Nano bentonite for plastic modification and preparation method thereof

A technology of nano-bentonite and bentonite, which is applied in the field of polymer material modification, can solve problems such as excessive surface energy of nano-powders, weak interfacial bonding, and poor material properties, so as to achieve favorable mechanical properties, mechanical properties, phase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

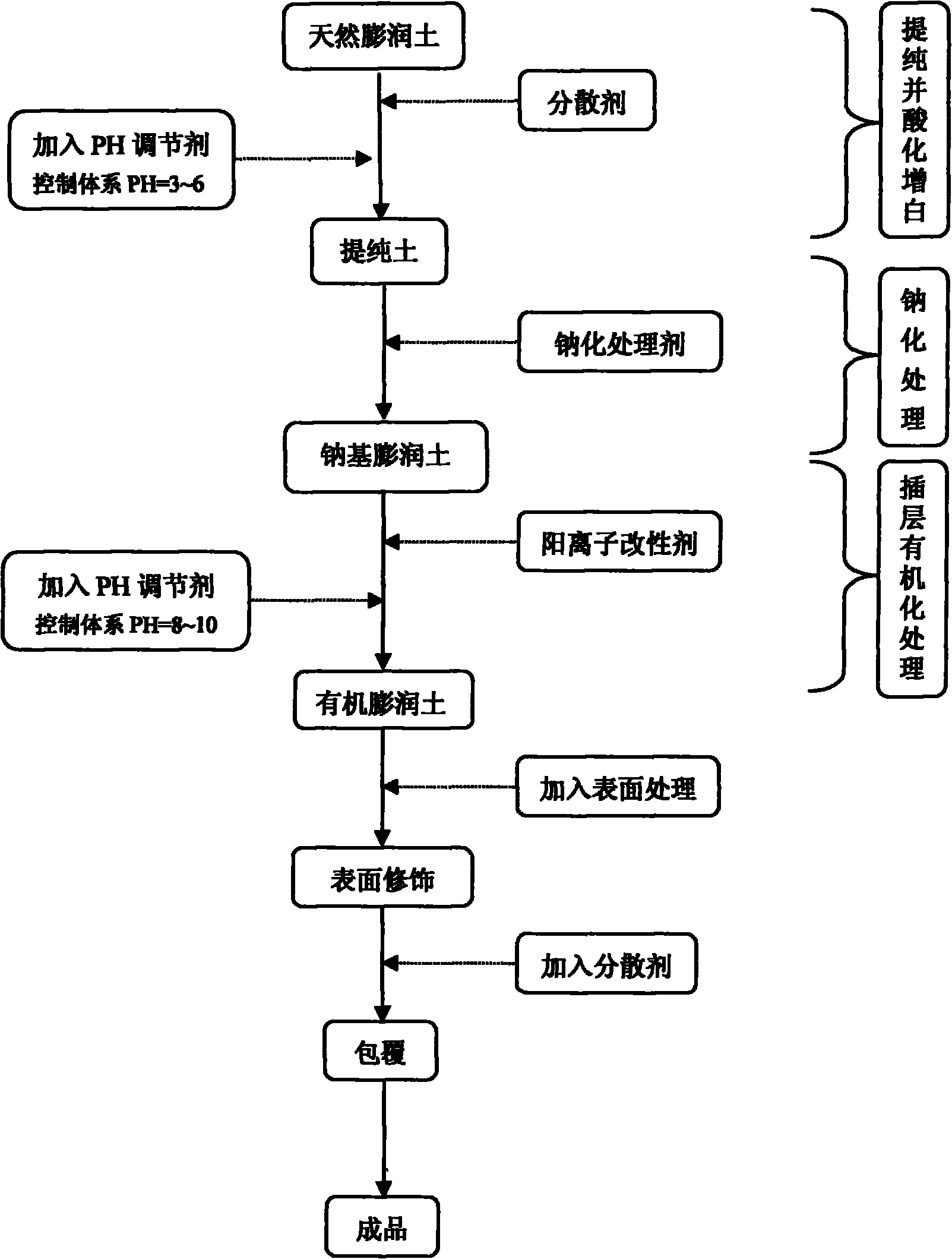

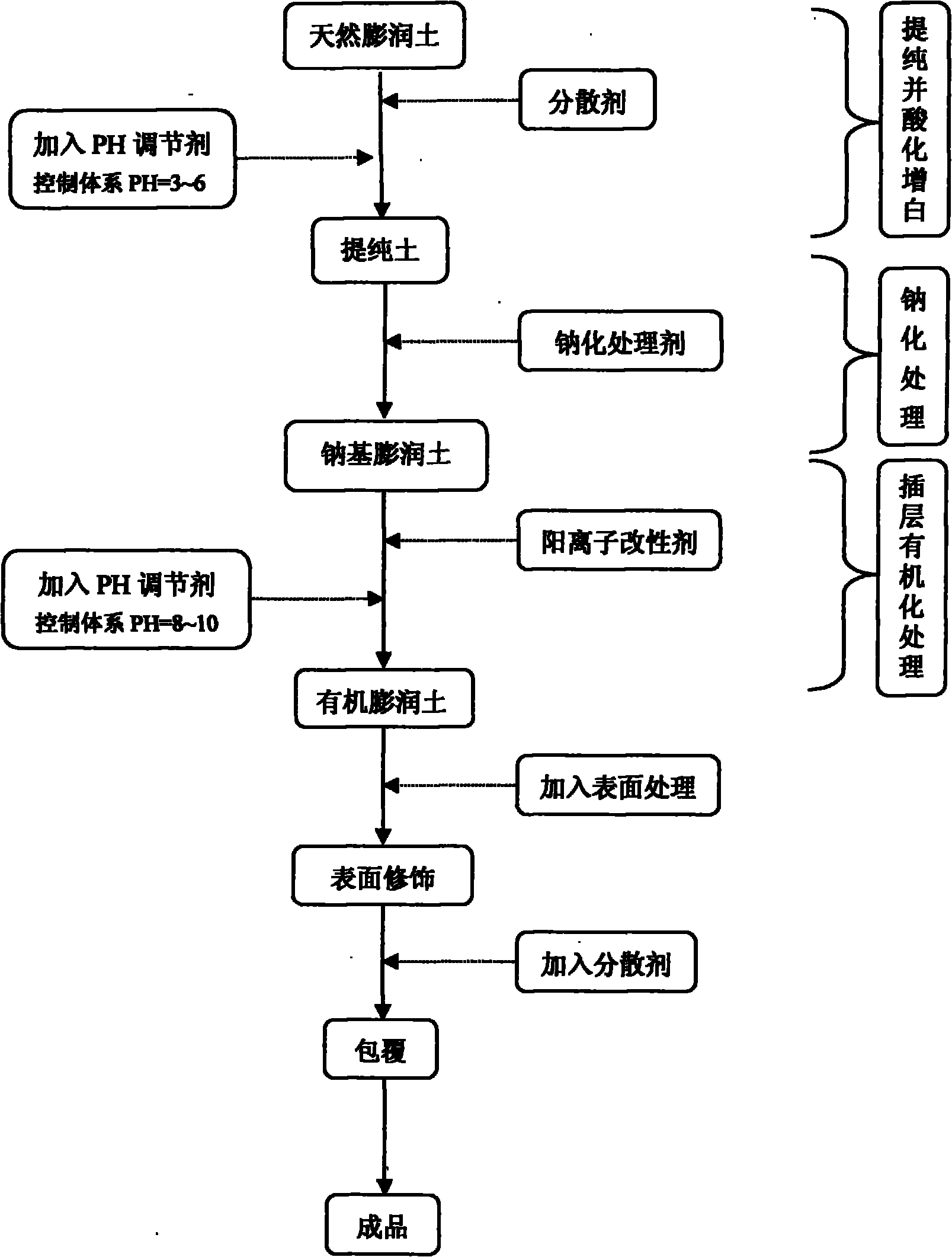

[0059] See attached figure 2 As shown, the preparation method is as follows:

[0060] (1) Purification and acidification whitening

[0061] Slowly place 100kg of natural bentonite in a container that has been added with 1000kg of water, stir at high speed for 1.5h, and let it stand for 6h to remove the coarse sand in the lower layer. Then add 3kg of sodium hexametaphosphate, add hydrochloric acid, control the pH of the system to be 6, after it is stirred at a high speed, further separate the detrital minerals (feldspar, carbonate, etc.) with finer particle size, and repeat the operation 2 times , to obtain bentonite slurry or suspension, which is dried and ground through a 1000-mesh sieve to obtain purified soil.

[0062] (2) Sodium treatment

[0063] Take by weighing 100kg the purified soil that above-mentioned step (1) makes, slowly pour in the container that fills 1000kg water, add the Na of 20kg 2 CO 3 , at a temperature of 70° C., reacted for 4 hours, and stirred at...

Embodiment 2

[0071] See attached figure 2 As shown, the preparation method is as follows:

[0072] (1) Purification and acidification whitening

