Liquid phase fluidized reduction method for preparing nanometer nickel powder

A technology of nanometer nickel powder and reduction method, which is applied in the field of preparation of nanometer nickel powder, can solve the problems of difficulty in liquid phase reduction of particle size and morphology, difficulty in industrialization, generation of waste water, etc., and achieves reduction of production cost, simple equipment and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

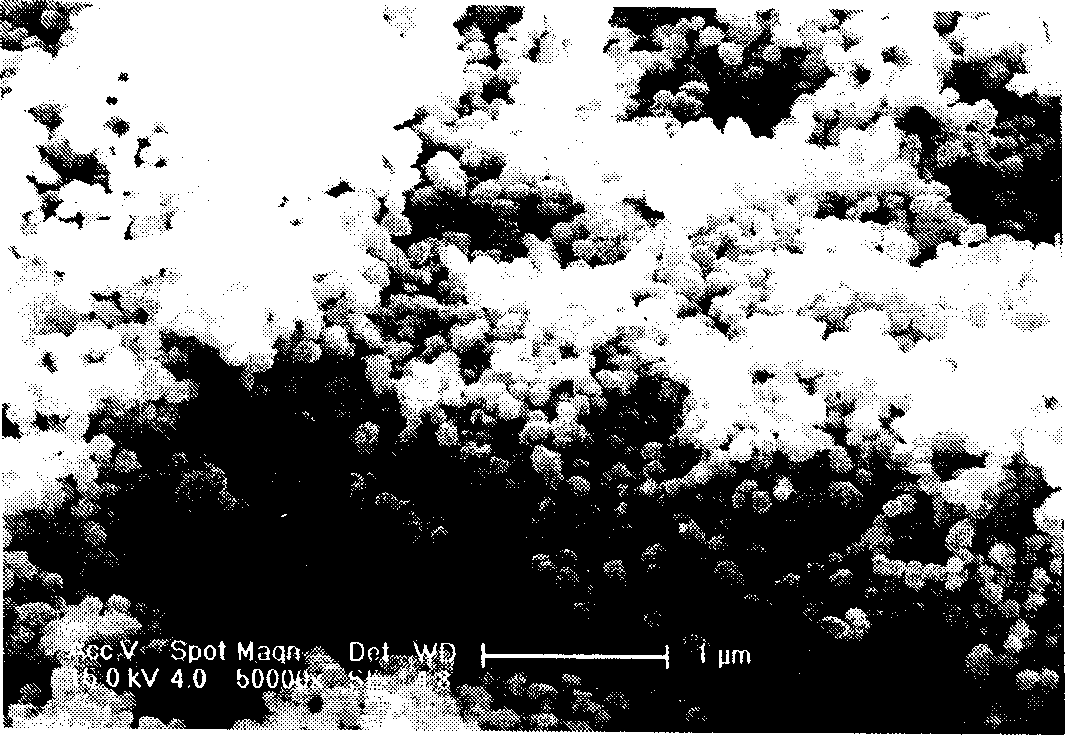

[0025] Example 1 Dissolve 14 g of nickel sulfate in 100 ml of distilled water, dissolve the theoretical ratio of NaOH in distilled water, mix the two solutions, and then add 0.1% CTAB solution to obtain Ni(OH) at pH 12 2 Colloid, the colloid was mixed with 5 mL of hydrazine hydrate, and flowed through the fluidized bed reactor at a speed of 1.5 L / min at a temperature of 60° C. After the reaction, it was cooled and filtered with suction to obtain a black solid powder. The solid is a ferromagnetic solid, and its surface morphology is shown in FIG. 1 . The nickel powder has a median diameter of 60nm measured by the small angle scattering method, an electron microscope statistical average particle diameter of 95nm, and a specific surface area of 8.8m 2 / g.

