Novel metallic film preparation technology on liquid phase substrate surface

A metal film and substrate surface technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of key parameters not being disclosed, achieve easy research and application, simple preparation process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

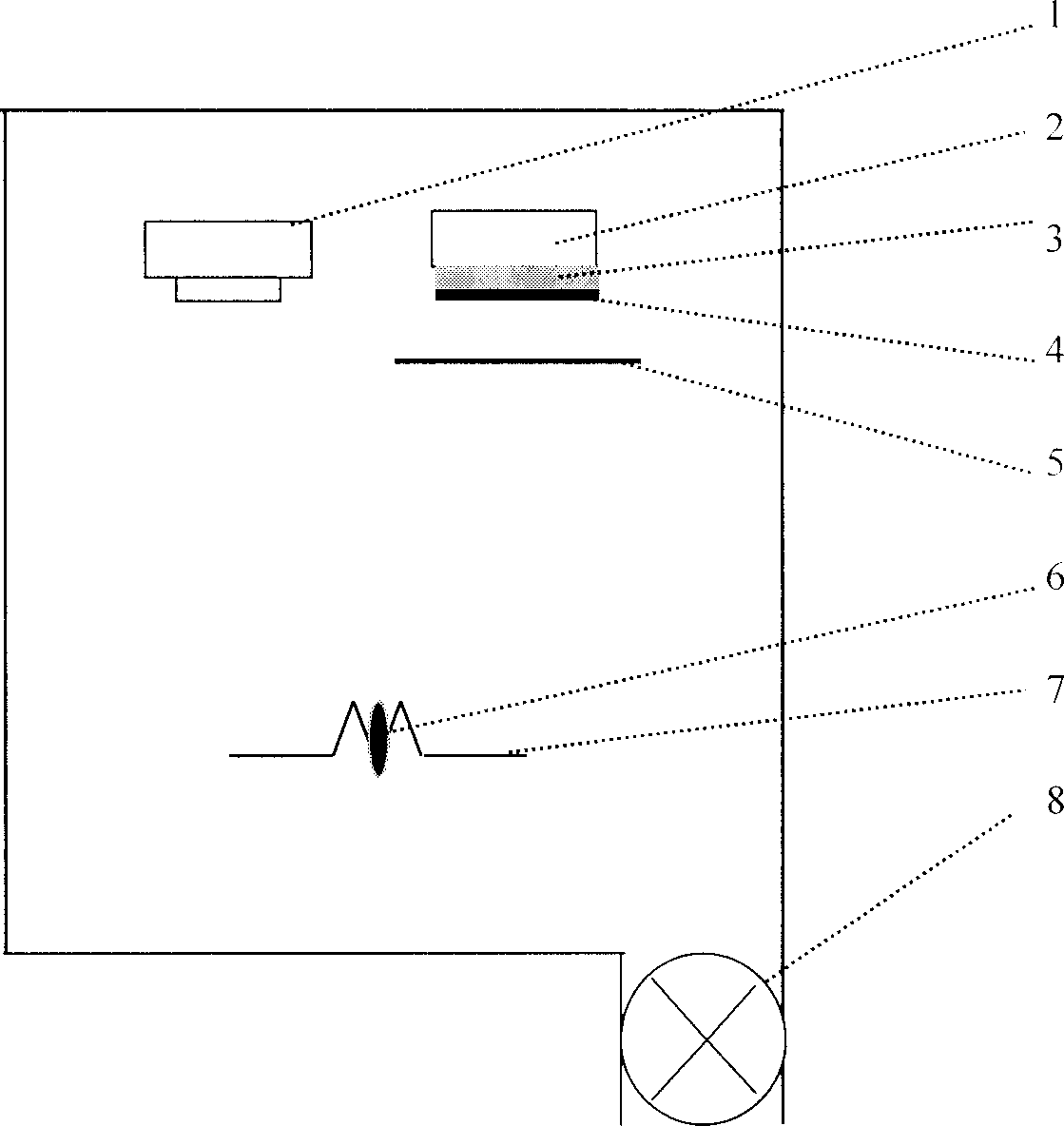

[0032] (a) refer to figure 1 , in the vacuum chamber of the vacuum evaporating device, a substrate frame composed of a brushed glass slide 3 coated with a liquid phase substrate 4 with a thickness of 0.2mm and an electric furnace 2, the liquid phase substrate can be made of diffusion pump silicone oil, liquid crystal, or melted glass , a kind of gallium, the evaporation source is formed by evaporating metal material 6 and heating tungsten wire 7, the material of metal evaporation source can be non-magnetic material Au, Ag, Al, Cu or magnetic material Fe, Ni with a purity of 99.9% to 99.99% One of. The liquid surface on the substrate rack faces the evaporation source (up, down, left, and right positions between them are not limited), and the distance between the substrate rack and the evaporation source is 10-15 cm, and they are separated by a baffle plate 5 . The crystal oscillator thickness gauge 1 is installed near the sample, and is used to control the deposition rate in c...

Embodiment 2

[0039] Deposit iron thin film on the surface of liquid phase substrate by radio frequency magnetron sputtering method:

[0040] (a) In the vacuum chamber of radio frequency magnetron sputtering, the liquid phase substrate adopts diffusion pump silicon oil, and the sputtering target material (i.e. thin film material) is a magnetic iron (Fe ) sheet material, the distance between the substrate holder and the sputtering source = 10 cm, and they are separated by a baffle.

[0041] (b) Evacuate the chamber to 6×10 with mechanical pump and molecular pump -4 Pa vacuum.

[0042] (c) Heating in an electric furnace can make the silicone oil adjustable between 5°C and 50°C. At this time, the vapor pressure of the silicone oil substrate is lower than the air pressure in the vacuum chamber;

[0043] (d) Increase the sputtering power to about 10W, degas the surface of the iron target and pre-sputter for 3 minutes. Then open the baffle to start coating. The growth rate of the thin film is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com