Polyurethane hard bubble foam and preparation method thereof

A polyurethane rigid foam and polyurethane technology, applied in the field of rigid foam foam and its preparation, can solve the problems of increased power consumption, poor thermal insulation performance, and inability to save electric energy, so as to reduce power consumption and improve thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

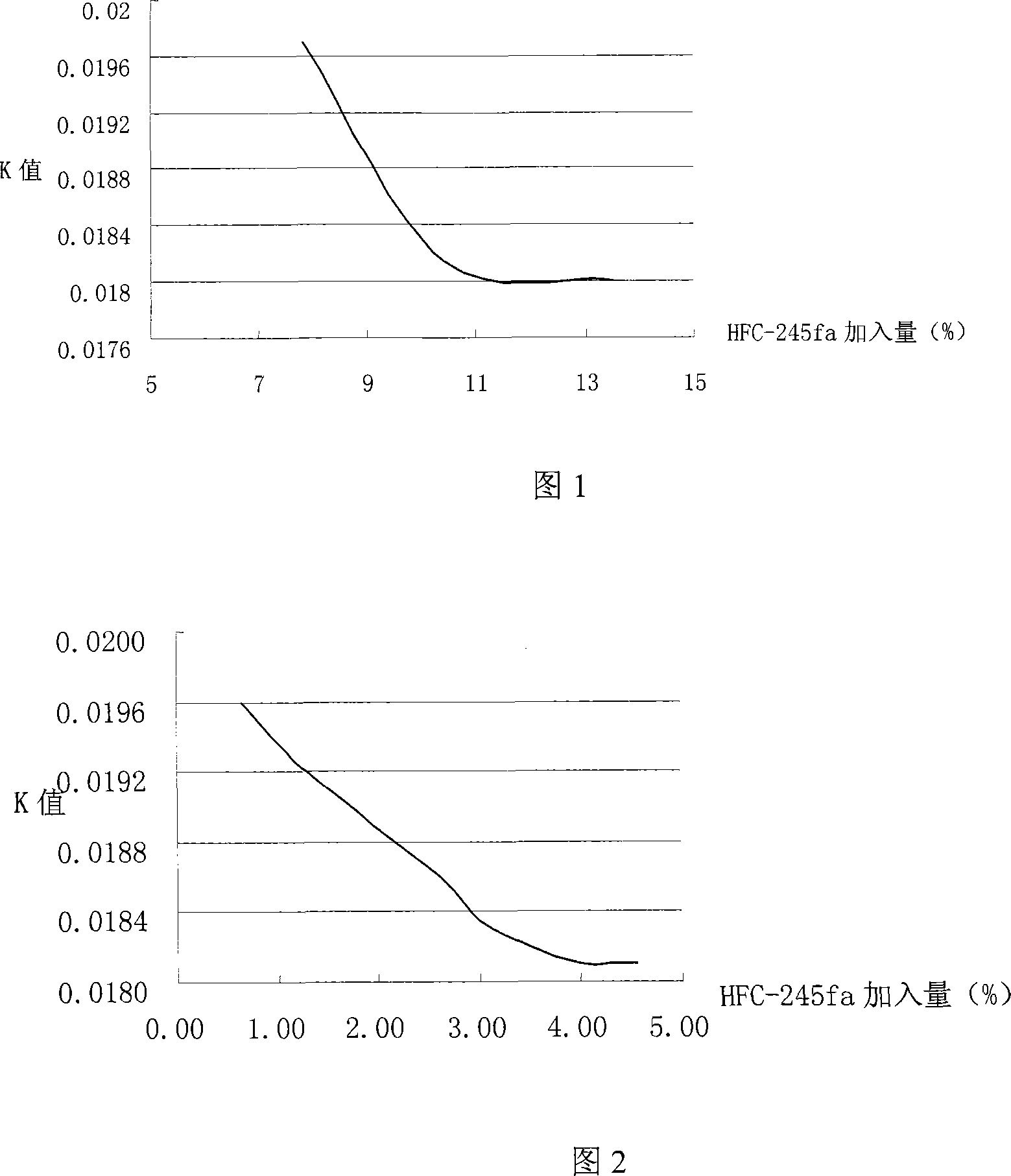

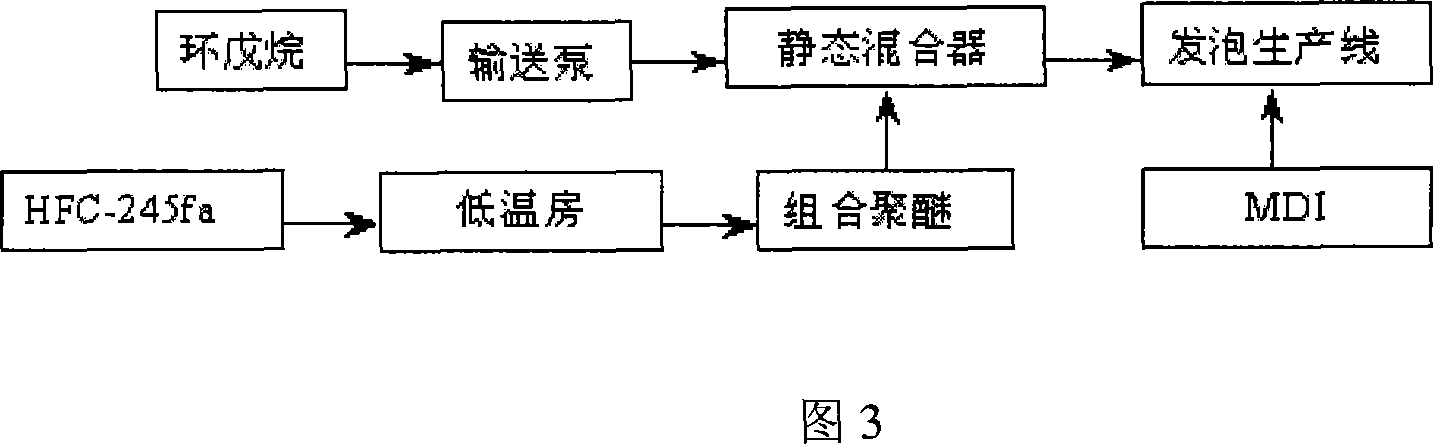

[0018] The invention discloses a polyurethane rigid foam, comprising polyurethane raw materials, wherein the polyurethane raw materials are C-pentane foaming agent, combined polyether POL and MDI, and adding HFC-245fa and HFC-245fa to the polyurethane raw material (combined polyether) The addition amount is 0.5% to 3% of the total weight of polyurethane raw materials, and HFC-245fa is used as a foaming auxiliary agent, that is, a nucleating agent, in the foaming system.

[0019] Illustrate below with specific embodiment when HFC-245fa joins in polyurethane insulation layer C-pentane (cyclopentane) foaming system as nucleating agent and existing alone with HFC-245fa (1,1,1,3, 3-pentafluoropropane) or C-pentane alone as the difference in blowing agent application:

[0020] Table 1. The amount of HFC-245fa used as a blowing agent and the foam K value are measured as follows:

[0021] component name

POL

MDI

HFC-245fa

HFC-245fa / total weight of raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com