A preparation method of polypyrrole/silver surface modified layered clay-polycaprolactone antibacterial nanocomposite film

A surface modification layer, polycaprolactone technology, applied in the field of active packaging applications, polymer materials, can solve problems such as agglomeration, high cost of silver nanoparticles, easy to control conditions, elongation at break and oxygen permeability performance Improved, good interface compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example provides a method for preparing a polypyrrole / silver surface-modified layered clay-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

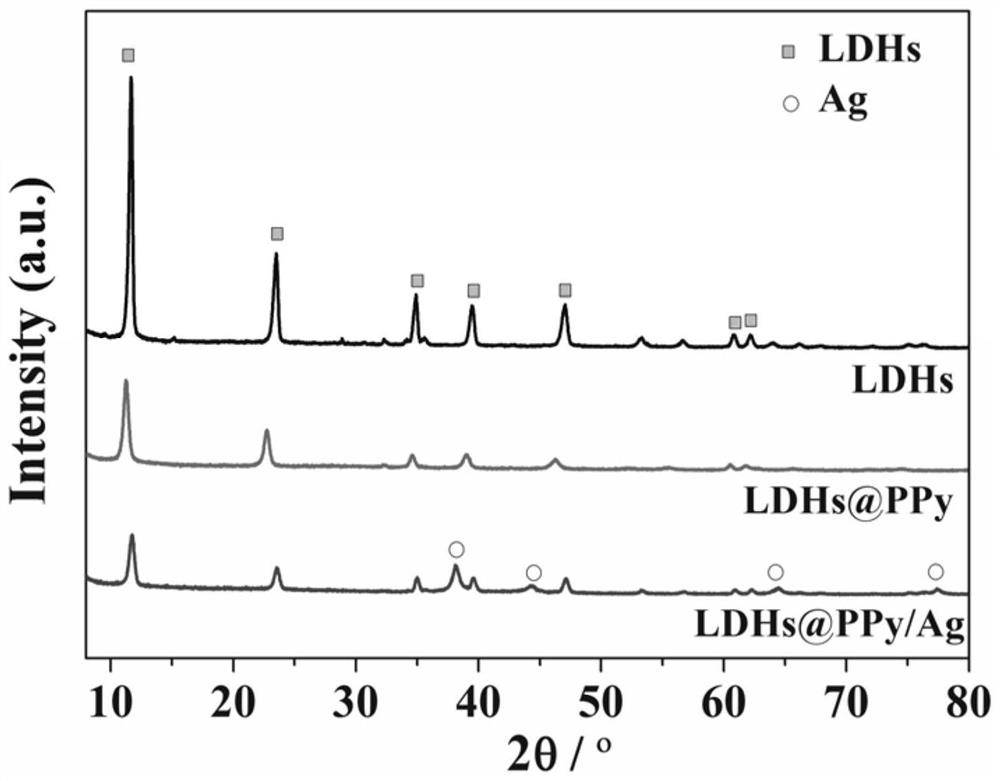

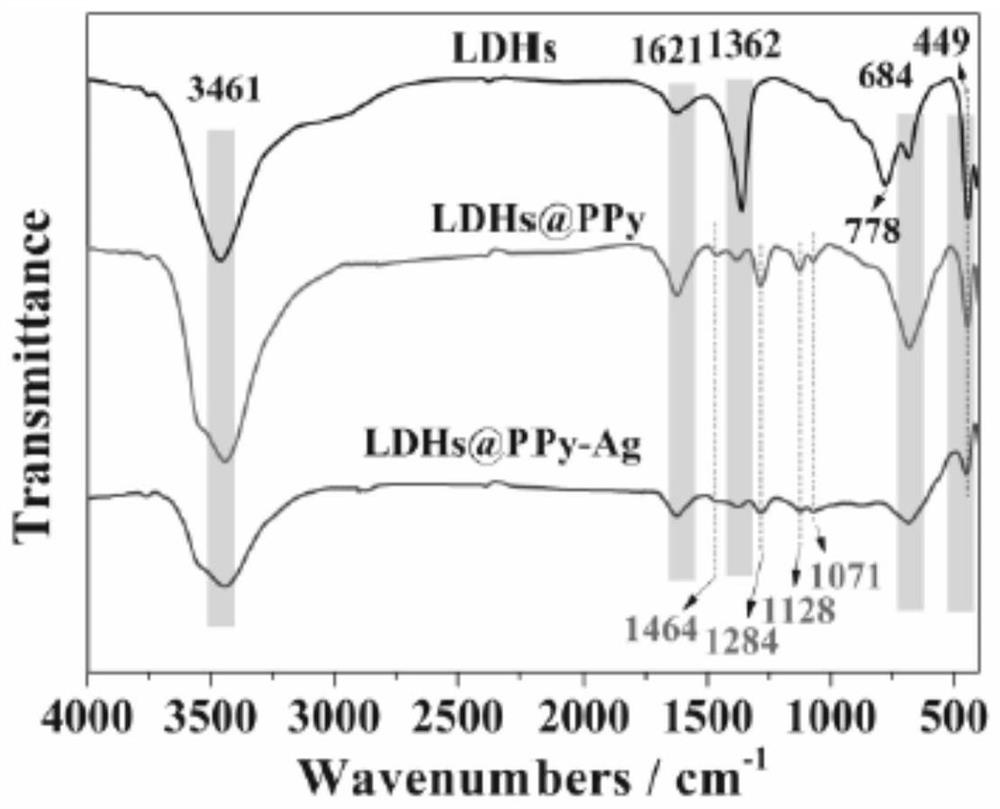

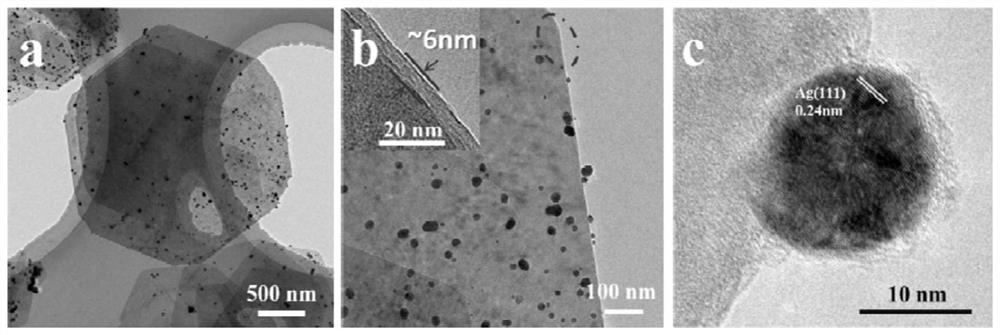

[0043] 1) Preparation of LDHs@PPy-Ag

[0044] Weigh 0.05g LDHs and disperse in 50mL deionized H 2O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.12g AgNO3 and dissolve it in the LDHs dispersion, stir ultrasonically for 5min, then magnetically stir, adsorb for 30min, and heat up to 70°C. Then 1.2 g of Py was added to 50 mL of deionized H 2 In O, sonicate for 10 min until Py is completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred by magnetic force for 60 min, and the temperature was 70°C. The reaction liquid began to gradually turn black. After the reaction was completed, it was centrifuged three times and then freeze-dried to obtain black LDHs@PPy-Ag powder.

[0045] 2) Preparation of LDHs@PPy-...

Embodiment 2

[0049] This example provides a method for preparing a polypyrrole / silver surface-modified layered clay-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