[0073] Slowly place 100kg of natural bentonite in a container that has been added with 1000kg of water, stir at high speed for 2 hours, and let it stand for 8 hours to remove the coarse sand in the lower layer. Then add the sodium hexametaphosphate of 2.5kg, add hydrochloric acid, the pH value of control system is 5, after its high-speed stirring, further separate the detritus mineral (feldspar, carbonate etc.) with finer particle size, repeat operation 3 Once, the bentonite slurry or suspension is obtained, dried and ground through a 1000-mesh sieve to obtain purified soil.

[0074] (2) Sodium treatment

[0075] Take by weighing 100kg the purified soil that above-mentioned step (1) makes, slowly pour in the container that fills 1000kg water, add the Na of 25kg 2 SO 4 , at a temperature of 70° C., reacted for 5 hours, and stirred at a high ...

Embodiment 3

[0083] See attached figure 2 As shown, the preparation method is as follows:

[0084] (1) Purification and acidification whitening

[0085] Slowly place 100kg of natural bentonite in a container that has been added with 1000kg of water, stir at high speed for 2 hours, and let it stand for 8 hours to remove the coarse sand in the lower layer. Then add the sodium hexametaphosphate of 3.5kg, add nitric acid, the pH value of control system is 4, after its high-speed stirring, further separate the detritus mineral (feldspar, carbonate etc.) with finer particle size, repeat operation 4 Once, the bentonite slurry or suspension is obtained, dried and ground through a 1000-mesh sieve to obtain purified soil.

[0086] (2) Sodium treatment

[0087] Weigh 100kg of the purified soil prepared by the above step (1), slowly pour it into a container filled with 1000kg of water, add 35kg of sodium chloride, react at a temperature of 70°C for 5 hours, and stir at a high speed. The sodium-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com