Patents

Literature

40results about How to "Heterogeneous nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano bentonite for plastic modification and preparation method thereof

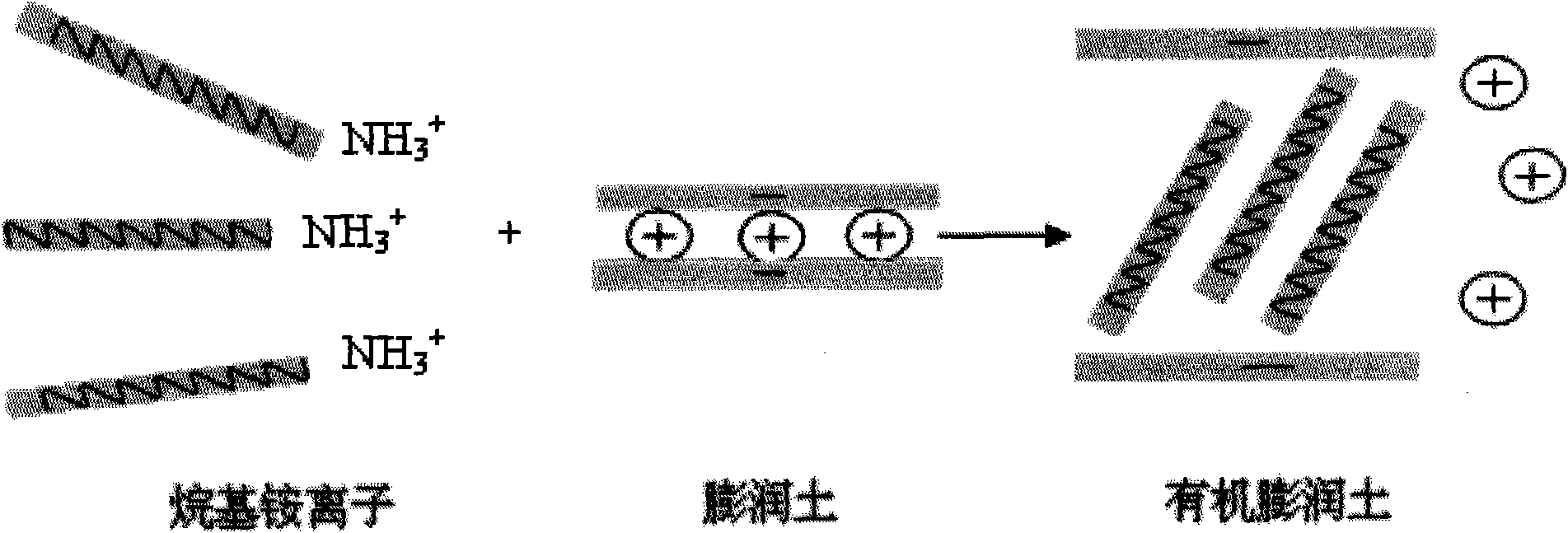

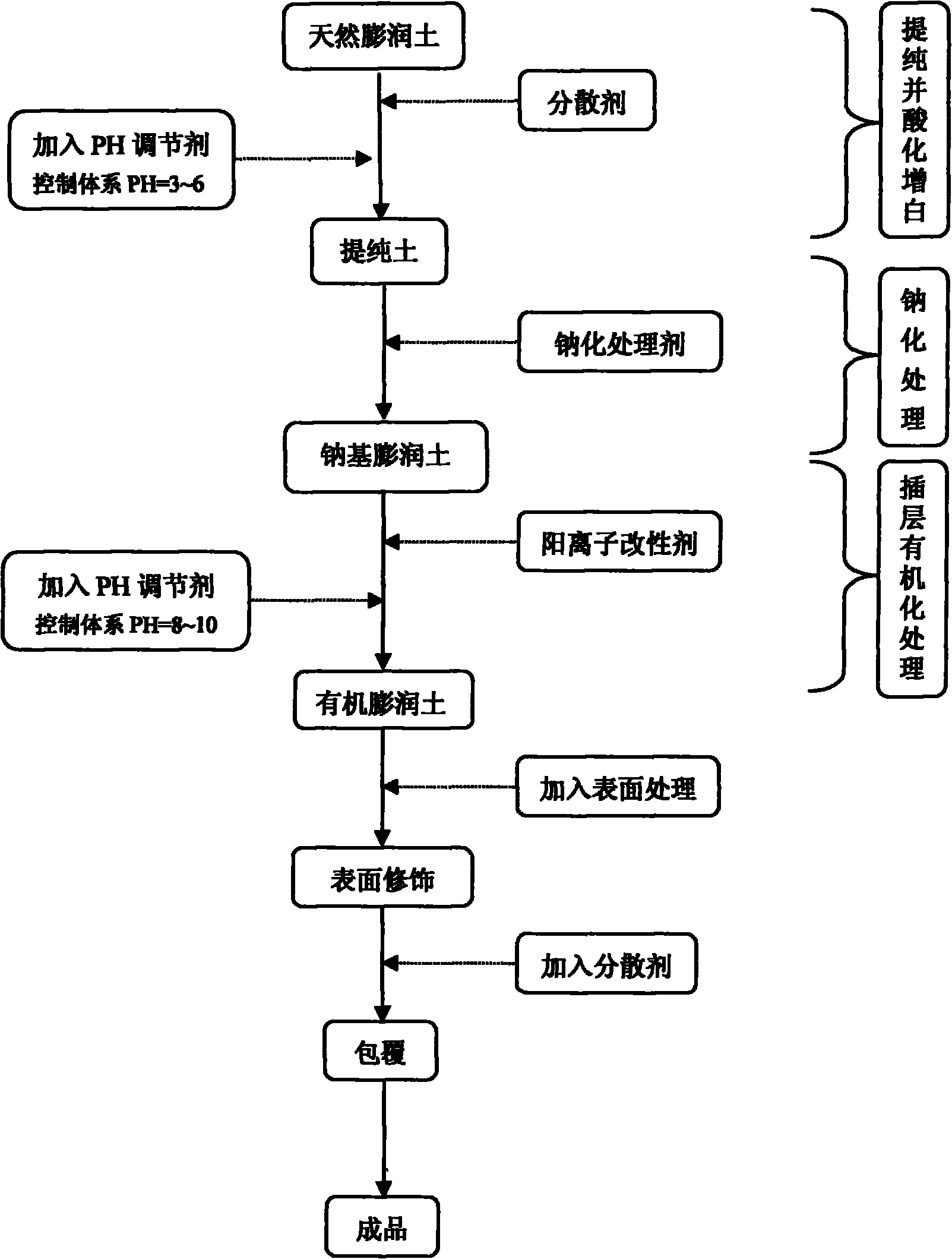

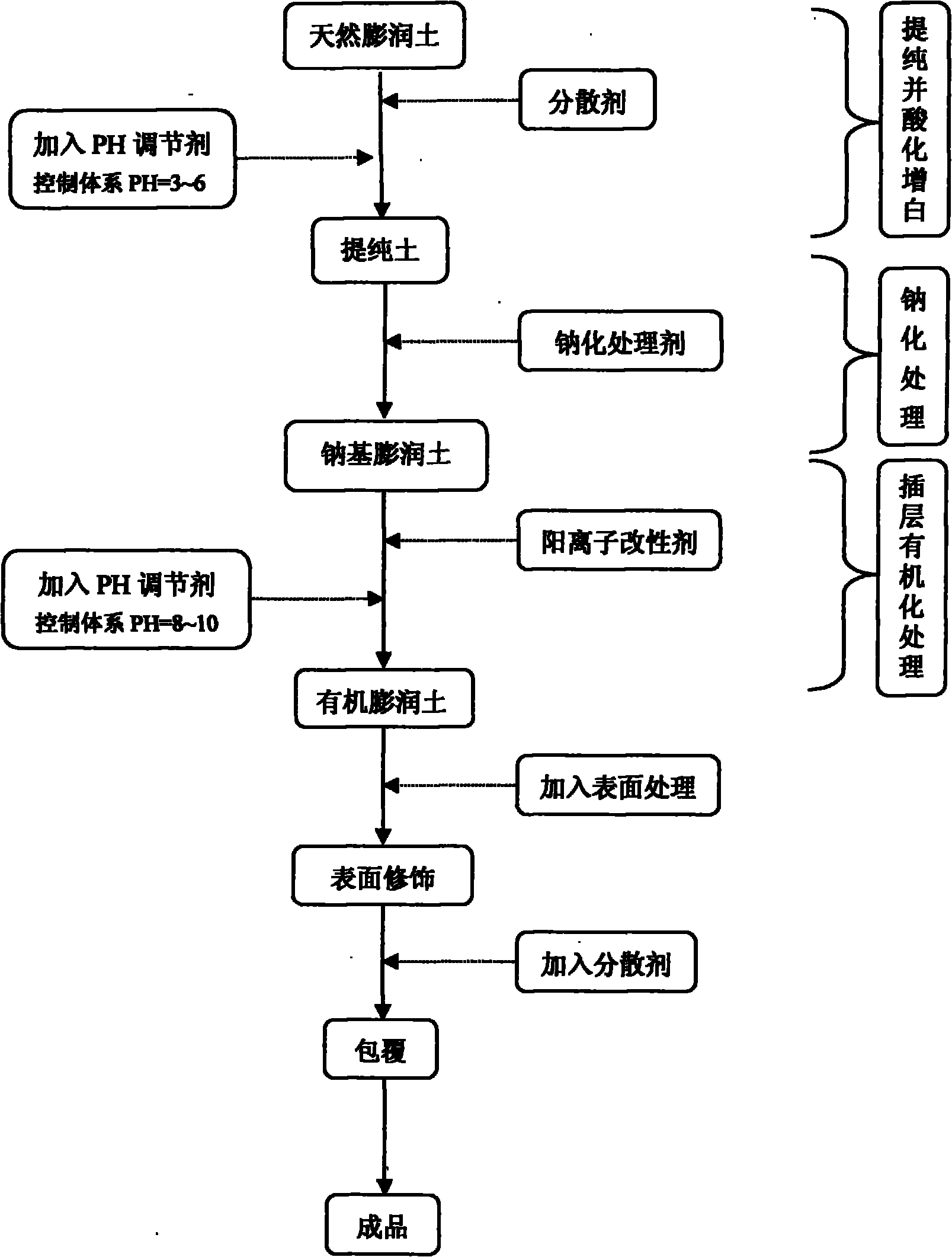

The invention relates to nano bentonite for plastic modification and a preparation method thereof, which is characterized in that a nano bentonite product for plastic modification is obtained through the special processing of natural bentonite in five steps of whitening through purification and acidification, sodium activation, intercalation organization, surface finishing and coating. The purity of the nano bentonite reaches more than 95 percent, the whiteness reaches more than 80 degrees, the interlayer spacing after intercalation organization reaches more than 2.7nm, and the thermal weight loss at the temperature of 280 DEG C is below 3 percent. The nano bentonite has good compatibility with a high molecular material (mainly a plastic material), is more beneficial to keeping mechanical performance, has good dispersive property, is easy to process, can perform the action of heterogeneous nucleation for crystallized plastics, improves the mechanical performance thereof, is used for plastic flame retardant modification, can reduce the addition of a flame retardant by 30 percent, and not only is beneficial to keeping the mechanical performance, but also can lower the cost.

Owner:苏州兰特纳米材料科技有限公司

High-rigidity high-transparency polypropylene composite material

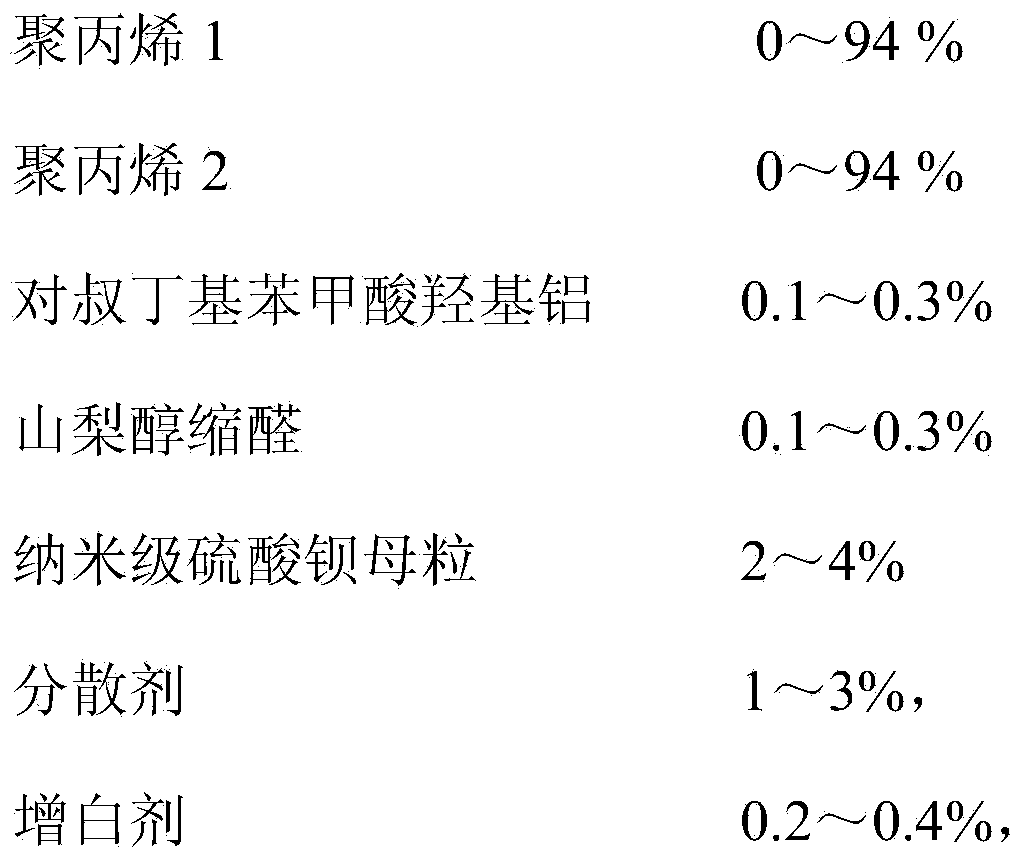

The invention discloses a high-rigidity high-transparency polypropylene composite material, and belongs to the technical field of high polymer alloy materials. The high-rigidity high-transparency polypropylene composite material is compounded by 2-4wt% of nanoscale barium sulfate master batch, 0.1-0.3wt% p-tertiary butyl hydroxyl aluminum benzoate and 0.1-0.3wt% sorbitol acetal as a nucleating agent of polypropylene. According to the high-rigidity high-transparency polypropylene composite material, the nanoscale barium sulfate master batch is added to achieve a certain compatible effect on two nucleating agents, so that the two nucleating agents are prevented from resisting against each other; and meanwhile, the effects of nucleating heterogeneously, promoting the polypropylene to quicken crystallization and refining spherocrystal effects are achieved, so that the rigidity and the transparency of a PP (polypropylene) product are further improved.

