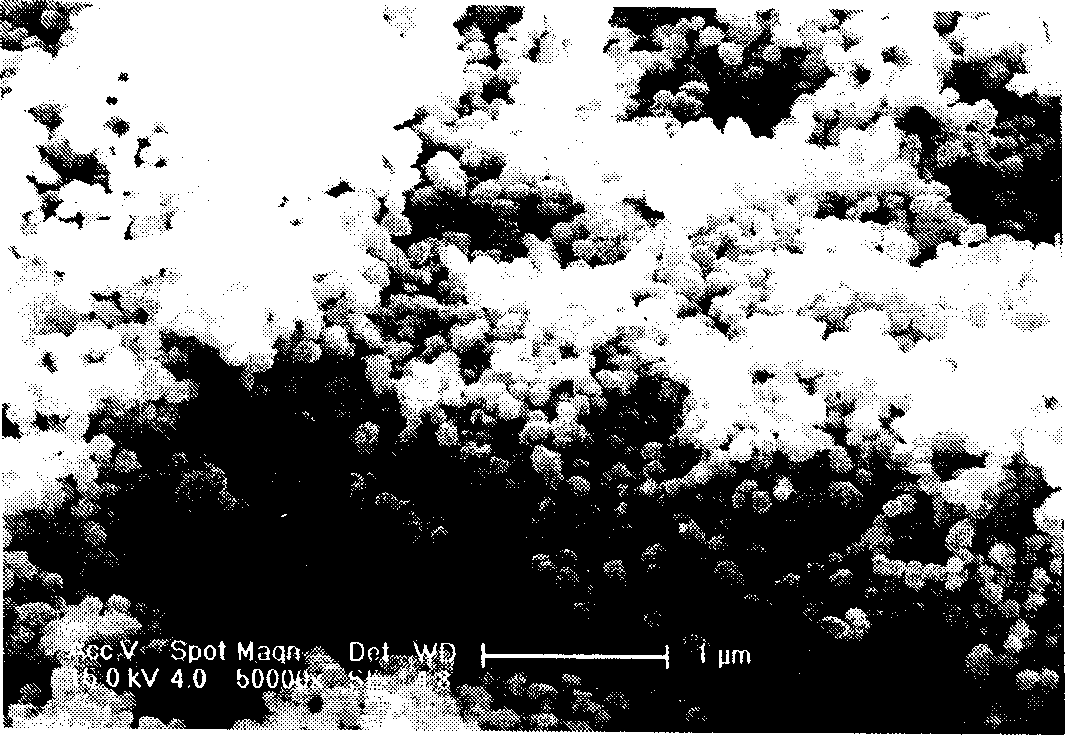

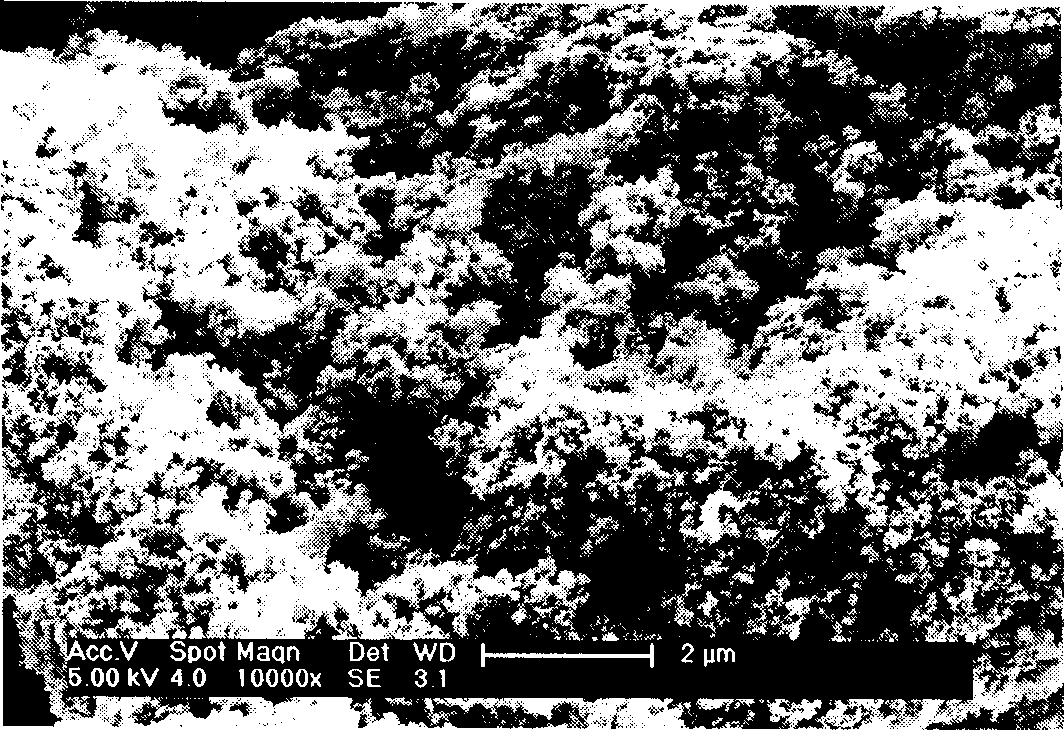

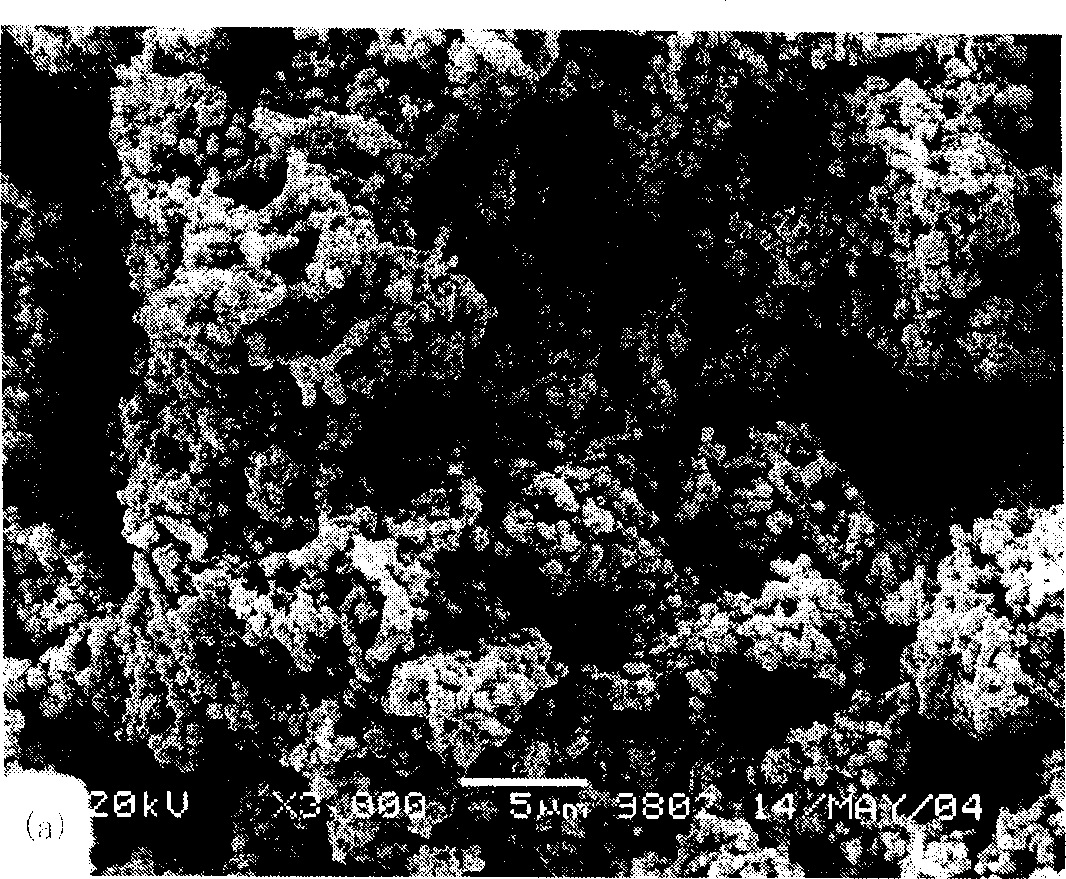

Liquid phase fluidized reduction method for preparing nanometer nickel powder

The invention relates to a method for preparing nanometer nickel powder, especially for preparing spherical nanometer nickel powder with grain size being 30-100 nm and specific surface area being larger than 8 m2 / g. The invention is characterized in that: dissolving nickel nitrate or nickel sulfate with deionized water, adding proper amount of surface activator to prepare nickel hydroxide slurry; fastening reaction on rapid heat transmission and even temperature fluid bed with reducer and accelerant to control core formation of nickel powder and crystal growth, preparing spherical nanometer nickel powder; desalting reacting liquid and returning it to reactor, moderating temperature and retention time; returning washing liquid to batching process. The invention controls size of nanometer nickel powder by controlling crystal growth time, and prepares spherical nanometer nickel powder with size being 30-100 nm and specific surface area being larger than 8 m2 / g; the reacting liquid and washing liquid are reused in process, the wastewater discharge is reduced, and the production is lowered.

Owner:CENT SOUTH UNIV

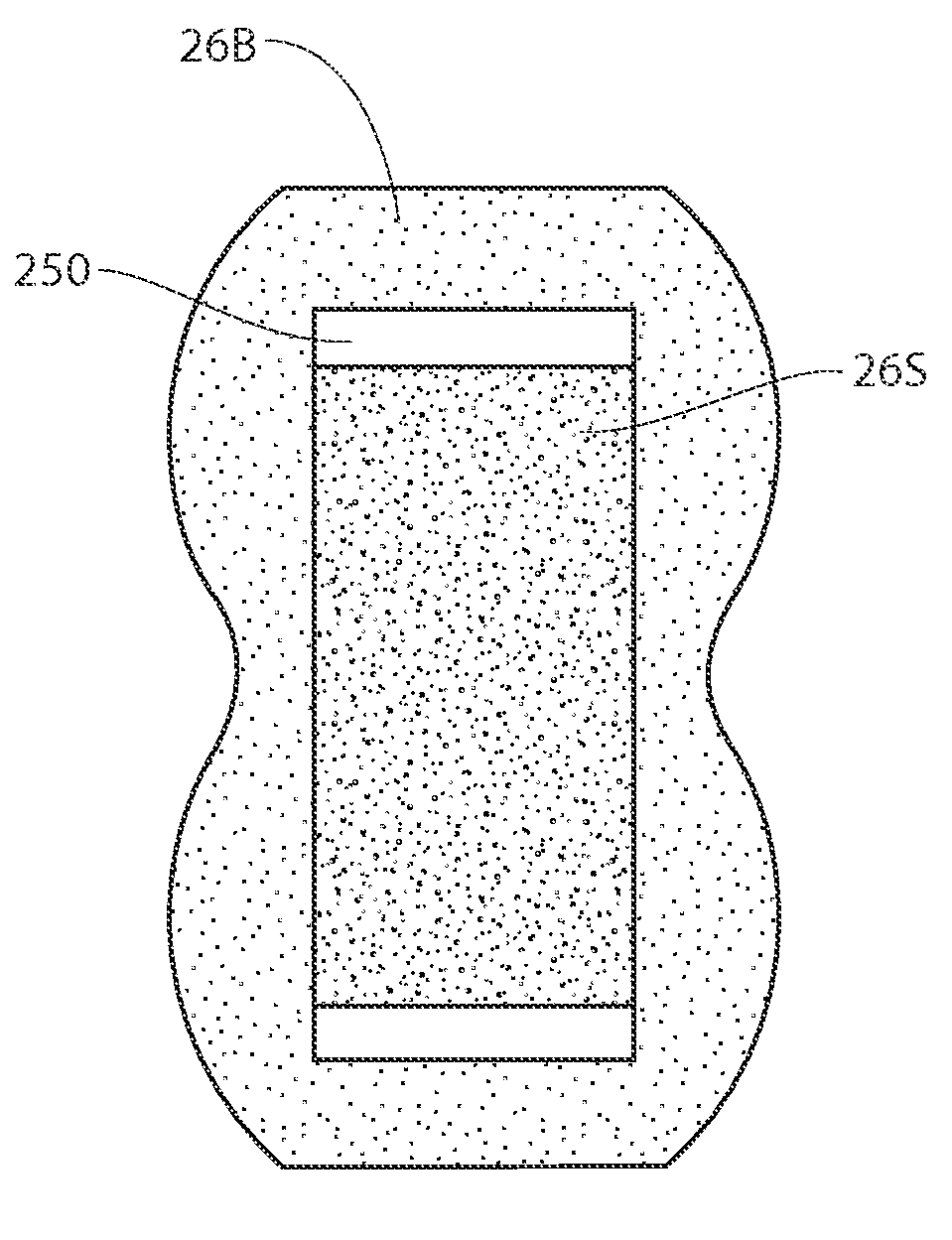

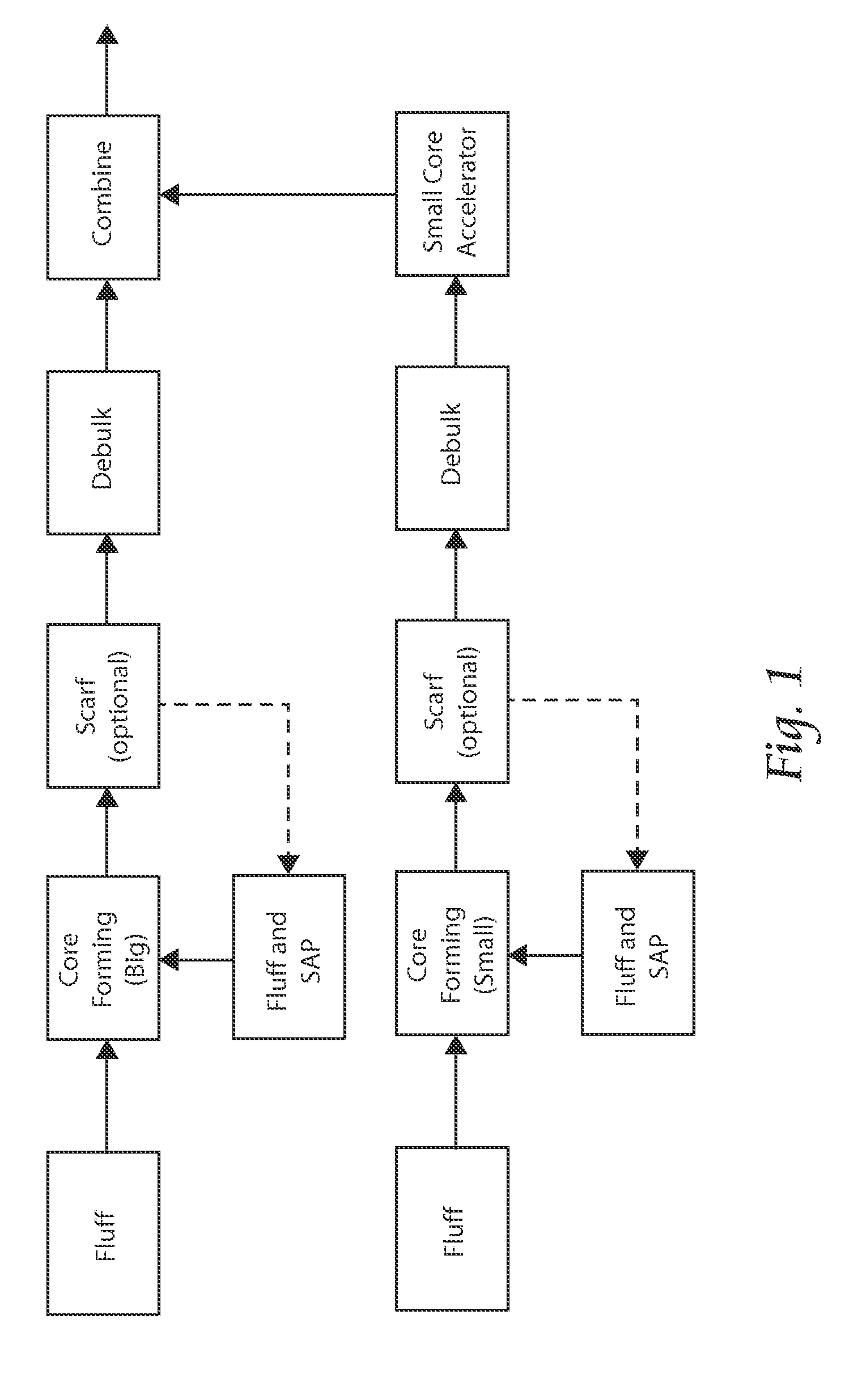

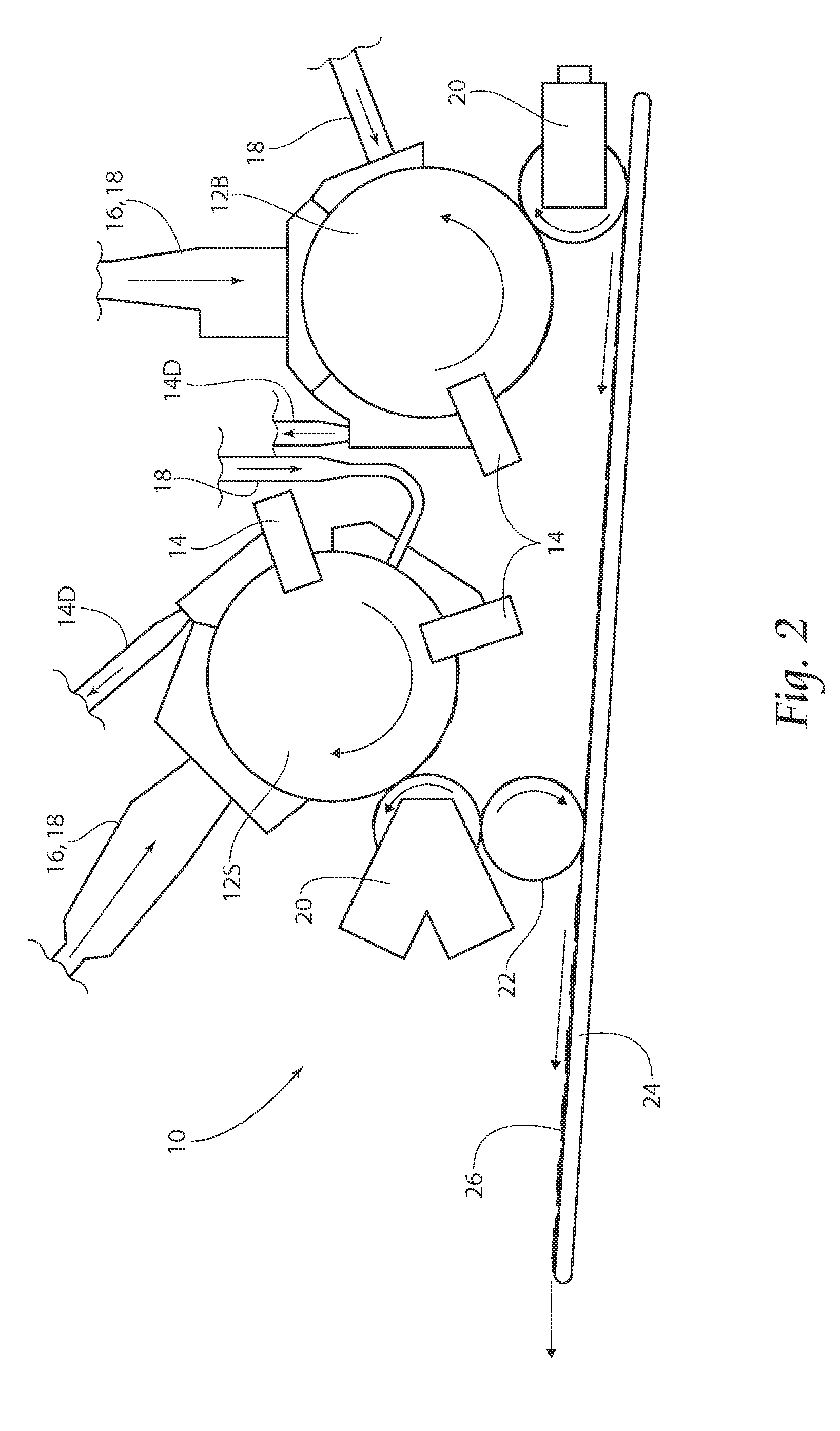

Apparatus and method for forming absorbent cores

Several variations of core formation techniques and machines to produced cores are disclosed, including a large and small discrete core, formed on a screen and combined; a large and small continuous core, formed on a web; and two and three-dimensional cores, formed on a screen, and core formation on a non-woven web.

Owner:CURT G JOA

Absorbent article having a multifunctional containment member

An absorbent article such as a diaper, training pant, and the like comprises a containment member that has a central zone and a barrier zone. The central zone has greater air flow according to the Air Permeability Test than the barrier zone. The barrier zone a greater hydrohead according to the Hydrostatic Head Pressure Test than the central zone. The containment member may be used for absorbent core formation and may have portions configured to serve as barrier leg cuffs for the finished absorbent article.

