Method for producing acrylic amide crystal

A technology of acrylamide crystals and production methods, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems that the secondary nucleation method has not been reported, and achieve low cost, simple method, and low water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation and detection of embodiment 1 acrylamide crystal

[0023] (1) Pass 2000kg of acrylamide aqueous solution with a temperature of 40°C and a concentration of 630g / L into a volume of 5m 3 In the jacketed stirred crystallization tank; the frozen brine with a temperature of -5°C is passed into the jacket to cool the acrylamide aqueous solution to 25°C;

[0024] (2) Add 1.6 kg of acrylamide crystals with a particle size of 0.2 mm to the acrylamide aqueous solution; continue to cool down to 6° C., and keep the temperature at 6° C. for 30 minutes to obtain the acrylamide crystallization mother liquor;

[0025] (3) Pour the acrylamide crystallization mother liquor into a two-stage pusher centrifuge for centrifugation; and dry the centrifuged product on a vibrating fluidized bed to obtain 261 kg of acrylamide crystals.

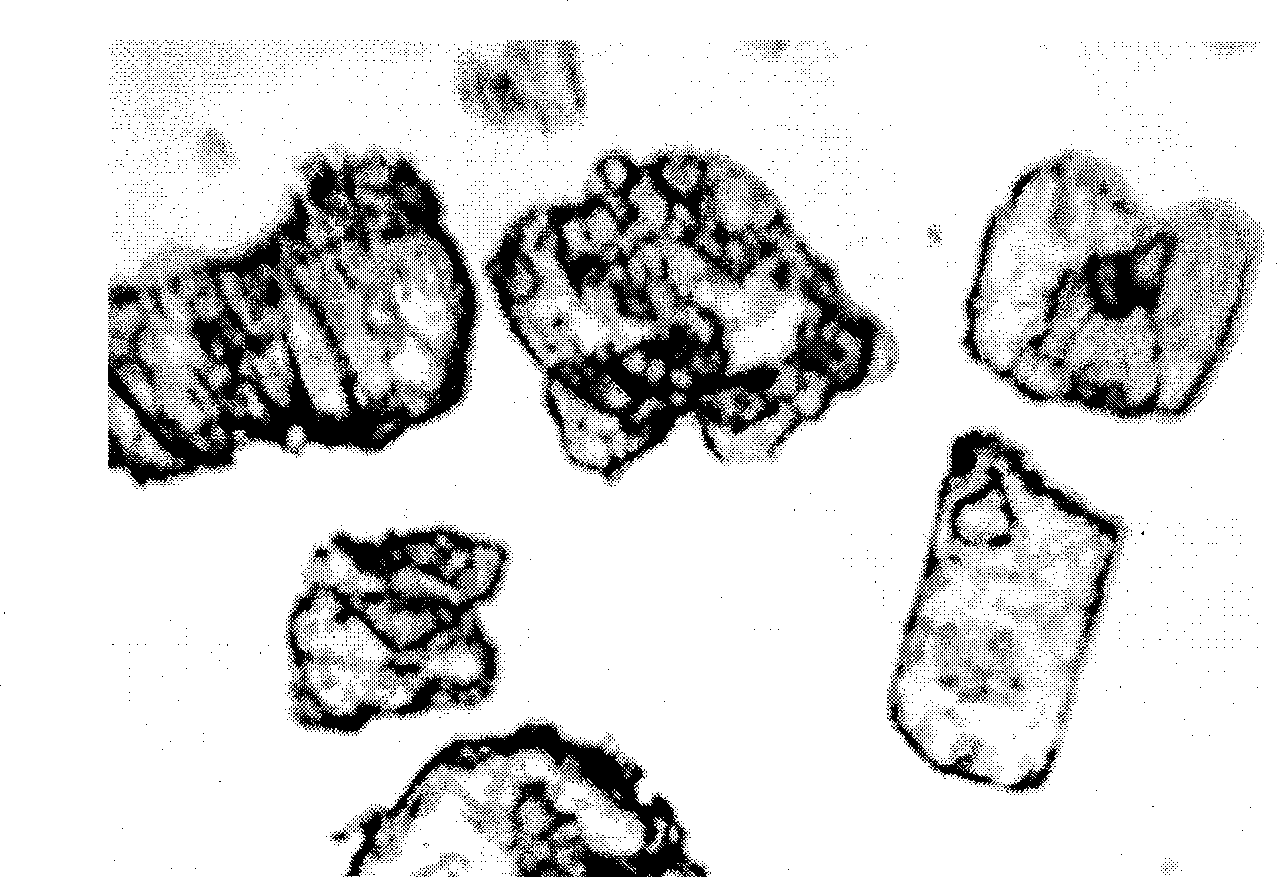

[0026] Microscopic observation of acrylamide crystals: take the centrifuged acrylamide crystals and place them under a microscope for observation. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com