Owner:广东顺威赛特工程塑料开发有限公司

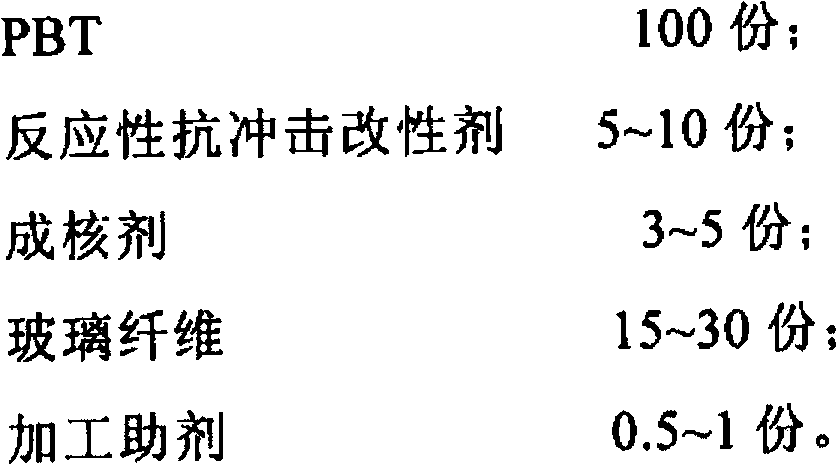

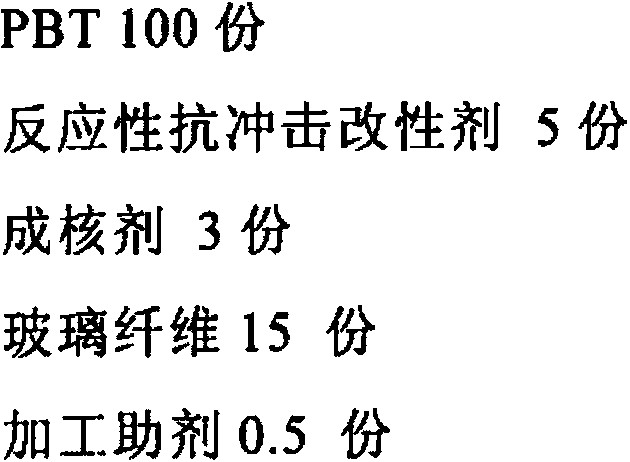

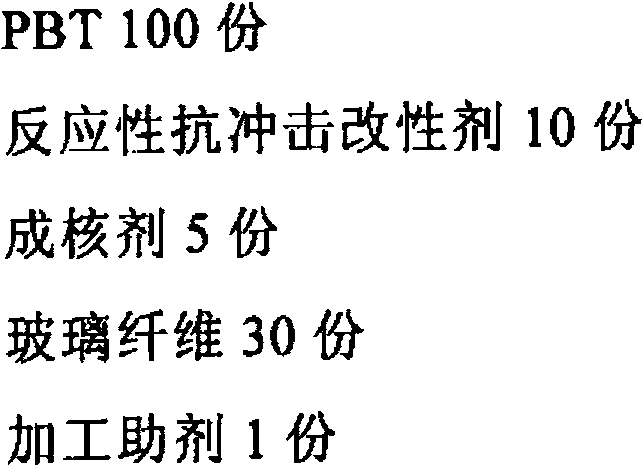

High-toughness and high-heatproof glass fiber reinforced PBT (Polybutylece Terephthalate) composite material and preparation method thereof

The invention relates to a high-toughness and high-heatproof glass fiber reinforced PBT (Polybutylece Terephthalate) composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 100 parts of PBT, 5-10 parts of reactive impact modifier, 3-5 parts of nucleating agent, 15-30 parts of glass fiber and 0.5-1 part of processing aid, wherein the reactive impact modifier is a compound of a toughening agent with reactive groups and a PBT thickening agent, and the mass ratio of the toughening agent with the reactive groups to the PBT thickening agent is (3:2)-(4:1). Compared with the prior art, the high-toughness and high-heatproof glass fiber reinforced PBT composite material has the advantages that the reactive impact modifier is prepared by compounding the PBT thickening agent and the toughening agent with the reactive groups, and the super-toughening of the PBT material is realized through reactive blending extrusion from the perspectives of a molecular chain and the external toughening of a reactive toughening agent. PBT crystal grains can be refined through the introduction of the nucleating agent, so that the toughness of the material is improved; and meanwhile, the nucleating agent plays a heterogeneous nucleation role, so that the crystallinity of PBT can be increased, and furthermore, the thermal property is greatly improved.

Owner:SHANGHAI SUNNY

Reinforced and toughened weather-resistant and flame-retardant glass fiber reinforced PA66 electric power fitting material and preparation method thereof

InactiveCN106566238AHigh phosphorus contentImprove flame retardant performanceCoatingsHalloysiteLiquid crystalline

The invention discloses a reinforced and toughened weather-resistant and flame-retardant glass fiber reinforced PA66 electric power fitting material and a preparation method thereof. The reinforced and toughened weather-resistant and flame-retardant glass fiber reinforced PA66 electric power fitting material is characterized by being prepared from PA66, glass fiber, melamine cyanurate, zinc borate, aluminum hypophosphite, bamboo charcoal, carbon fiber, silicone rubber, waterborne polyurethane, maleic anhydride grafted polypropylene, a bovine serum albumin solution, potassium titanate whiskers, graphene oxide, a thermotropic liquid crystalline polymer, a halloysite nanotube, a carboxylic multiwalled carbon nanotube, hydroxyl acrylic resin, tripoli, aliphatic polyisocyanate and the like which serve as raw materials. The preparation method comprises the following steps: wrapping the melamine cyanurate with zinc borate to obtain a composite flame retardant; modifying the surface of the glass fiber with bovine serum albumin, and preparing a graphite oxide coated glass fiber composite material according to the electrostatic adsorption principle; spraying a prepared tripoli-containing acrylic polyurethane composite coating on the PA66 to form a coating layer to realize higher corrosion resistance and good mechanical property; and obtaining the reinforced and toughened weather-resistant and flame-retardant glass fiber reinforced PA66 electric power fitting material.

Owner:马鞍山市华能电力线路器材有限责任公司

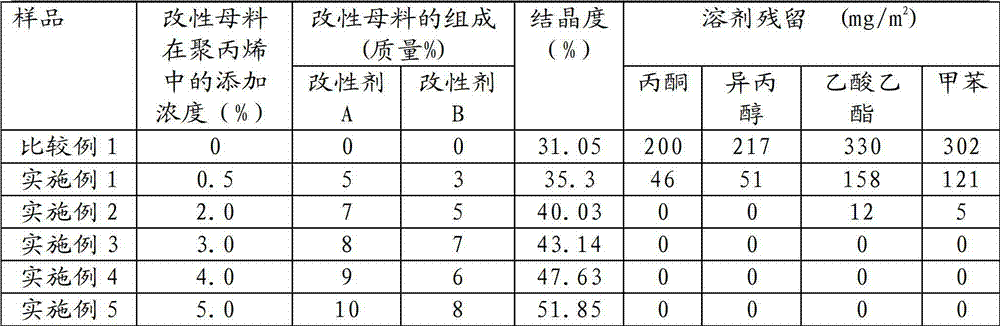

Polypropylene modified master batch and low-residual solvent polypropylene flexible package thin film

InactiveCN102964683AHigh crystallinityReduce the proportion of amorphous regionsFlexible coversWrappersKetonePolypropylene

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Gadolinium-holmium ion-implanted nickel-plating neodymium-iron-boron magnet and preparation method thereof

InactiveCN105931785AImprove coercive forceFacilitate Orientation FormingMagnetic materialsPermanent magnet manufactureHolmiumRare earth

The invention discloses a gadolinium-holmium ion-implanted nickel-plating neodymium-iron-boron magnet, prepared from the following components by mass percent: 25-35% of Pr-Nd, 0.5-1.5% of B, 0.1-1% of Al, 0-0.2% of Cu, 1-2% of Co, 0.1-1% of Ga, 0.02-0.08% of Nb, 0.01-0.05% of Zr, 0.1-1% of mesoporous silica, and the balance of Fe and a small amount of inevitable impurities. The sintered neodymium-iron-boron magnet is uniform in crystal structure; an area close to the core of the magnet is lower in content of heavy rare earth, so that the residual magnetism of the magnet is enabled basically not to be influenced; an area close to the surface of the magnet is higher in content of the heavy rare earth, so that the coercive force of the magnet is remarkably improved; therefore, the disadvantages of the sintered neodymium-iron-boron magnet are comprehensively overcome, and the advantages of the sintered neodymium-iron-boron magnet are greatly improved.

Owner:安徽万磁电子股份有限公司

A secondary aluminum grain refinement process and secondary aluminum treatment process

ActiveCN106591616BGood lattice matchingPlay the effect of degassing and impurity removalIngotMechanical property

The invention provides a secondary aluminum grain refinement process and a secondary aluminum treatment process and relates to the technical field of aluminum alloys. The secondary aluminum grain refinement process comprises the steps of (1) preparing a raw material and putting the raw material into a smelting furnace for smelting; (2) feeding molten aluminum filtered for the first time into a refining furnace through a flow guide chute, introducing inert gases at 1680-1800 DEG C, adding 0.1wt%-0.2wt% of Al-Ti-C refiner, conducting stirring under a vacuum condition, lowering the temperature to 1000-1250 DEG C at the speed of 50 DEG C per minute, adding 0.1wt%-0.2wt% of Al-Ti-C refiner, and then conducting secondary filtering; and (3) putting the molten aluminum into a pig casting machine to conduct ingot bar forming to obtain aluminum alloys. By means of the secondary aluminum grain refinement process, grains can be effectively refined, and the mechanical properties of alloys such as toughness and strength can be improved. The secondary aluminum treatment process including the recycled grain refinement process is easy to operate and friendly to environment and the quality of manufactured finished products is high.

Owner:重庆顺博铝合金股份有限公司

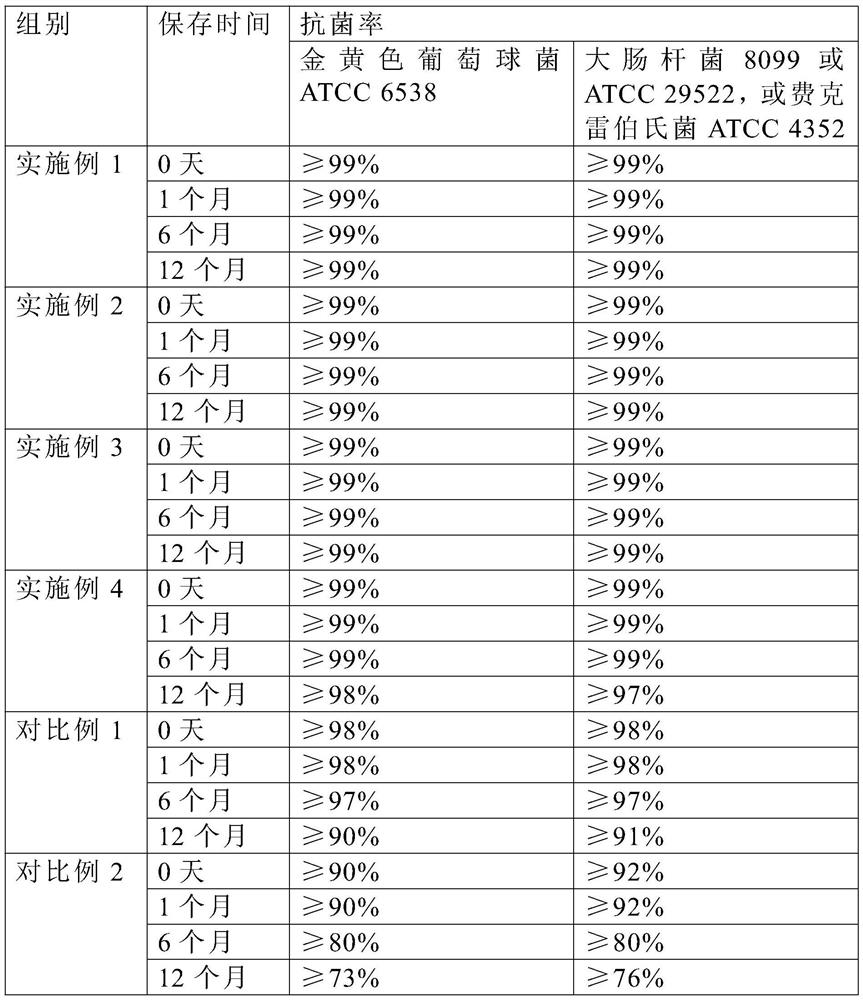

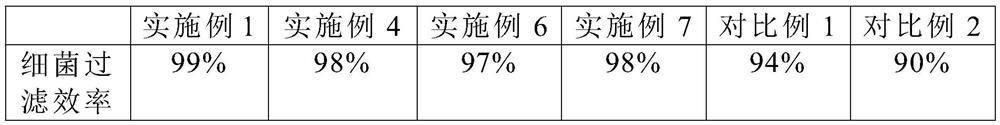

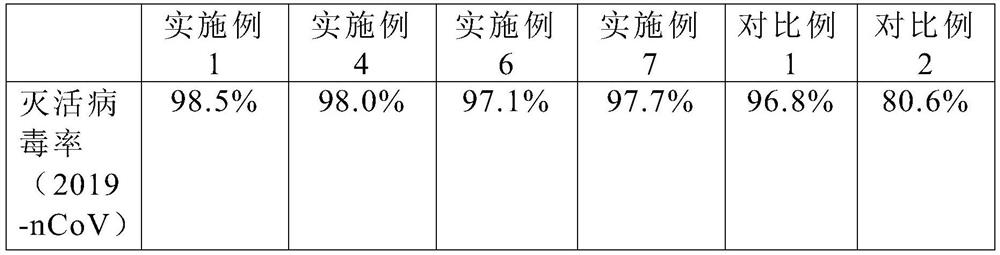

Manufacturing method and application of nano-copper antibacterial and antiviral melt-blown cloth master batch

ActiveCN113334611AImproved particle size and distributionWell combinedNanotechnologyPolypropylenePolyester

The invention belongs to the technical field of materials, and relates to a manufacturing method of nano-copper antibacterial and antiviral melt-blown cloth master batch. The method comprises the following steps of mixing and hybridizing graphene, nano-copper, microporous silicon dioxide and a nano-microcapsule wrapping material to obtain a nano-microcapsule-coated graphene composite material; and mixing and melting the nano-microcapsule-coated graphene composite material and a polypropylene material, and carrying out extrusion granulation to obtain the nano-copper antibacterial and antiviral melt-blown cloth master batch. The invention also relates to application of the nano-copper antibacterial and antiviral melt-blown cloth master batch obtained by the preparation method in melt-blown cloth with antibacterial and virus-inactivating properties. According to the method and application, the nano-copper is used as an antibacterial auxiliary agent to form the nano-microcapsule-coated graphene composite material, and the nano-microcapsule-coated graphene composite material and the polypropylene material form the melt-blown non-woven fabric master batch so that the nano-copper can be firmly embedded in a polyester fiber molecular structure to form a non-dissolution type antibacterial fiber, and then the fiber and the non-woven fabric obtain continuous antibacterial property.