Owner:THE PROCTER & GAMBLE COMPANY

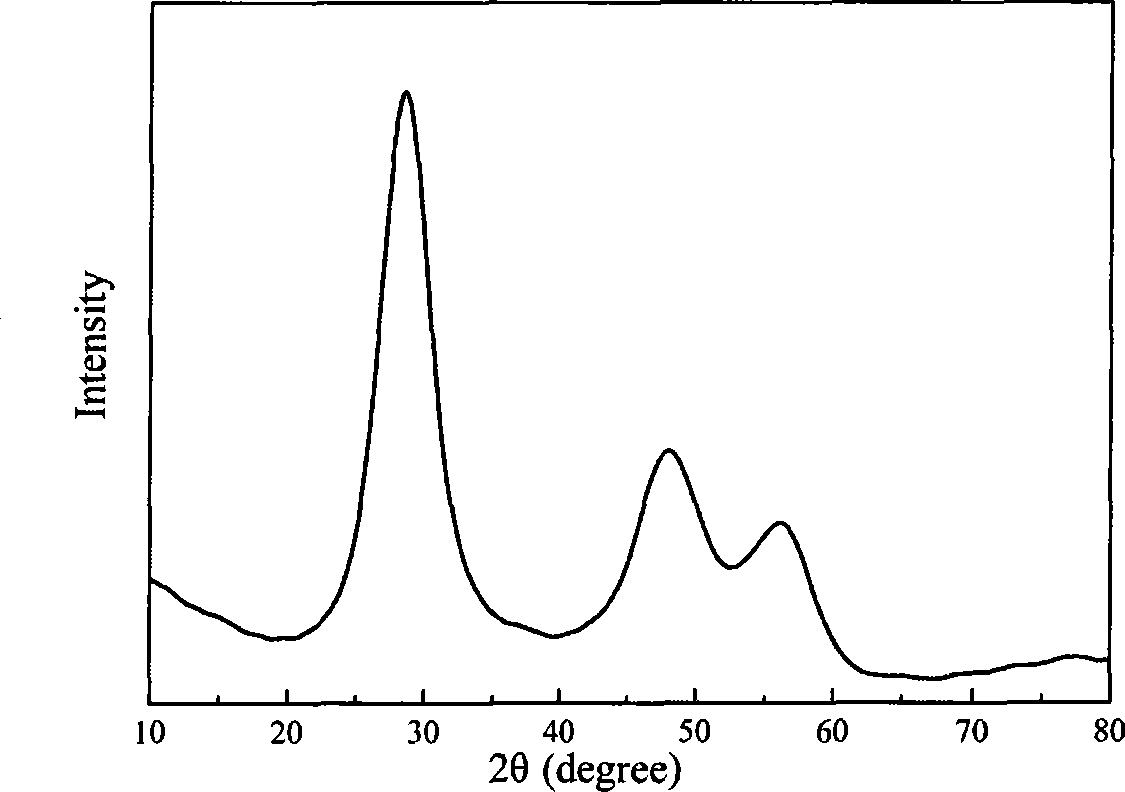

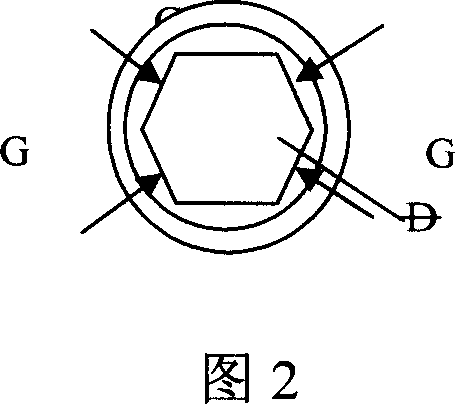

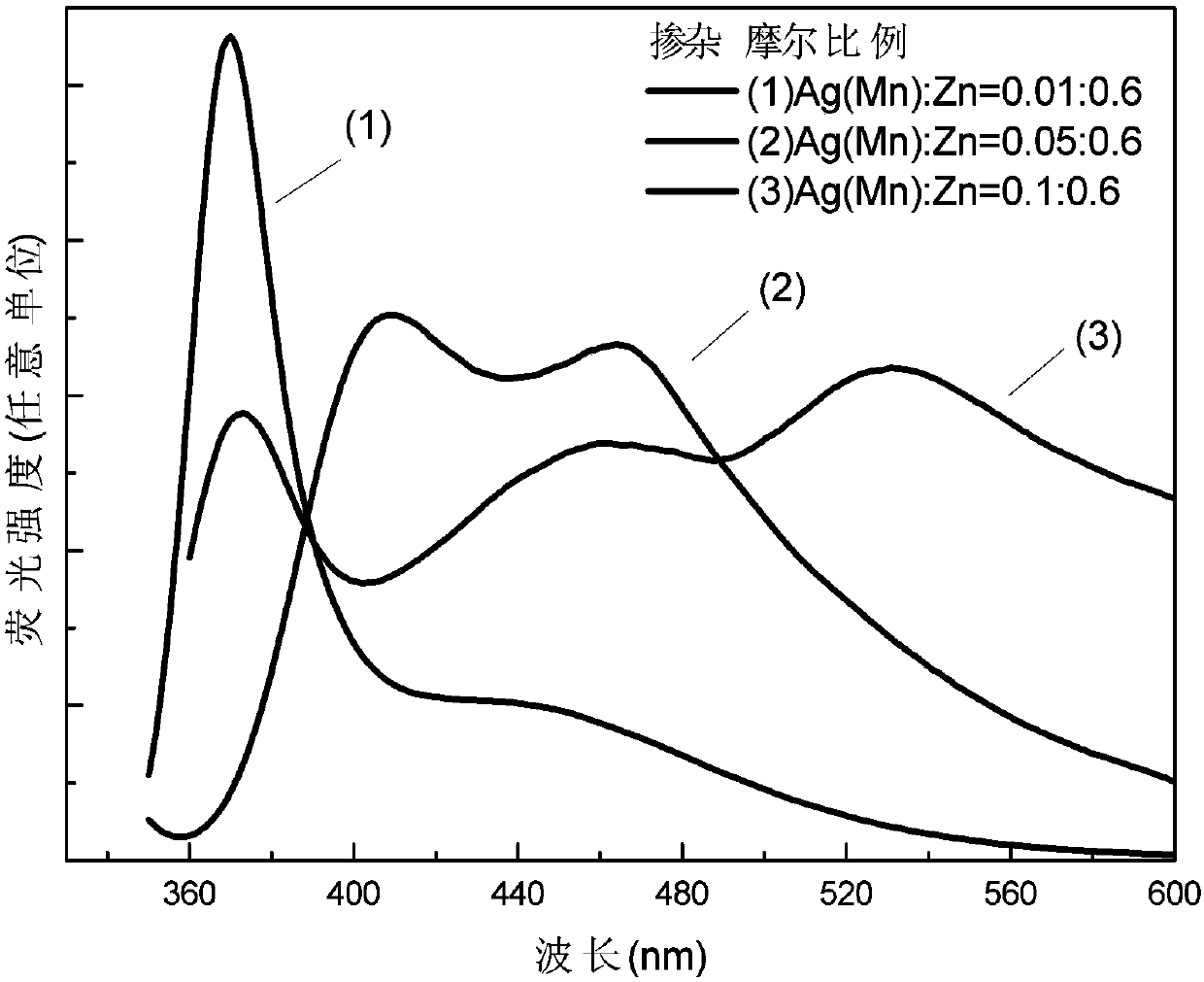

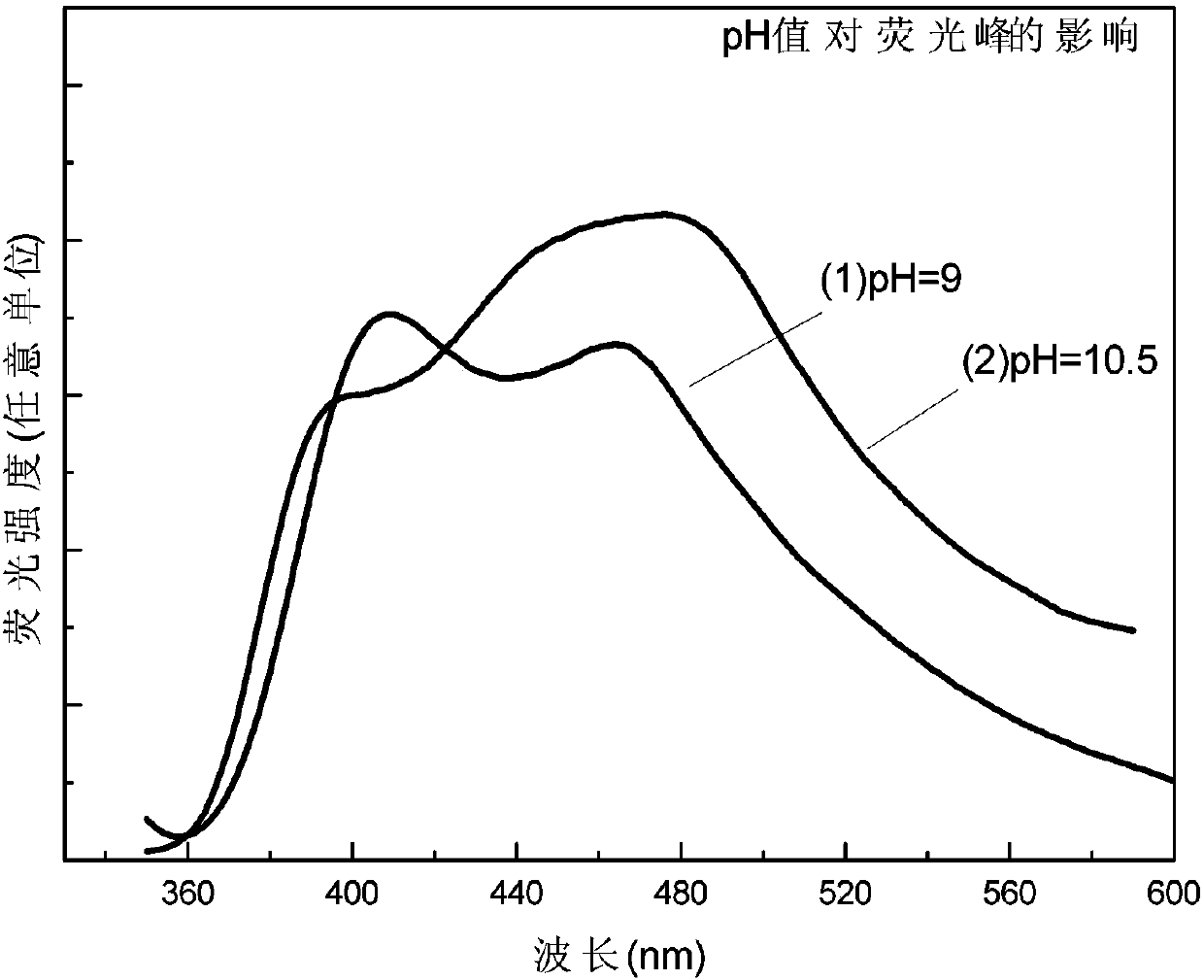

Aqueous phase method for manufacturing core formation doping ZnS:Mn and ZnS:Mn/ZnS nanocrystalline

InactiveCN101245242AHigh fluorescence intensityGood light stabilityLuminescent compositionsSolubilityWater baths

The invention discloses a water phase preparation method of nucleating doped nano-crystal of ZnS: Mn and ZnS: Mn or ZnS, deionized water is regarded as solvents, zinc salt is regarded as the source of zinc ion, manganese salt is regarded as the source of manganese ion, sodium sulfide is regarded as the source of sulfur ion, mercapto carboxylic acid is regarded as stabilizer, water bath or oil bath is used for controlling the reaction temperature, the whole reaction process is carried on in the air, the method has the advantages of the low cost, the simple operation, the whole process being carried on in the air, innocuity, and no pollution, the nano-crystal of ZnS: Mn and ZnS: Mn or ZnS has the high strength, the good light stability, and the good water solubility, the method of the invention can realize the mass production of the nano-crystal of ZnS: Mn and ZnS: Mn or ZnS.

Owner:CENT SOUTH UNIV

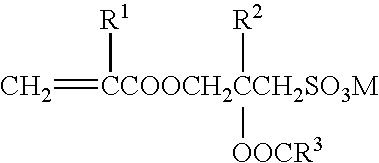

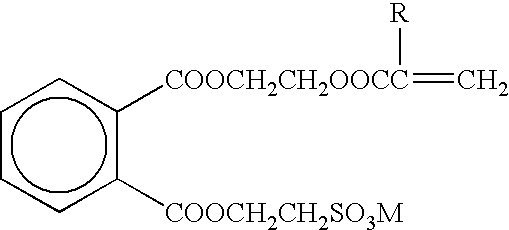

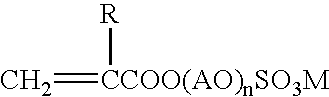

Synthetic resin emulsion, easily water-swellable pressure-sensitive adhesive compositions containing the same and process for production of the emulsion

InactiveUS7317056B2Excellent fundamental adhesive propertyEasily swollen with waterEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerEmulsion

There is provided a synthetic resin emulsion comprising polymer particles having a core / shell structure, wherein the shell comprises a copolymer of an unsaturated carboxylic acid and a hydrophilic comonomer, the core comprises a copolymer of a monomer mixture comprising a radically polymerizable main monomer and a radically polymerizable functional monomer, and the monomers constituting the monomer mixture are selected so that the glass transition point (Tg) of the copolymer produced by polymerization is −20° C. or below, and the synthetic resin emulsion has been produced by adding the monomer mixture for core formation and a pH adjustor to an aqueous copolymer solution, which has not been neutralized, produced by polymerizing the unsaturated carboxylic acid and the hydrophilic comonomer in an aqueous medium, and allowing a polymerization reaction to proceed. The use of the synthetic resin emulsion can provide a pressure-sensitive adhesive which has excellent adhesive properties such as adhesive strength, cohesive force and tackiness and can be easily swollen with water without any treatment with an alkali.

Owner:CELANESE INT CORP

Process for making light waveguide element

InactiveUS6974714B2Precise vertical optical axis alignmentMinimize changesSemiconductor/solid-state device manufacturingOptical articlesVertical alignmentChemical vapor deposition

A process for making a light waveguide element is made by forming only an upper clad layer (40) and a core layer (32) without etching an optical axis height-adjusting sections. By using plasma chemical vapor deposition (CVD) which is good at controlling the film thickness, it is possible to provide without difficulty a light waveguide element with a height-adjusting section that has a precise film thickness, making it possible to provide precise optical axis vertical alignment upon mounting. By forming alignment markers in the same photolithography as that of the core formation, it is possible to provide precise horizontal optical axis alignment.

