Application of ion liquid block polymer in supercritical carbon dioxide microcellular foaming

The technology of block polymer and diblock polymer is applied in the field of ionic liquid block polymer synthesis, which can solve the problems of unsatisfactory adsorption effect, low nucleation efficiency, and reduced foam material performance due to addition amount. To achieve the effect of easy control, enhanced solubility, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

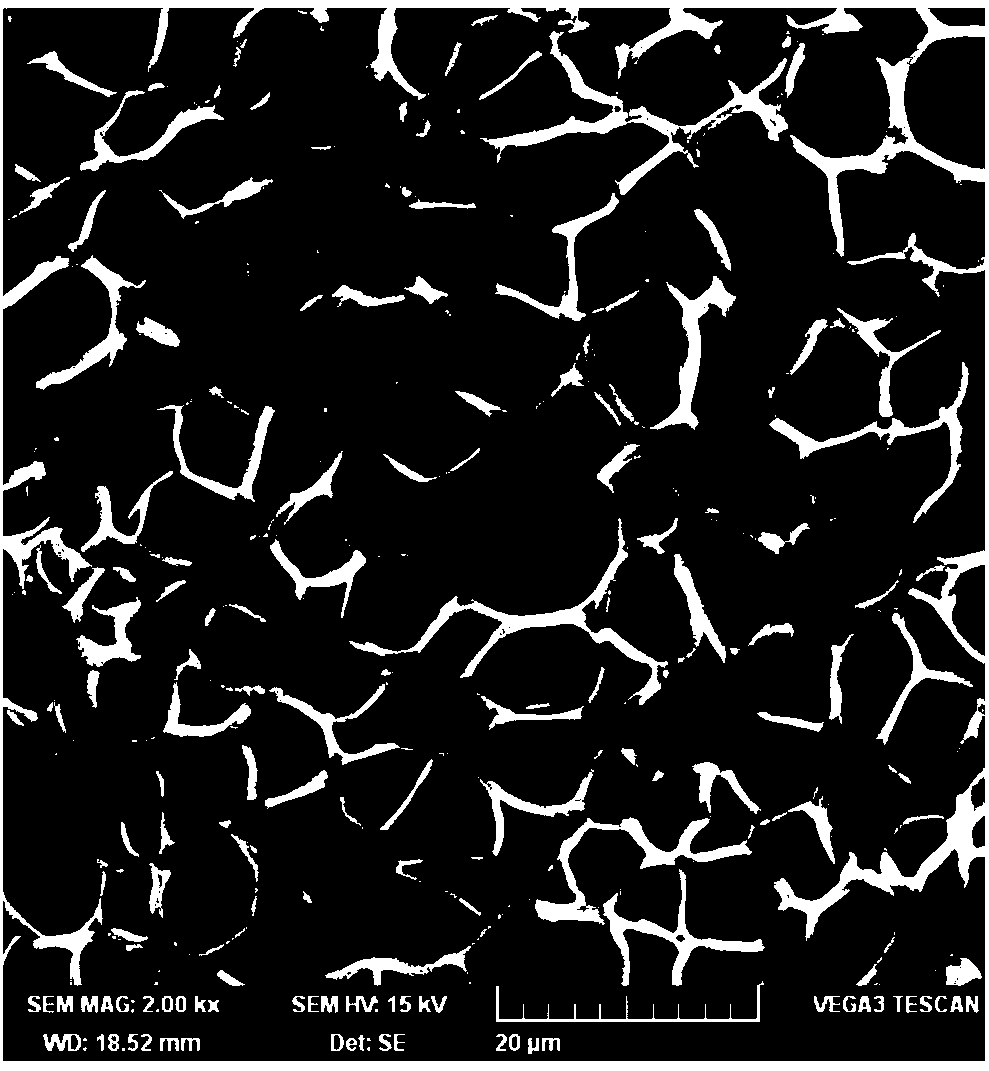

[0043] 0.1050 gram of cyanomethyl dodecyl trithiocarbonate (CTA), 3.9225 gram of styrene (ST), 0.01 gram of azobisisobutyronitrile (AIBN), and 6 gram of toluene were carried out under nitrogen protection for RAFT reaction, Stir the reaction at 80°C for 24 hours, then cool down to 0-5°C to terminate the reaction to synthesize PS-CTA. Add 4.6151 grams of p-chloromethylstyrene monomer (VBC) and 0.0041 grams of azobisisobutyronitrile (AIBN) in the reaction solution after the PS-CTA is synthesized, react under the same conditions for 24 hours, and then react the reactant Vacuum drying gave 5.5223 g of the block polymer PS-b-PVBCl of monomer I and monomer II.