Owner:SHANGYOU JINGHE NANO TECH CO LTD +3

Dysprosium-yttrium ion implanted galvanized neodymium-iron-boron magnet and preparation method for same

InactiveCN105931786AImprove coercive forceFacilitate Orientation FormingMagnetic materialsPermanent magnet manufactureRare earthCrystal structure

The invention discloses a dysprosium-yttrium ion implanted galvanized neodymium-iron-boron magnet, which consists of the following components in percentage by mass: 25 to 35 percent of Pr-Nd, 0.5 to 1.5 percent of B, 0.1 to 1 percent of Al, 0 to 0.2 percent of Cu, 1 to 2 percent of Co, 0.1 to 1 percent of Ga, 0.02 to 0.08 percent of Nb, 0.01 to 0.05 percent of Zr, 0.1 to 1 percent of mesoporous silica and the balance of Fe and inevitable impurities in a material. The produced sintered neodymium-iron-boron magnet is uniform in crystal structure; the heavy rare earth content of an area close to a core of the magnet is slightly low, so that influence on the residual magnetism of the magnet is substantially avoided; the heavy rare earth content of an area close to the surface of the magnet is slightly high, so that the coercivity of the magnet is remarkably improved, the shortcomings of the sintered neodymium-iron-boron magnet are comprehensively overcome, and the advantages of the sintered neodymium-iron-boron magnet are greatly improved.

Owner:安徽万磁电子股份有限公司

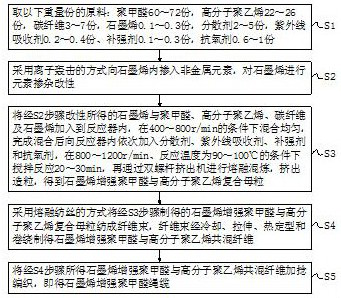

Preparation process of graphene reinforced polyformaldehyde rope

ActiveCN112626893AEvenly dispersedHigh modulusArtificial filament heat treatmentMelt spinning methodsFiberPolyoxymethylene

The invention belongs to the technical field of polyformaldehyde ropes, and particularly relates to a preparation process of a graphene reinforced polyformaldehyde rope. The preparation process comprises the following steps: S1, taking the following raw materials in parts by weight: 60-72 parts of polyformaldehyde, 22-26 parts of high-molecular polyethylene, 3-7 parts of carbon fibers, 0.1-0.3 part of graphene, 2-5 parts of a dispersant, 0.2-0.4 part of an ultraviolet ray absorber, 0.1-0.3 part of a reinforcing agent, and 0.6-1 part of an antioxidant. According to the preparation process, the polyformaldehyde, high-molecular polyethylene, carbon fibers and graphene are used as main raw materials, so that the polyformaldehyde rope has the characteristics of high modulus, high toughness and high wear resistance, and also has good high-temperature resistance; the graphene plays a role in heterogeneous nucleation of the polyformaldehyde, so that the polyformaldehyde rope has high tensile strength and excellent mechanical properties, the strength and wear resistance of polyformaldehyde fibers are further improved, graphene layers can be separated and prevented from gathering, and thus the graphene is dispersed more uniformly.