Owner:NEOPHOTONICS CORP

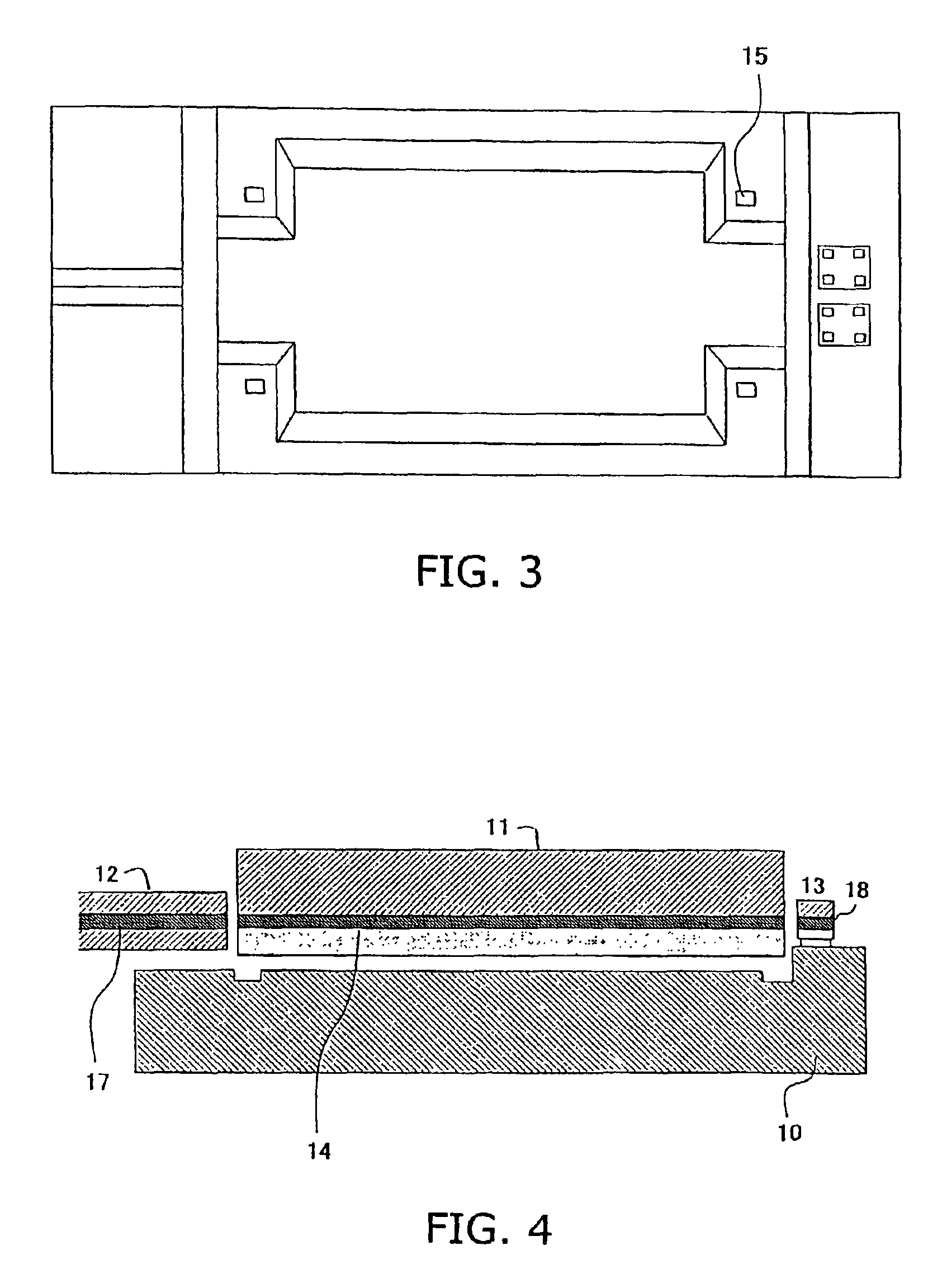

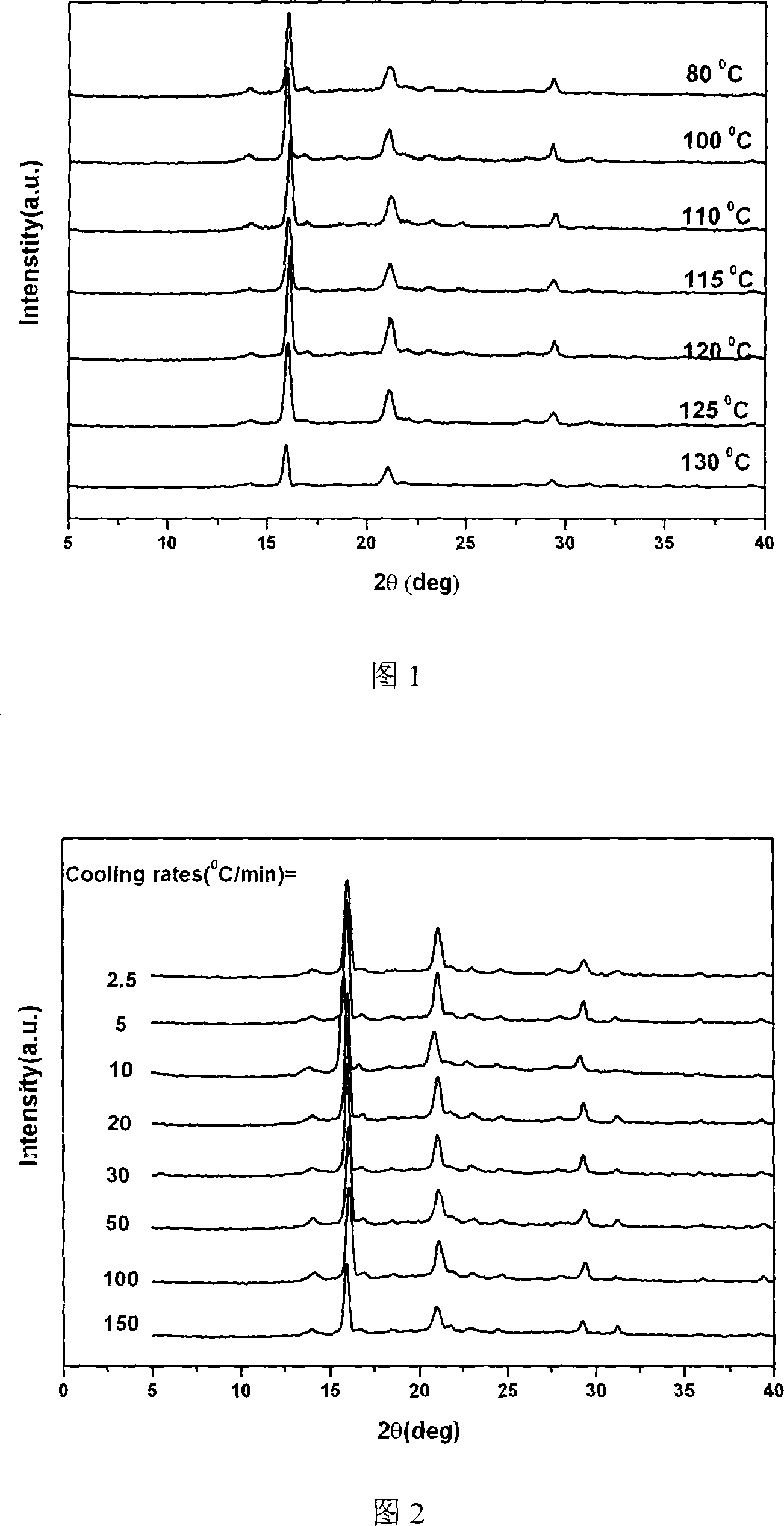

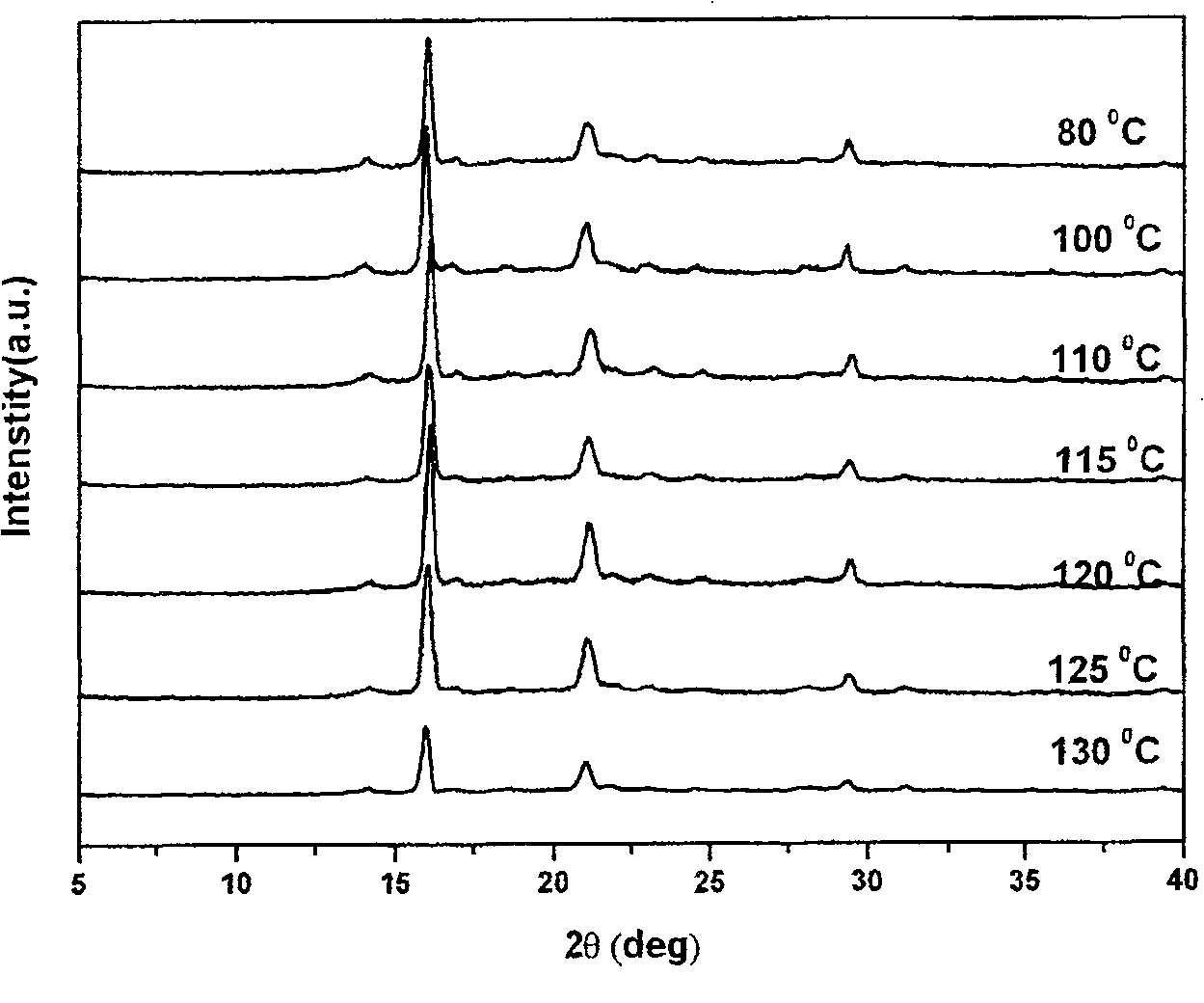

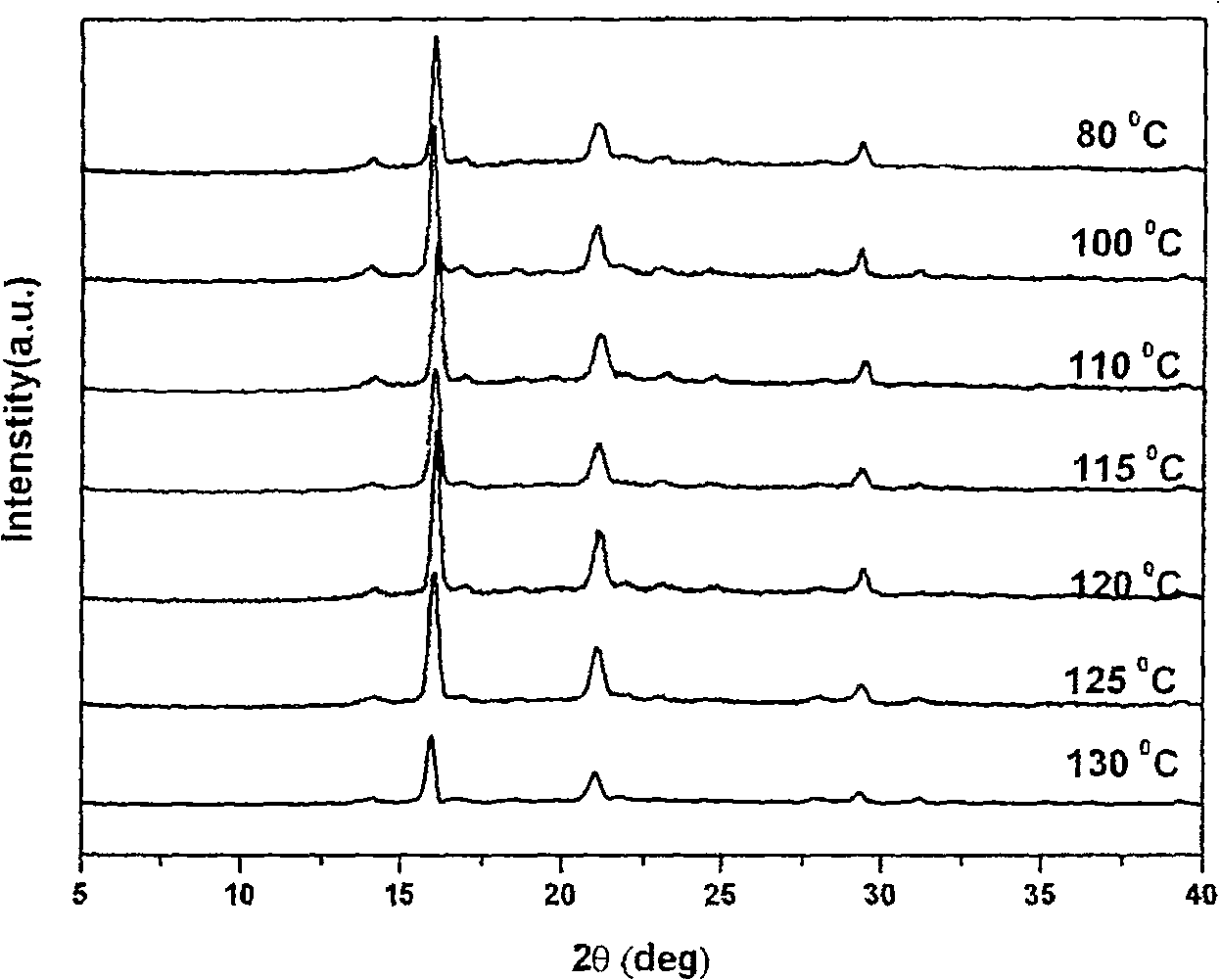

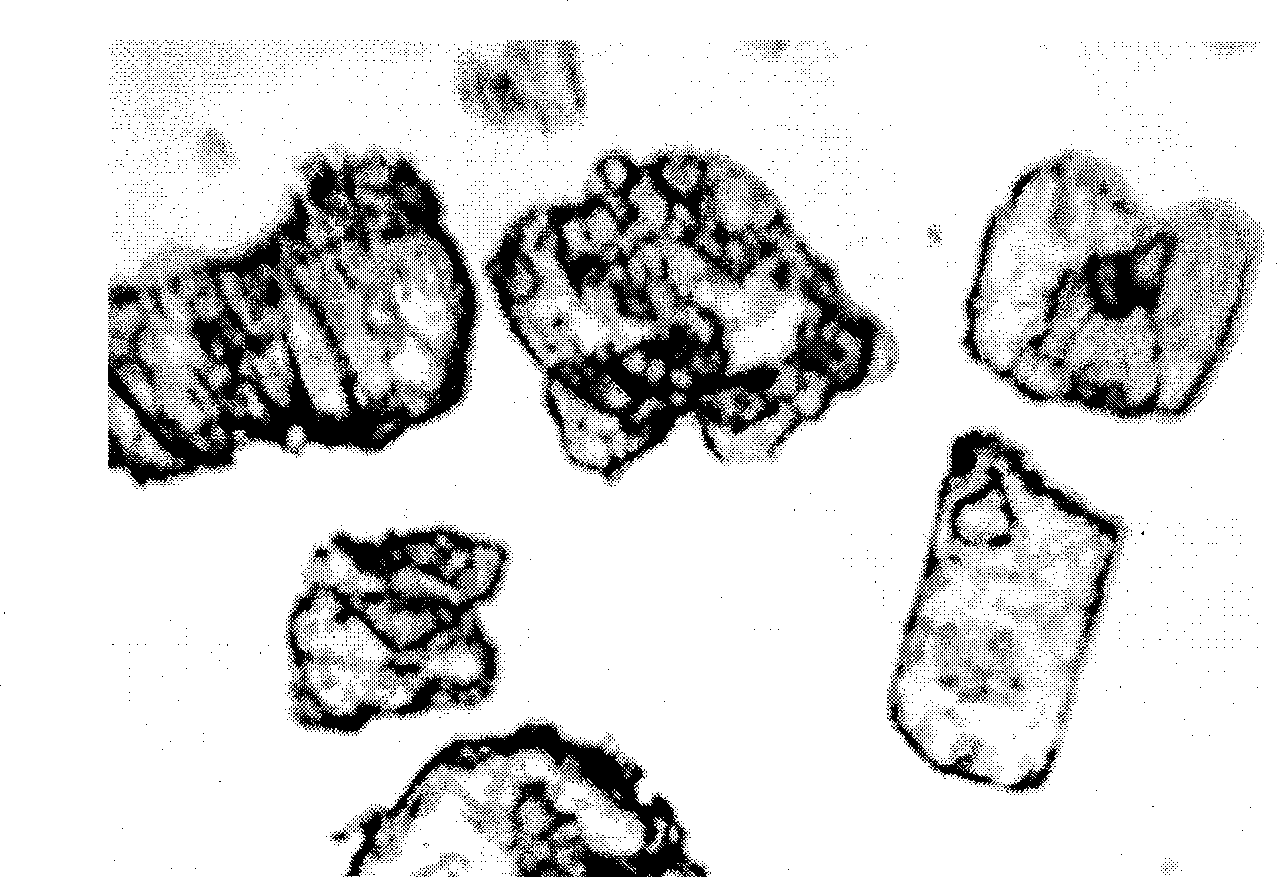

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771AIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771BIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

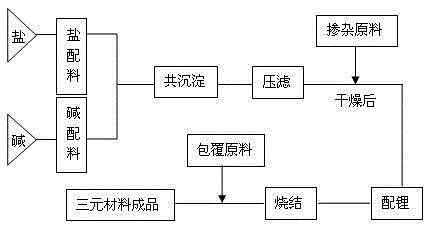

Preparation method of ternary cathode material

InactiveCN105261737AHigh tap densityIncrease capacityPositive electrodesBatteriesFilter pressCrystal growth

The invention discloses a preparation method of a ternary cathode material. The method comprises the following steps of 1, uniformly mixing and integrating a salt ingredient and an alkali ingredient in a solution mode to form a mixture solution; 2, carrying out deposition on the mixture solution formed in the step 1 to form precursor grains, and controlling core formation and a crystal growth speed of co-precipitation reaction through parameter adjustment; 3, adding positive ions in a liquid phase to the precursor grains for doping modification after carrying out washing and filter pressing on the precursor grains formed in the step 2, and drying the precursor grains; and 4, adding lithium to the dried raw material, and carrying out calcination and surface coating modification to obtain a finished product of the ternary material. By the method, the product manufactured according to the method has technical effects of high tap density, high capacity and high cycle performance.

Owner:SICHUAN KENENG LITHIUM BATTERY

Novel metallic film preparation technology on liquid phase substrate surface

InactiveCN1730716AEasy to operateUnique microstructureVacuum evaporation coatingSputtering coatingGrain structureVacuum evaporation

Disclosed is a novel metallic film preparation technology on liquid phase substrate surface, which comprises using liquid phase material whose saturated vapor tension is lower than the vacuum evaporation pressure as substrate, employing magnetron sputtering or thermal deposition method, evaporating the metal atoms with energy of argon ions in high speed movement or tungsten filament heated by electric current, then depositing the evaporated metal atoms onto liquid phase substrate surface, finally growing metallic film having polycrystalline grain structure through diffusion, core formation, rotation and agglomeration. The film has substantially no internal stress.

Owner:ZHEJIANG UNIV

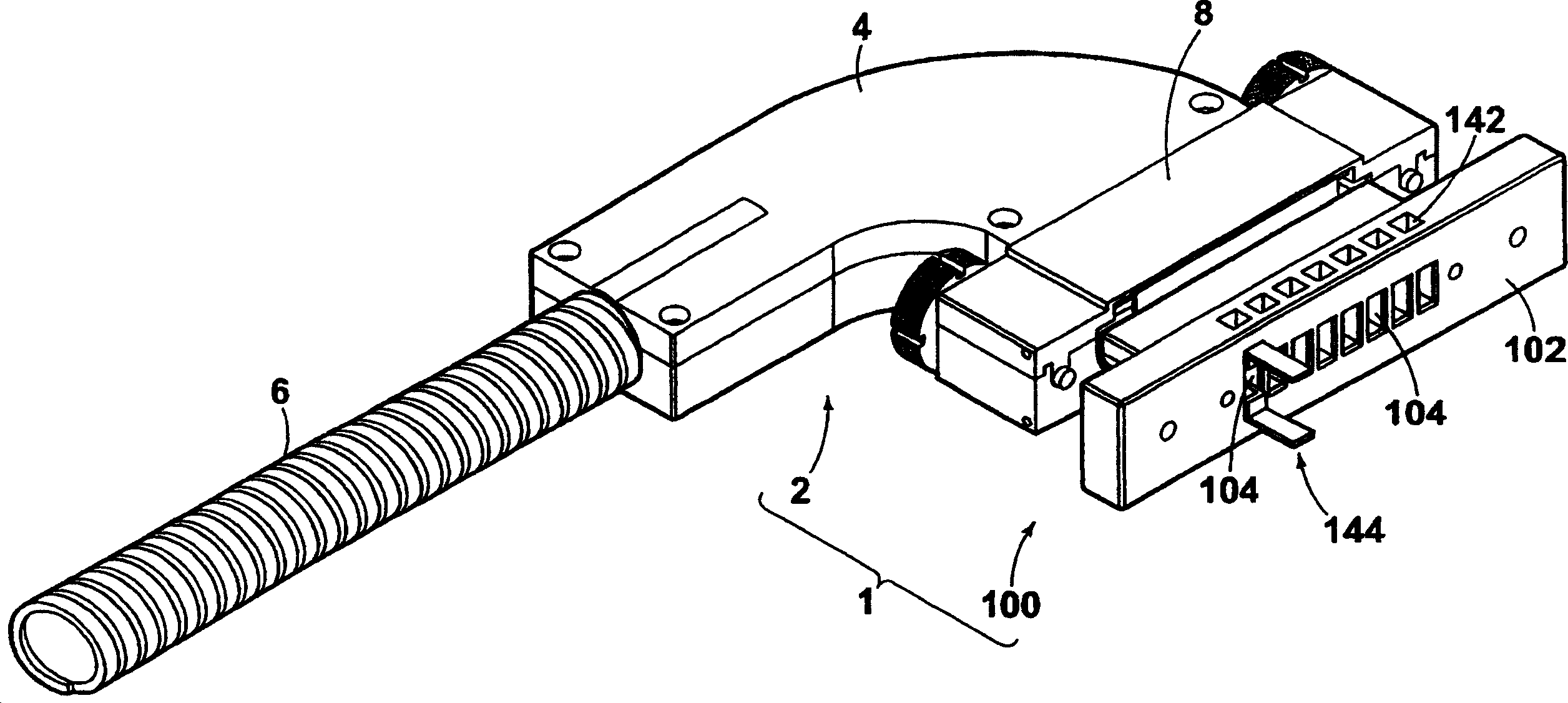

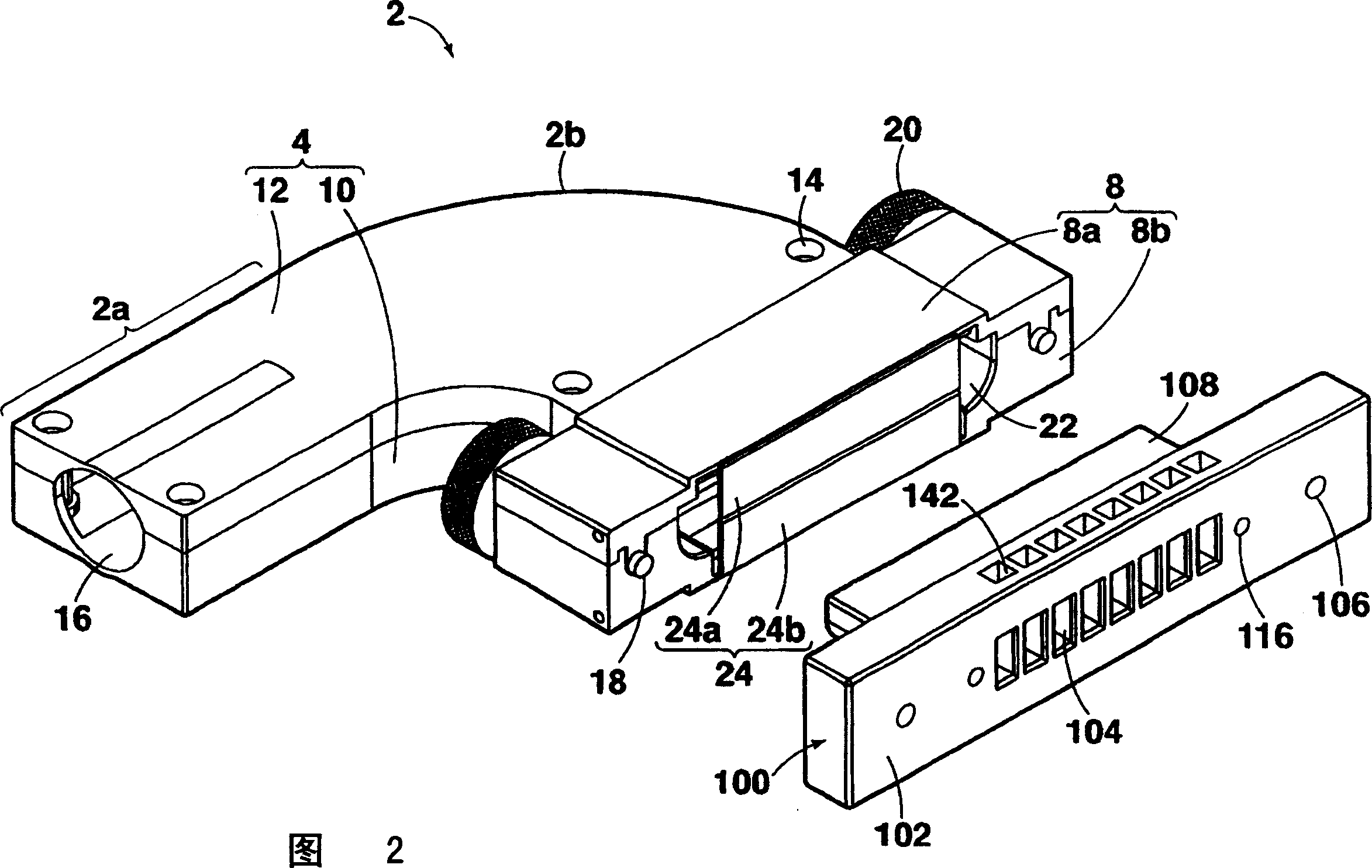

High pressure coring assembly and method

A wireline or drill pipe retrievable coring tool with an inner barrel to receive a core, a bottom coring tool valve operable to seal off a bottom of the inner barrel and at least one pressure canister operable to receive fluid from the core in the inner barrel. The pressure canister is operable to significantly reduce the pressure inside the inner barrel utilizing an expandable chamber to receive fluid from the core as the tool is removed from the wellbore. In one embodiment, a bottom valve mechanism moves the cored formation materials out of the way of the bottom valve before the bottom valve is closed.

