A kind of recycled and toughened modified composition of waste polypropylene and its preparation method

A technology of toughening and modifying waste polypropylene, which is applied in the field of polymer materials, can solve the problems of not being suitable for making high-grade products and poor mechanical properties of recycled polypropylene, and achieve the effects of improving rigidity, toughness, and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

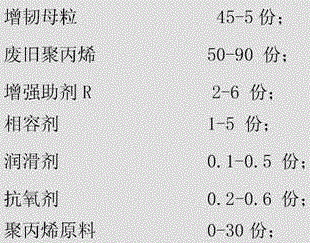

[0024] Step 1: Take each component by the following parts by weight:

[0025]

[0026] Put the above ingredients into a high-speed mixer and dry mix for 3 minutes. After mixing evenly, add them to a twin-screw extruder for extrusion. The temperature of the extruder is set at 210°C and the speed is 100r / min. After cooling in cold water, pelletize to obtain the mixture toughened masterbatch.

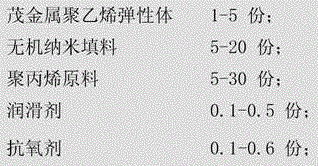

[0027] Step 2: Take each component by the following parts by weight:

[0028]

[0029] Put the prepared mixture into a high-speed mixer and dry mix for 3 minutes. After mixing evenly, add it to a twin-screw extruder for extrusion. The temperature of the extruder is set at 210°C and the speed is 100r / min. After the material is cooled by cold water, it is cut into pellets, and the preparation is completed. The mechanical properties parameters are shown in Table 1.

Embodiment example 2

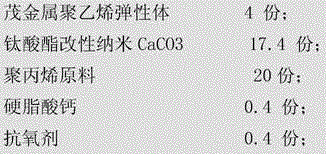

[0031] Step 1: Take each component by the following parts by weight:

[0032]

[0033]

[0034] Put the above ingredients into a high-speed mixer and dry mix for 3 minutes. After mixing evenly, add them to a twin-screw extruder for extrusion. The temperature of the extruder is set at 210°C and the speed is 100r / min. After cooling in cold water, pelletize to obtain the mixture toughened masterbatch.

[0035] Step 2: Take each component by the following parts by weight:

[0036]

[0037] Put the prepared mixture into a high-speed mixer and dry mix for 3 minutes. After mixing evenly, add it to a twin-screw extruder for extrusion. The temperature of the extruder is set at 210°C and the speed is 100r / min. After the material is cooled by cold water, it is cut into pellets, and the preparation is completed. The mechanical properties parameters are shown in Table 1.

[0038] Table 1 Experimental results

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com