Owner:扬州神龙绳业有限公司

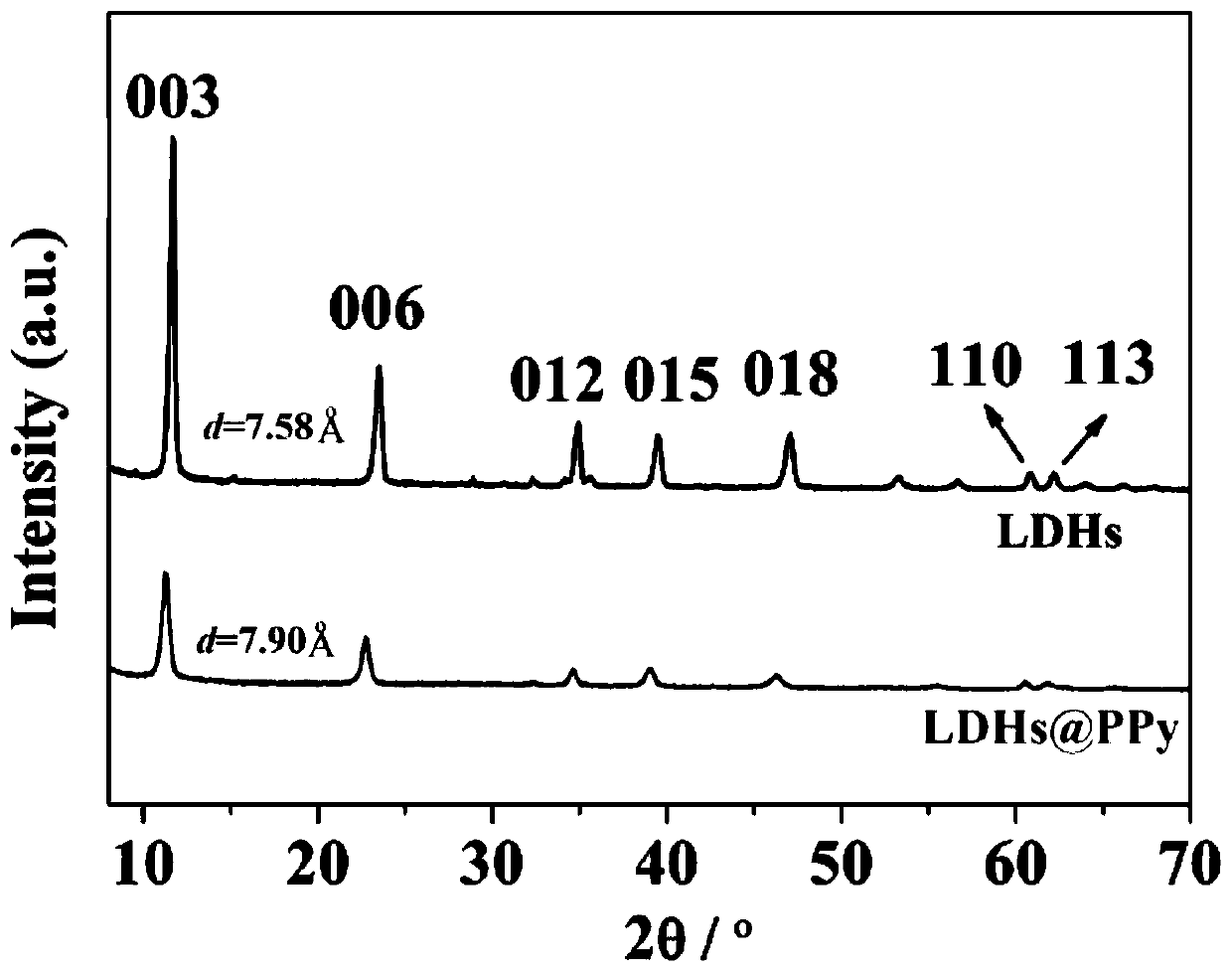

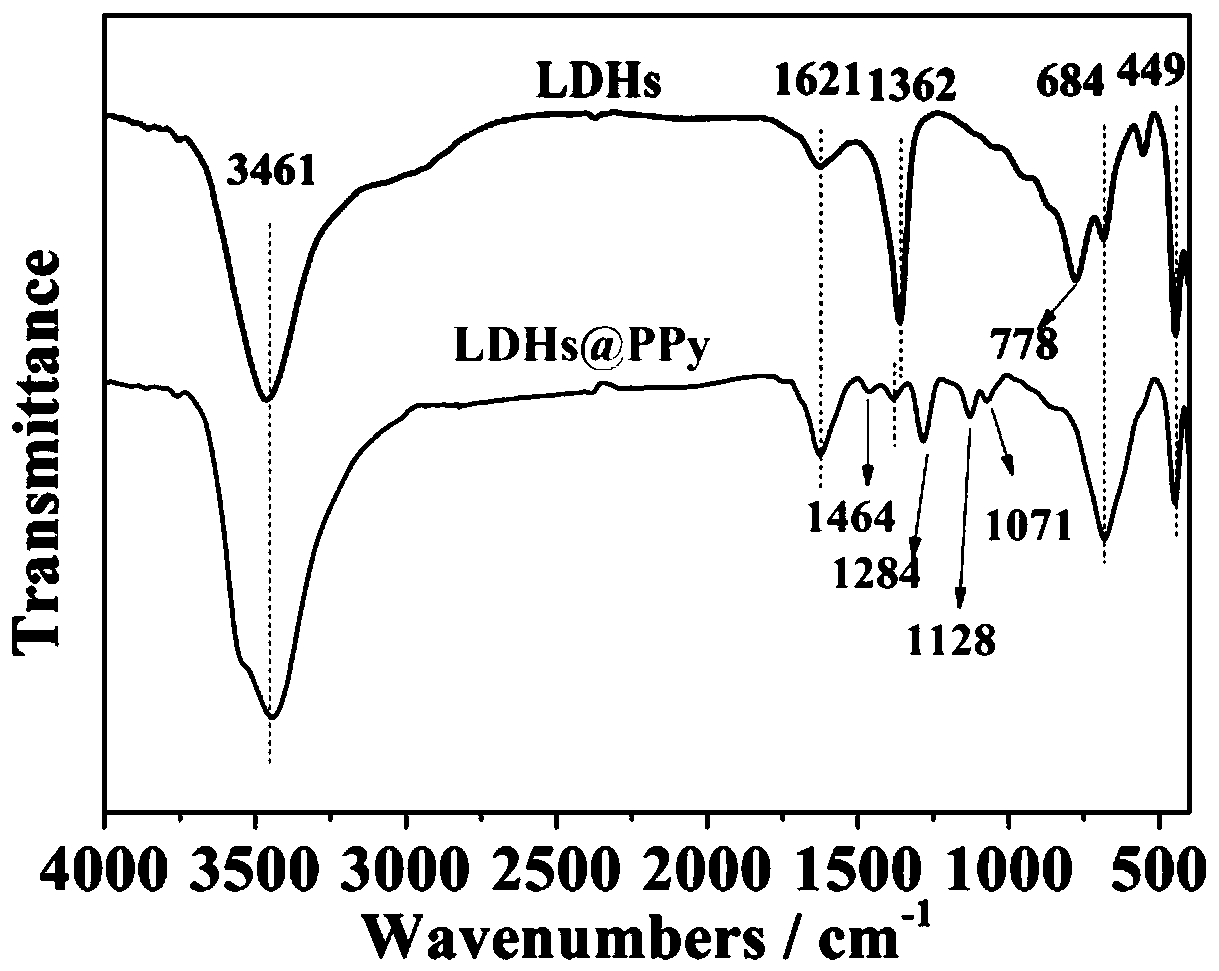

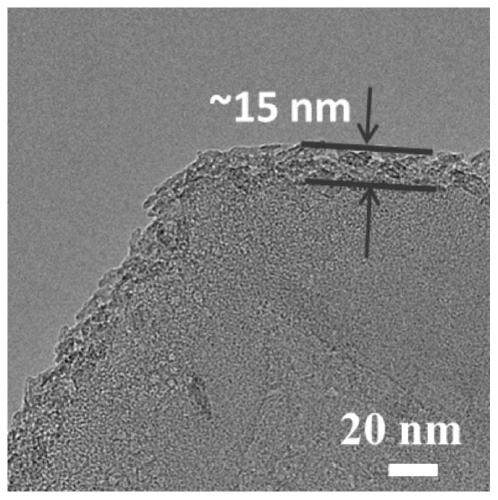

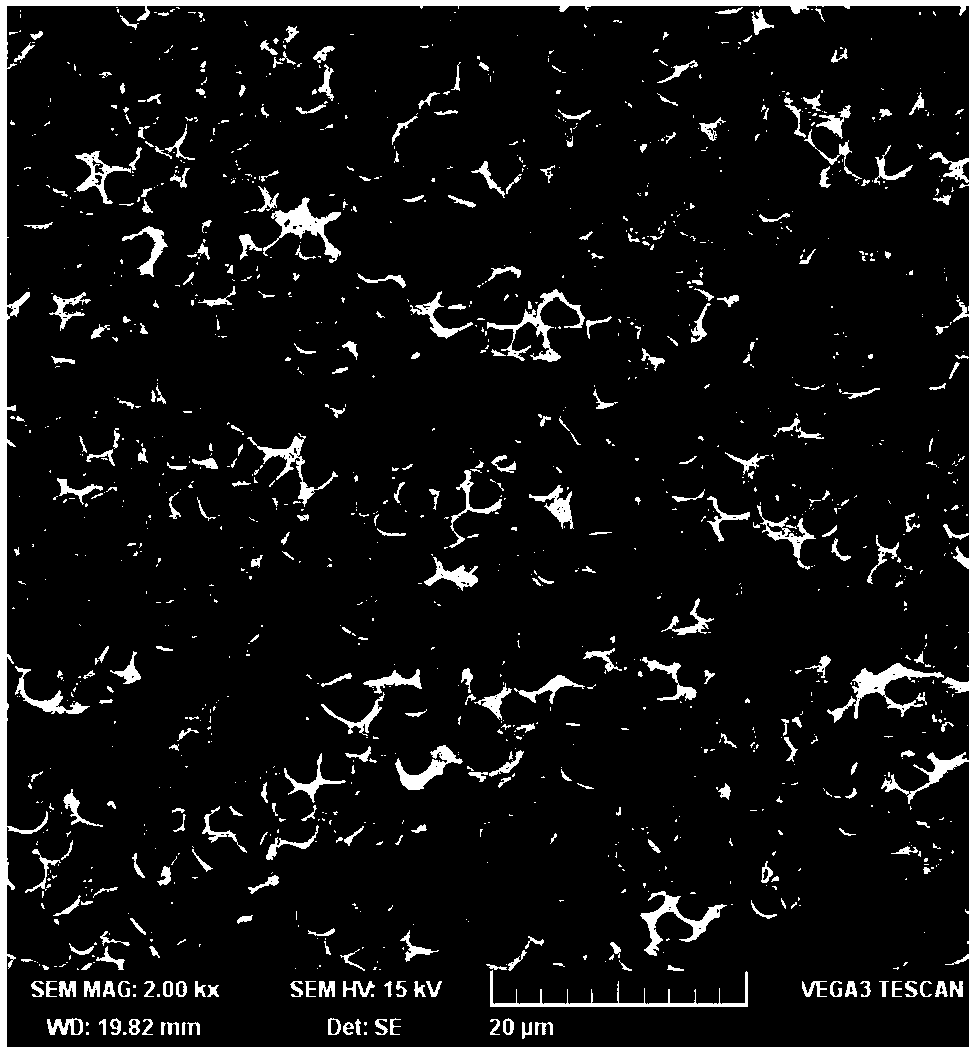

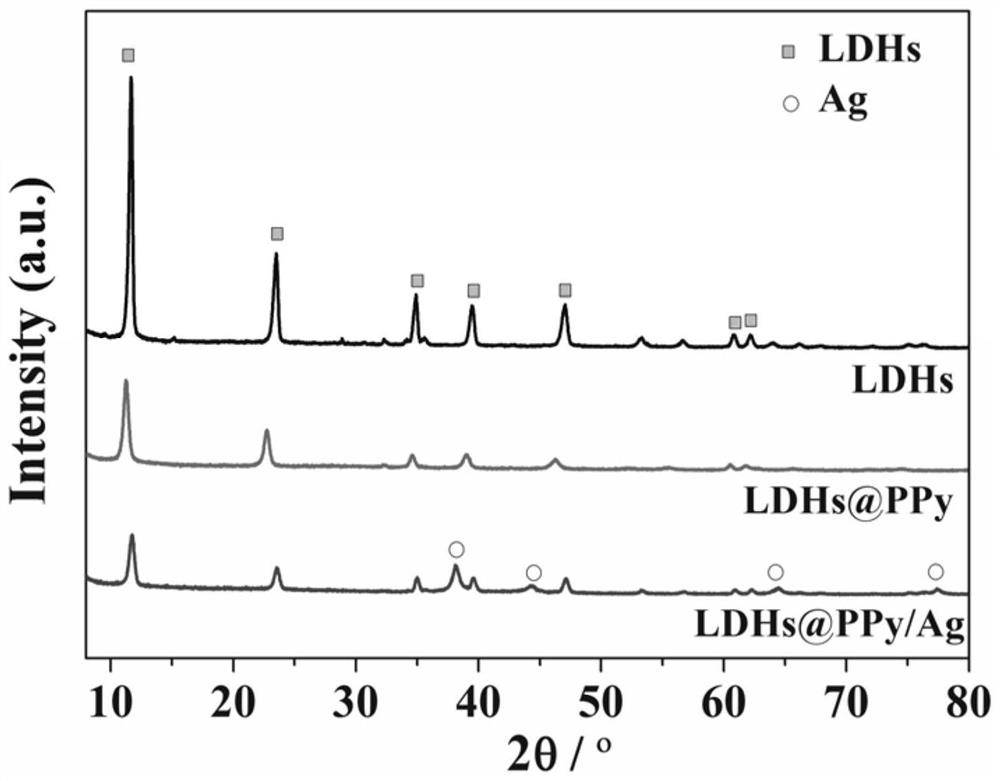

Preparation method of PPy (polypyrrole)-PCL (polycaprolactone) antibacterial nanocomposite film

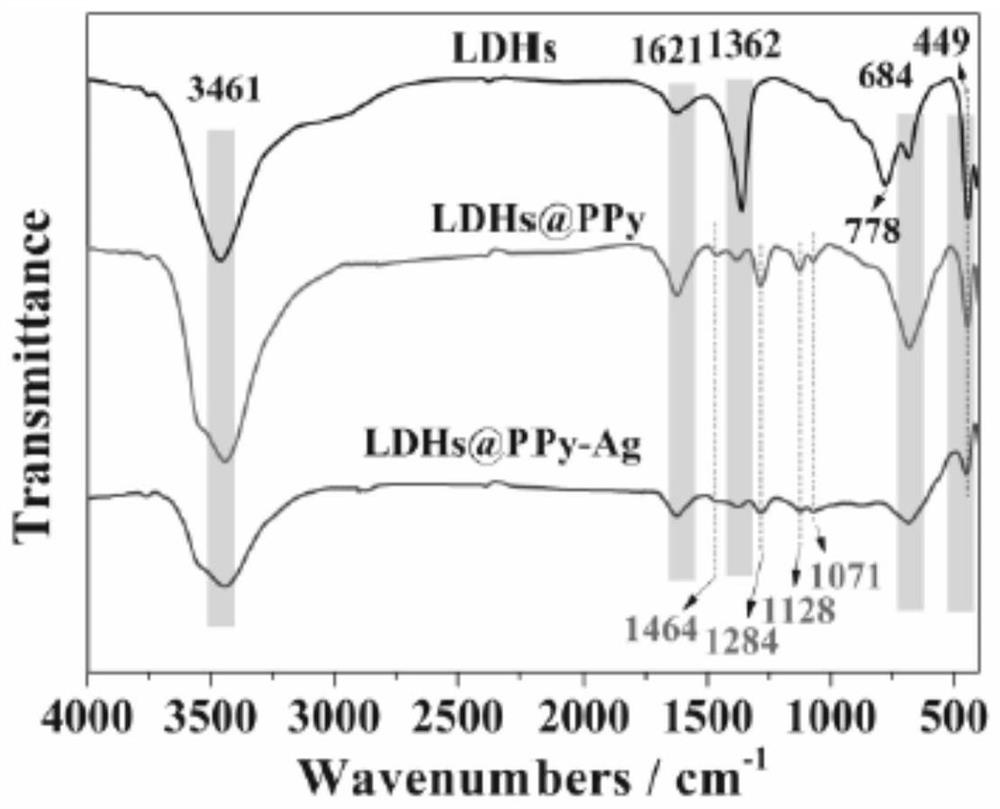

The invention provides a preparation method of a PPy (polypyrrole)-PCL (polycaprolactone) antibacterial nanocomposite film. The preparation method comprises steps as follows: PPy surface modified LDHs(layered double hydroxides) clay antibacterial powder (LDHs@PPy) is obtained from PPy coated LDHs clay formed through a chemical oxidation reaction of Py (pyrrole) on the surface of the LDHs clay under the initiation function of soluble Fe<3+> salt; then, a LDHs@PPy / PCL nanocomposite film is prepared from LDHs@PPy and PCL through solution pouring. The interfacial compatibility and the binding force between LDHs and a substrate PCL are increased by a surface organic coating PPy, the blocking property, the mechanical performance and the like of the final nanocomposite are improved, the composite film is endowed with antibacterial performance, and the application of the surface modified LDHs clay / bio-based polymer composite in the field of active packaging is finally extended. The preparation method is simple and is suitable for large-scale production, and conditions are easy to control.

Owner:XIAMEN UNIV OF TECH

Application of ion liquid block polymer in supercritical carbon dioxide microcellular foaming

The invention discloses a preparation method of a two-block polymer containing ion liquid. The preparation method comprises the following step of performing RAFT (reversible addition-fragmentation chain transfer) reaction, quaternarization reaction and ion exchange reaction on a RAFT reagent, a monomer I, a monomer II, a monomer III, an initiator and salt in a solvent, so as to obtain the ion liquid block polymer. The ion liquid block polymer can be used as an additive to be applied into the supercritical CO2 (carbon dioxide) foaming of the polymer, and be used for preparing the polymer microcellular foaming material. The size of the foam pore of the prepared foaming material can be reduced to 2 mum or below, and the nucleating rate of the foam pore is increased by three times or above.

Owner:TAIZHOU UNIV

Preparation method of corrosion-resistant chemical barrel material

InactiveCN110698766AProblems with corrosion resistanceHas the following advantages: In order to solve the problems of corrosion resistancePolypropylene compositesPlasticulture

The invention relates to the technical field of new material processing, and discloses a preparation method of a corrosion-resistant chemical barrel material. According to the preparation method, nanometer ceramic material modified polypropylene composite plastic is used for preparing a chemical barrel material master batch; chemical reaction between a corrosive medium and the surface of the chemical barrel material is prevented; a interface structure is protected; excellent performances of corrosion resistance, wear resistance, low relative density and the like are realized; the preparationmethod can be used for plastic enhancement, and the effect of promoting plasticization can also be achieved; after being treated and added into the polypropylene blended plastic, the corrosion-resistant chemical barrel material has an excellent reinforcing effect, the material microstructure can greatly improve the corrosion resistance, mechanical properties and aging resistance of blended materials, the corrosion-resistant chemical barrel material can be well dispersed in the blended materials, and the chemical properties are basically kept stable after immersion in corrosive liquid for a long time.

