Optically transparent wet nonwoven cellulose fiber fabric

A technology of cellulose fibers and non-woven fabrics, which is applied in the field of products or composite materials, devices for manufacturing cellulose fiber non-woven fabrics, and can solve problems such as the application of synthetic polymer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

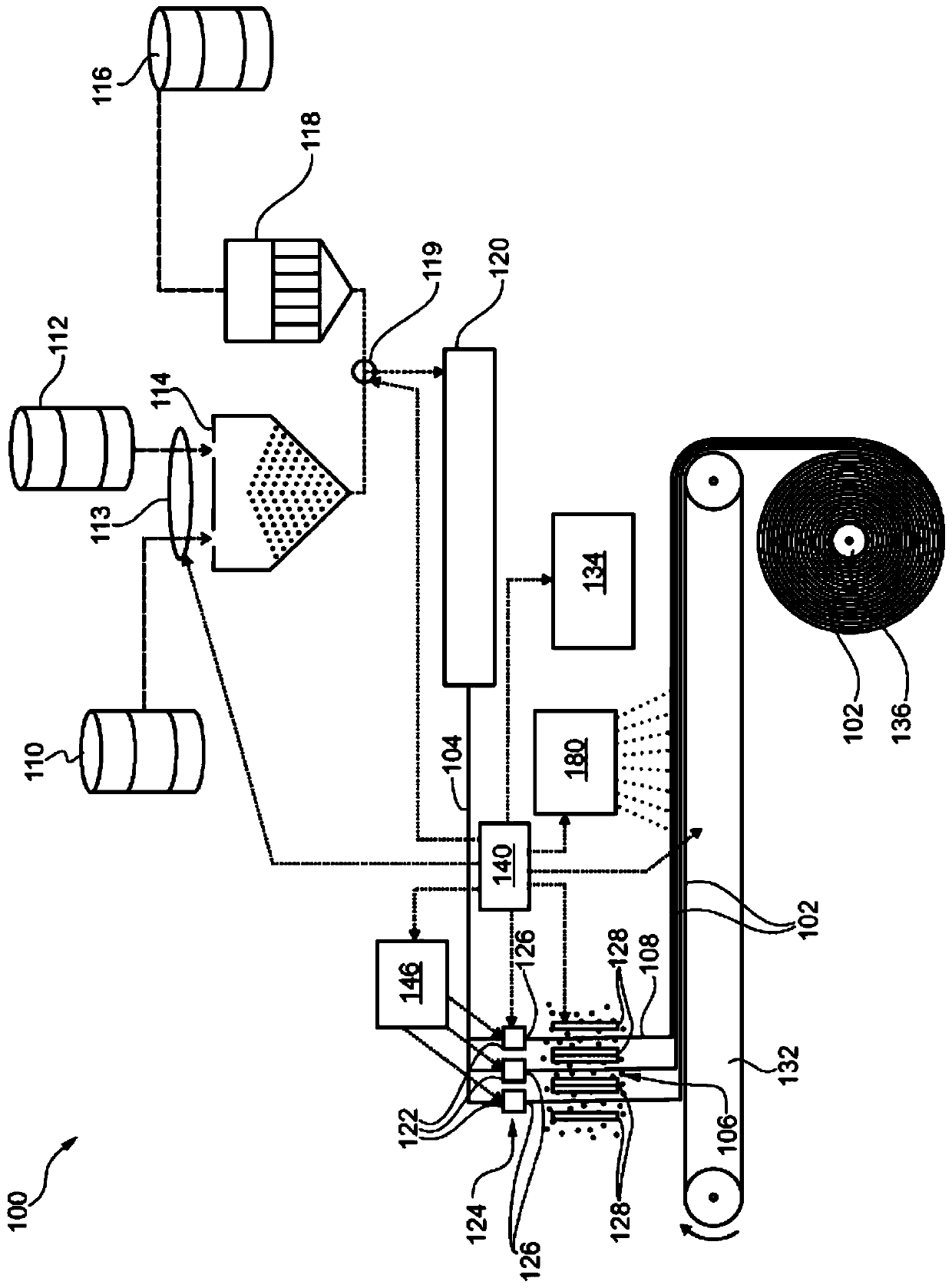

Method used

Image

Examples

Embodiment Construction

[0023] In the following, other exemplary embodiments of a cellulose fiber nonwoven fabric, a method of manufacturing a cellulose fiber nonwoven fabric, a device, a product or a composite material for manufacturing a cellulose fiber nonwoven fabric, and a method of use are described.

