Organic ammonium phosphate nucleating agent for polypropylene transparency and preparation method thereof

A technology of transparent nucleating agent and organic phosphoric acid, which is applied in the field of material science, can solve the problems of poor dispersion and achieve the effects of easy acquisition, high nucleation efficiency and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 of the present invention: Preparation of organophosphate ammonium salt polypropylene transparent nucleating agent, 0.1mol 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate was added to 5mol Disperse in methanol, heat to 40°C, stir to disperse, keep a constant temperature at 40°C, prepare 0.1mol NaOH to make a NaOH solution with a mass percentage concentration of 20%, add the prepared NaOH solution and react for 0.5h, then add the mass percentage The ammonium salt solution with a concentration of 27% was continued to react at constant temperature for 3 hours, and finally the finished product was obtained after suction filtration, washing and drying, and the yield was 89.41%.

[0015] In order to verify the effect of the present invention further, the product of embodiment 1 is carried out following experimental analysis:

[0016] KBr tablet IR analysis: 2958cm -1 The absorption peak is saturated C-H stretching vibration absorption; 1606cm -1 、1479cm -1 It...

Embodiment 2

[0018] Example 2 of the present invention: preparation of organophosphate ammonium salt polypropylene transparent nucleating agent, 0.1mol 2,2'-methylenebis(4,6-di-tert-butylphenyl) phosphate was added to 5mol Disperse in methanol, heat to 40°C, stir to disperse, keep constant temperature at 40°C, add 30% by mass concentration of ammonia water (NH 3 ·H 2 The total amount of O is 0.15mol) After reacting for 3 hours, the finished product was finally obtained after suction filtration, washing and drying, and the yield was 92.45%.

[0019] The product of embodiment 2 is carried out following experimental analysis:

[0020] KBr tablet IR analysis: 3680cm -1 ~3080cm -1 An obvious broad peak appears at , which is caused by intramolecular hydrogen bonding; 2958cm -1 The absorption peak is saturated C-H stretching vibration absorption; 1606cm -1 、1479cm -1 It is the vibration absorption of the benzene ring skeleton; 1363cm -1 for -CH 3 Bending vibration absorption; 1178cm -1 、...

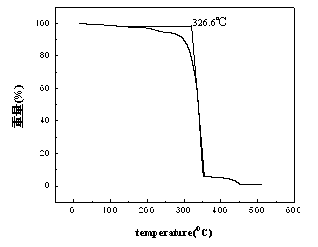

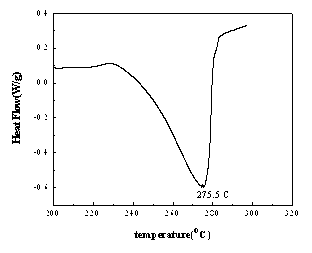

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com