Owner:安徽天路新材料股份有限公司

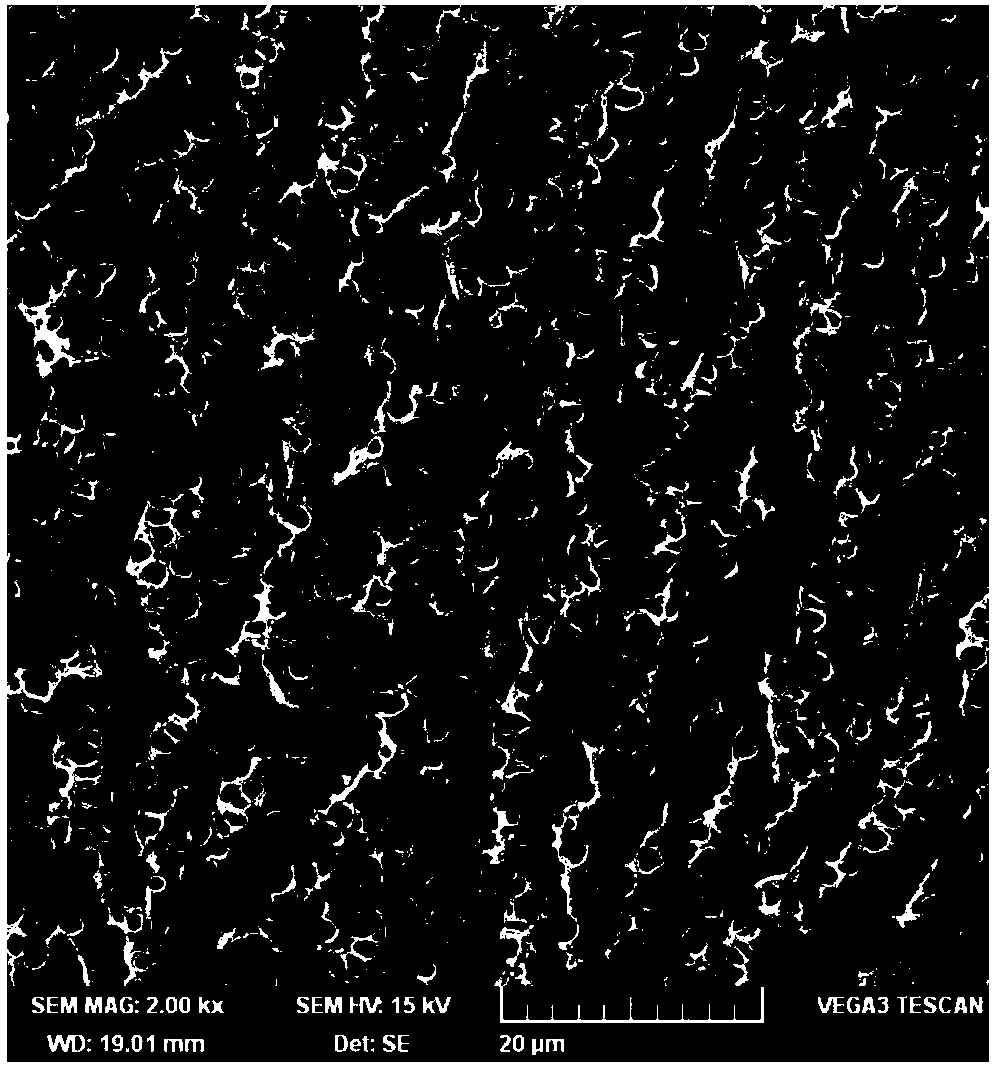

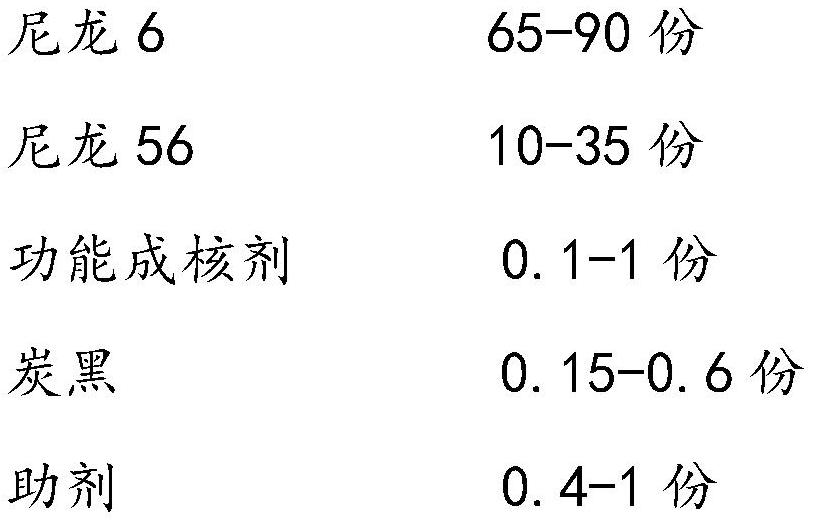

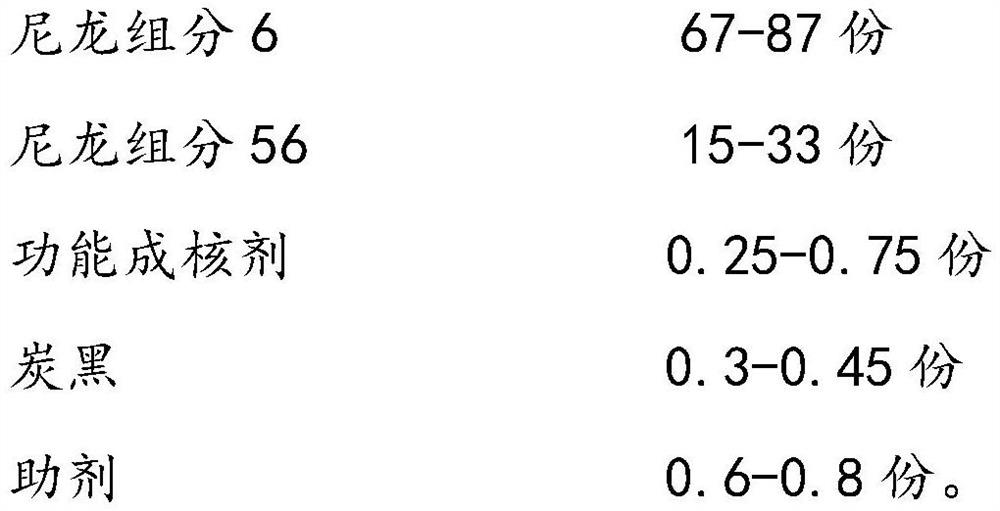

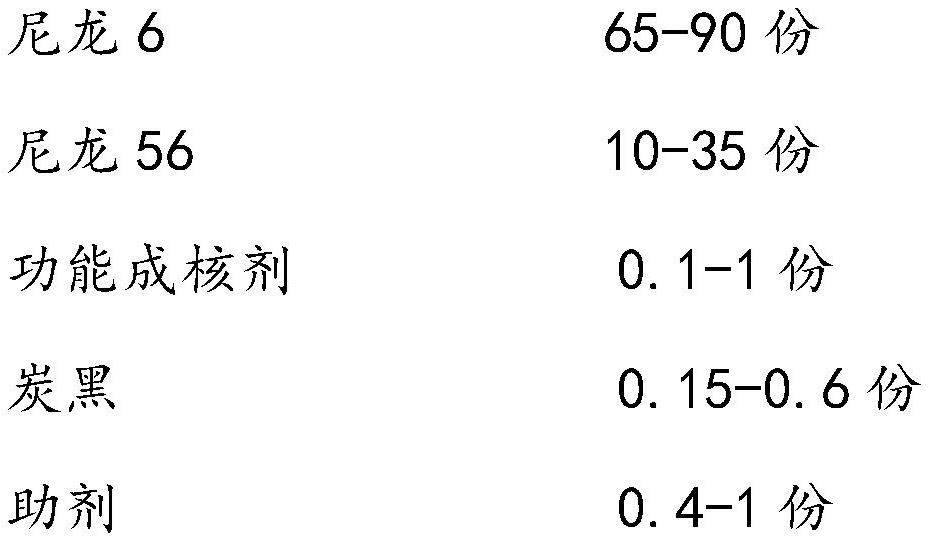

High-brightness black composite nylon material as well as preparation method and application thereof

The invention discloses a high-brightness black composite nylon material and a preparation method thereof. The high-brightness black composite nylon material is prepared from the following raw materials in parts by weight: 65-90 parts of nylon 6, 10-35 parts of nylon 56, 0.1-1 part of a functional nucleating agent, 0.15-0.6 part of carbon black and 0.4-1 part of an auxiliary agent, the functional nucleating agent is a polyamide-amine dendrimer grafted carboxylated carbon nano tube. The high-brightness black composite nylon material prepared by the invention has the advantages of low cost, good appearance and scratch resistance, meets the performance requirements of good appearance and scratch resistance when the high-brightness black composite nylon material is applied to automobile exterior trimming, and meanwhile, compared with a high-brightness black material which takes special nylon as a matrix in the market at present, the high-brightness black composite nylon material has the advantages of low cost, good appearance and scratch resistance. The obvious price advantage is realized.

Owner:SHANGHAI KINGFA SCI & TECH +1

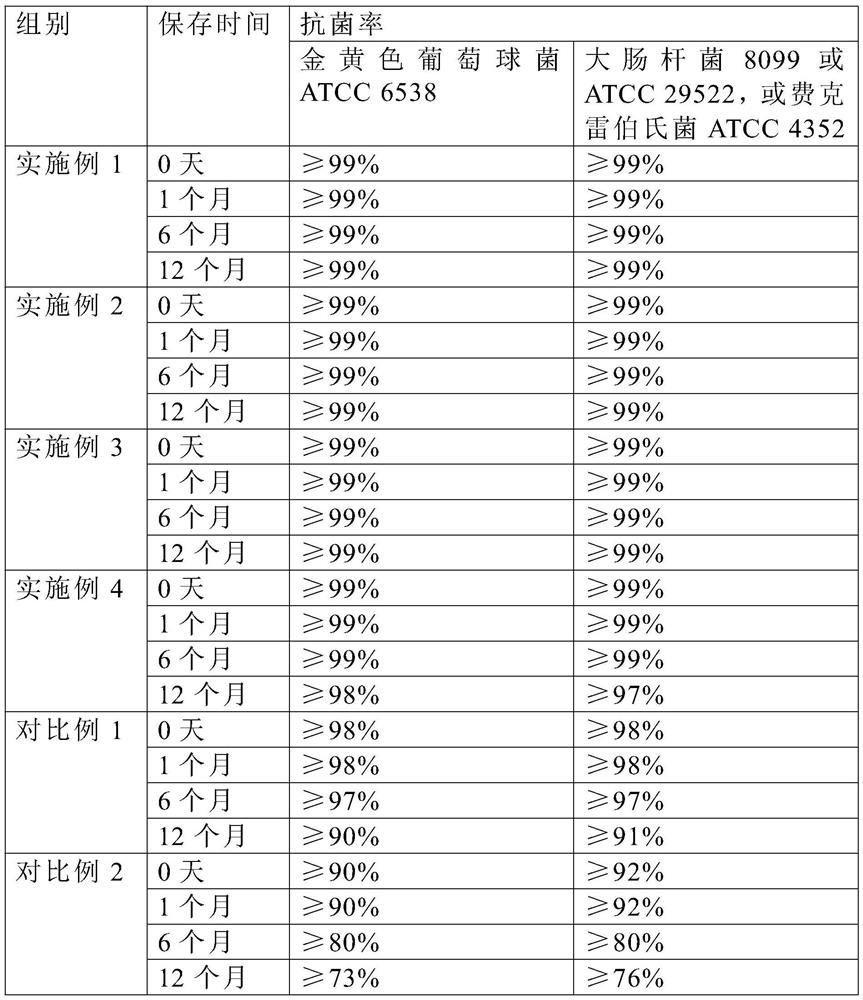

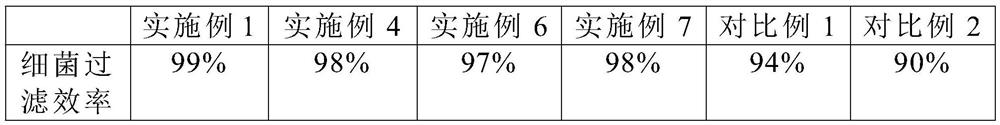

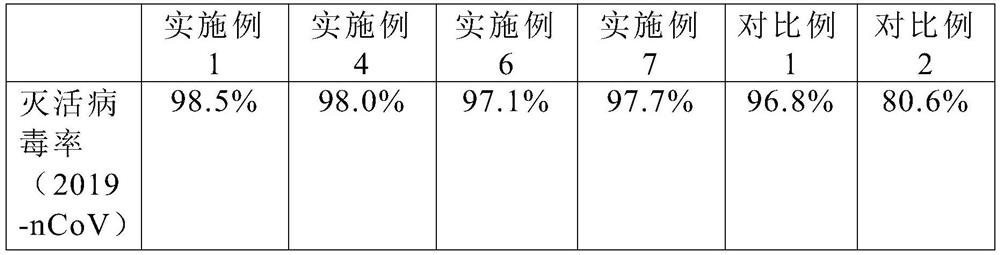

Manufacturing method and application of nano-copper antibacterial and antiviral meltblown masterbatch

ActiveCN113334611BImprove stabilityExtended storage timeTransportation and packagingMetal-working apparatusPolyesterFiber

The application belongs to the technical field of materials, and relates to a method for manufacturing nano-copper antibacterial and antiviral melt-blown cloth master batches, comprising the following steps: mixing graphene, nano-copper, microporous silica and nano-microcapsule wrapping materials to obtain Nano-microcapsule-coated graphene composite material; nano-microcapsule-coated graphene composite material and polypropylene material are mixed, melted, extruded and granulated to obtain nano-copper antibacterial and antiviral melt-blown cloth masterbatch. It also relates to the application of the nano-copper antibacterial and antiviral meltblown cloth masterbatch obtained by the above manufacturing method in a meltblown cloth with antibacterial and virus inactivation properties. Using nano-copper as an antibacterial additive to form nano-microcapsule-coated graphene composite material, and forming a melt-blown non-woven fabric masterbatch with polypropylene material, can make nano-copper firmly embedded in the molecular structure of polyester fiber to form a non-dissolving type Antibacterial fibers, so that fibers and nonwovens can obtain continuous antibacterial properties.

Owner:SHANGYOU JINGHE NANO TECH CO LTD +3

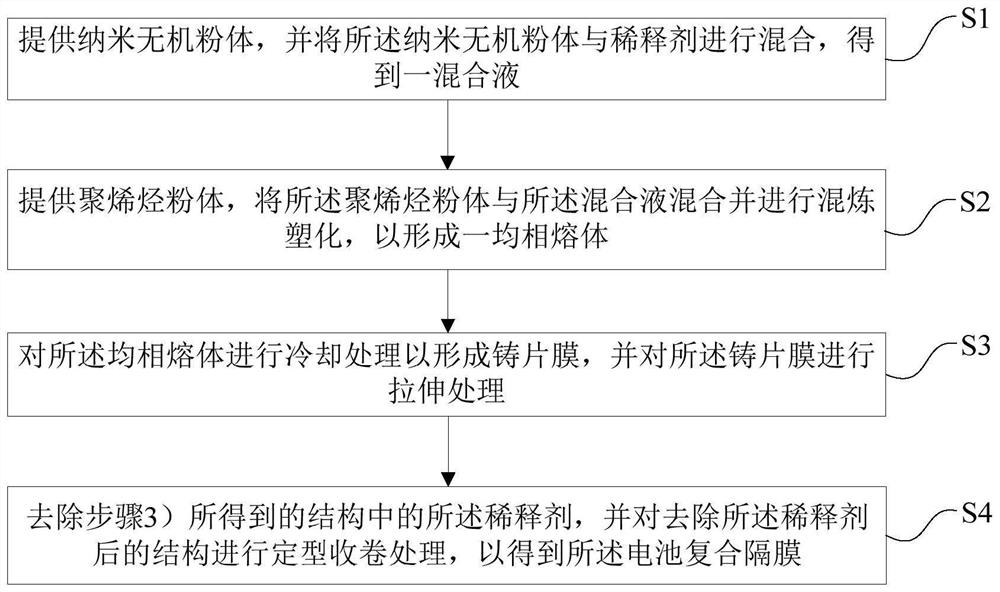

Battery composite diaphragm, lithium ion battery and preparation method

ActiveCN109065802BHigh mechanical strengthImprove thermal stabilityMaterial nanotechnologyCell seperators/membranes/diaphragms/spacersPolyolefinPhysical chemistry

The invention provides a battery composite separator, a lithium ion battery and a preparation method. The preparation of the battery composite separator includes: mixing nano-inorganic powder and a diluent to obtain a mixed liquid; mixing polyolefin powder and the mixed liquid and performing Mixing and plasticizing to form a homogeneous melt; cooling the homogeneous melt to form a cast film, stretching the cast film; removing the diluent, and performing shaping and winding treatment to obtain the battery composite Diaphragm. In the present invention, nano-scale inorganic powder is added to the polyolefin separator through an in-situ blending method. The nano-inorganic powder has high thermal stability and can reduce the thermal shrinkage of the lithium battery separator after being heated; the nano-inorganic powder has a large specific The surface area and polar functional groups on the surface can improve the lyophilicity between the polyolefin separator and the electrolyte; the nano-inorganic powder plays a heterogeneous nucleation role in the system and can increase the crystallization of polyolefin during the polyolefin molding process. degree and improve the mechanical strength of the diaphragm.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