[0044] Get 1.2 grams of PS-b-PVBCl and place it in a round-bottomed flask, add 8 milliliters of DMF and 0.5721 grams of methylimidazole, stir and react at 80°C for 24 hours, then drop to 20-25°C to prepare PS-b-PVBnMeImCl, and then Add 1.1 g of NaBF to the reaction solution 4 And continue to react for 24 hours, after the re...

Embodiment 2

[0047] Get 1.2 grams of PS-b-PVBCl and place it in a round-bottomed flask, add 8 milliliters of DMF and 0.8652 grams of butylimidazole, stir and react at 80°C for 24 hours, and then drop to normal temperature to prepare PS-b-PVBnButImCl, then add it to the reaction solution Add 2.5 g lithium bis(trifluoromethanesulfonyl)imide (LiNTF 2 ) and continued to react for 24 hours, after the reaction was finished, the reactant was poured into 80 milliliters of methanol to separate out the product, the resulting mixed solution was suction filtered, and the filter cake was vacuum-dried to obtain 1.9321 gram of PS-b-PVBnButImNTF 2 .

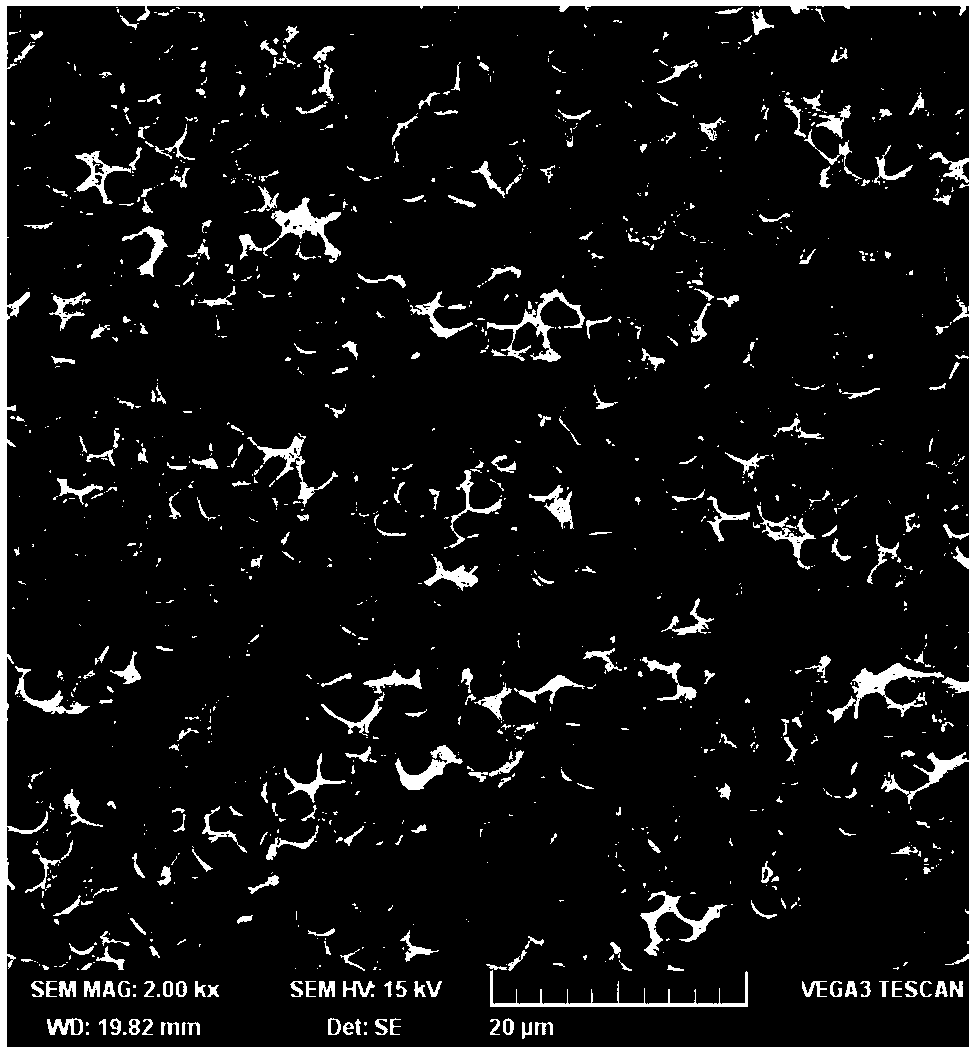

[0048] Take 0.3 g of PS-b-PVBnButImNTF 2 , 5.7 grams of GPPS, extruded with a micro-extruder at 200 ° C for sample preparation, put into an autoclave and sealed, and a small amount of CO 2 Purge for 2 minutes, heat the autoclave to 90 °C, and inject CO into the autoclave 2 , the control pressure is 13.8MPa. After being saturated at constant temperature a...

