Production technique for high-grade fine-particle diamond with high grade of transparency

An artificial diamond, high transparency technology, applied in the application of ultra-high pressure process, etc., to achieve good results and improve transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

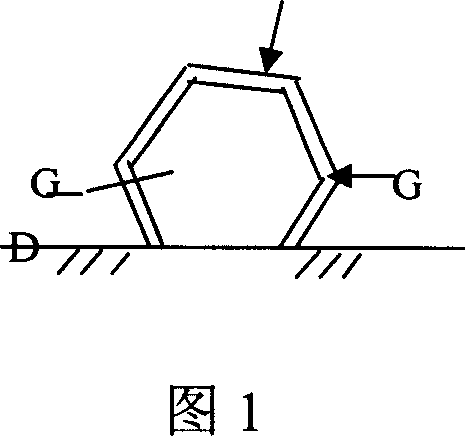

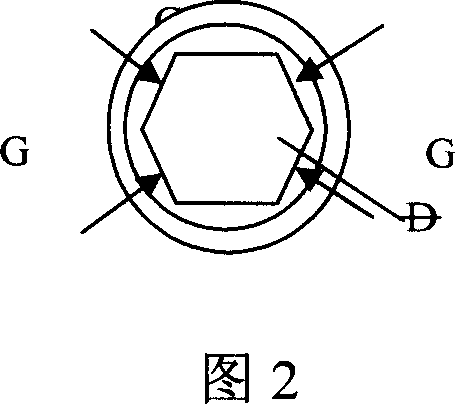

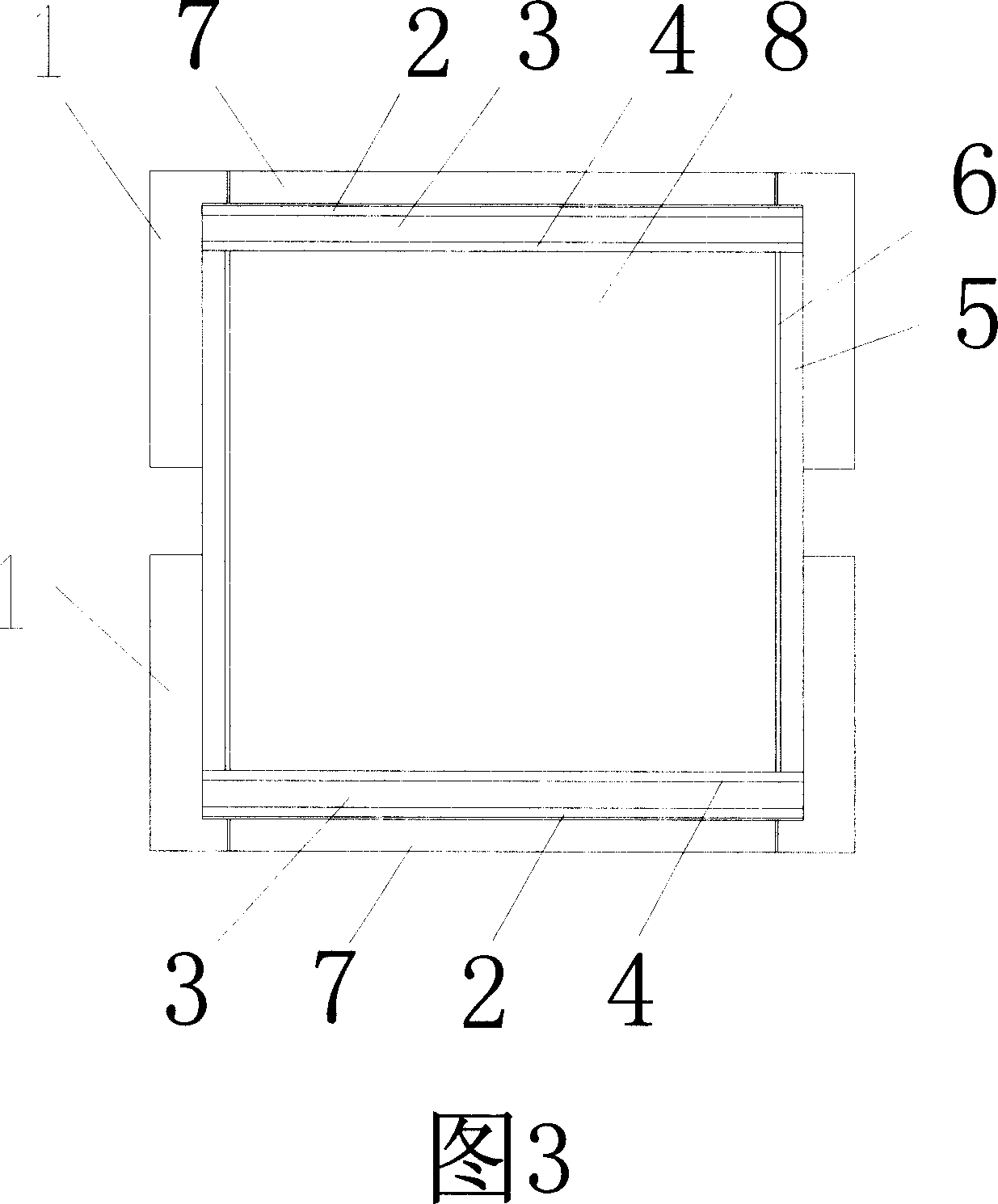

[0023] 1. Press: TDS034 series 6×21MN six-sided top press produced by Hunan Taishan Machinery Co., Ltd. It has Chinese characteristics and is a spherical bottom hinged press with a cylinder diameter of Φ500mm;

[0024] 2. Control system: JY-ZIC artificial diamond press electrical control device produced by Changsha Shuangjin Automation Co., Ltd., with a pressure accuracy of 0.01MPa and a temperature accuracy (indicated by current) of 3A;

[0025] 3. Pyrophyllite block: 58×58×58mm 3 (two section type)

[0026] 4. Dolomite liner: Φ 外 46mm×Φ 内 38mm;

[0027] 5. Cavity: Φ38mm;

[0028] 6. Graphite column: Φ38mm×32mm

[0029] 7. Synthesis process:

[0030] Synthetic pressure: generally 96-98MPa;

[0031] Heating pressure: 650-750MPa;

[0032] Synthesis temperature: 2-5% higher than the usual temperature in the early stage;

[0033] Suspension pressure: 80-92% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0034] Pause ti...

Embodiment 2

[0041] 1. Press: TDS034 series 6×21MN six-sided top press produced by Hunan Taishan Machinery Co., Ltd. It has Chinese characteristics and is a spherical bottom hinged press with a cylinder diameter of Φ500mm;

