Aqueous phase method for manufacturing core formation doping ZnS:Mn and ZnS:Mn/ZnS nanocrystalline

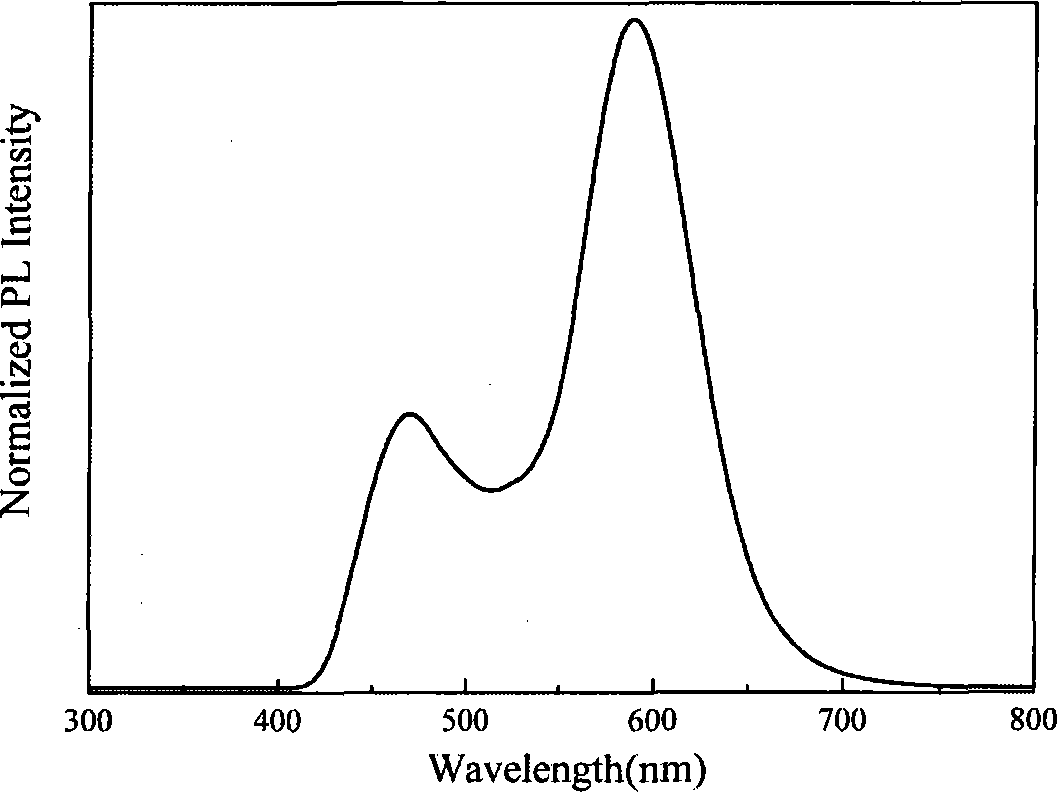

A water-phase preparation and nanocrystal technology, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of complex operation and high reaction temperature, and achieve the effects of good water solubility, good photostability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

