High-rigidity high-transparency polypropylene composite material

A technology of high transparency and composite materials, which is applied in the field of polypropylene composite materials, high rigidity and high transparency polypropylene composite materials, can solve the problems of reducing the haze of polypropylene, the decline of impact resistance, difficulties, etc., and achieve accelerated crystallization, Effect of improving rigidity and transparency, and refining spherulites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

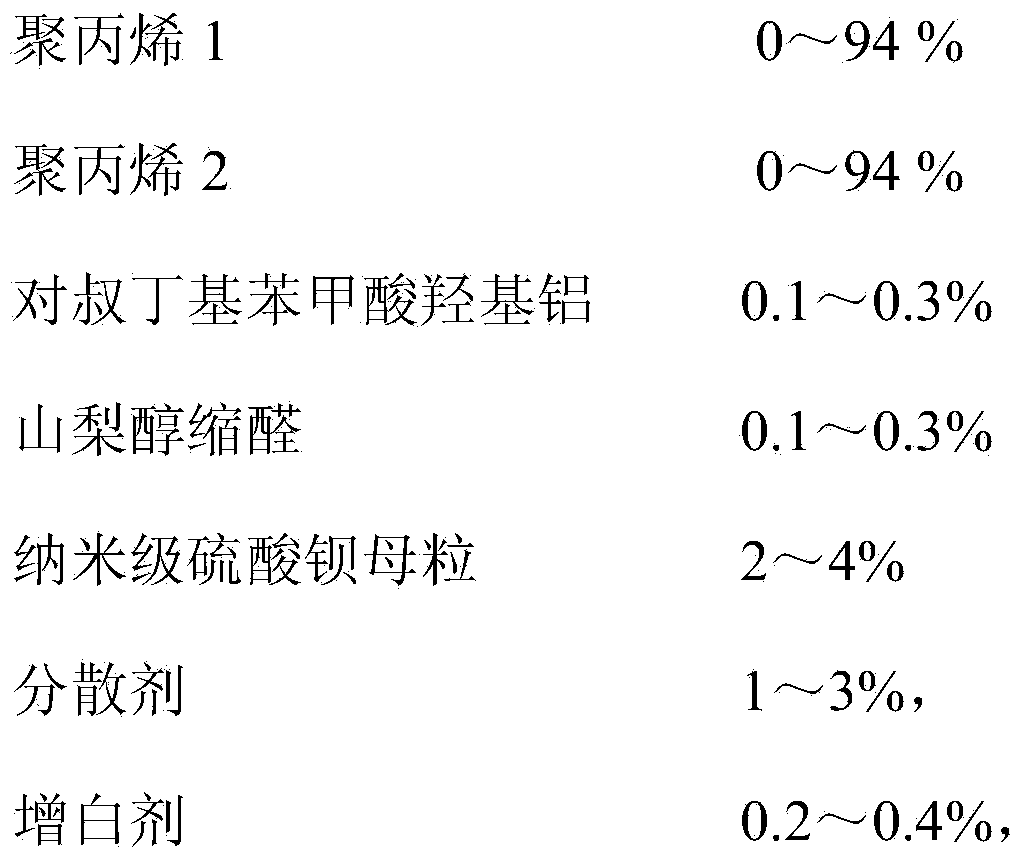

[0016] A high-rigidity and high-transparency polypropylene composite material, which includes the following mass percentage components:

[0017]

[0018]

[0019] The sum of the percentages of the above components is 100%.

[0020] The preparation method of the present invention is to mix the raw materials from the first barrel feeding section of a twin-screw extruder with a length-to-diameter ratio of 32-68 into the twin-screw machine at a speed of 180-500 rpm and a temperature of 180-230 It can be extruded and granulated at ℃.

[0021] The present invention will be further described below in conjunction with specific embodiments:

[0022] The ratios of Examples 1-5 and Comparative Examples 1-3 are shown in Table 1:

[0023] Table 1:

[0024]

[0025] The preparation method of Example 1-5 is the same as that of Comparative Example 1-3:

[0026] After mixing the raw materials, the first section of the twin-screw extruder with a length-to-diameter ratio of 32-68 is added to the twin-scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com