Owner:CORPRO TECH CANADA LTD

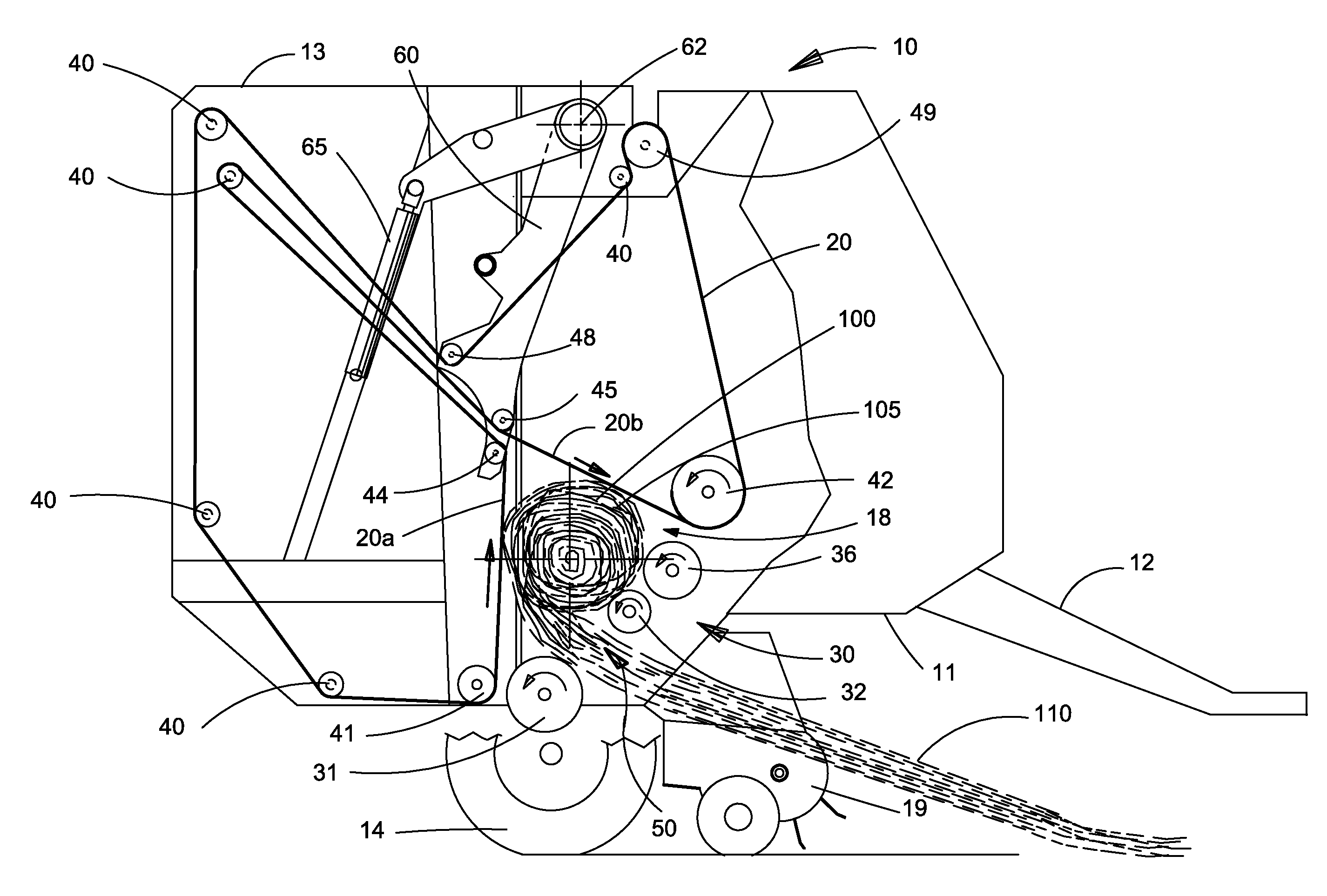

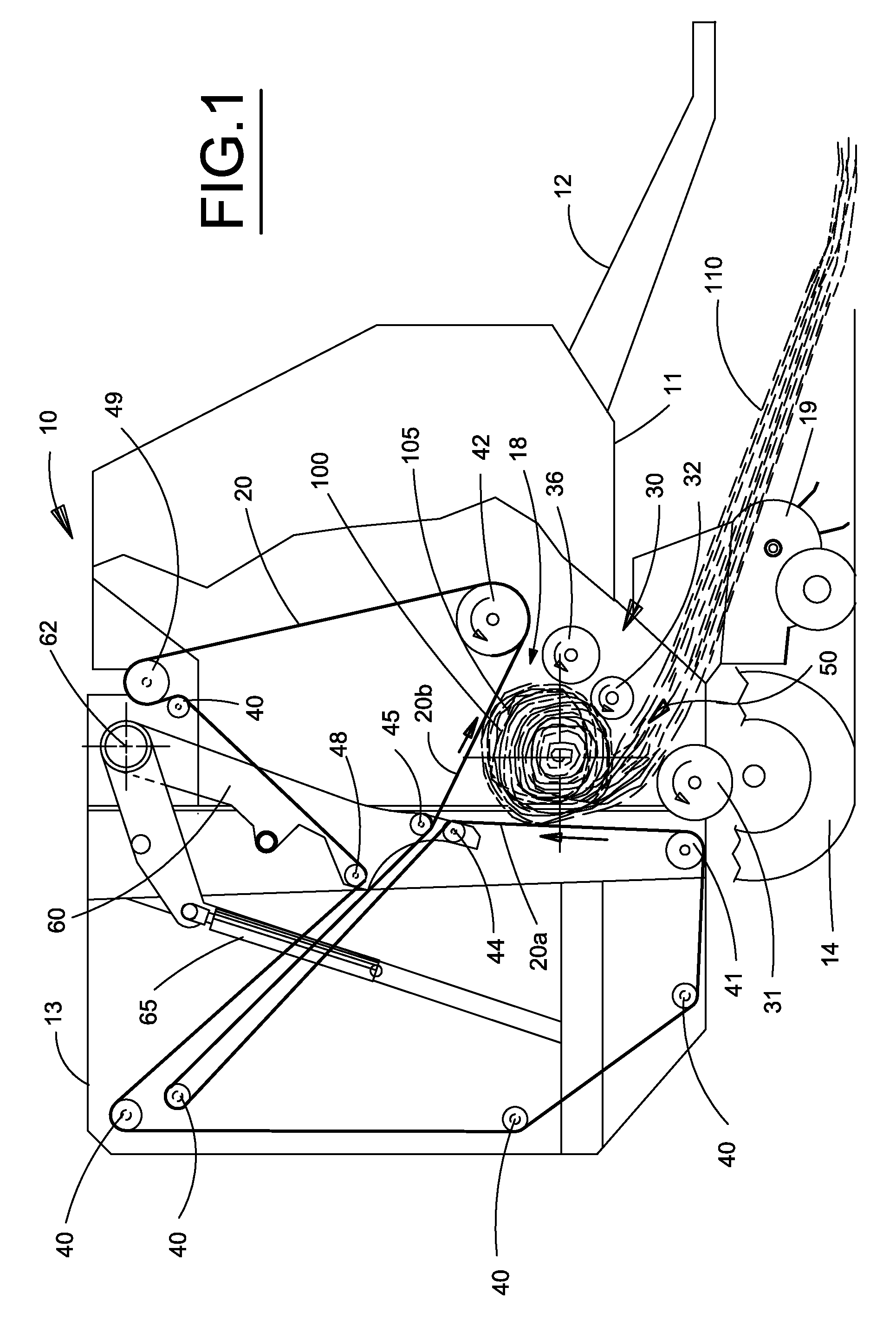

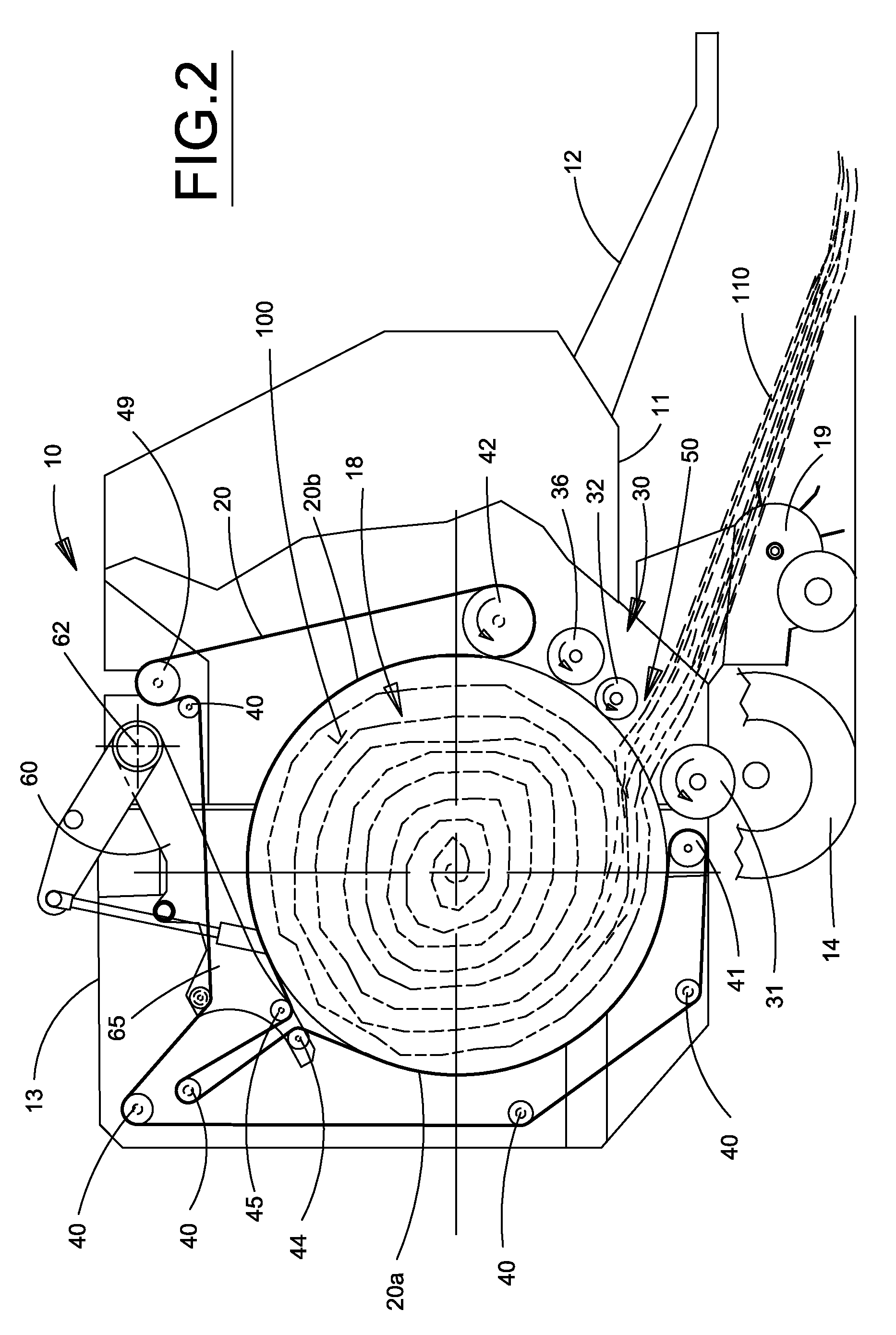

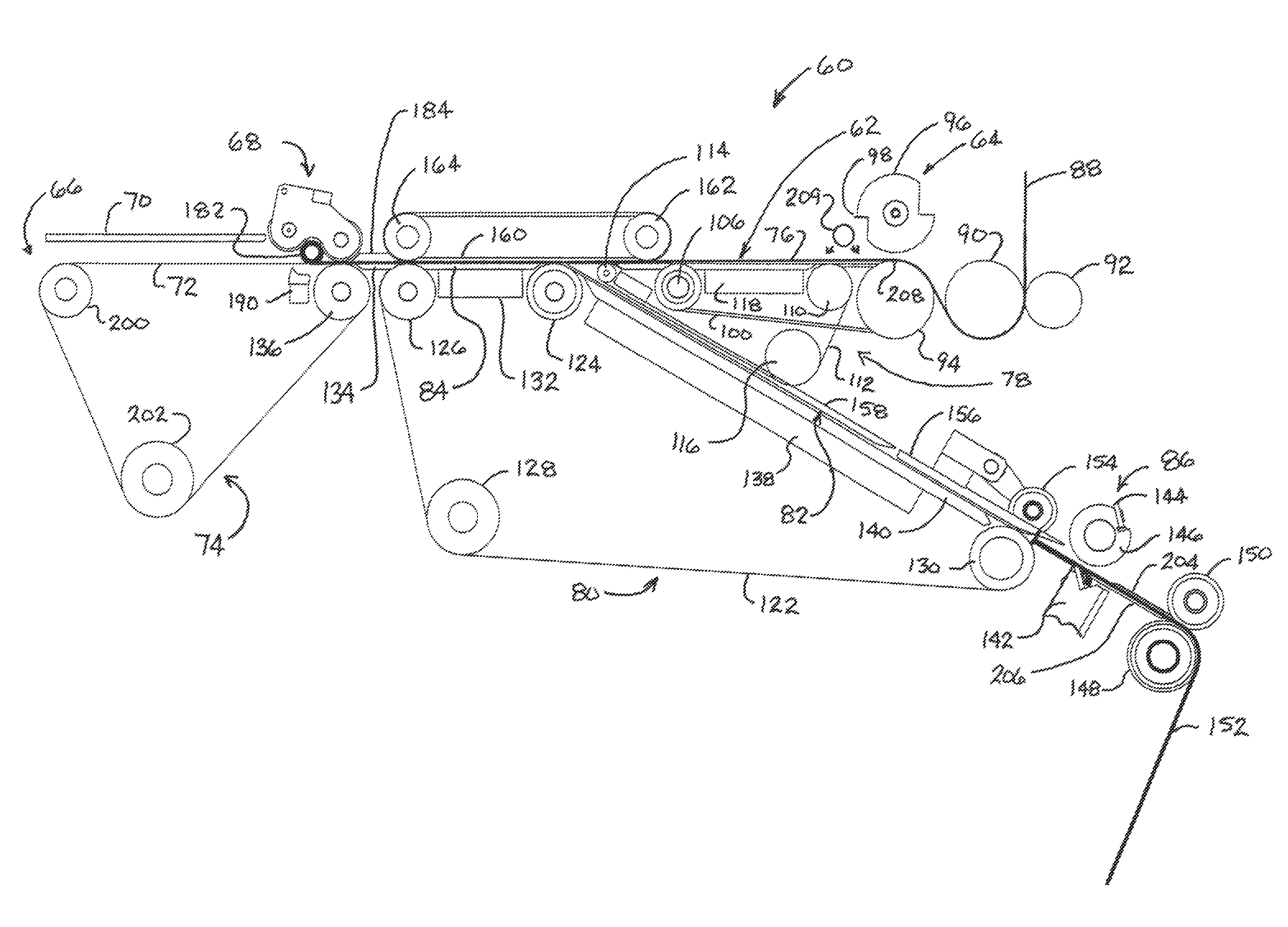

Belt routing in a round baler

An improved mechanism for directing movement of a plurality of side-by-side belts in a round baler wherein a bale chamber is optimally configured for bale core formation thereby reducing the need for an aggressive surface on the belts to initiate rotation of the incoming crop material. As the bale expands, the improved mechanism enables the unguided span of belts surrounding the periphery of the bale to be minimized by positioning intermediate guide rolls generally equidistantly from idler rolls bounding the belt guides defining the bale forming chamber. Further, the improved mechanism reduces the friction force between the crop and the belts necessary to initiate crop rolling for bale core formation enabling smooth-surfaced belts to be used which reduce trash generation.

Owner:BLUE LEAF I P INC

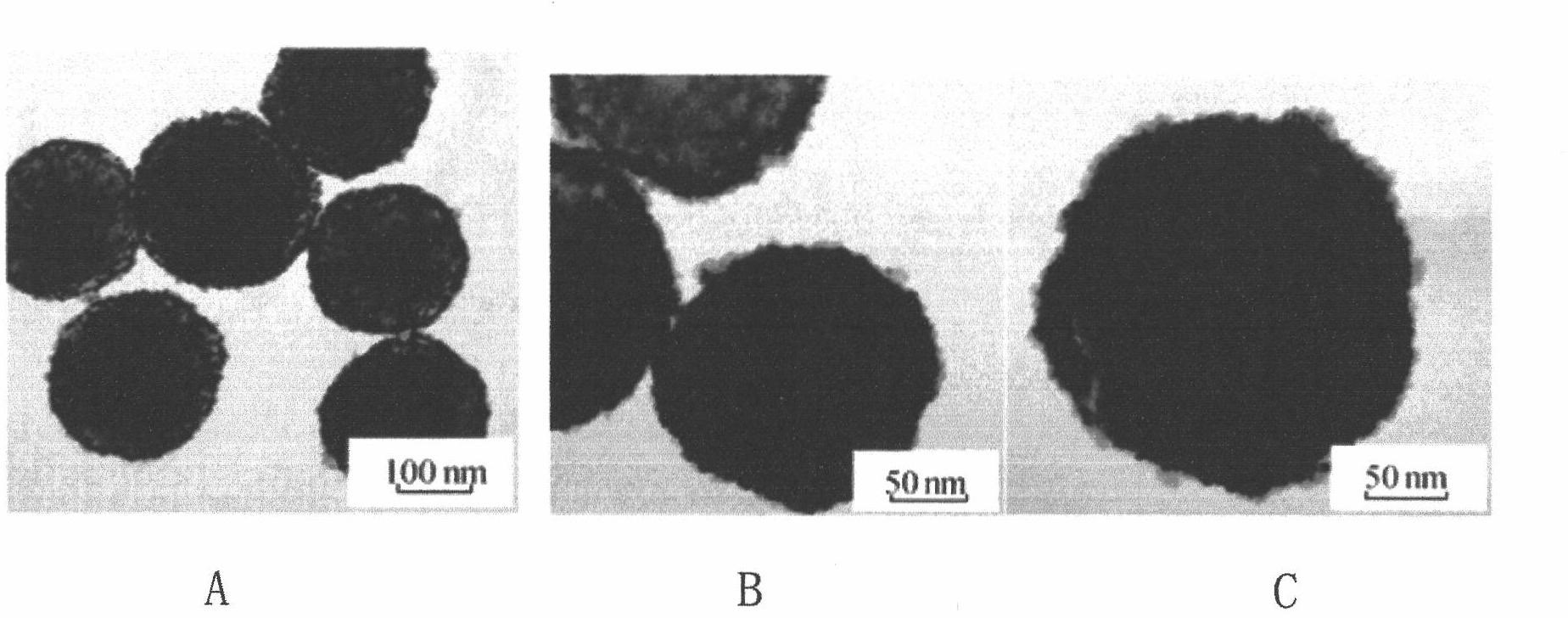

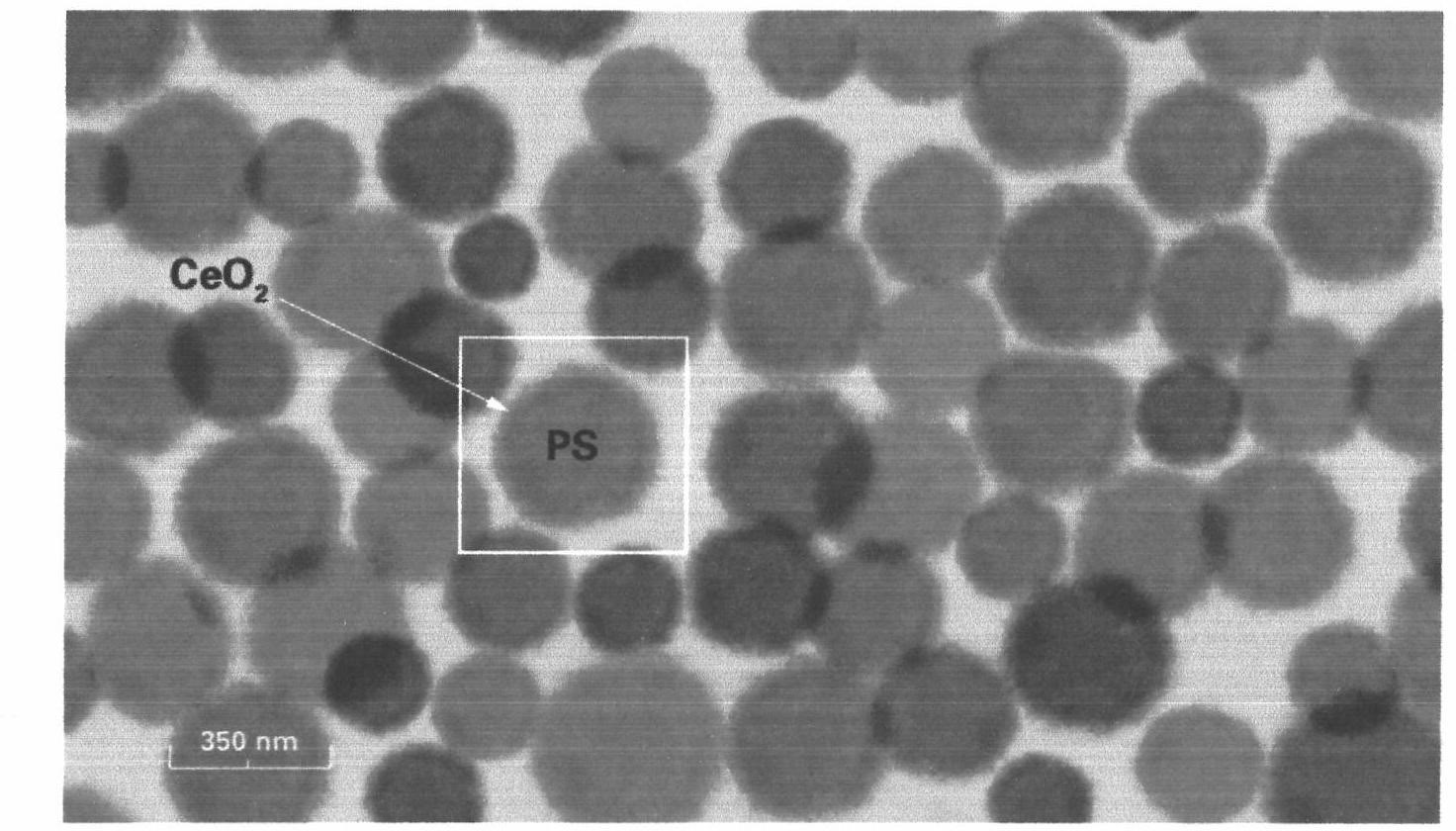

Composite abrasive grain as well as preparation method and application thereof

The invention provides a composite abrasive grain which is prepared by utilizing a simpler preparation process and adopting an in-situ core formation method, is uniformly coated and takes polymethacrylate as a core and cerium oxide as a shell. By virtue of the unique mechanical characteristics of soft inside, hard outside and non-rigidity of the core-shell organic / inorganic composite abrasive grain, the synergy between the elasticity of the organic microsphere inner core and the surface hardness and high chemical activity of the CeO2 shell layer is fully exerted as expected during a CMP (chemical-mechanical polishing) process, thus high-quality ultra-smooth polished surfaces are obtained.