Embodiment 3

[0050] Get 1.2 grams of PS-b-PVBCl and place it in a round-bottomed flask, add 8 milliliters of DMF and 1.3227 grams of trimethylamine aqueous solution, stir and react at 80°C for 24 hours, then drop to normal temperature to prepare PS-b-[VBTMA]Cl, and then Add 1.2 g of NaBF to the reaction solution 4 And continue to react for 24 hours, after the reaction, the reactant is poured into 80 milliliters of methanol to separate out the product, the resulting mixed solution is suction filtered, and the filter cake is vacuum-dried to obtain 1.7222 grams of PS-b-[VBTMA][BF 4 ].

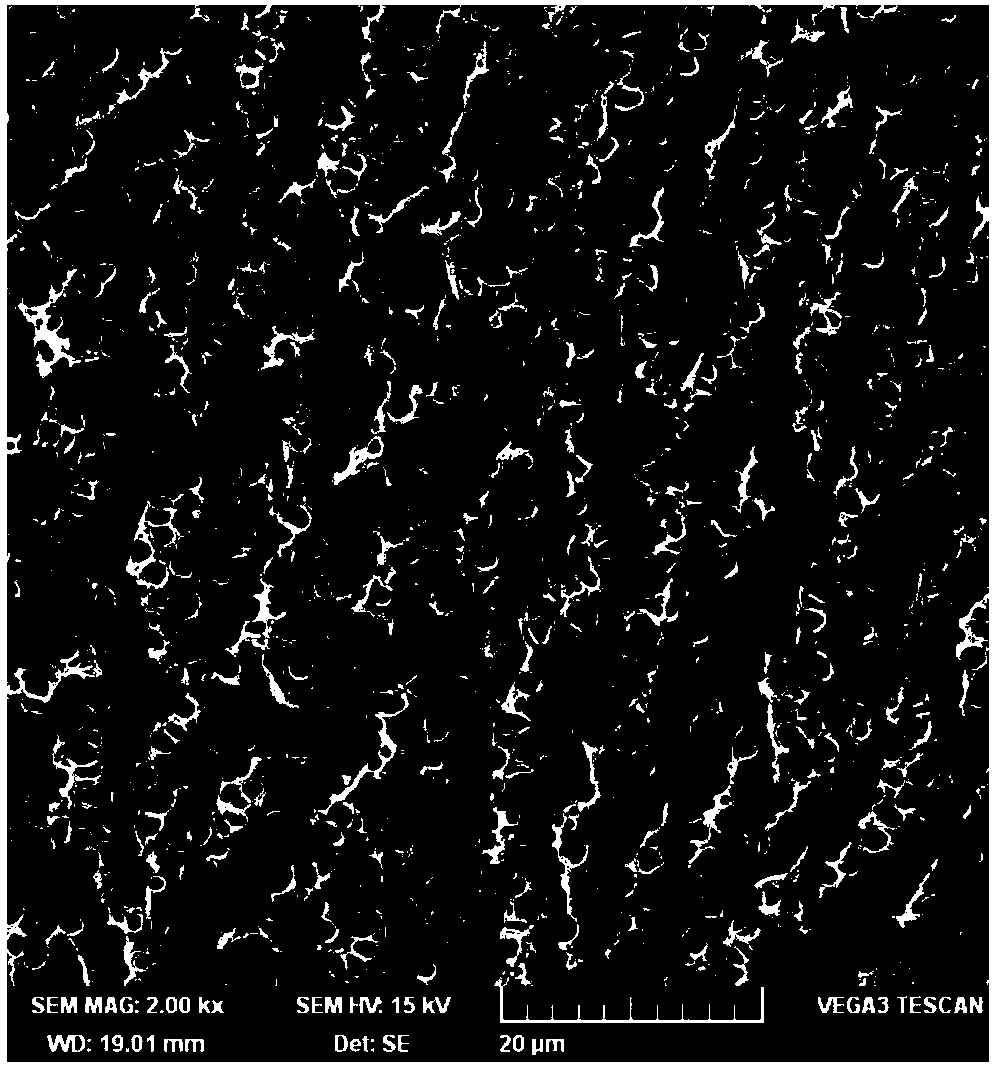

[0051] Take 0.3 g of PS-b-[VBTMA][BF 4 ], 5.7 grams of GPPS, extruded with a micro-extruder at 200 ° C for sample preparation, then packed into an autoclave and sealed, with a small amount of CO 2 Purge for 2 minutes, heat the autoclave to 90 °C, and inject CO into the autoclave 2 , the control pressure is 13.8MPa. After being saturated at constant temperature and pressure for 12 hours, release to atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com