[0042] 2. Control system: JY-ZIC artificial diamond press electrical control device produced by Changsha Shuangjin Automation Co., Ltd., with a pressure accuracy of 0.01MPa and a temperature accuracy (indicated by current) of 3A;

[0043] 3. Pyrophyllite block: 58×58×58mm 3 (two-section type);

[0044] 4. Dolomite liner: Φ 外 46mm×Φ 内 38mm;

[0045] 5. Cavity: Φ38mm;

[0046] 6. Graphite column: Φ38mm×32mm

[0047] 7. Synthesis process:

[0048] Synthetic pressure: generally 96-98MPa;

[0049] Heating pressure: 670-750MPa;

[0050] Synthesis temperature: 2-10% higher than the usual temperature in the early stage;

[0051] Suspension pressure: 83-91% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0052] Pause ...

Embodiment 3

[0059] 1. Press: TDS034 series 6×21MN six-sided top press produced by Hunan Taishan Machinery Co., Ltd. It has Chinese characteristics and is a spherical bottom hinged press with a cylinder diameter of Φ500mm;

[0060] 2. Control system: JY-ZIC artificial diamond press electrical control device produced by Changsha Shuangjin Automation Co., Ltd., with a pressure accuracy of 0.01MPa and a temperature accuracy (indicated by current) of 3A;

[0061] 3. Pyrophyllite block: 58×58×58mm 3 (two-section type);

[0062] 4. Dolomite liner: Φ 外 46mm×Φ 内 38mm;

[0063] 5. Cavity: Φ38mm;

[0064] 6. Graphite column: Φ38mm×32mm;

[0065] 7. Synthesis process:

[0066] Synthetic pressure: generally 96-98MPa;

[0067] Heating pressure: 680-740MPa;

[0068] Synthesis temperature: 2-8% higher than the usual temperature in the early stage;

[0069] Suspension pressure: 85-90% of the synthetic pressure, the difference between the two suspension pressures is 0.10-0.15MPa;

[0070] Pause ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com