Owner:CHENGDU TIMES LIVE SCI & TECH

Method for producing acrylic amide crystal

InactiveCN101391967AQuality improvementReduce water contentCarboxylic acid amide separation/purificationHigh concentrationCentrifugation

The invention discloses a production method of acrylamide crystals, which pertains to the field of biochemical industry. The method mainly comprises the steps that: acrylamide aqueous solution with high concentration is treated with cooling crystallization in a jacket-stirring crystallization kettle, after the temperature is reduced to 20 to 30 DEG C, acrylamide fine crystals with the granularity of 0.08 to 0.80mm are added to be taken as seed crystals to induce the acrylamide crystals to carry out secondary core formation, the temperature is reduced to 3 to 6 DEG C and the crystals grow for 20 to120min, and then the acrylamide crystals are obtained after centrifugation and drying. The production method does not need additional new equipment, is not easy to form crystal scars in the crystallization process, and has high crystal granularity, good crystal quality and less energy consumption.

Owner:TSINGHUA UNIV +1

Multi- core optical connector assembly

InactiveCN1707299APrecise positioningFirmly connectedCoupling light guidesEngineeringMechanical engineering

The first guide means are formed by the inner configuration of the engagement portion of the plug housing and the outer configuration of the engagement portion of the socket housing to be guided and inserted into said engagement portion of the plug housing. The second guide mechanism is formed by a guide post and a guide post hole. The third guide mechanism is formed by the inner configuration of the engagement portion of the receptacle housing, and the outer configuration of the first multi-core ferrule of the plug-side optical connector to be inserted into the engagement portion of the receptacle housing. The fourth guide mechanism is formed by the guide pin of the second multi-core ferrule and the guide pin hole of the first multi-core ferrule for receiving the guide pin. During the mating process of the receptacle-side optical connector and the plug-side optical connector, the above-mentioned first, second, third, and fourth guide mechanisms work in this order.

Owner:TYCO ELECTRONICS JAPAN GK

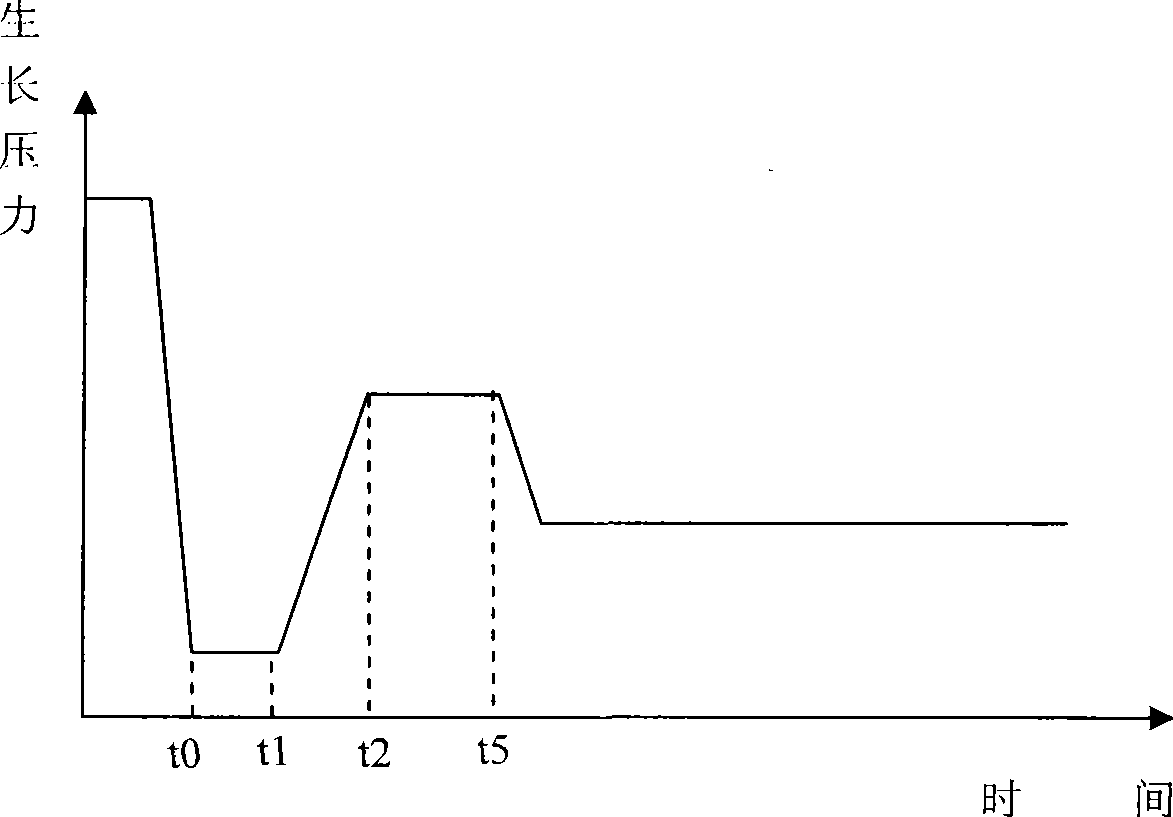

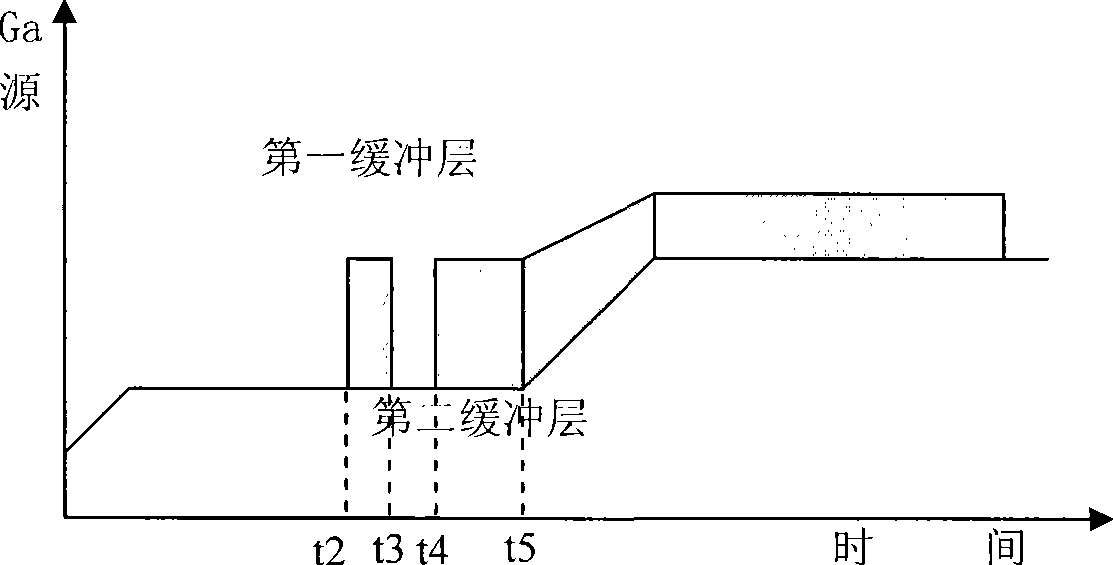

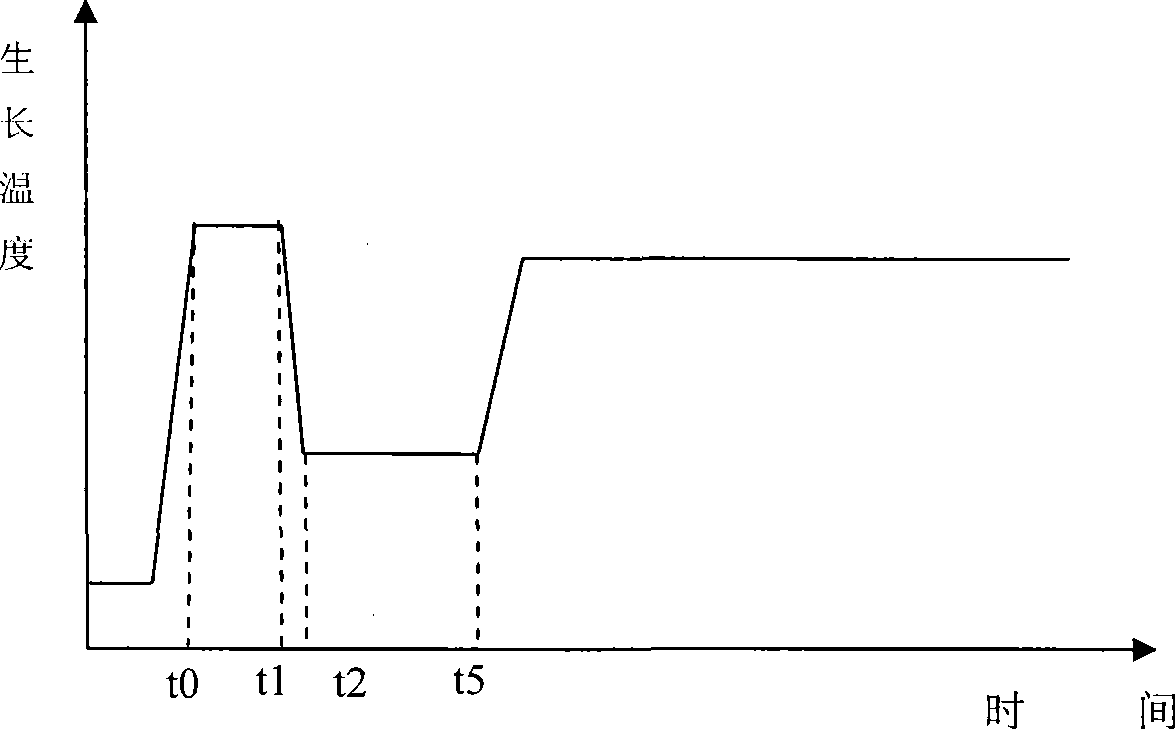

Method for preparing iso-temperature double-buffering layer of sapphire substrate

InactiveCN101471400AImprove crystal qualityHigh room temperature mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesBeam sourceTime segment

The invention relates to a processing method of blue stone underlay synthermal double-buffer layers, which comprises the following steps: firstly, putting a blue stone underlay into a reaction cavity for hydrogenating process and getting clean blue stone underlay, secondly, inputting reacting gas into the reaction cavity to create the reacting atmosphere and keeping the temperature and the pressure in a setting range in the cavity, thirdly, inputting beam source containing Ga into the reaction cavity in the first time segment for growing the first buffer layer, fourthly, bypassing the beam source containing Ga and keeping inputting reacting gas in the set time segment after finishing growing the first buffer layer, fifthly, keeping inputting the reacting gas and inputting the beam source containing Ga into the reaction cavity in the second time segment for growing the second buffer layer. In the twice core formation growth, the gap created between crystal nucleus is beneficial for releasing stress created by the mismatching of GaN and Al2O3 crystal lattices, and is beneficial for the transition of GaN three-dimensional growth to two-dimensional growth, thereby forming a plane surface, and improving crystallization quality of GaN.

Owner:深圳市方大国科光电技术有限公司

Semiconductor nanoparticle production method, semiconductor nanoparticle, and phosphor using the same

InactiveUS20120305845A1High luminous intensityImprove reliabilityMaterial nanotechnologyPolycrystalline material growthPhosphorSemiconductor Nanoparticles

A method of producing a semiconductor nanoparticle of the present invention includes a core formation step of heating a first solution including group 13 element-containing fatty acid salt, a group 13 element-containing halide, and alkali metal amide to obtain a nanoparticle core made of a group 13 element-containing nitride, and a shell formation step of heating a second solution including the nanoparticle core, group 13 element-containing fatty acid salt, and alkali metal amide to obtain a semiconductor nanoparticle having the nanoparticle core covered with a shell layer made of a group 13 element-containing nitride.

