Preparation method of modified polyester chip and polyester film

A technology for modifying polyester and slicing, applied in the field of polyester materials, can solve the problems of dispersibility, stability or compatibility of nucleating agents, can not meet the needs of high-end fields, fogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

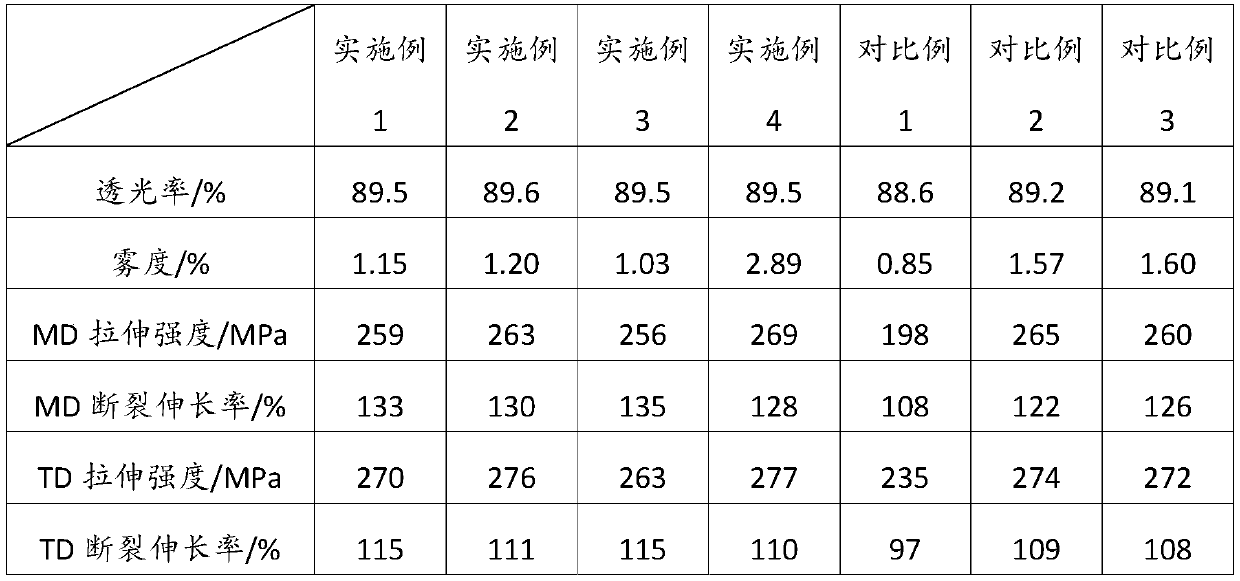

Examples

Embodiment 1

[0018] Disperse POSS-octahydroxypropyldimethylsilyl in ethylene glycol, ultrasonically disperse for 0.5h, and then mix with terephthalic acid, biphenyl dicarboxylic acid, 1,2-propylene glycol, zinc acetate, antimony glycol , the content of POSS-octahydroxypropyl dimethyl silyl is 0.8wt%, the molar ratio of terephthalic acid and biphenyl dicarboxylic acid is 15:1, and the molar ratio of zinc acetate and ethylene glycol antimony is 1:5 , the total molar weight of zinc acetate and ethylene glycol antimony is 0.08% of the total molar weight of terephthalic acid and biphenyl dicarboxylic acid, the molar ratio of ethylene glycol and 1,2-propanediol is 10:1, and the total alkyd molar The ratio is 2:1.

[0019] Heat the mixture of the above-mentioned components to 235°C until the water output reaches 95% of the theoretical value, vacuumize for the first time to a pressure of 0.03MPa, raise the temperature to 260°C, react at constant temperature and pressure for 2 hours, and then vacuu...

Embodiment 2

[0021] Disperse POSS-octahydroxypropyldimethylsilyl in ethylene glycol, ultrasonically disperse for 0.5h, and then mix with terephthalic acid, biphenyl dicarboxylic acid, 1,2-propylene glycol, zinc acetate, antimony glycol , the content of POSS-octahydroxypropyl dimethyl silyl group is 1wt%, the mol ratio of terephthalic acid and biphenyl dicarboxylic acid is 20:1, the mol ratio of zinc acetate, ethylene glycol antimony is 1:4, The total molar weight of zinc acetate and ethylene glycol antimony is 0.1% of the total molar weight of terephthalic acid and biphenyl dicarboxylic acid, the molar ratio of ethylene glycol and 1,2-propanediol is 12:1, and the total alkyd-acid molar ratio 1.8:1.

[0022] Heat the mixture of the above components to 240°C until the water output reaches 95% of the theoretical value, vacuumize for the first time until the pressure is 0.05MPa, raise the temperature to 265°C, react at constant temperature and pressure for 1.5h, and then vacuumize for the seco...

Embodiment 3

[0024] Compared with Example 1, the difference is that the content of POSS-octahydroxypropyldimethylsilyl is 0.5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com