Preparation method of ternary cathode material

A technology of positive electrode material and mixed solution, which is applied in the field of preparation of ternary positive electrode materials, can solve the problems of low tap density, low capacity, and low cycle performance, and achieve the effects of high tap density, high capacity, and high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a preparation method of a ternary positive electrode material, which solves the problems of the high-nickel LiNi0.7Co0.15Mn0.15O2 ternary positive electrode material in the prior art, and the product has low tap density, low capacity, and poor cycle performance. Low technical problems, the technical effects of high tap density, high capacity and high cycle performance of the products manufactured by the method are realized.

[0018] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

Embodiment 1

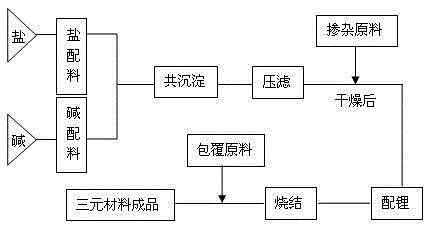

[0021] Please refer to figure 1 , on the basis of the existing 532 series ternary material production, this application adopts the self-developed co-precipitation method, lithium mixing and roasting synthesis process, and performs cation doping modification and surface carbon coating technology in the liquid phase to produce high nickel LiNi0.7Co0.15Mn0.15O2 ternary cathode material, the product has the advantages of high tap density, high capacity and high cycle performance.

[0022] 1. Key technologies and processes

[0023] (1) Co-precipitation process to prepare the key technology of nickel-drill-manganese ternary material precursor with dense crystallization, moderate material particle size and narrow particle size distribution;

[0024] (2) The key process of cationic doping modification pretreatment after washing and pressing the precursor;

[0025] (3) The key technology of controlling the material structure and electrochemical performance by adjusting the lithium co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com