Owner:SHARP KK

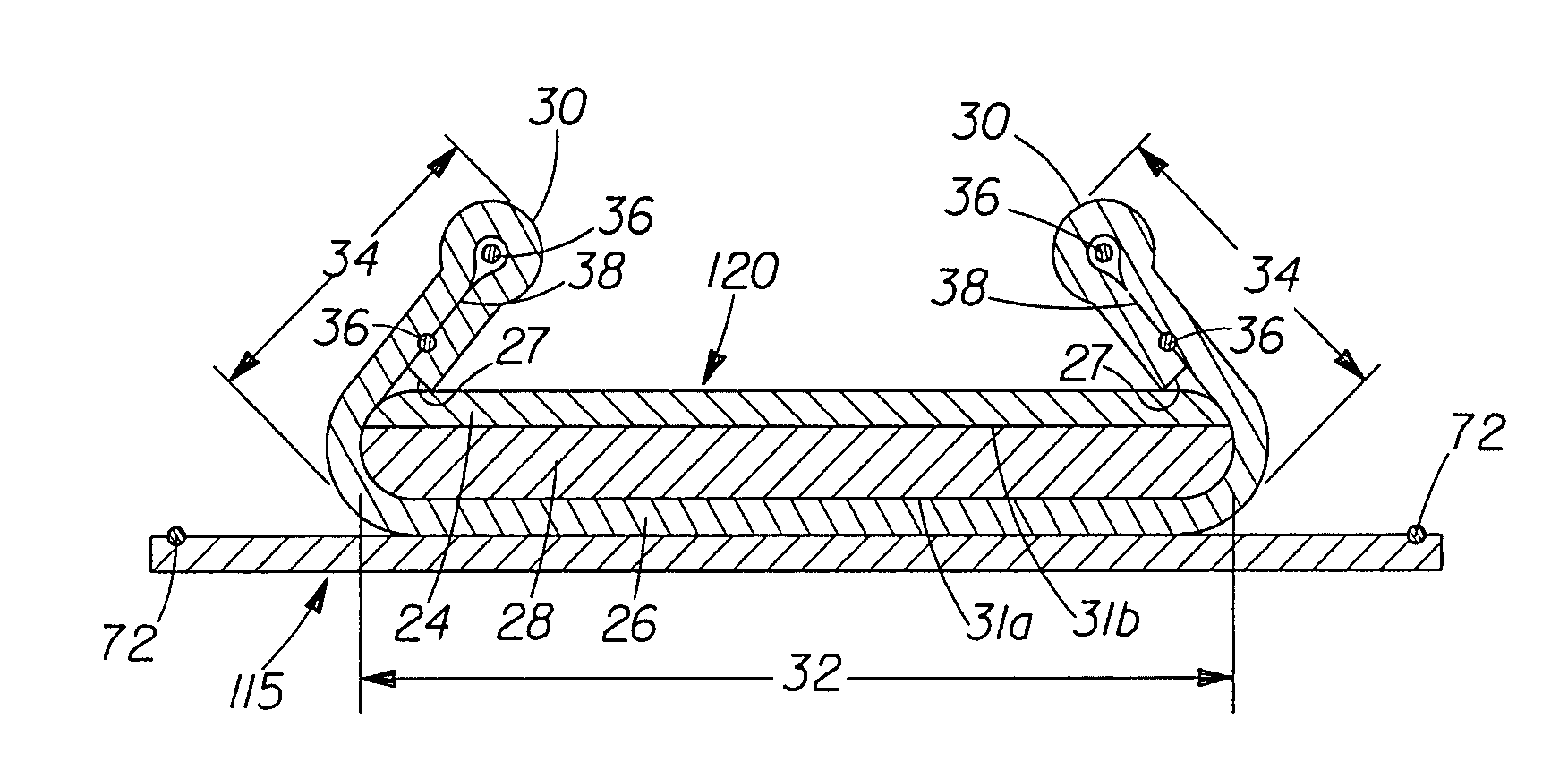

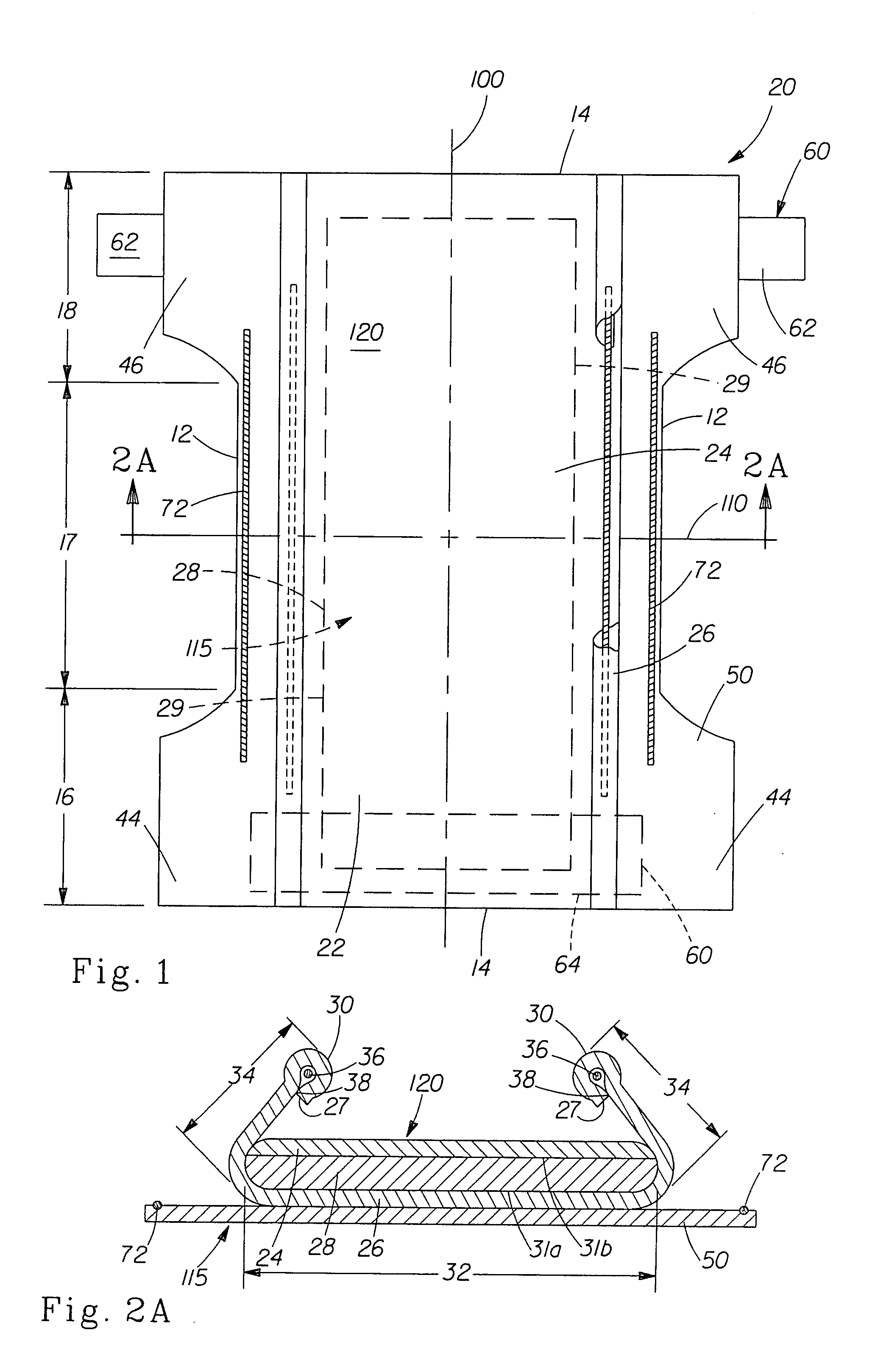

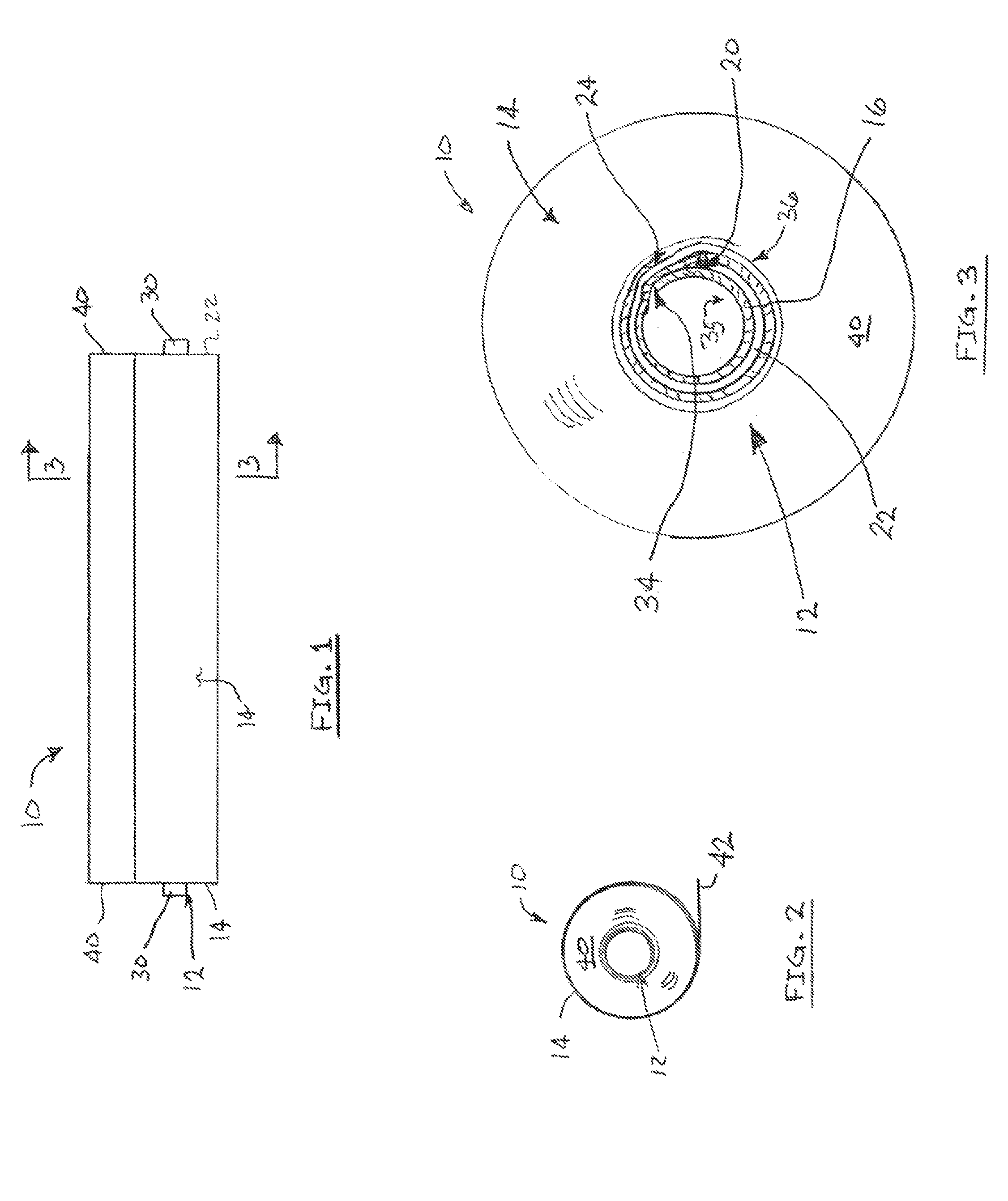

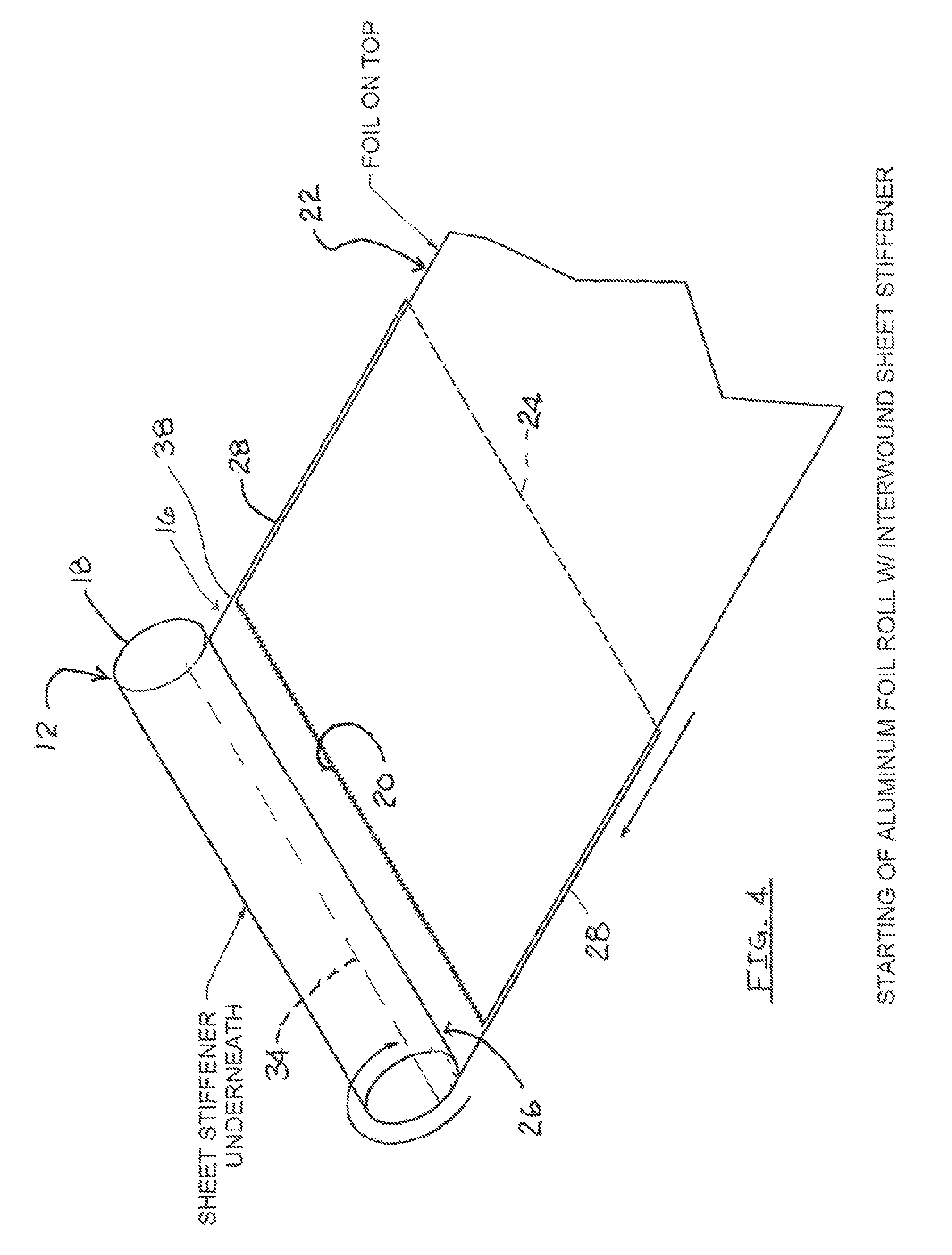

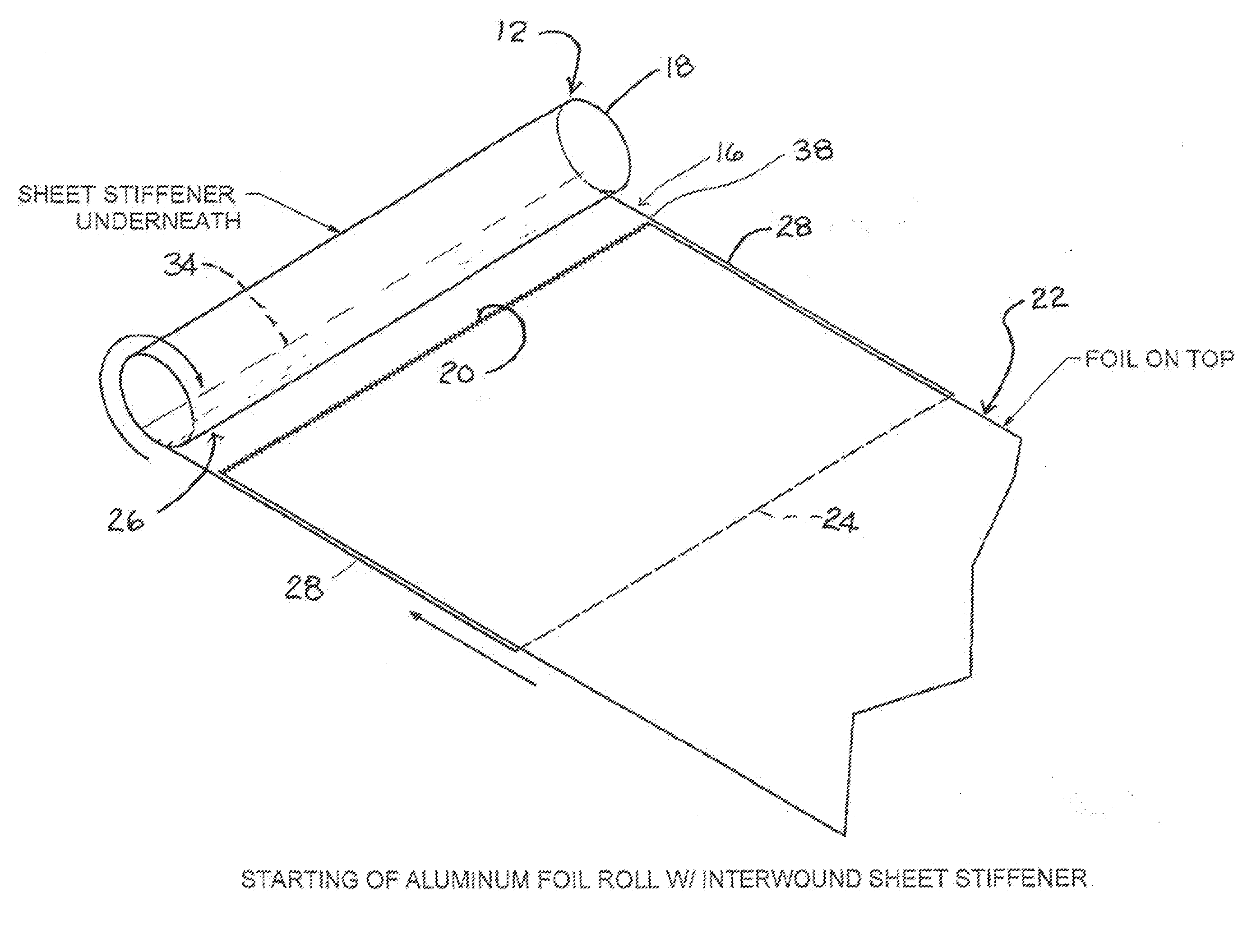

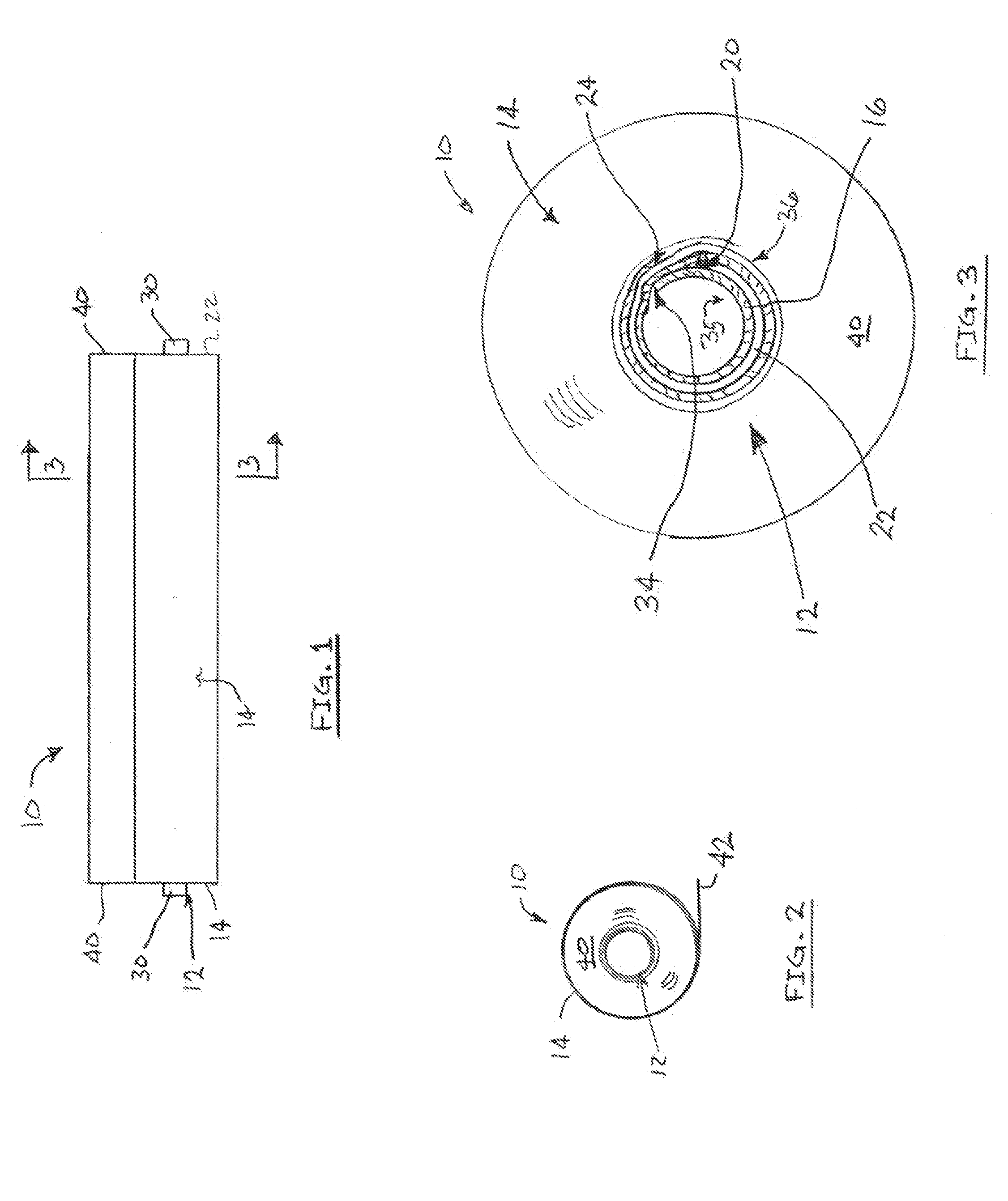

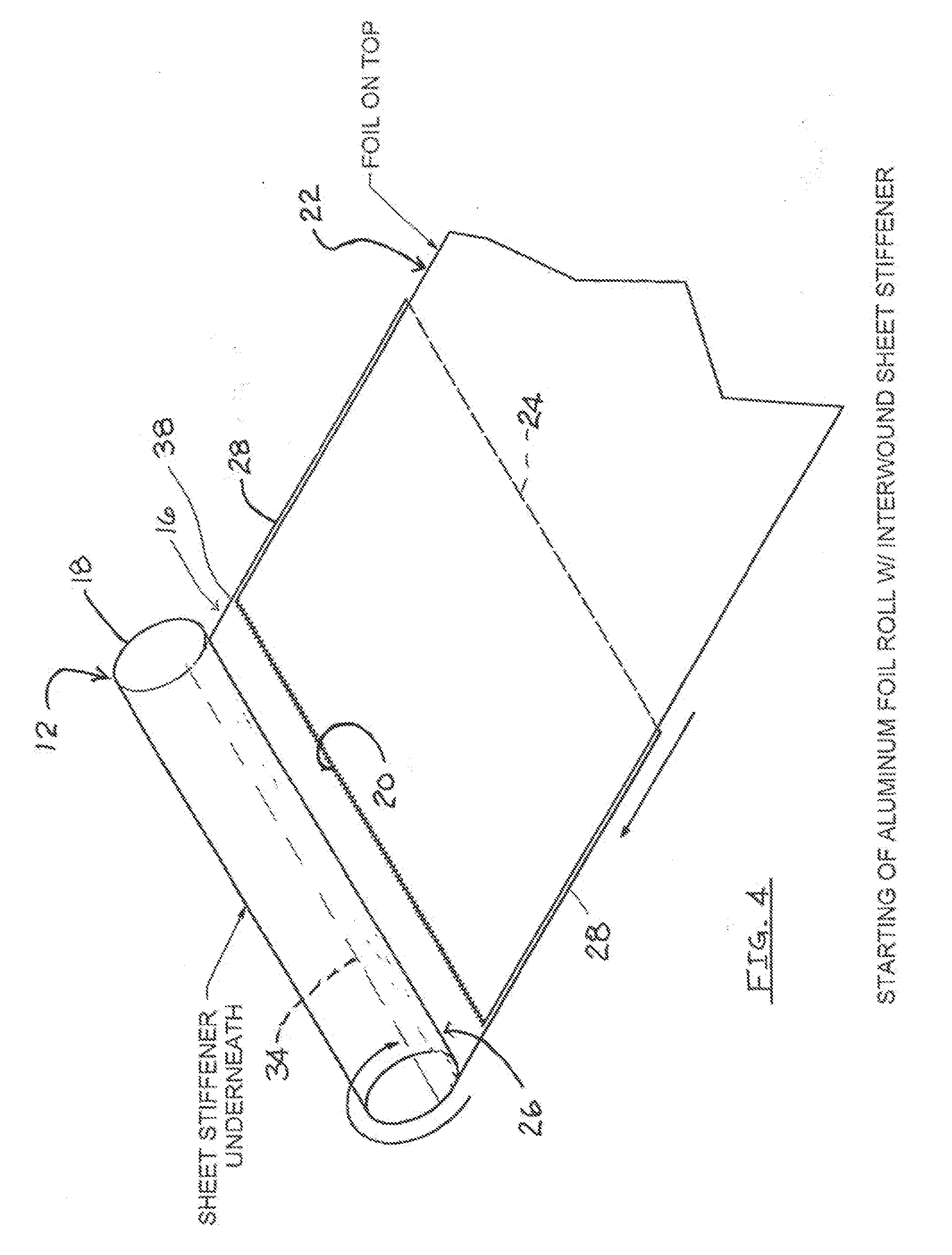

Foil roll with wound stiffening core, apparatus for winding the roll and method

A foil roll having a wound stiffener core formed from an initially flat sheet of stiffener material fed into a spiral roll winder simultaneously with a feed end of a foil web. An apparatus and method for spirally winding a foil roll with a wound stiffener core in which a stiffener sheet is fed into a roll winder in adjacent outward contact with a foil web and a leading edge of the stiffener slightly ahead of a feed end of a foil web. The stiffener sheet is outwardly disposed from the foil web and in adjacent contact with the roll starter guides to prevent contact between guides and the foil web during initial core formation. Roll starter guides are moved from contact with the outer periphery of the roll once the initial core is formed allowing a desired length of foil web to be spirally wound around the core without damage to the web. The apparatus is configured to receive a continuous supply of foil and stiffener web material, cut each to predetermined lengths, and sequentially form wound core foil rolls at an economically high rate.