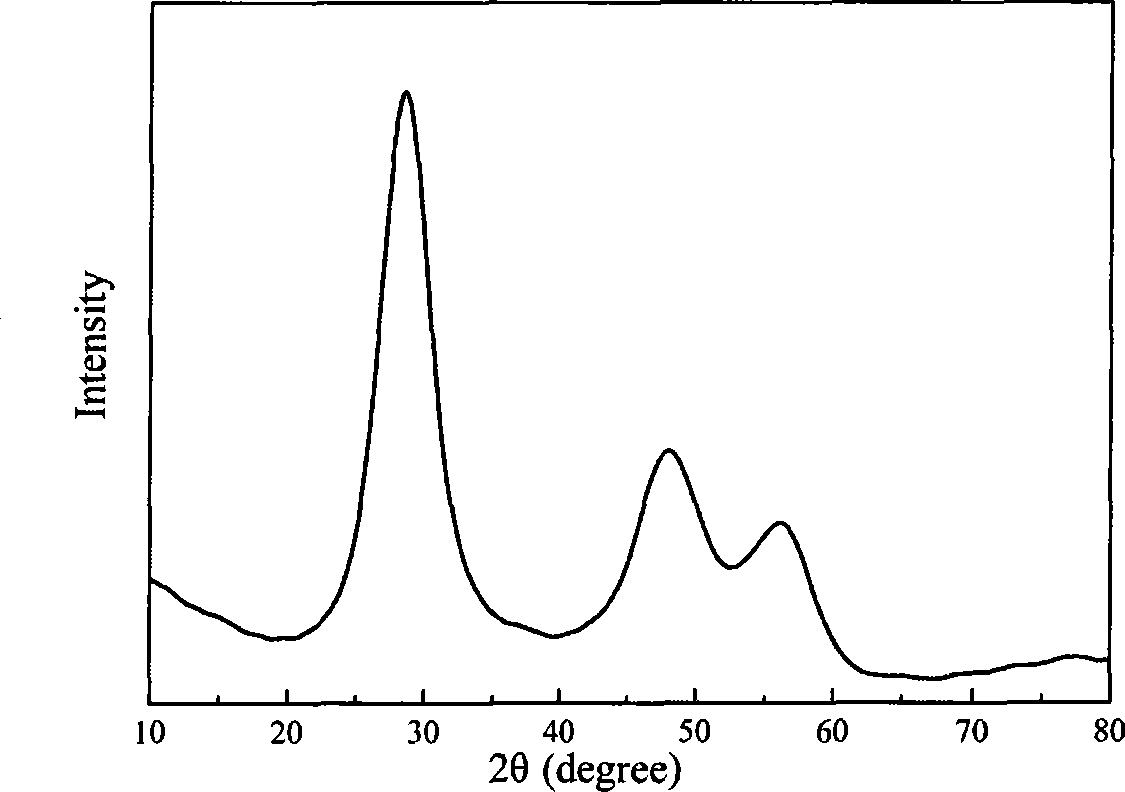

Embodiment 1

[0025] 1. Take 2.4508g (0.01mol) of manganese acetate, add 100ml of 0.12M thioglycolic acid (TGA) aqueous solution at 25°C, adjust the pH to 4.5 with 10M NaOH, stir well, store at room temperature for later use, and control the mole of Mn and thioglycolic acid The ratio is 1:1.2;

[0026] 2. Take 2.1951g (0.01mol) of zinc acetate, add 100ml of 0.12M thioglycolic acid aqueous solution at 25°C, adjust the pH to 4.5 with 10M NaOH, stir well, store at room temperature for later use, and control the molar ratio of Zn to thioglycolic acid to 1 : 1.2;

[0027] 3. Take 4.8036g (0.01mol) of sodium sulfide, add 200ml of deionized water at 25°C, stir well, and store at room temperature for later use;

[0028] 4. Take 1ml of the Mn-TGA solution (Mn precursor) prepared in step 1, quickly add it into 200ml of the S precursor solution prepared in step 3 at 80°C, and stir vigorously at 80°C for 20min.

[0029] 5. Take 100ml of the Zn-TGA solution (Zn precursor) prepared in step 2, quickly a...

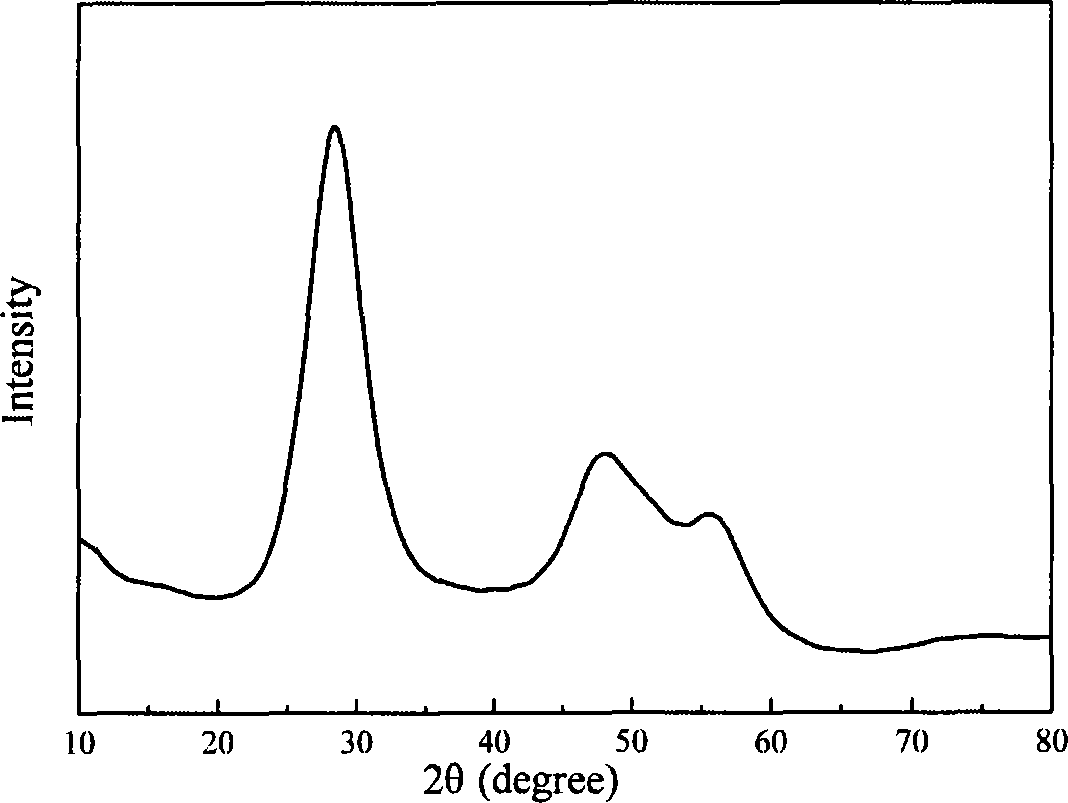

Embodiment 2

[0033] 1, prepare ZnS by process 1-5 in embodiment 1: Mn nano crystal aqueous solution, wherein the zinc precursor volume in step 1 is changed into 75ml, the aging time in step 5 is changed into 10h;

[0034] 2. Quickly add 25ml of Zn-TGA solution to the solution obtained in step 1 at 80°C, and stir vigorously for 2 hours;

[0035] 3. Obtain ZnS:Mn / ZnS nanocrystalline phosphor according to step 6 in Example 1.

Embodiment 3

[0037] The temperature of the water bath in Example 1 or Example 2 was changed to 65° C., all the other reaction processes and conditions were unchanged, and the obtained results were the same as those in Example 1 or Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com