Preparation process of graphene reinforced polyformaldehyde rope

A formaldehyde cable and preparation process technology, which is applied in textile cables, rayon manufacturing, conjugated synthetic polymer rayon and other directions, can solve the problems of poor graphene dispersibility, poor high temperature resistance, insufficient strength, etc. The effect of uniform dispersion, improved strength and wear resistance, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

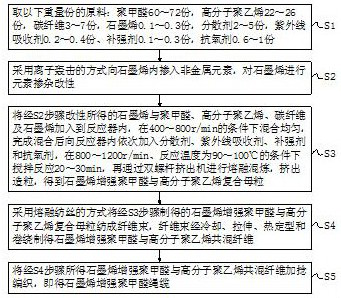

[0025]Seefigure 1The present invention provides the following technical solution: a preparation process of a graphene reinforced polyoxaldehyde cable, including the following preparation steps:

[0026]Step S1: Take the weight of the weight of the weight: 60 parts of polyoxyoly, 26 parts of polymer polyethylene, 7 parts of carbon fiber, 0.3 graphene, 5 parts of the dispersant, 0.4 parts of the ultraviolet absorber, and 0.3 reinforcing agents, antioxidant 1 part;

[0027]Step S2: The non-metallic element is incorporated into the graphene by means of ion bombardment, and graphene is doped.

[0028]Step S3: The graphene obtained by modifying the S2 step is added to the polyoxymethylene, polymer polyethylene, carbon fibers, and graphene, mixed uniform under 400 r / min, and completed the mixed reactor. The dispersant, ultraviolet absorber, reinforcing agent, and antioxidants were added, and the reaction was stirred at 8000 r / min, and the reaction temperature was stirred at 90 ° C for 20 min, a...

Embodiment 2

[0038]Seefigure 1The present invention provides the following technical solution: a preparation process of a graphene reinforced polyoxaldehyde cable, including the following preparation steps:

[0039]Step S1: Take the weight of the weight of the following weight: 72 parts of polyoxycehyde, 2 polyethylene polyethylene polyethylene, 3 carbon fibers, 0.1 parts of the graphene, 2 parts of the dispersant, 0.2 parts of the ultraviolet absorbent, and antioxidant 0.6 parts of the agent;

[0040]Step S2: The non-metallic element is incorporated into the graphene by means of ion bombardment, and graphene is doped.

[0041]Step S3: The graphene obtained by modifying the S2 step is added to the polyoxymethylene, polymer polyethylene, carbon fibers, and graphene, mixed under the conditions of 600R / min, and completed the mixed reactor. The dispersant, ultraviolet absorber, reinforcing agent, and antioxidants were added, and the reaction was stirred at 1000 R / min, and the reaction temperature was sti...

Embodiment 3

[0051]Seefigure 1The present invention provides the following technical solution: a preparation process of a graphene reinforced polyoxaldehyde cable, including the following preparation steps:

[0052]Step S1: Take the weight of the weight of the following weight: 67 polyoxymethylene, 24 parts of polymer polyethylene, 5 parts of carbon fiber, 0.1 parts of the graphene, 3 parts of the dispersant, 0.2 parts of the ultraviolet absorber, and the reinforcing agent. 0.6 parts of the agent;

[0053]Step S2: The non-metallic element is incorporated into the graphene by means of ion bombardment, and graphene is doped.

[0054]Step S3: The graphene obtained by modifying the S2 step is added to the polyoxymethylene, polymer polyethylene, carbon fibers, and graphene, mixed under the conditions of 700 R / min, and the mixing is completed in the reactor. The dispersant, the ultraviolet absorber, the reinforcing agent, and the antioxidant were added, and the reaction was stirred at 1100 r / min, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com