Owner:ELSNER ENGINEERING WORKS INC

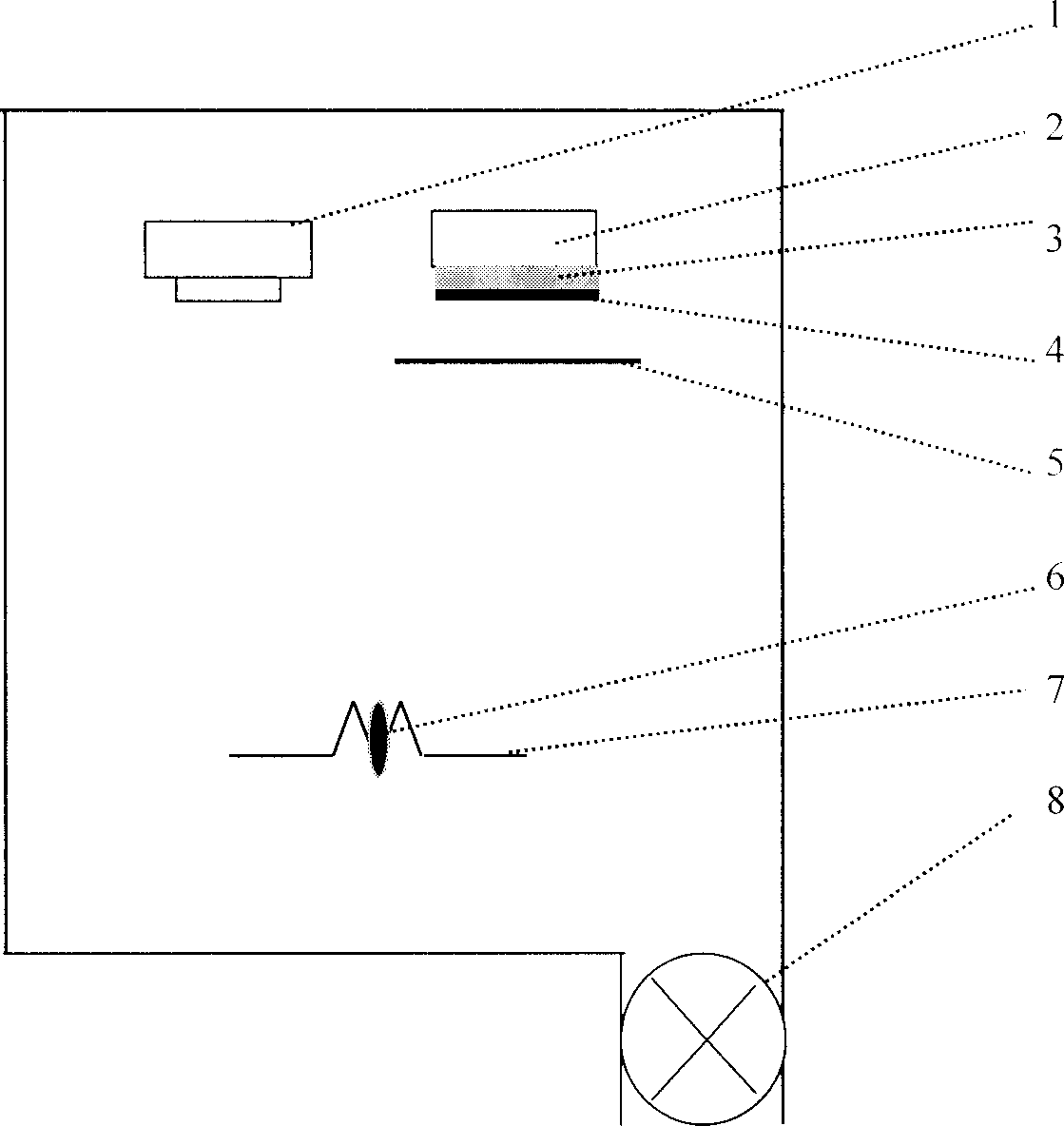

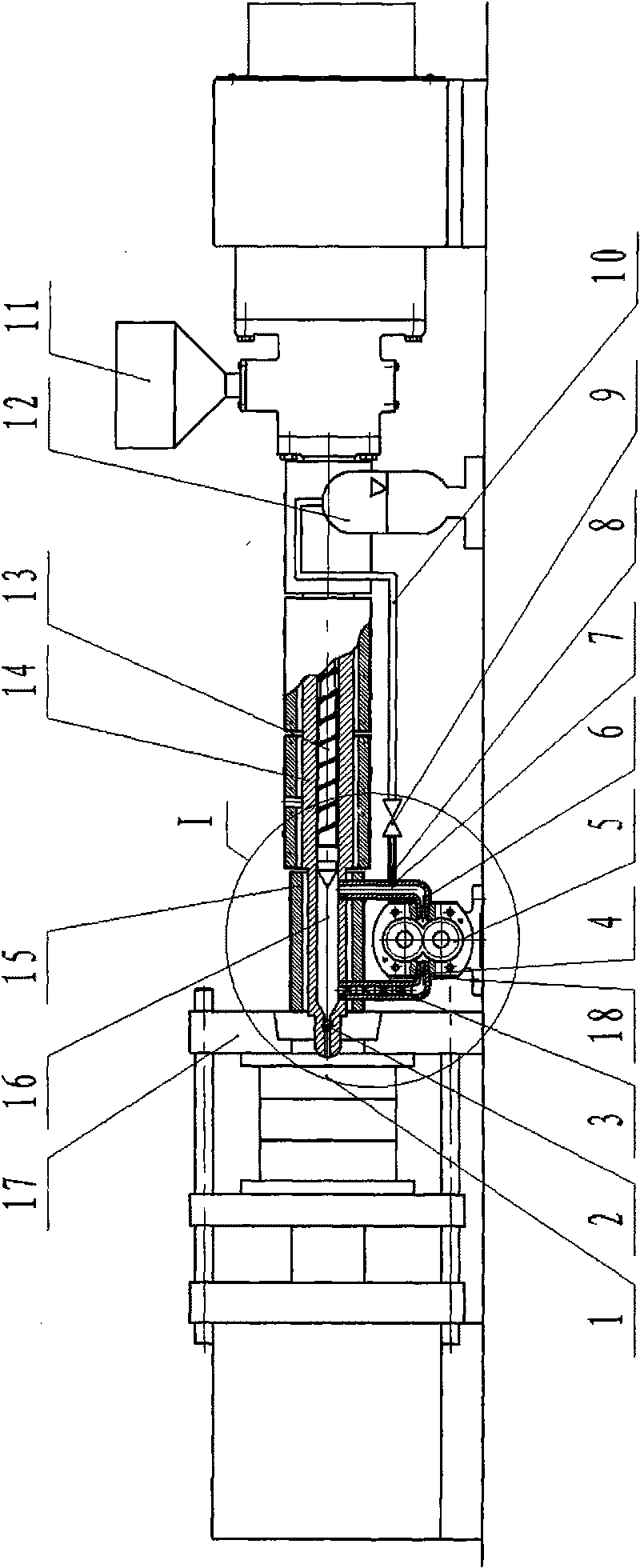

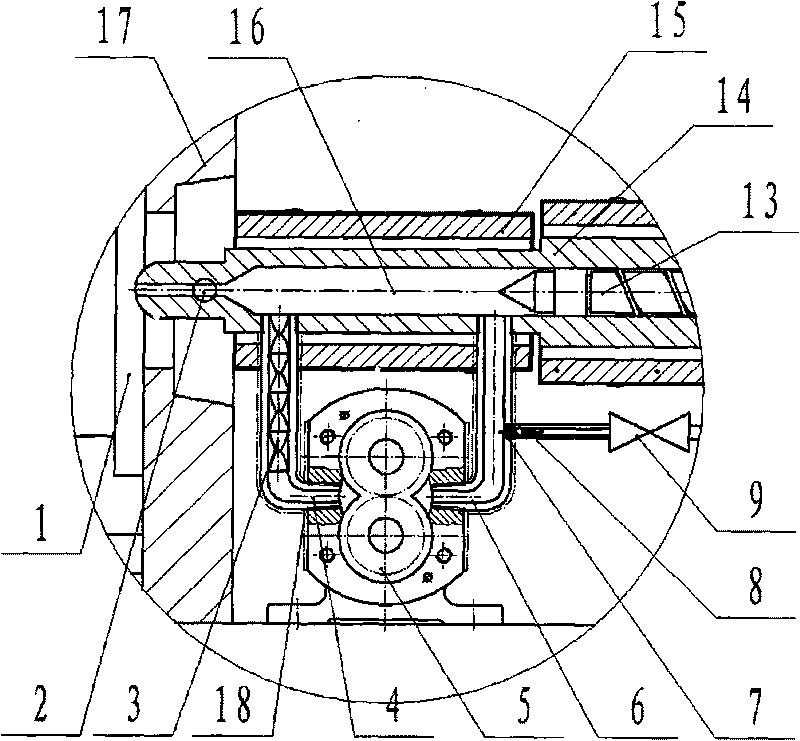

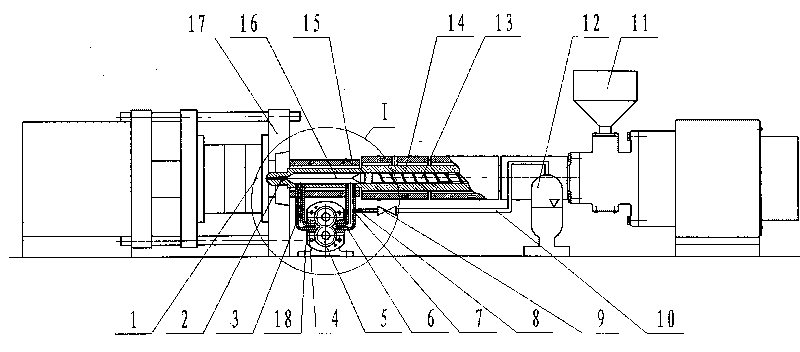

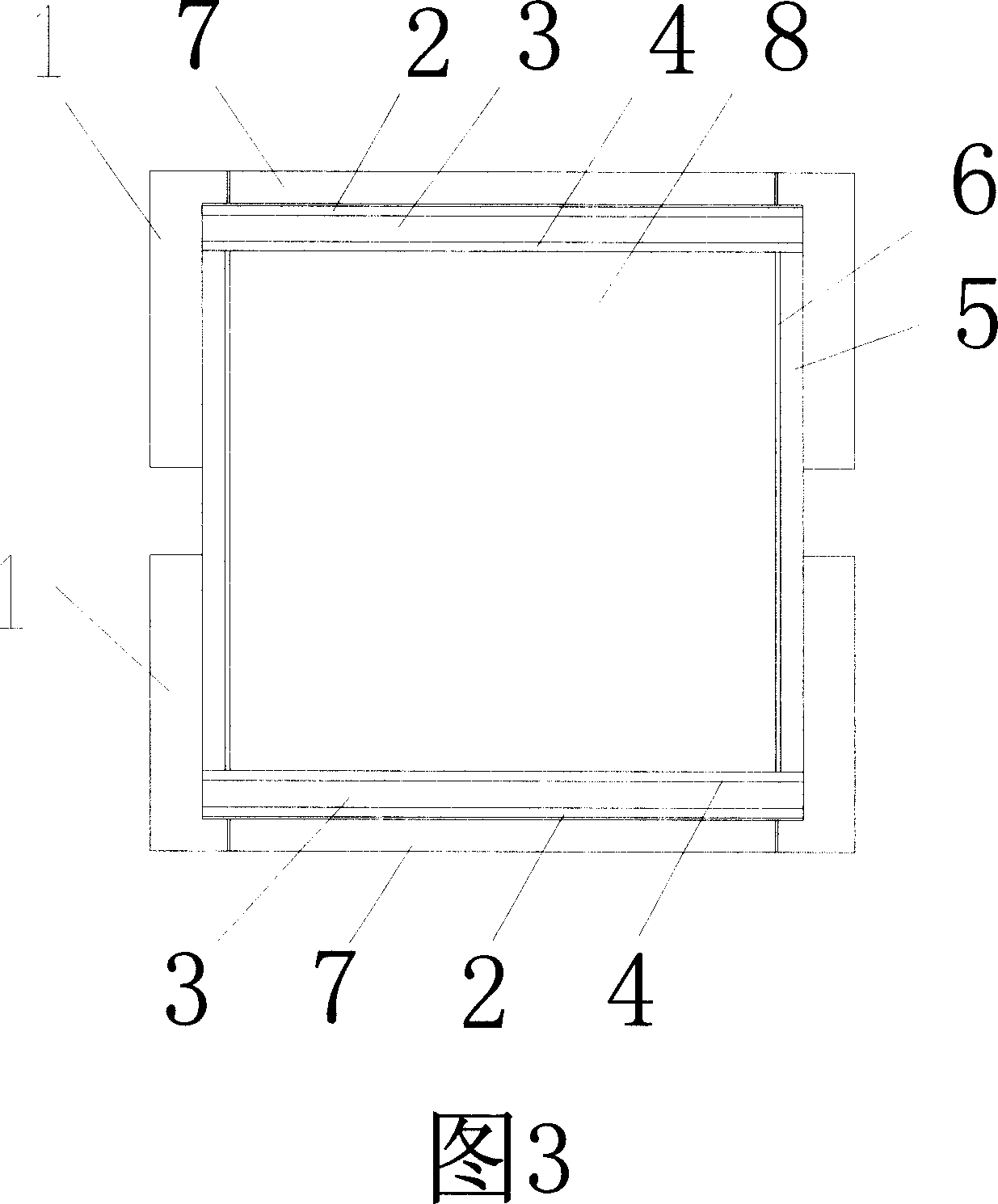

Micro-foam injection molding machine and molding process thereof

The invention relates to a micro-foam injection molding machine and molding process thereof, which belongs to the field of polymer material processing. The micro-foam injection molding machine mainly comprises an injection molding system, a clamping system and a micro-foam system, and the clamping system is the same as the clamping system of the conventional injection molding machine; two ports on the machine barrel front end of the injection molding system are respectively connected with the micro-foam system, a controllable on-off nozzle is arranged at the foremost end of the injection molding system, and the front end of a threaded rod is provided with a material storage area; and the micro-foam system comprises a gear pump, hybrid components, a gas injection device and a heating device. By introducing the micro-foam system, the injection molding system front end of the conventional injection molding machine is improved, with the introduction of the pressure boost gear pump into the micro-foam system, the pressure boost gear pump can circularly and ceaselessly drive the molding of the molten mass / gas homogeneous system in the material storage area and the core formation of the cell, the efficiency is high, and the molded cell is small and uniform; moreover, the device configuration is simple, and the device is easy to operate and control; and the invention has the advantages of low molded product weight, stable dimension, short molding cycle and energy conservation.

Owner:BEIJING UNIV OF CHEM TECH

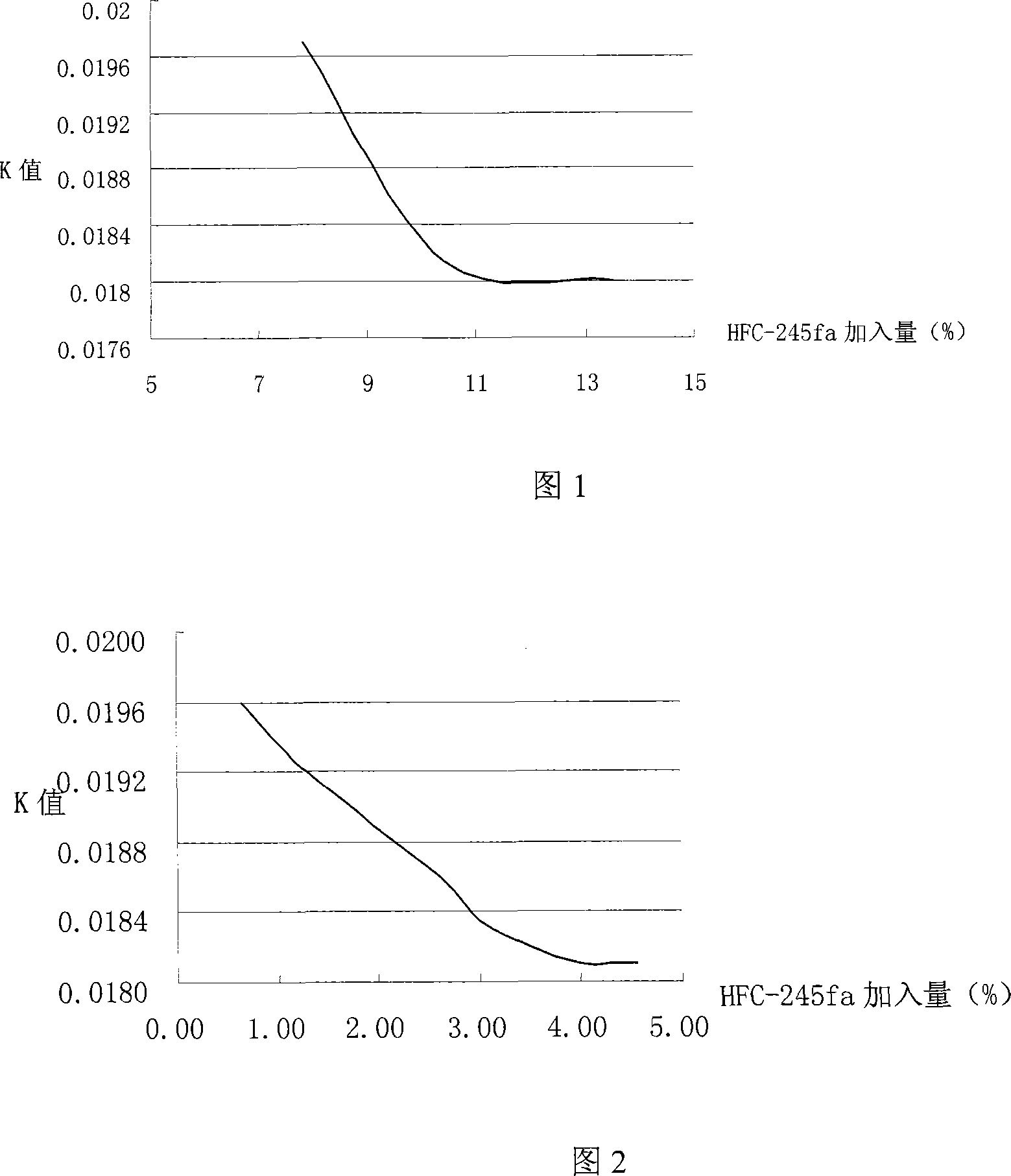

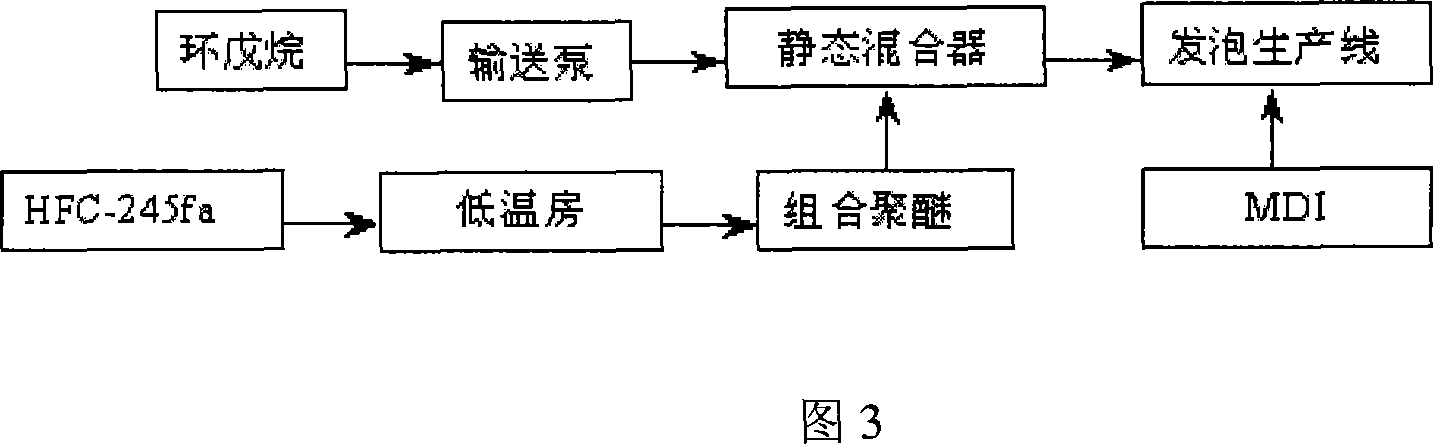

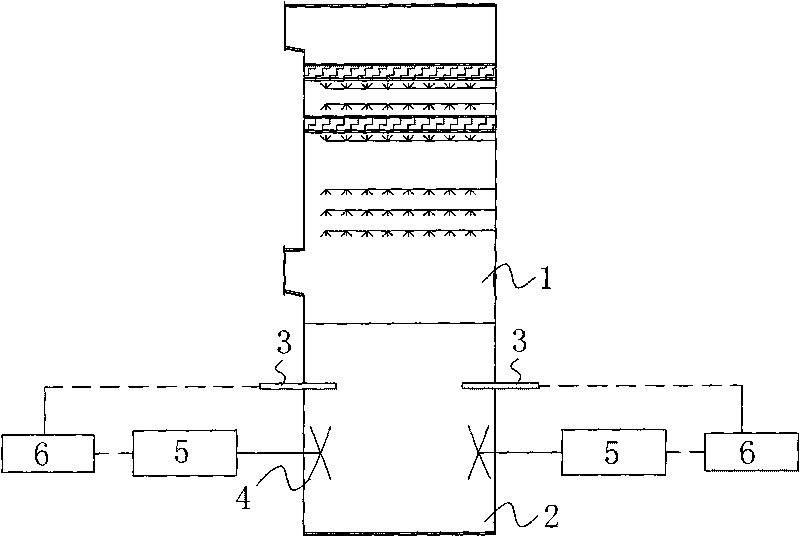

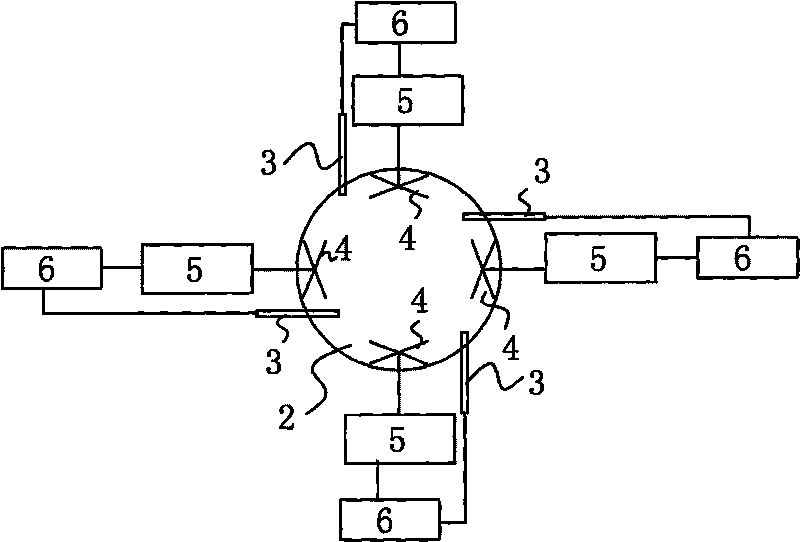

Polyurethane hard bubble foam and preparation method thereof

The invention discloses a kind of hard polyurethane foam and the preparation method. Said polyurethane foam comprises polyurethane raw material, which includes C-pentane foaming agent, combined polyether POL and MDI, the HFC-245fa is added into combined polyether, the adding amount is 0.5- 3% of total weight of raw material. The HFC-245fa is used as core formation agent. The invention is characterized in that it can distinctively and effectively reduce k value of PU foam, increases thermal insulation property and saves energy.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

Method for improving quality of desulphurization gypsum in flue gas desulfurization process and flue gas desulfurization system

ActiveCN101732976AWell mixedReduce the rate of new nuclei generationCalcium/strontium/barium sulfatesDispersed particle separationEngineeringSlurry

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Foil roll with wound stiffening core, apparatus for winding the roll and method

InactiveUS20100327100A1Low costReduce storage costsArticle deliveryWebs handlingLeading edgeHigh rate

A foil roll having a wound stiffener core formed from an initially flat sheet of stiffener material fed into a spiral roll winder simultaneously with a feed end of a foil web. An apparatus and method for spirally winding a foil roll with a wound stiffener core in which a stiffener sheet is fed into a roll winder in adjacent outward contact with a foil web and a leading edge of the stiffener slightly ahead of a feed end of a foil web. The stiffener sheet is outwardly disposed from the foil web and in adjacent contact with the roll starter guides to prevent contact between guides and the foil web during initial core formation. Roll starter guides are moved from contact with the outer periphery of the roll once the initial core is formed allowing a desired length of foil web to be spirally wound around the core without damage to the web. The apparatus is configured to receive a continuous supply of foil and stiffener web material, cut each to predetermined lengths, and sequentially form wound core foil rolls at an economically high rate.