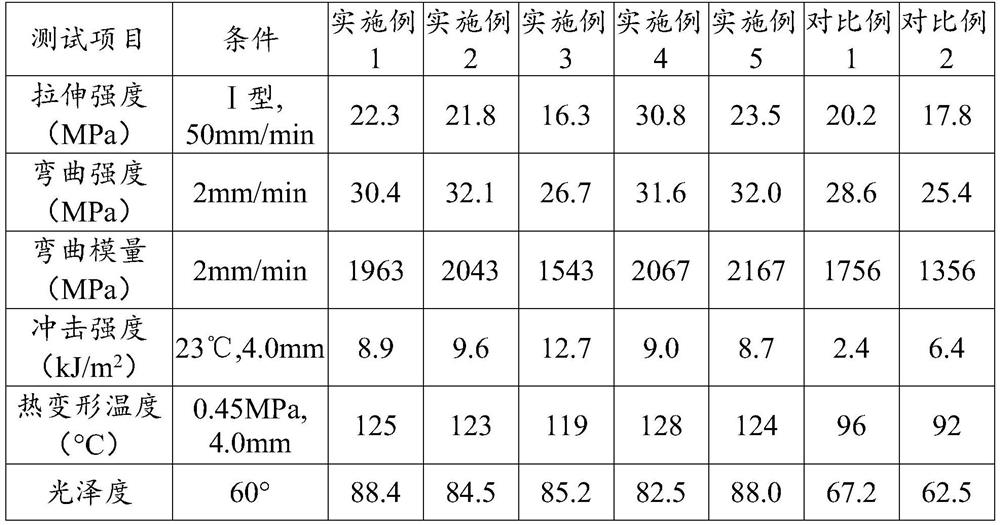

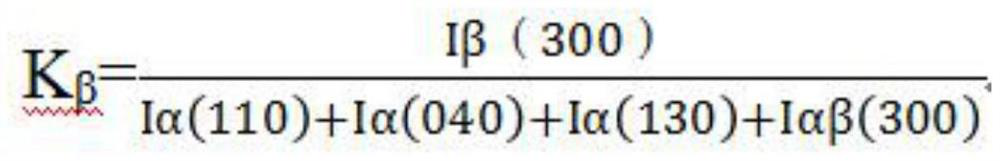

A kind of high β crystal polypropene material and preparation method thereof

ActiveCN110564054BSimple manufacturing methodImprove mechanical propertiesPolymer scienceCrystallinity

The invention discloses a polypropylene material with high β crystal form, which adopts 95.8-98.9 parts of polypropylene, 0.2-0.6 parts of β-type nucleating agent, and 0.5-2 parts of (3-aminopropyl) dimethylethoxysilane , 0.2-0.6 parts of heat stabilizer, 0.2-1 part of processing aid are mixed by high mixer and twin-screw extruder extrusion granulation; the preparation method of the present invention is simple and effective, and the crystallinity of the polypropylene material obtained Higher, the relative content of the β crystal form can be increased from 45% of ordinary modification to more than 98%, and the prepared high β crystal form polypropylene material has more excellent mechanical properties, thermal properties and gloss, so that the product of the present invention has Excellent prospects for industrialization.

Owner:合肥科拜尔新材料股份有限公司

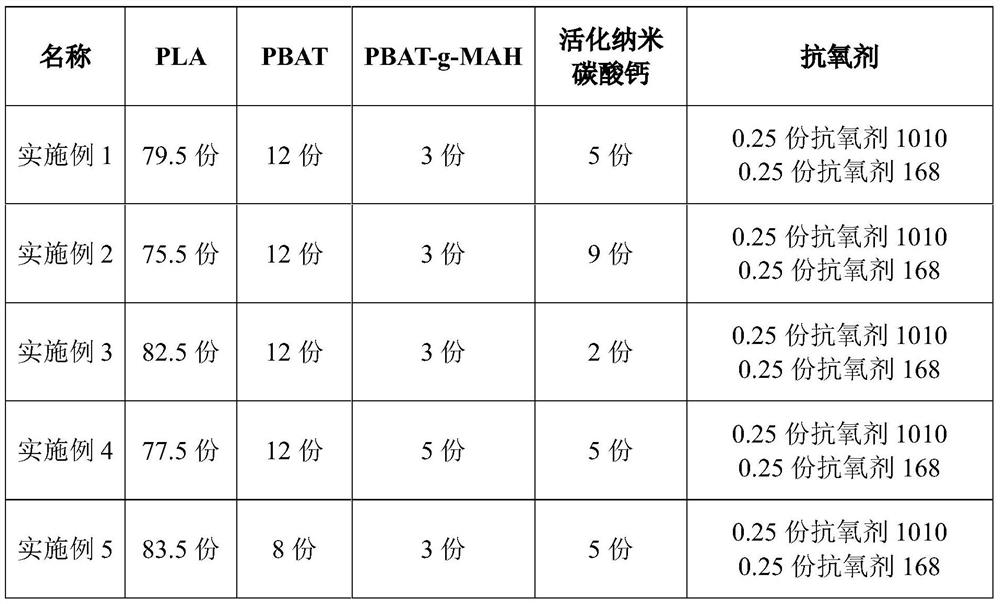

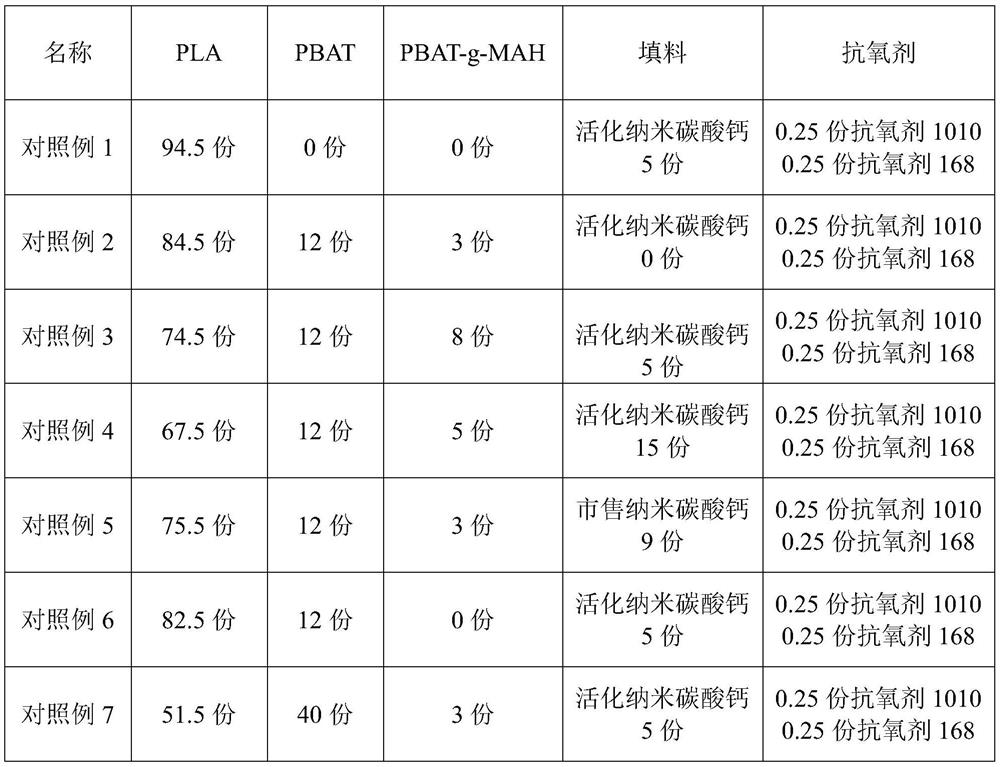

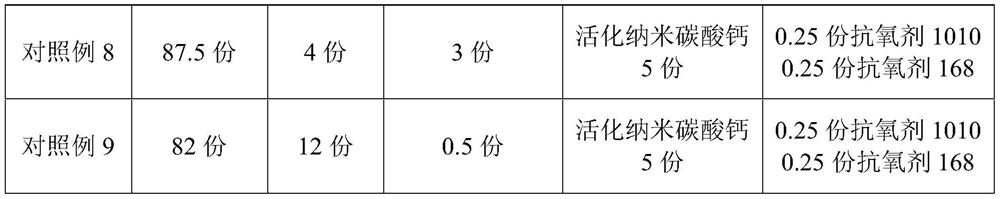

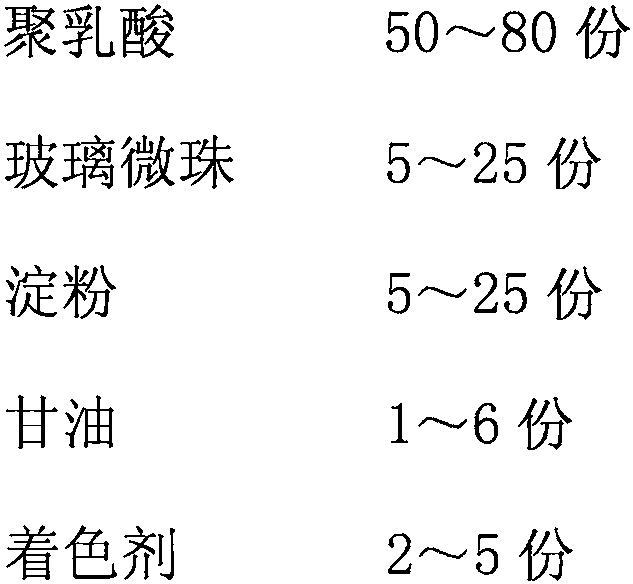

A heat-resistant and impact-resistant polylactic acid composite material and its preparation method and application

The invention discloses a heat-resistant and impact-resistant polylactic acid composite material as well as a preparation method and application thereof. The heat-resistant and impact-resistant polylactic acid composite material includes the following components calculated in parts by weight: 60-90 parts of polylactic acid, 5-25 parts of polybutylene terephthalic acid / adipate, 1-25 parts of compatibilizer 5 parts, 1-9 parts of active nano-calcium carbonate and 0.1-1 part of antioxidant; the active nano-calcium carbonate is prepared by modifying nano-calcium carbonate. The preparation method provided by the present invention adopts the technology of first banburying and then blending, so that the prepared heat-resistant and shock-resistant polylactic acid composite material is more uniformly dispersed, and has excellent mechanical properties, impact resistance, heat resistance and complete biological properties. Degradability, it has a good application prospect in the field of heat-resistant packaging such as hot meal containers.

Owner:宁波昌亚新材料科技股份有限公司

Mesoporous-material-added zinc-plated neodymium-iron-boron magnet and preparation method thereof

InactiveCN106024239AImprove antioxidant capacityImprove microstructureTransportation and packagingMetal-working apparatusCorrosionMachinability

The invention discloses a mesoporous-material-added zinc-plated neodymium-iron-boron magnet which is composed of the following components in percentage by mass: 25-35% of Pr-Nd, 1-2% of B, 0.1-1% of Al, 0-0.2% of Cu, 1-2% of Co, 0.1-0.3% of Ga, 0.1-1% of Nb, 0-0.1% of Zr, 0.1-1% of mesoporous silicon dioxide, and the balance of Fe and small amounts of inevitable impurities in the material. By starting with the neodymium-iron-boron magnet raw material powder ground by an air flow grinder, the micron-sized raw material powder is directly coated and plated by zinc, thereby enhancing the oxidation resistance of the neodymium-iron-boron raw material. By adding the mesoporous silicon dioxide, the nano component and neodymium-iron-boron magnet main phase are compounded into the grain boundary phase, thereby enhancing the coercivity of the magnet on the premise of keeping the magnetic remanence basically constant; and the produced neodymium-iron-boron magnet has the advantages of uniform crystal form structure, excellent corrosion resistance, obviously higher machinability, excellent oxidation resistance and high coercivity.

Owner:安徽万磁电子有限公司

Preparation method of modified polyester chip and polyester film

The invention discloses a preparation method of a modified polyester chip and a polyester film. The method comprises the following steps: dispersing POSS-octahydroxy propyl dimethyl silicon in ethylene glycol, performing ultrasonic dispersion, then mixing with terephthalic acid, biphenyl dicarboxylic acid, 1, 2-propylene glycol, zinc acetate and ethylene glycol antimony, controlling the molar ratio of alcohol to acid to be not less than 1.5: 1, heating to 230-240 DEG C until the water yield reaches 95% or above of a theoretical value, vacuumizing for the first time, heating to 260-265 DEG C, carrying out constant-temperature and constant-pressure reaction for 1-2 hours, vacuumizing for the second time to increase the vacuum degree, carrying out constant-temperature and constant-pressure reaction for 0.5-1 hour at 265-275 DEG C, reducing the pressure, discharging, cooling and granulating to prepare the modified polyester chip. The prepared polyester chip can be used for preparing a biaxially oriented polyester film, and has good mechanical properties and optical properties.

