Soil stabilizer, self-compacting high-flow-state backfill material and construction method of self-compacting high-flow-state backfill material

A soil curing agent and self-compacting technology, applied in filling, excavation, infrastructure engineering and other directions, can solve the problems of seismic performance hazards of tall buildings, difficult construction, poor compressive strength, etc., to improve self-compacting performance and Compressive performance, reduction of construction equipment and manpower, effect of wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

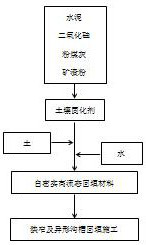

[0075] combine figure 1 As shown, the preparation method of the above-mentioned self-compacting high-fluidity backfill material comprises the following steps:

[0076] (1) Weigh the soil and soil curing agent, stir evenly, and prepare the dry backfill material;

[0077] (2) Take water and add it to the dry material of the backfill material in step (1), and stir evenly to obtain a self-compacting high-fluidity backfill material.

[0078] The present application also provides a construction method for backfilling narrow and special-shaped trenches by using the above-mentioned self-compacting high-fluidity backfill material, which specifically includes the following steps:

[0079] Clean the trench; prepare self-compacting high-fluid backfill material; pour self-compact high-fluid backfill material into the trench; maintain self-compact high-fluid backfill material in the trench.

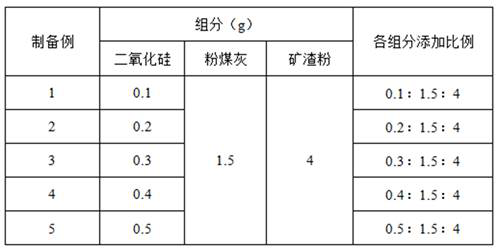

preparation example 1-5

[0084] Preparation Examples 1-5 respectively provide a soil stabilizer.

[0085] The difference between the above preparation examples lies in the addition amount of silicon dioxide in the soil curing agent, as shown in Table 1 for details.

[0086] In addition to silicon dioxide, fly ash, and slag powder, the soil curing agent provided in Preparation Examples 1-5 also includes cement and a water reducer. Among them, the cement is P0 42.5 ordinary portland cement 10g, and the water reducer is 0.15g.

[0087] The preparation method of above-mentioned each preparation example is as follows:

[0088] Mix P0 42.5 ordinary Portland cement, fly ash, slag powder, water reducing agent and silica, and stir evenly to prepare the soil curing agent.

[0089] The addition amount of each component in the soil solidifying agent that table 1 preparation example 1-5 provides

[0090]

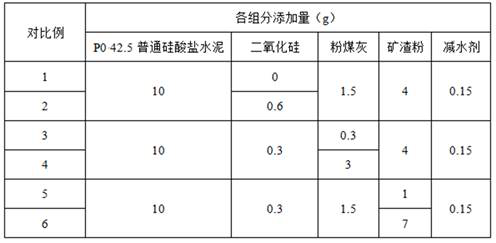

preparation example 6-13

[0092] Preparation Examples 6-13 respectively provide a soil stabilizer.

[0093] The difference between the above preparation examples and the preparation example 3 lies in the addition ratio of silicon dioxide, fly ash and slag powder in the soil curing agent, as shown in Table 2 for details.

[0094] The addition amount of each component in the soil solidifying agent that table 2 preparation example 3, preparation example 6-13 provide

[0095]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com