Owner:ELSNER ENGINEERING WORKS INC

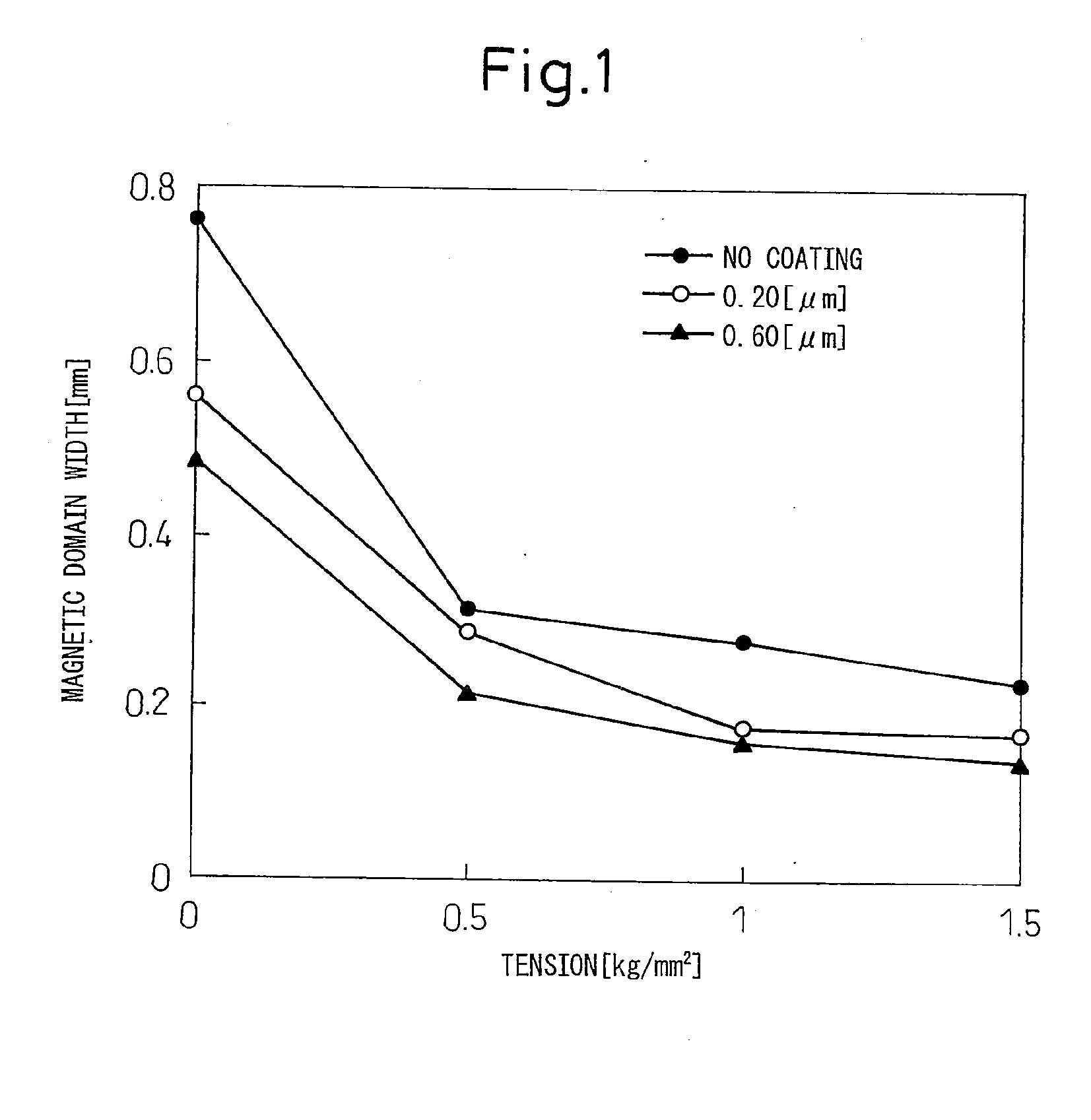

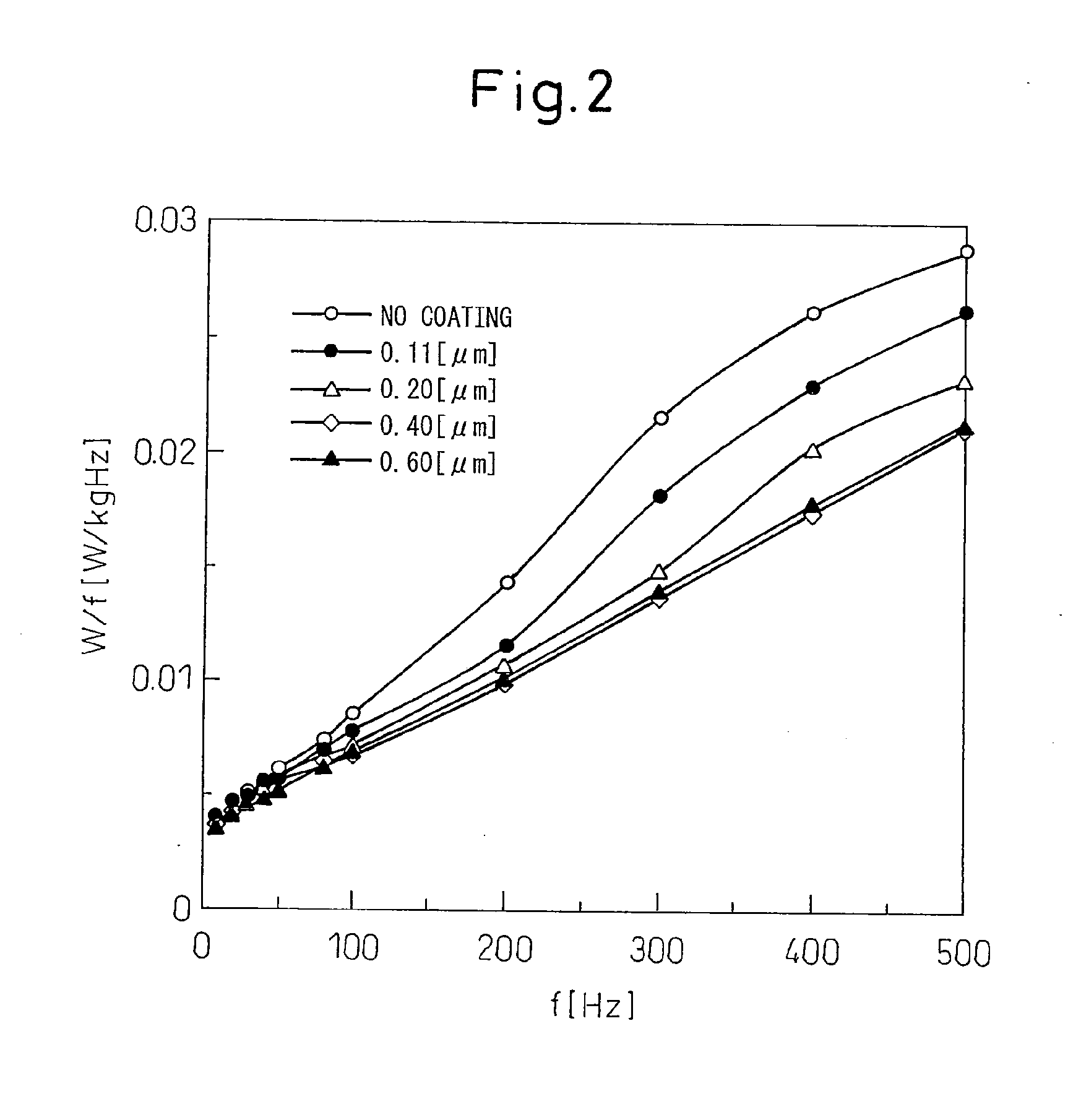

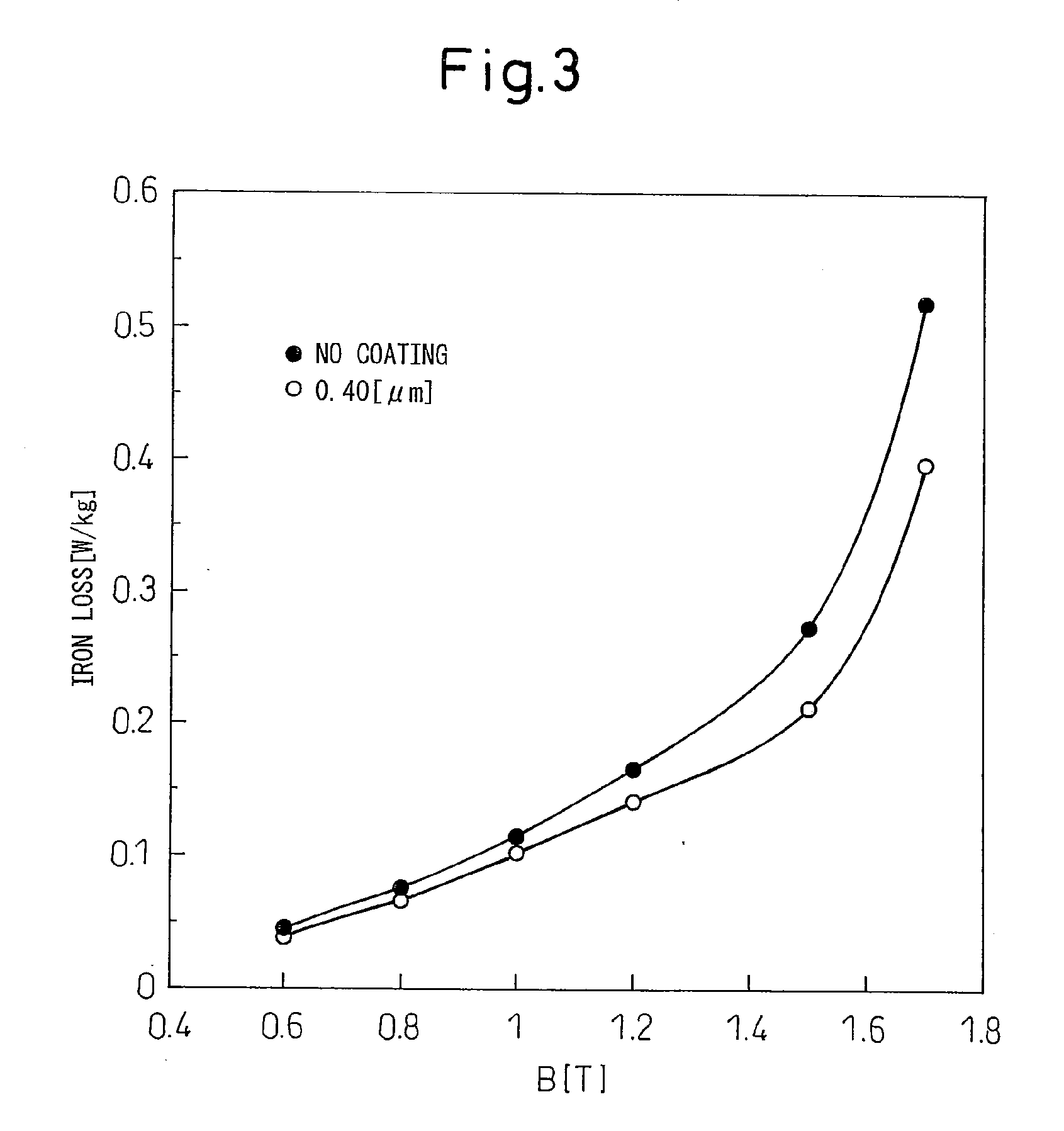

Grain-oriented electrical steel sheet excellent in magnetic properties

InactiveUS20100279142A1Good effectImprove workabilityInsulating substrate metal adhesion improvementMetallic material coating processesElectrical steelVolumetric Mass Density

The present invention enables magnetic domain control by the method of forming a magnetic coating layer of an Ni—Fe alloy comprised of Fe: 10 to 50 mass % and Ni: 90 to 50 mass % on the surface of grain-oriented electrical steel sheet having mainly {110}<001> orientation texture so that even if annealing after core formation, the iron loss improving effect will not be lost and the magnetic flux density will not be greatly reduced.

Owner:NIPPON STEEL CORP

Production technique for high-grade fine-particle diamond with high grade of transparency

The invention relates to an excellent transparent man made diamond sand manufacturing, using alloy powder and graphite dust compressed under super high pressure and temperature to synthesize diamond. The synthesized pressure is 96-98MPa, temperature rising pressure being 650-750MPa, synthesized temperature increased 2-10% than usual, temporary stopping pressure being 80-92% of the synthesized pressure, with a gap of 0. 10-0. 15MPa and time interval 120-180s and pressure maintaining time being 5-20s. Using the growing mechanism of intermiscibility, core formation, growing, and counter growing, it improves the product transparency when it starts extracts slag under high temperature, realizing fine and highly transparent diamond.

Owner:彭国强 +1

Production method of high-tenacity fiber pulling rope

ActiveCN105648807AHigh tensile strengthExtended service lifeBraidTextile cablesEngineeringHeat setting

The invention relates to a production method of a high-tenacity fiber pulling rope. The high-tenacity fiber pulling rope is prepared through nine steps including material selection, wire doubling, wire twisting, heat setting, rope core formation, connecting buckle formation, double-sheath formation, coating and injection molding. The production method has the advantages as follows: with the adoption of the production method, the tensile strength of the rope is enhanced, the service life is prolonged, and the rope has the characteristics of lightness, softness and good insulating property.

Owner:SHUNYUAN ELECTRIC RUGAO CITY ROPE BELT WEAVING CO LTD

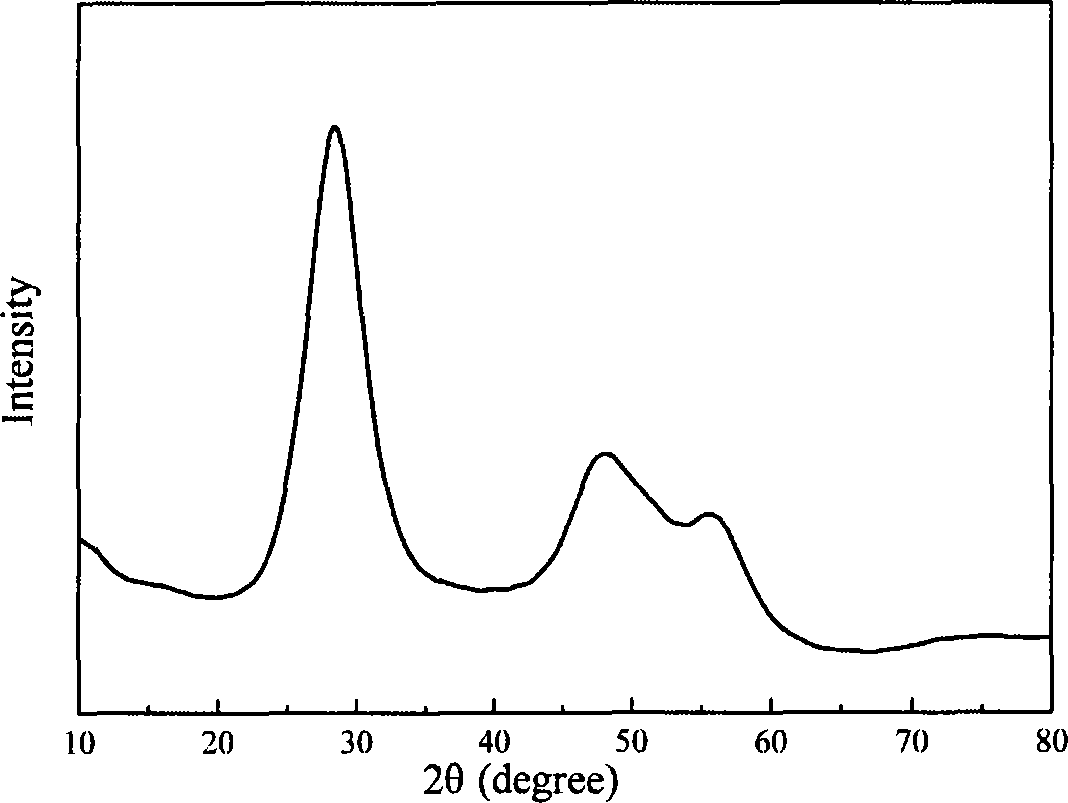

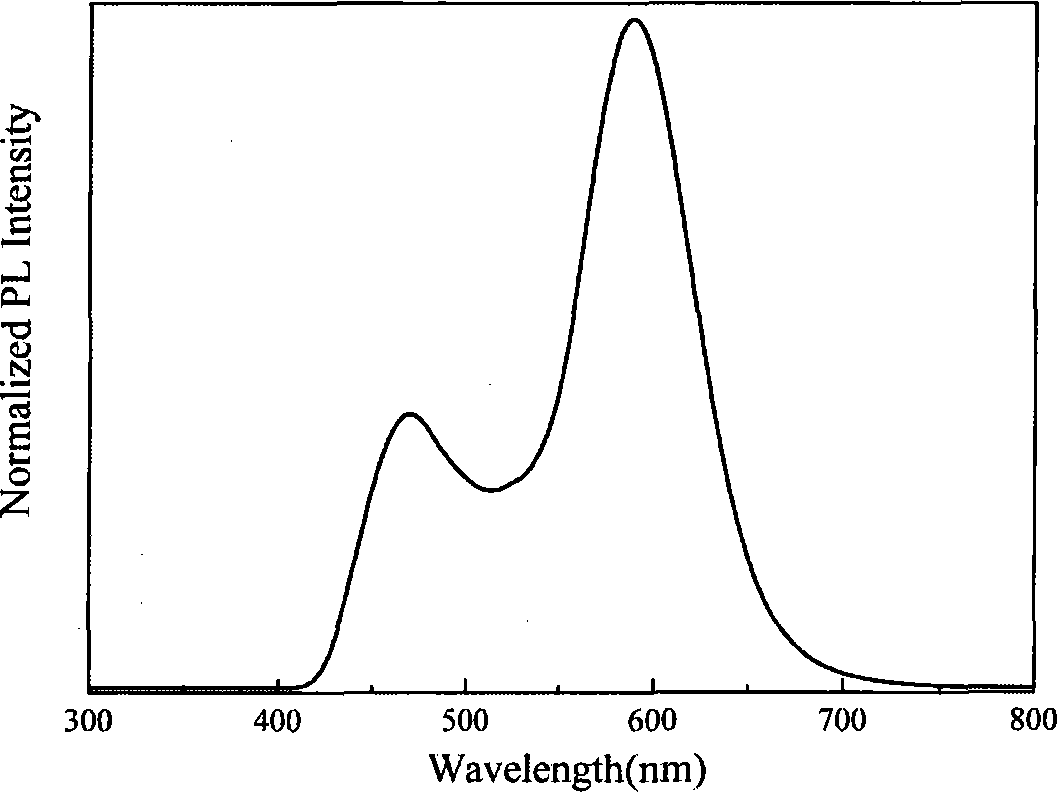

Preparation method of Ag-Mn doped ZnSe and ZnS core-shell structure quantum dot

InactiveCN108048093ALow priceLow costNanoopticsEnergy efficient lightingMANGANESE ACETATEReaction rate

The invention discloses a preparation method of an Ag-Mn doped ZnSe and ZnS core-shell structure quantum dot. The preparation method comprises the following steps of adopting a mixed solution of zincacetate and silver acetate as a core formation precursor, adding high-activity sodium hydrogen selenide at the temperature of 80-100 DEG C to obtain an Ag-doped ZnSe nanocrystal core; and then adopting a mixed solution of zinc acetate and manganese acetate as a shell layer precursor, adding sodium sulfide at the temperature of 80-100 DEG C to obtain an Mn-doped ZnS shell layer. According to the preparation method provided by the invention, by adopting the zinc acetate, the silver acetate and the manganese acetate, the cost is low, and the reaction rate is easily controlled; only by adding a very small amount of an alkaline solution, a pH value can be regulated into a strong alkaline range; the nanocrystal core and the shell layer are prepared by adopting a one-pot method respectively, so that the operation step is simplified, and the preparation method is liable to popularization and large-scale production; the core and the shell adopting a ZnSe / ZnS quantum dot are doped with Ag+ and Mn2+ respectively, and an Ag:ZnSe / Mn:ZnS quantum dot is prepared; a single fluorescence peak, different double fluorescence peak combination or three fluorescence peaks are provided, so that white fluorescence can be modulated; the structure has a white light emitting ability, and a fluorescence material is provided to the field of white light LED.

Owner:HUBEI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com