Multi- core optical connector assembly

A technology for optical connectors and components, applied in the directions of optical components, optics, light guides, etc., can solve the problems of inability to insert and ensure that multi-core ferrules are aligned with each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

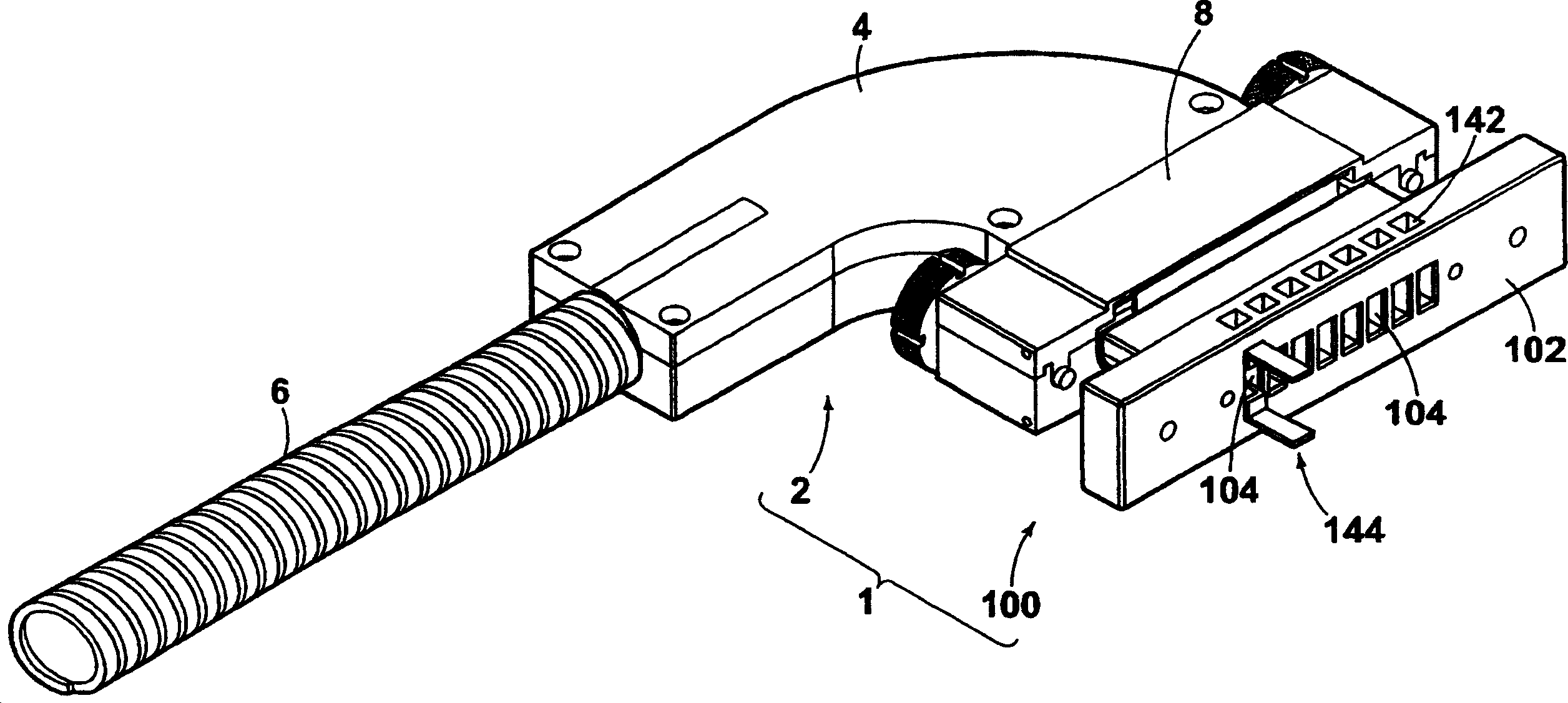

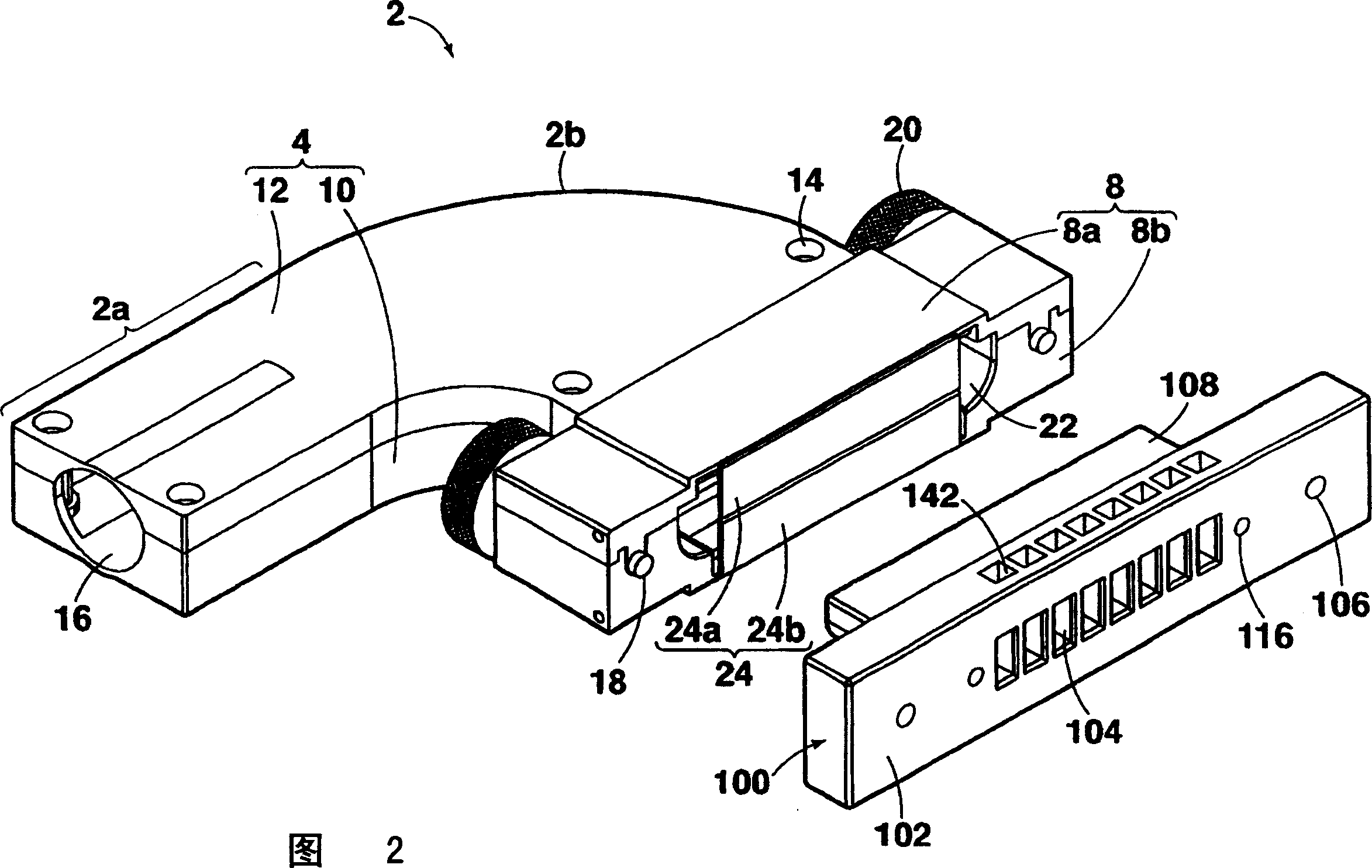

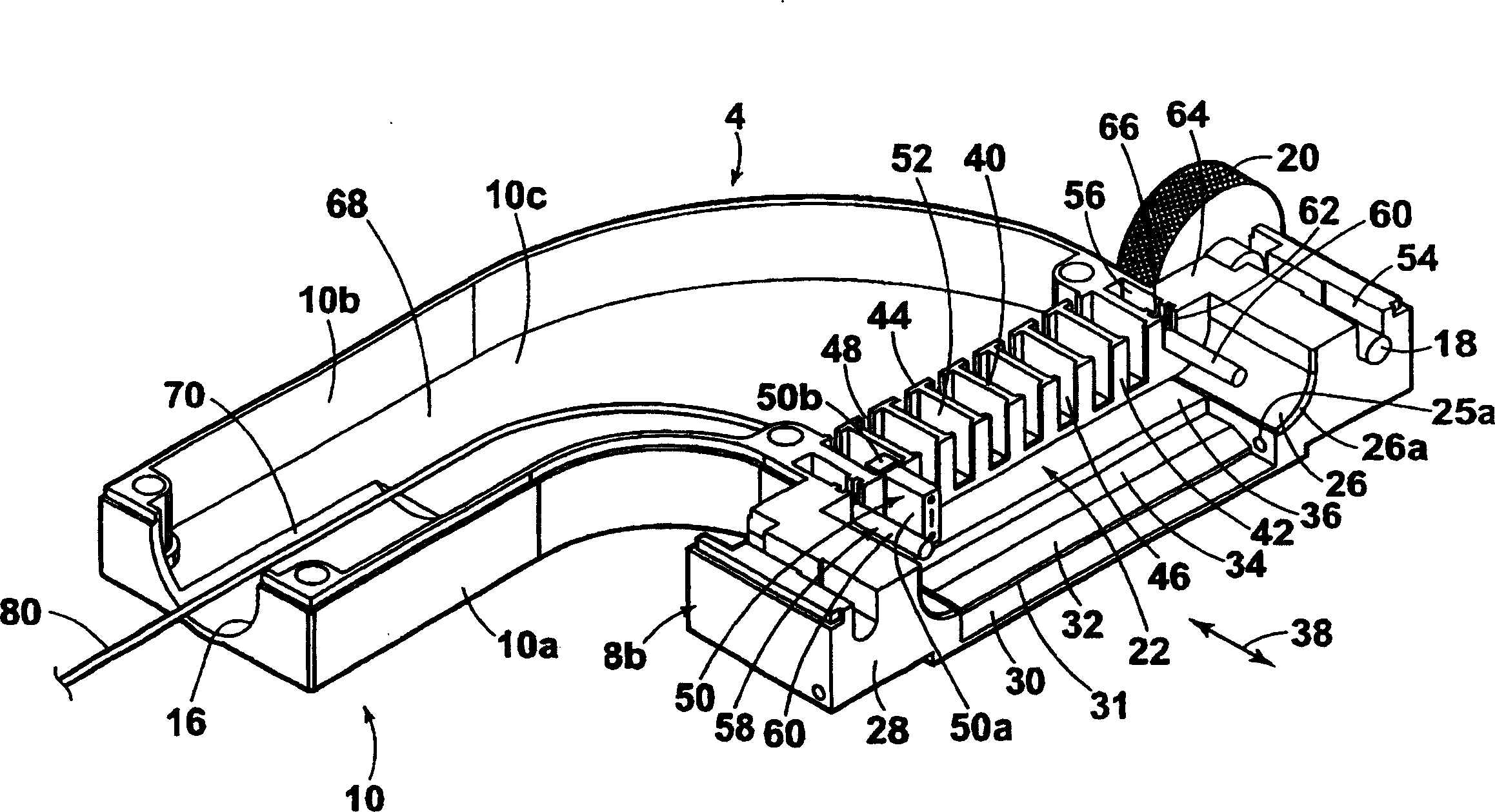

[0049] Embodiments of the multi-core optical connector assembly of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a perspective view showing the appearance of the multi-fiber optical connector module 1 (hereinafter simply referred to as "module") of the present invention. Such as figure 1 As shown, the assembly 1 is composed of a plug-side optical connector 2 and a receptacle-side optical connector 100 . The plug-side optical connector 2 has a housing 4 (plug housing) formed of die-cast aluminum or molded of conductive resin. A metal pipe 6 is connected to the casing 4 . Fiber optic cables are arranged in this tube 6 . Thus, the tube 6 needs to be flexible but still strong enough to prevent crushing. A rectangular joint portion 8 is formed on the housing 4 . The joint portion 8 is connected to the receptacle-side optical connector 100 .

[0050] Such as figure 1As shown, the receptacle-side optical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com