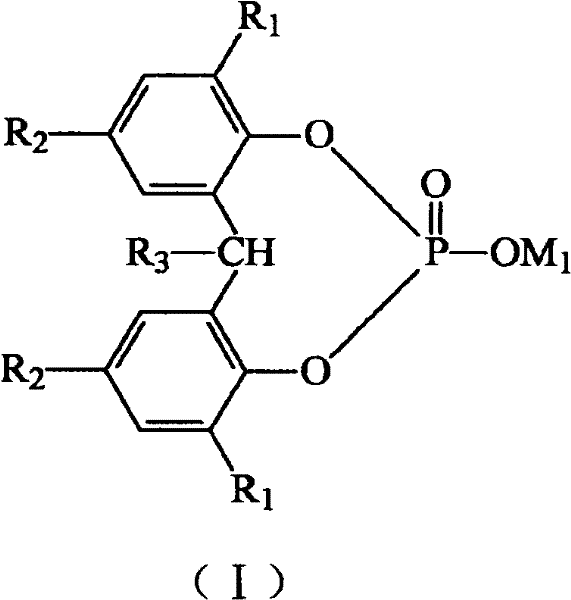

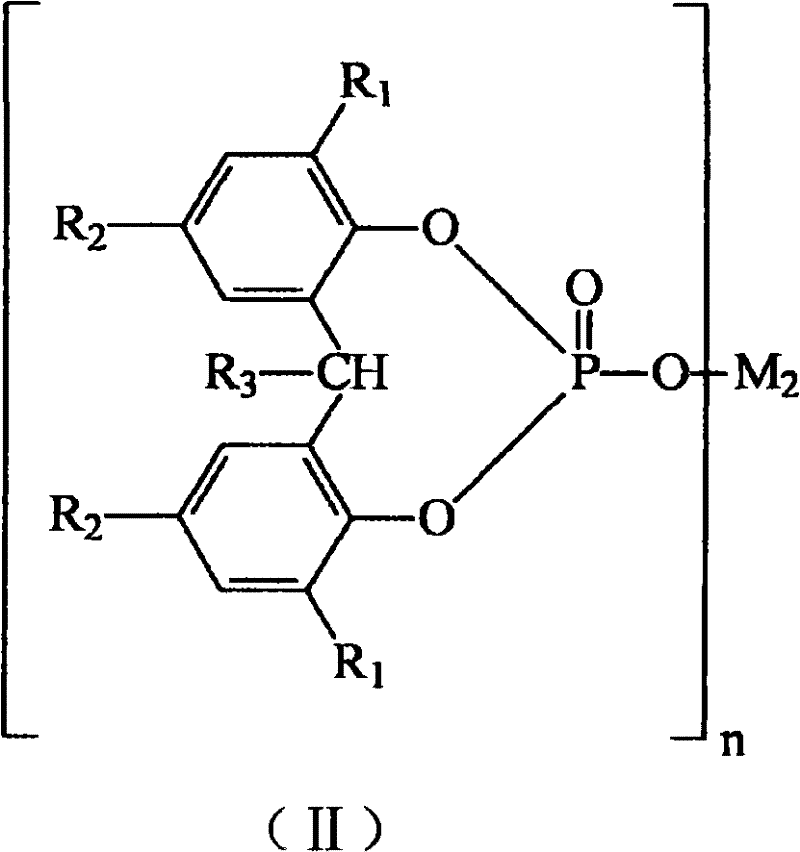

Ultrasonic preparation method of fine transparent nucleating agent

A transparent nucleating agent, ultrasonic technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. , to achieve the effect of improving optical transparency, improving nucleation efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Weigh 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate raw material, add it to methanol, according to mass ratio, 2,2'-methylene-bis(4, Sodium 6-di-tert-butylphenoxy)phosphate:methanol=1:6. The above solution was placed in a water bath of an ultrasonic generator, the temperature of the water bath was 30° C., the ultrasonic frequency was 59 kHz, and the ultrasonic power density was 150 watts per liter of solution. Stir while ultrasonically oscillating to completely dissolve the above raw materials. Then add a mass concentration of 5% aluminum chloride aqueous solution, in molar ratio, 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate:aluminum chloride=2:1 ; Under the conditions of pH=4 and temperature 50° C., ultrasonic vibration reaction was carried out for 2 hours.

[0036] The obtained white precipitate was collected by suction filtration, and the filter cake was washed with water until the filtrate was neutral, and then dried at 80°C for 2 hour...

Embodiment 2

[0038] Weigh 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphate raw material, add it to methanol, by mass ratio, 2,2'-methylene-bis(4, 6-di-tert-butylphenoxy)phosphate:methanol=1:6. The above solution was placed in a water bath of an ultrasonic generator, the temperature of the water bath was 30° C., the ultrasonic frequency was 59 kHz, and the ultrasonic power density was 150 watts per liter of solution. Stir while ultrasonically oscillating to completely dissolve the above raw materials. Then add the aluminum chloride aqueous solution that mass concentration is 5%, in molar ratio, 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) phosphate: aluminum chloride=2:1 ; Under the conditions of pH = 6 and temperature 50°C, carry out ultrasonic oscillation reaction for 2 hours; then add lithium laurate, according to the mass ratio, 2,2'-methylene-bis(4,6-di-tert-butylphenoxy ) Phosphate: lithium laurate=2:1, and continue ultrasonic oscillation for 20 minutes.

[0039] The obtained w...

Embodiment 3

[0041] Weigh 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate raw material, add it to methanol, according to mass ratio, 2,2'-methylene-bis(4, Sodium 6-di-tert-butylphenoxy)phosphate:methanol=1:6. The above solution was placed in a water bath of an ultrasonic generator, the temperature of the water bath was 30° C., the ultrasonic frequency was 59 kHz, and the ultrasonic power density was 150 watts per liter of solution. Stir while ultrasonically oscillating to completely dissolve the above raw materials. Then add a mass concentration of 5% aluminum chloride aqueous solution, in molar ratio, 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate:aluminum chloride=2:1 ; Under the conditions of pH=4 and temperature 50°C, carry out ultrasonic oscillation reaction for 2 hours; then add sodium stearate and silicate, according to the mass ratio, 2,2'-methylene-bis(4,6-di-tert Butylphenoxy)sodium phosphate: sodium stearate: silicate = 4:2:1, continue ultrasonic osci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com