Preparation method of Ag-Mn doped ZnSe and ZnS core-shell structure quantum dot

A technology of core-shell structure and quantum dots, applied in the field of chemistry, can solve the problem of high cost and achieve the effect of low cost, simplified operation steps and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

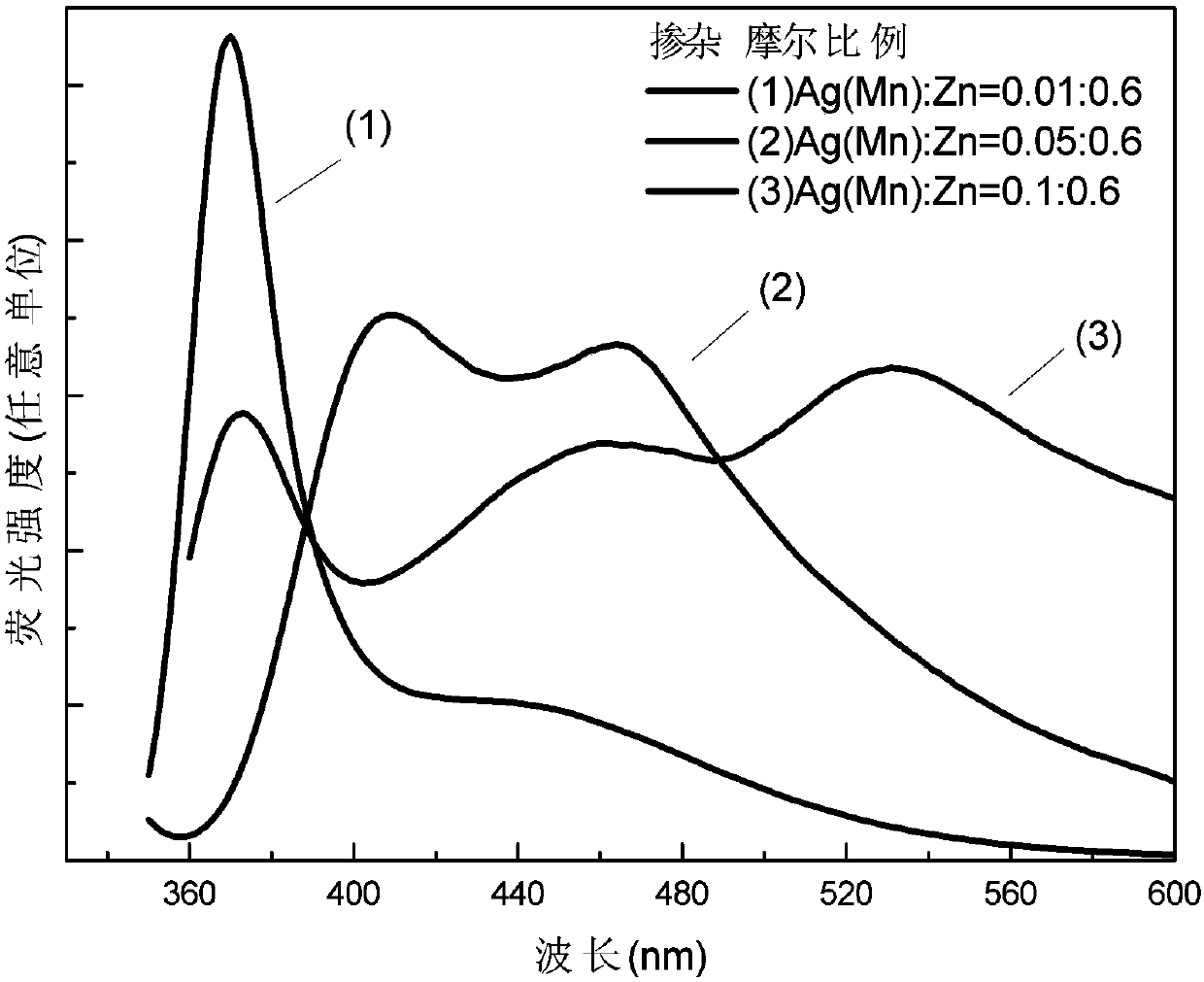

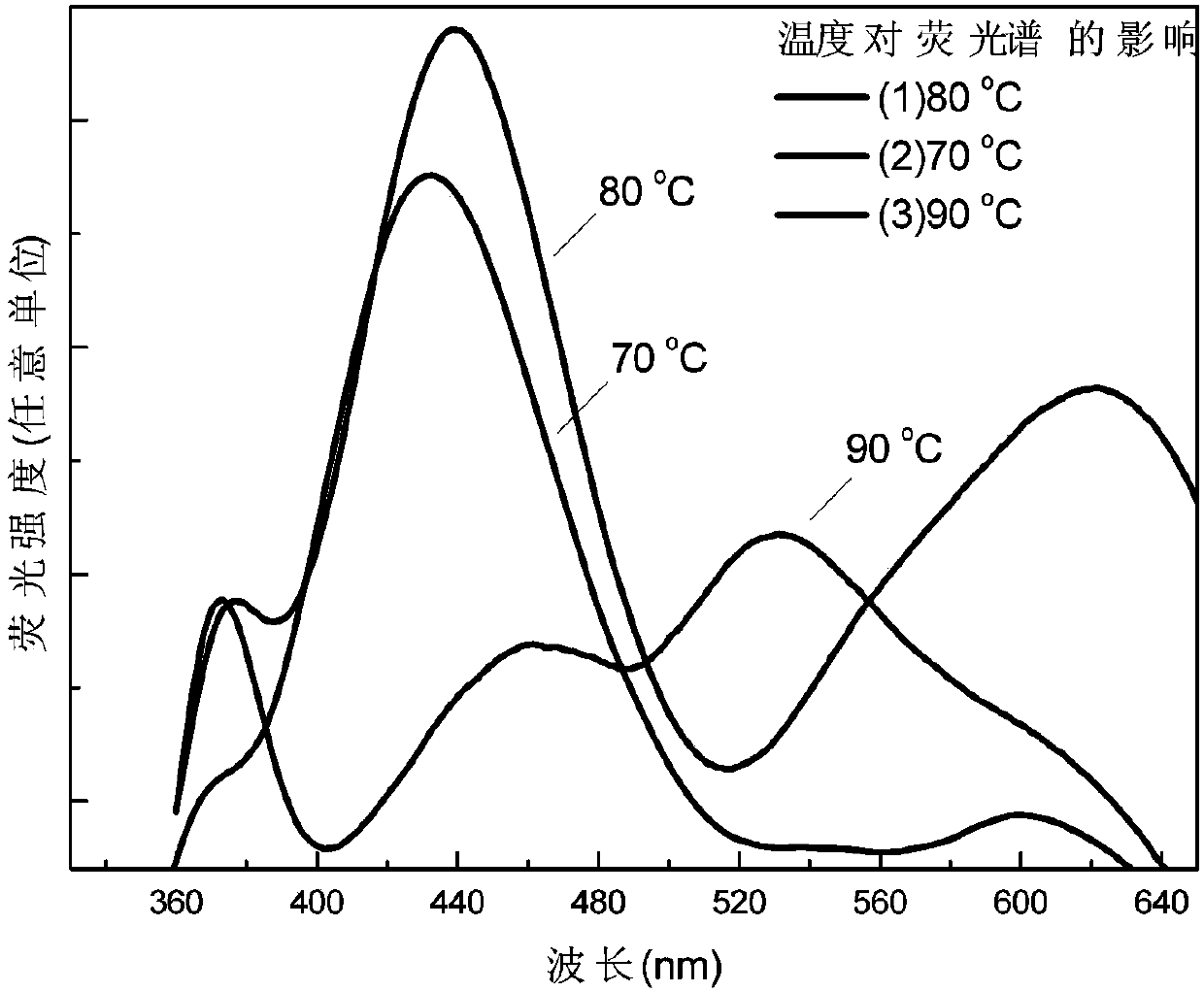

[0021] Embodiment 1: 0.012g of selenium powder and 0.021g of sodium borohydride are placed in a 25ml double-necked bottle, 3ml of secondary deionized water is added, and magnetic stirring is performed at room temperature for at least 30min; 0.5mmol of zinc acetate and 0.01, 0.05, 0.1 Three ratios of mmol silver acetate, add 30ml secondary deionized water, add 0.5mmol glutathione as a ligand, stir magnetically at room temperature and dropwise add sodium hydroxide solution to pH 9, then pour it into a three-neck bottle, Nitrogen deoxygenated for 30 minutes; then heated to 90 degrees Celsius, 1ml of sodium selenium hydride solution was injected into the three-necked bottle, and kept at 90 degrees Celsius and magnetically stirred for 60 minutes; to obtain Ag:ZnSe nanocrystal core; 0.1mmol zinc acetate and 0.01, 0.05 , three ratios of 0.1mmol manganese acetate, add 10ml secondary deionized water, add 0.1mmol glutathione as a ligand, stir magnetically at room temperature and add sodi...