[0024] In one embodiment, a plurality of jets may be used to form multiple layers of the fabric, which may be arranged in series along the conveying direction of the fabric, for example. Each injector can form each of the multiple layers. However, alternatively, for example, only the first layer of the fabric may be formed first. Subsequently, the layer can be transported again along the fiber transport unit, and the same ejector can be used to form a second layer on the first layer. This process can be repeated as many times as needed. In the latter embodiment, a single ejector in the device may be sufficient.

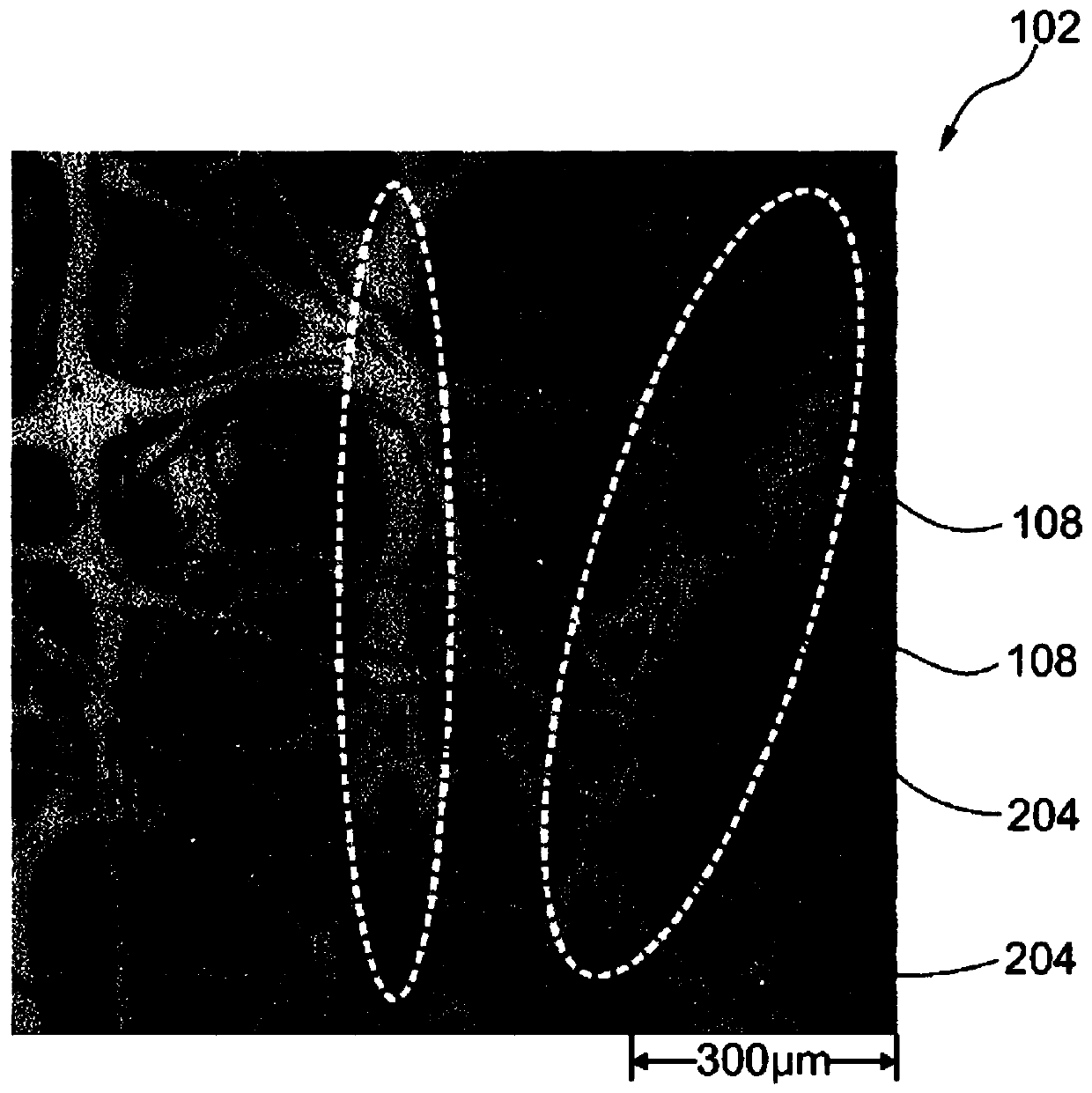

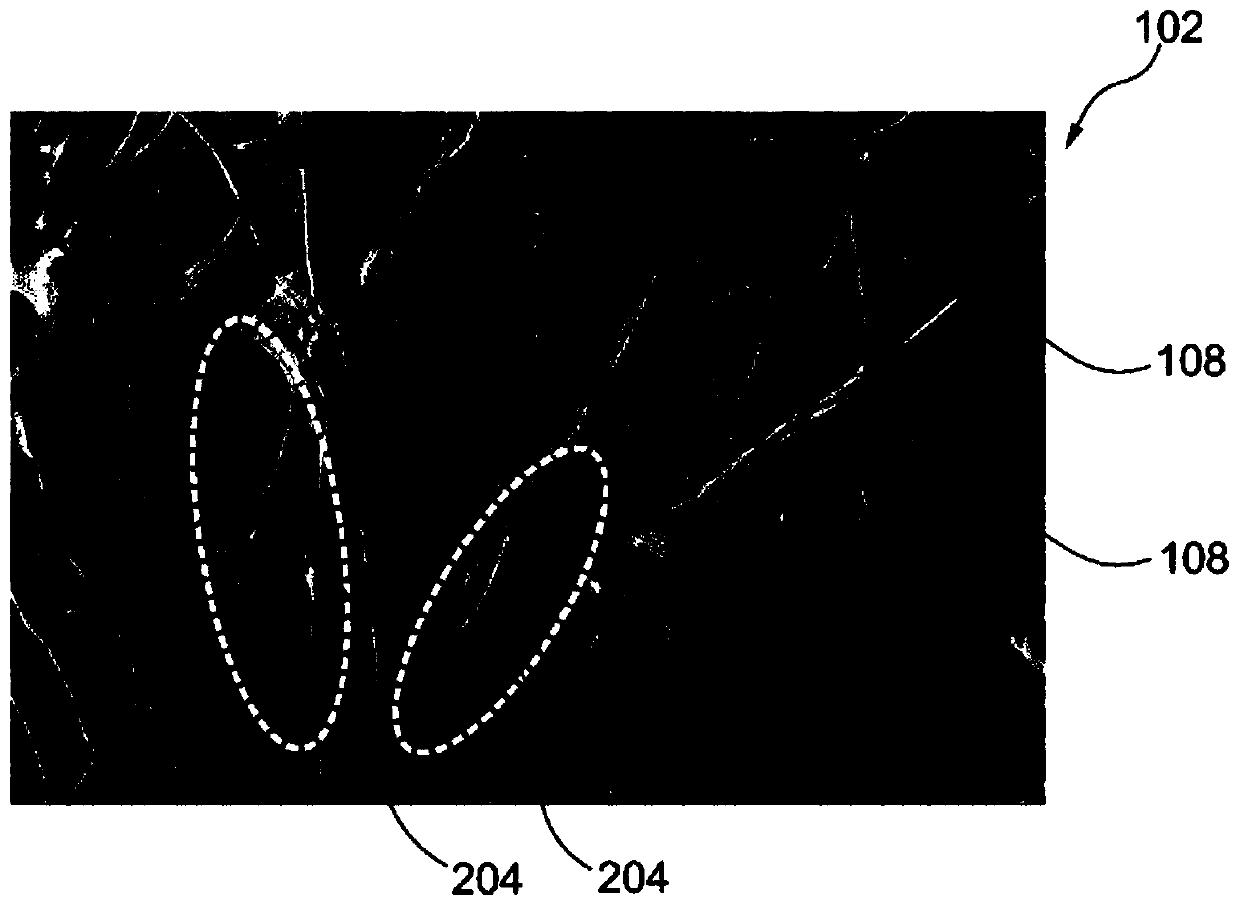

[0025] In one embodiment, when the fabric is dry (ie, the fibers and the gaps between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com