Embodiment 2

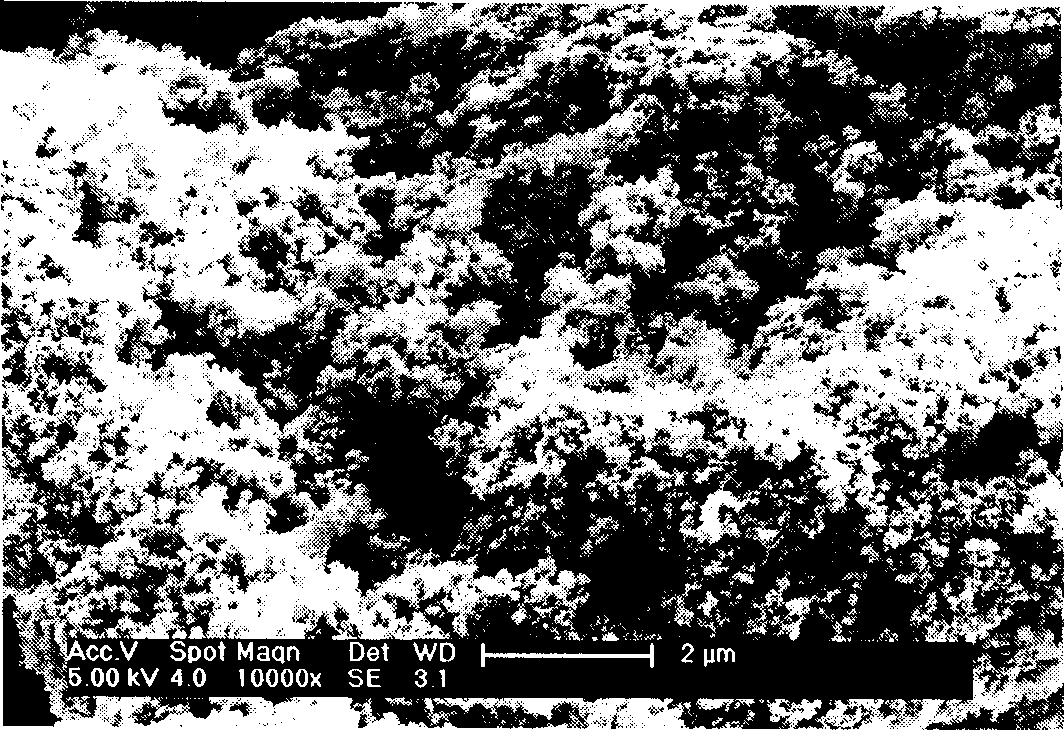

[0026] Example 2 Dissolve 14g of nickel sulfate in 100ml of distilled water, dissolve the theoretical ratio of NaOH in distilled water, mix the two solutions, and then add 0.1% CTAB solution to obtain Ni(OH) at pH 12 2 Colloid, 0.1% cobalt sulfate in the system, change the surfactant to SDS, and the reducing agent to NaBH 4 , the amount of reducing agent added is 0.8g, and the flow rate of 3L / min passes through the fluidized bed reactor at a reaction temperature of 90°C. After the reaction, black ferromagnetic powder is obtained. The scattering particle size is 28nm, and the electron microscope statistical particle size is 50nm , the specific surface area is 42.59m 2 / g, the morphology of nickel powder is shown in Figure 2.

Embodiment 3

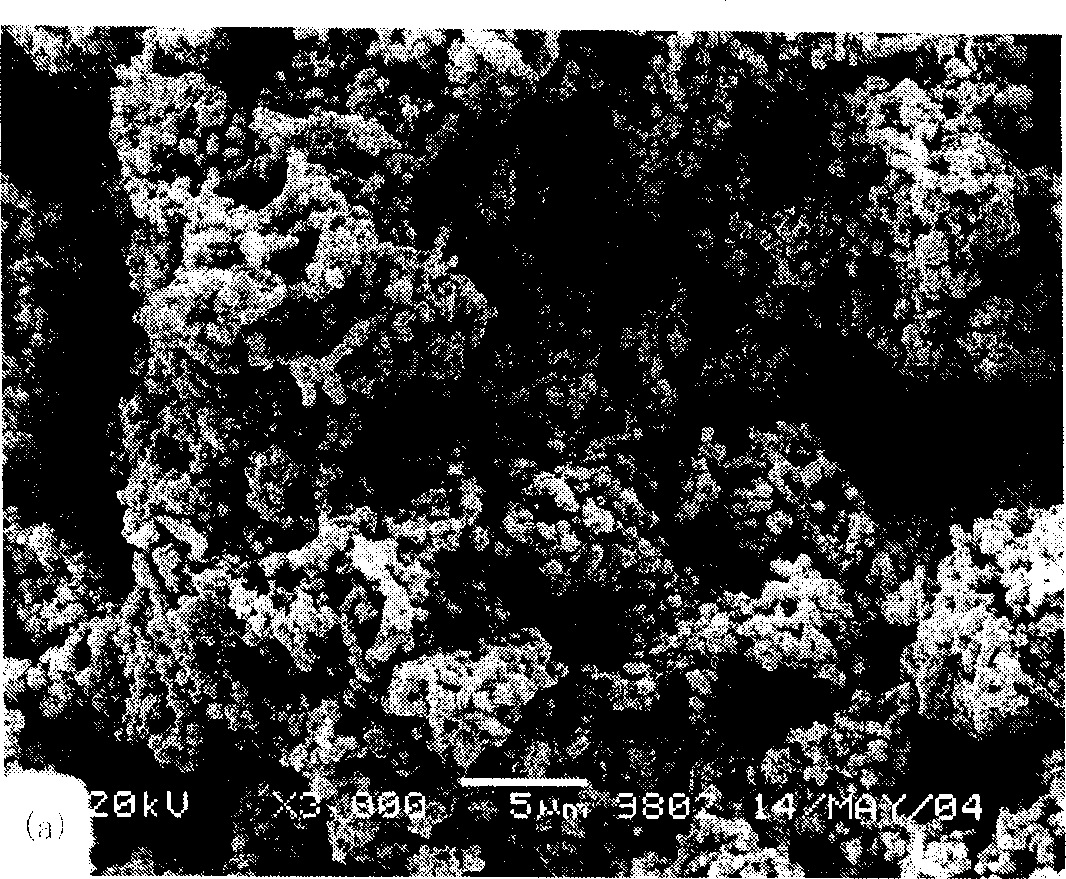

[0027] Example 3 Dissolve 14g of nickel sulfate in 100ml of distilled water, dissolve the theoretical ratio of NaOH in distilled water, mix the two solutions, and then add 0.1% CTAB solution to obtain Ni(OH) at pH 12 2 Colloid; add 5ml of hydrazine hydrate and 0.2% ammonium tungstate to the pH12 colloid. The colloid was passed through a fluidized bed reactor at a flow rate of 0.8 L / min at a temperature of 100° C. After the reaction was completed, the black ferromagnetic powder was obtained by cooling, vacuum filtration, and water washing. The surface morphology of the black ferromagnetic powder is shown in Figure 3, the scattering median diameter is 78nm, the statistical average particle diameter is 92nm, and the specific surface area is 8.02m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com