Owner:中山市泓溢薄膜科技有限公司

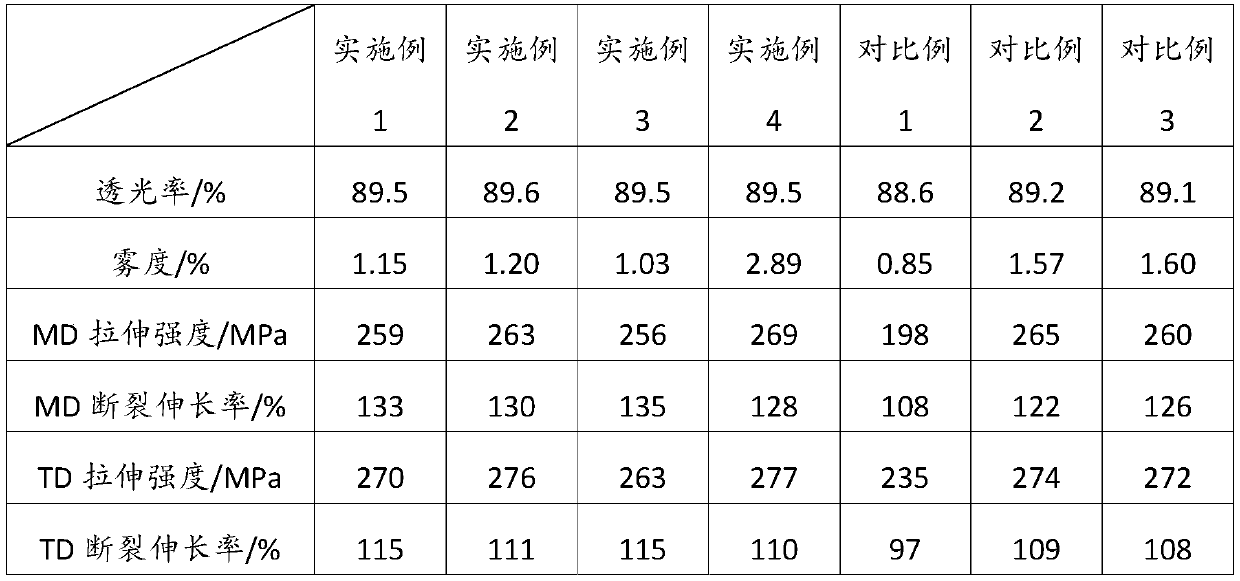

A kind of recycled and toughened modified composition of waste polypropylene and its preparation method

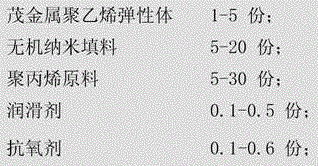

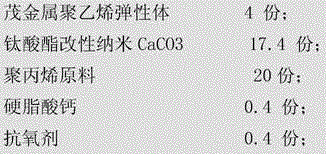

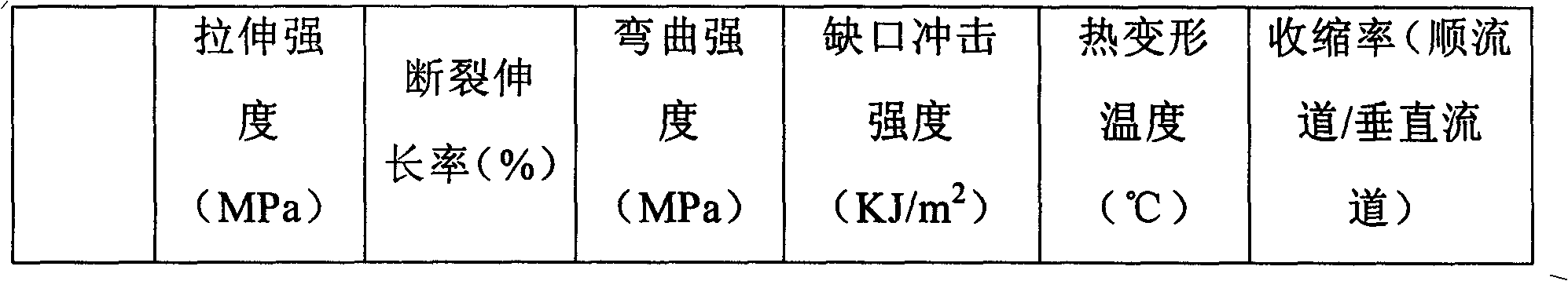

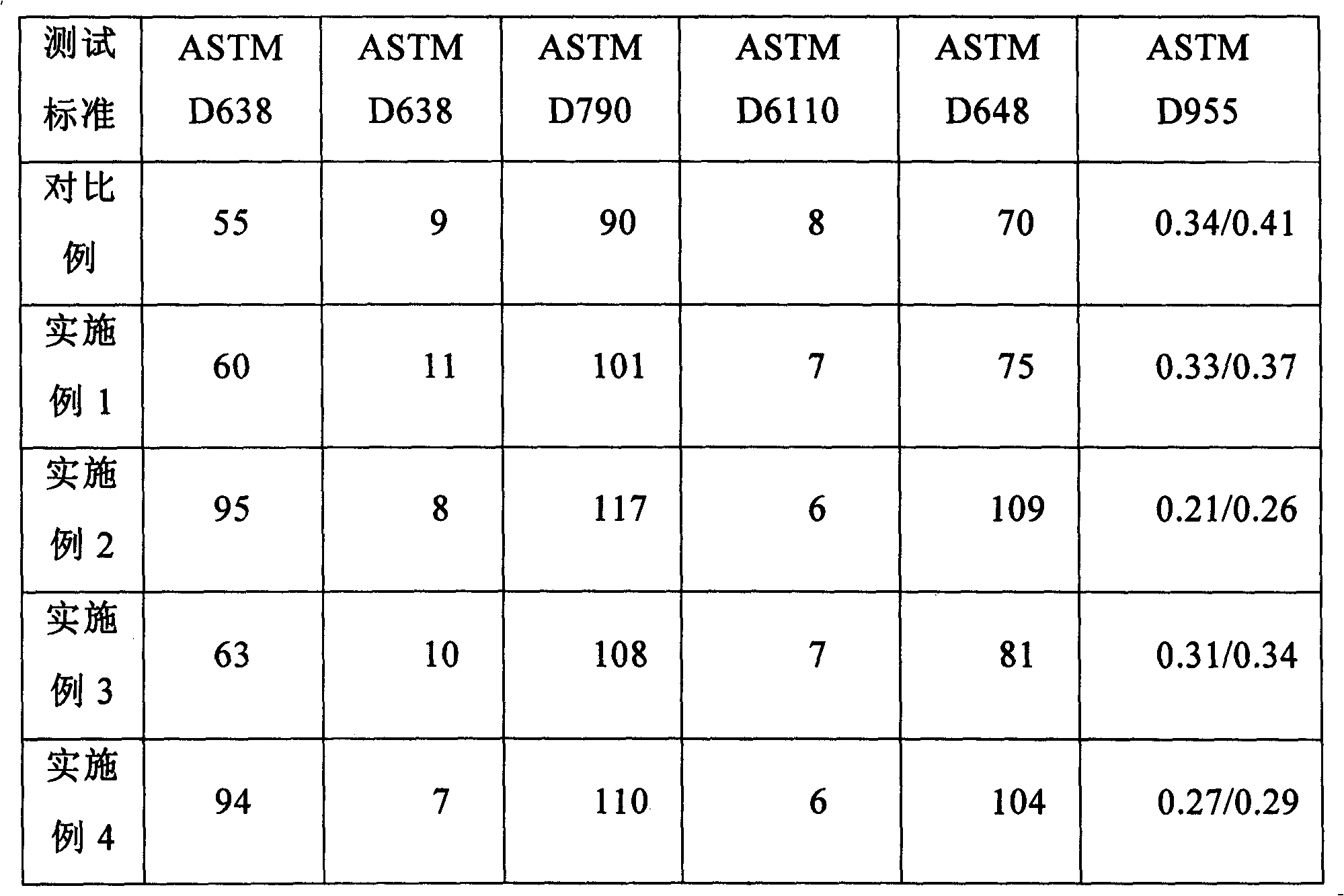

The invention discloses a waste polypropylene regenerated toughening-modified composition and a preparation method thereof, belonging to the technical field of high polymer materials. The waste polypropylene regenerated toughening-modified composition is prepared from the following components in parts by weight: 45-5 parts of toughening master batch, 50-90 parts of waste polypropylene, 2-6 parts of reinforcing assistant R, 1-5 parts of compatilizer, 0.1-0.5 part of lubricant, 0.2-0.6 part of antioxidant and 0-30 parts of polypropylene raw material. The method adopts a two-step process for blending and granulation and comprises the following steps: 1. uniformly mixing a metallocene polyethylene elastomer, an inorganic nano filler, a polypropylene raw material, a lubricant and an antioxidant, melting and granulating to obtain the toughening master batch; and 2. uniformly mixing the toughening master batch, waste polypropylene, reinforcing assistant R, compatilizer, polypropylene raw material, lubricant and antioxidant, melting and granulating. The formed part has the characteristics of high strength, favorable toughness, low production cost and the like.

Owner:FENGFAN

Gadolinium/yttrium-ion-implanted zinc-plated neodymium-iron-boron magnet and preparation method thereof

InactiveCN106024238AImprove antioxidant capacityImprove diffusion efficiencyTransportation and packagingMetal-working apparatusYttriumSintered magnets

The invention discloses a gadolinium / yttrium-ion-implanted zinc-plated neodymium-iron-boron magnet which is composed of the following components in percentage by mass: 25-35% of Pr-Nd, 0.5-1.5% of B, 0.1-1% of Al, 0-0.2% of Cu, 1-2% of Co, 0.1-1% of Ga, 0.02-0.08% of Nb, 0.01-0.05% of Zr, 0.1-1% of mesoporous silicon dioxide, and the balance of Fe and small amounts of inevitable impurities in the material. The sintered neodymium-iron-boron magnet has uniform crystal form structure; the heavy rare earth content in the region adjacent to the magnet core is lower, thereby preventing the magnetic remanence of the magnet from being influenced basically; the heavy rare earth content in the region adjacent to the magnet surface is higher, thereby obviously enhancing the coercivity of the magnet; and the defects of the neodymium-iron-boron sintered magnet are comprehensively improved, and the advantages are greatly enhanced.

Owner:安徽万磁电子有限公司

Transparent nucleating agent master batch for blow molding PE and preparation method of transparent nucleating agent master batch

PendingCN114479253ARefined spherulitesThe number of spherulites per unit area increasesBlow moldingPolymer science

The invention discloses a transparent nucleating agent master batch for blow molding PE and a preparation method of the transparent nucleating agent master batch. The transparent nucleating agent master batch for blow molding PE is prepared from the following components in parts by weight: 60-80 parts of polyethylene, 12-28 parts of nano butadiene styrene rubber, 3-7 parts of nano silicon dioxide, 0.1-0.5 part of an antioxidant, 0.1-0.3 part of a lubricant and 0.1-0.3 part of a dispersing agent. When the prepared transparent nucleating agent master batch for blow molding is added into blow molding PE, the spherocrystal size of polyethylene resin is reduced, and the structure is finer and more uniform, so that the crystallization temperature of a blow molding PE film is remarkably improved, the transparency is improved, and the haze is reduced. The film has the characteristics of high transparency and low haze, and can be widely applied to the requirements of various film products.

Owner:HEFEI GENIUS NEW MATERIALS

Talcum powder-polyester composite material and preparation method thereof

The invention relates to a talcum powder-polyester composite material and a preparation method thereof. The method comprises: (1) mixing 1 part by weight of a coupling agent, 10-100 parts by weight of glycol and 0.1-10 parts by weight of water, adjusting a pH value to 1-6 with acid, and hydrolyzing for 0-1 hour; (2) mixing the coupling agent hydrolysate and 30-1000 parts by weight of the talcum powder for 5 minutes to obtain the active talcum powder; and (3) mixing 0.1-10 parts by weight of the active talcum powder, 70-80 parts by weight of terephthalic acid and 20-30 parts by weight of the glycol with stirring, adding 0.01-1 part by weight of a catalyst, heating to 70-90 DEG C, dehydrating under vacuum until the water content is less than 1.0 %, re-heating to 220-240 DEG C, esterifying for 6-10 hours, adding 0.01-1 part by weight of an additive, vacuumizing to a vacuum degree of 80 Pa or less under a temperature of 240-260 DEG C, and polymerizing for 1-3 hours to obtain the product.

Owner:HEFEI GENIUS NEW MATERIALS

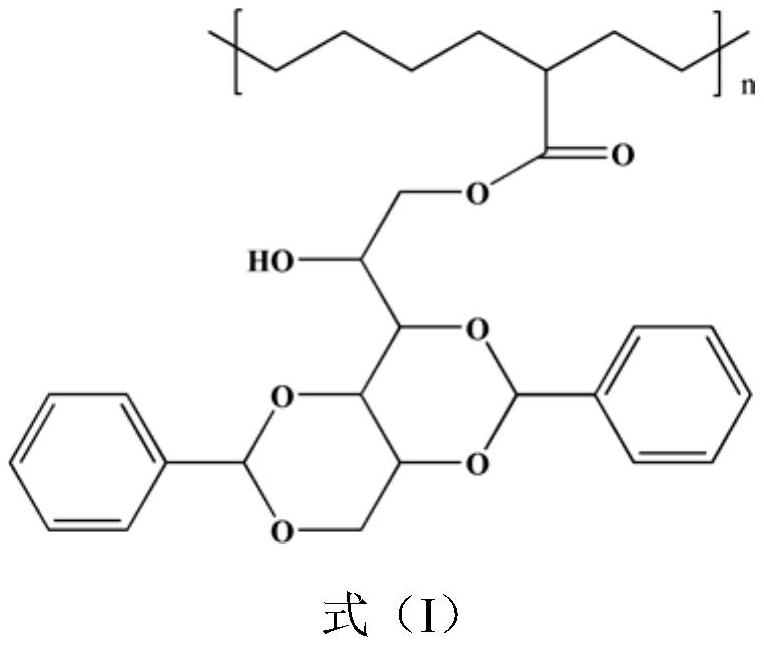

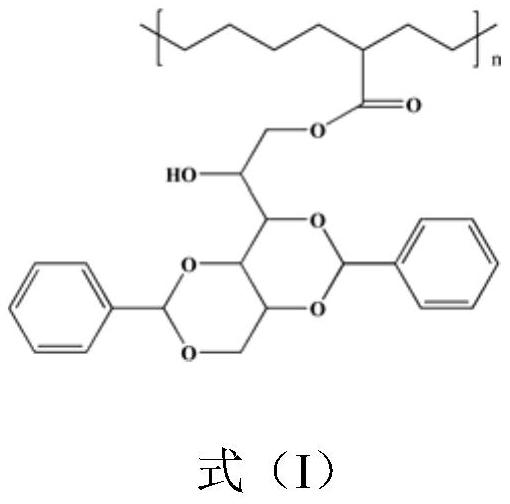

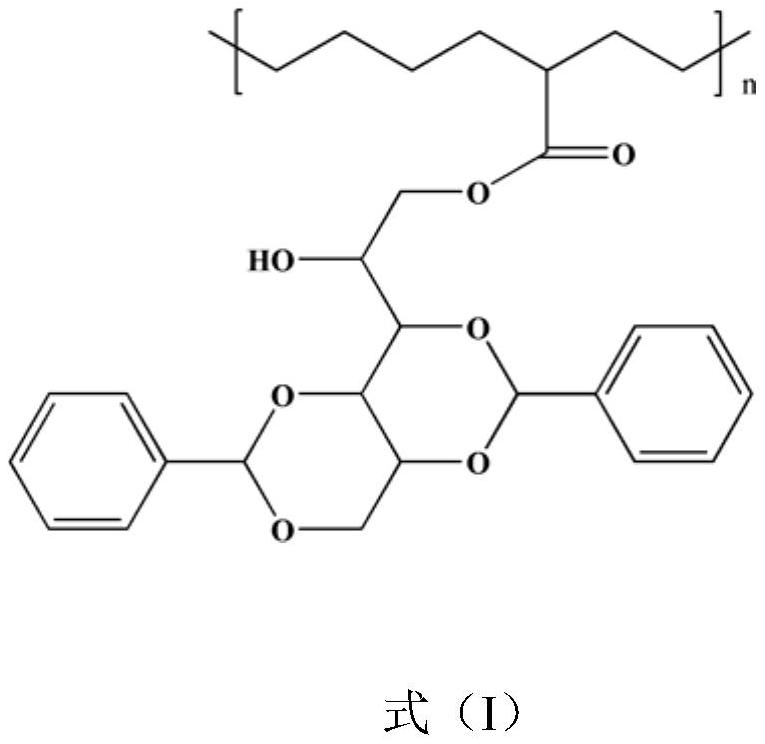

PET auxiliary agent, synthetic method thereof and application of PET auxiliary agent in improvement of mechanical properties of recycled PET