[0050] 1) Preparation of LDHs@PPy-Ag

[0051] Weigh 0.05g LDHs and disperse in 50mL deionized H 2 O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.05g AgNO3 and dissolve it in the LDHs dispersion, stir ultrasonically for 5min, then magnetically stir, adsorb for 20min, and heat up to 60°C. Then 1.0 g of Py was added to 50 mL of deionized H 2 O, sonicate for 5 min until Py is completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred by magnetic force for 120 minutes, and the temperature was 60°C, and the reaction solution began to gradually turn black. After the reaction was completed, it was centrifuged three times and then freeze-dried to obtain black LDHs@PPy-Ag powder.

[0052] 2) Preparation of L...

Embodiment 3

[0055] This example provides a method for preparing a polypyrrole / silver surface-modified layered clay-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

[0056] 1) Preparation of LDHs@PPy-Ag

[0057] Weigh 0.05g LDHs and disperse in 50mL deionized H 2 O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.075g AgNO3 and dissolve it in the LDHs dispersion, stir ultrasonically for 5min, then magnetically stir, adsorb for 30min, and heat up to 80°C. Then measure 0.375g Py into 50mL of deionized H 2 O, sonicate for 20 min until Py is completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred by magnetic force for 200 min, and the temperature was 80°C, and the reaction liquid began to gradually turn black. After the reaction was finished, it was centrifuged and washed five times, and then freeze-dried to obtain black LDHs@PPy-Ag powder.

[0058] 2) Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com