Embodiment 2

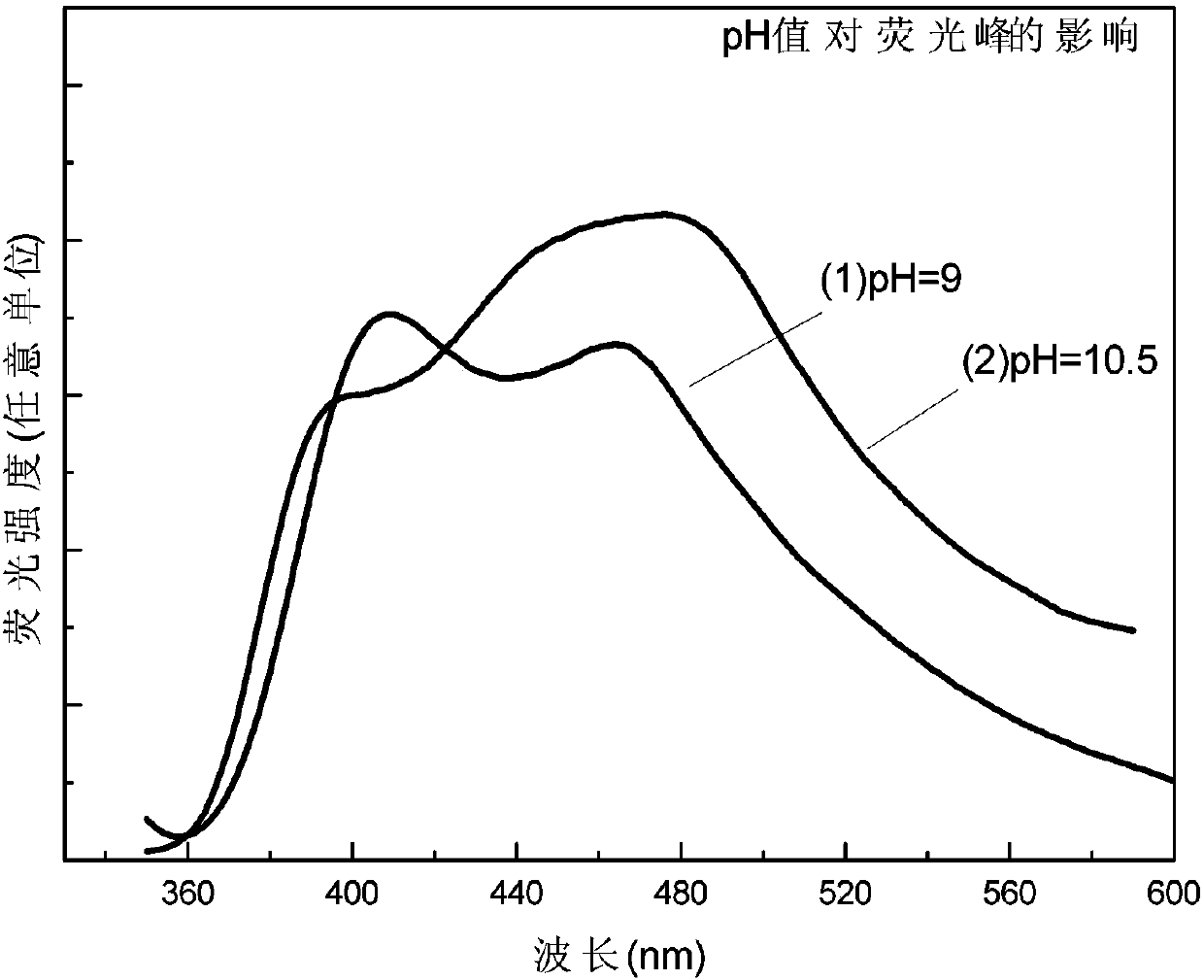

[0022] Embodiment 2: 0.012g of selenium powder and 0.021g of sodium borohydride are placed in a 25ml double-necked bottle, 3ml of secondary deionized water is added, and magnetically stirred at room temperature for at least 30min; 0.5mmol of zinc acetate and 0.05mmol of silver acetate, Add 30ml of secondary deionized water, add 0.5mmol of glutathione as a ligand, stir magnetically at room temperature and dropwise add sodium hydroxide solution to pH 9 and 10.5 respectively, then pour it into a three-necked bottle, and blow nitrogen to remove oxygen 30min; then heated up to 90°C, poured 1ml of the sodium selenium hydride solution into the three-necked bottle, kept at 90°C and stirred magnetically for 60min; obtained the Ag:ZnSe nanocrystal nucleus; mixed three ratios of 0.1mmol zinc acetate and 0.05mmol manganese acetate , add 10ml secondary deionized water, add 0.1mmol glutathione as a ligand, magnetically stir at room temperature and dropwise add sodium hydroxide solution to pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com