ActiveCN114292285AImprove compatibilityImprove crystallization abilityOrganic chemistryPlastic recyclingChemistryComposite material

The invention relates to the field of high polymer materials, and discloses a PET auxiliary agent, a synthesis method thereof and an application of the PET auxiliary agent in improvement of mechanical properties of recycled PET, and the PET auxiliary agent is synthesized by reacting dibenzylidene sorbitol and long-carbon-chain lignite wax acid under catalysis of dimethylaminopyridine. A synthetic method of a PET auxiliary agent comprises the following steps: step I, dispersing dibenzylidene sorbitol in xylene, adding long-carbon-chain montan wax acid and dimethylaminopyridine, and carrying out a reaction; and II, after the reaction is finished, carrying out suction filtration, washing and drying to obtain the target PET auxiliary agent. The PET auxiliary agent can be used as a mechanical property accelerant for recovering PET, and the straight-chain molecular structure of the long carbon chain part can promote the addition and rearrangement of the molecular chain in the crystallization process of the recovered PET and the epiphytic crystallization around the long carbon chain, so that the crystallization promoting effect of the dibenzylidene sorbitol part is further enhanced; the recycled PET is induced to generate microcrystals or shish-kebab, so that the mechanical property of the recycled PET is improved.

Owner:深圳市那鸿科技有限公司

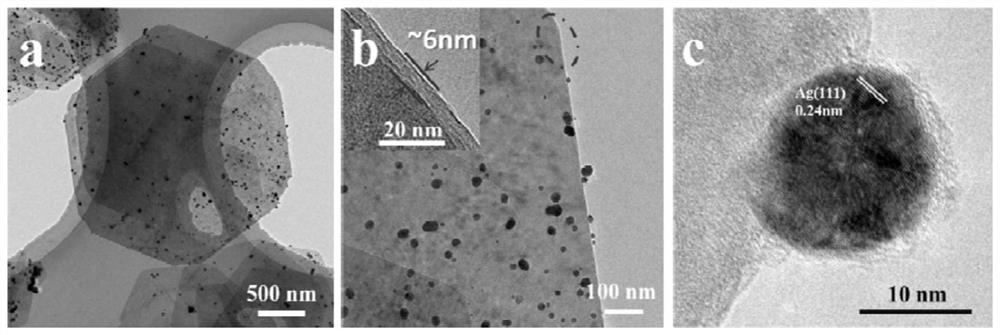

A preparation method of polypyrrole/silver surface modified layered clay-polycaprolactone antibacterial nanocomposite film

The invention provides a preparation method of polypyrrole / silver surface modified layered clay-polycaprolactone antibacterial nanocomposite film. + Salt-induced chemical oxidation of pyrrole Py on the surface of layered clay LDHs, the chemical oxidation of newly formed PPy can combine and reduce silver ions into metallic silver nanoparticles AgNP, and then form polypyrrole PPy-coated clay LDHs to obtain polypyrrole surface modification Layered clay antibacterial powder LDHs@PPy‑Ag; finally, LDHs@PPy‑Ag / PCL nanocomposite films were prepared by solution casting of LDHs@PPy‑Ag and polycaprolactone PCL. The invention increases the interface compatibility and bonding force between LDHs and the substrate PCL through the surface organic coating PPy, improves the mechanical properties and gas barrier properties of the final nanocomposite material, and endows the composite film with excellent antibacterial properties, and finally expands the composite film. The application of the material in the field of active packaging has the advantages of simple preparation method and easy control of conditions, and is suitable for large-scale production.

Owner:XIAMEN UNIV OF TECH

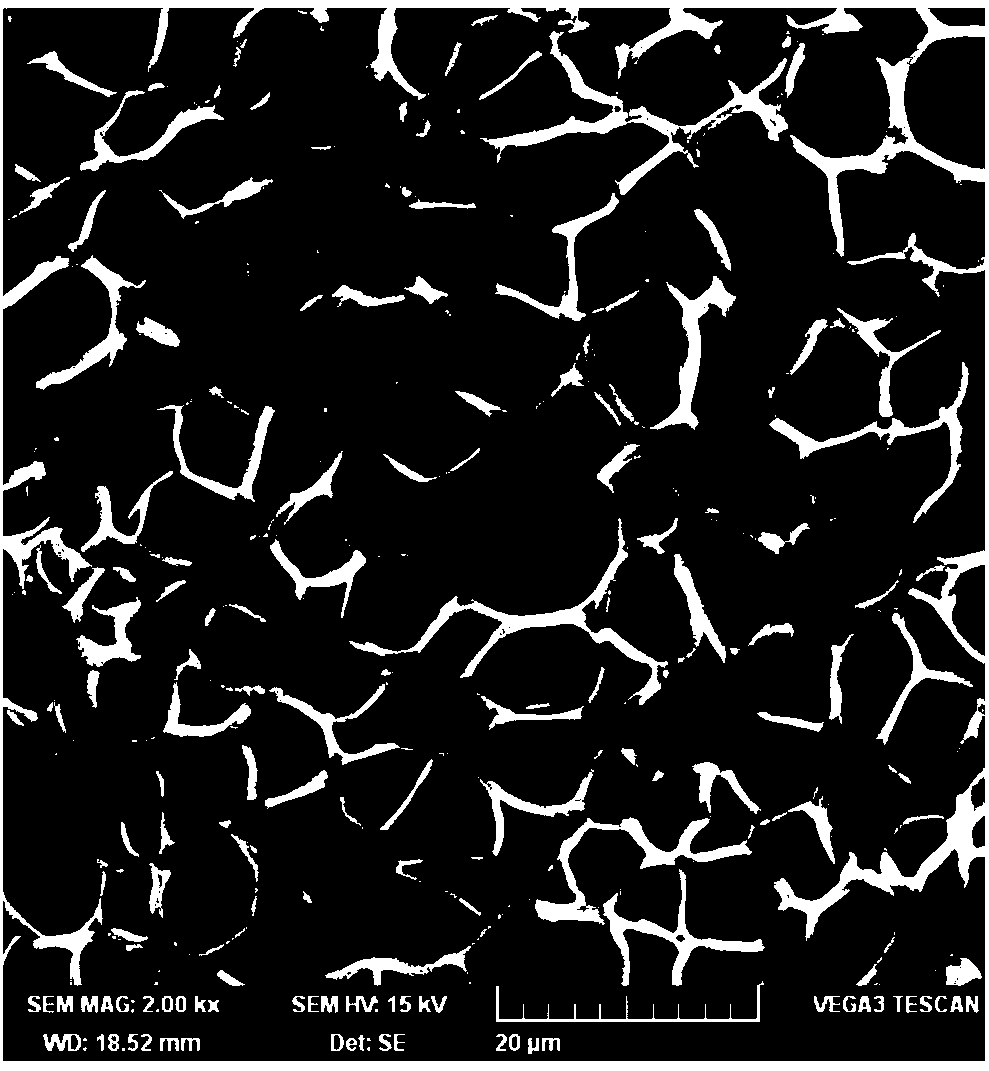

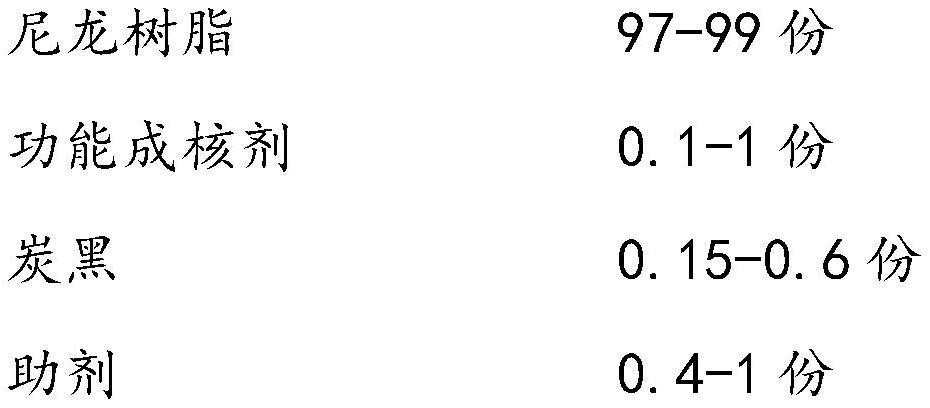

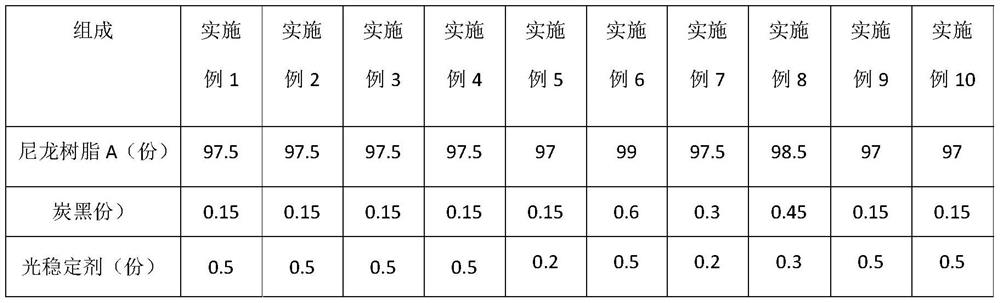

High-brightness black nylon material as well as preparation method and application thereof

The invention discloses a high-brightness black nylon material as well as a preparation method and application thereof. The high-brightness black nylon material is specifically prepared from the following raw materials in parts by weight: 97 to 99 parts of nylon resin, 0.1 to 1 part of functional nucleating agent, 0.15 to 0.6 part of carbon black and 0.4 to 1 part of auxiliary agent, the functional nucleating agent is a polyamide-amine dendrimer grafted carboxylated carbon nano tube. The high-brightness black nylon material prepared by the invention has good appearance and solvent resistance, meets the performance requirement of good appearance when the high-brightness black nylon material is simultaneously applied to automotive interiors, and has good solvent resistance at the same time.

Owner:SHANGHAI KINGFA SCI & TECH +1

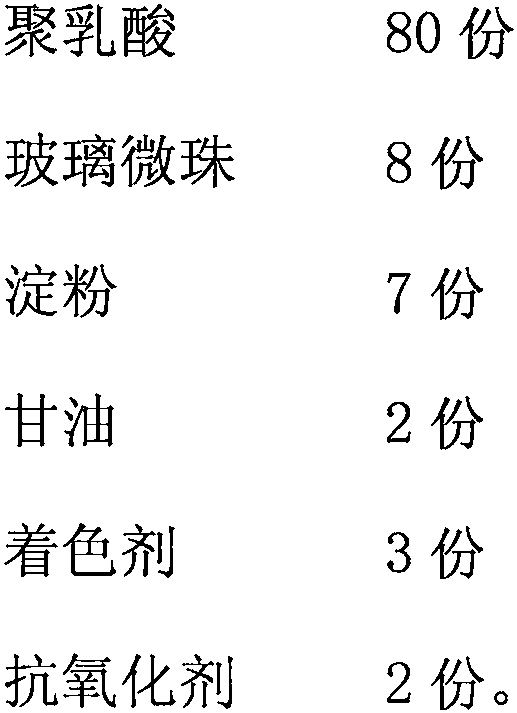

A kind of preparation method of polylactic acid composite material and product

ActiveCN110218426BImprove heat resistanceImprove mechanical propertiesCoatingsPolymer scienceInjection molding machine

Owner:ZHEJIANG NORMAL UNIVERSITY

Propeller rapid forming technology

InactiveCN107363470AImprove efficiencyGood liquidityRotary propellersFoundry mouldsPropellerCorrosion

Owner:GUANGZHOU PANYU YUANHANG PROPELLERS MFGCO LTD

Yellowing-resistant polypropylene plastic and preparation method thereof

PendingCN114806018AInhibit migrationGood yellowing resistancePolymer scienceHindered amine light stabilizers

The invention relates to an anti-yellowing polypropylene plastic and a preparation method thereof, and belongs to the technical field of plastics, the anti-yellowing polypropylene plastic comprises the following raw materials by weight: 80-90 parts of polypropylene, 2-3 parts of modified zinc oxide, 10-12 parts of a flame retardant, 5-6 parts of a compatilizer, 2-3 parts of a filler and 1-3 parts of a lubricant; the preparation method comprises the following steps: mixing the raw materials, extruding by using a double-screw extruder, water-cooling, pelletizing and carrying out injection molding. In order to delay or inhibit the aging process of polypropylene, 2, 2, 6, 6-tetramethylpiperidine-4-alcohol containing a hindered amine structure is selected as a raw material, a modifier containing the hindered amine structure is grafted on the surface of zinc oxide through substitution, addition and other reactions in sequence, the surface polarity of zinc oxide is reduced, the dispersity of zinc oxide in polypropylene is improved, and meanwhile, the aging resistance of polypropylene is improved. The migration of the modifier can be prevented; the anti-yellowing effect is good.

Owner:界首市亚鑫塑业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com