Preparation method of PPy (polypyrrole)-PCL (polycaprolactone) antibacterial nanocomposite film

A technology of polycaprolactone and nanocomposite, which is applied in the field of polymer materials and active packaging applications, can solve the problems of surface coating and modification of LDHs that have not yet been retrieved, and achieve good interface compatibility, simple preparation method, and oxygen penetration The effect of sexual performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a polypyrrole-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

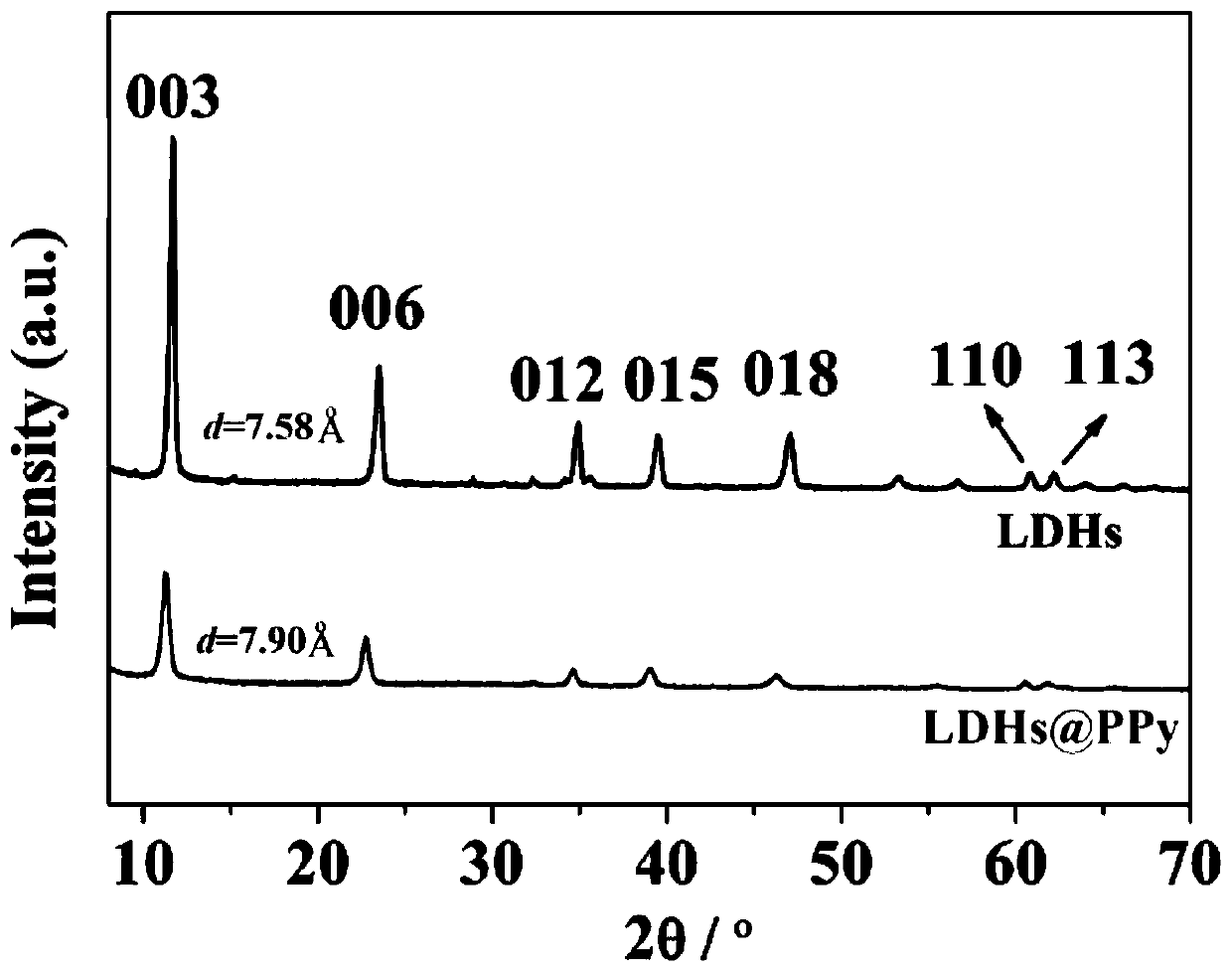

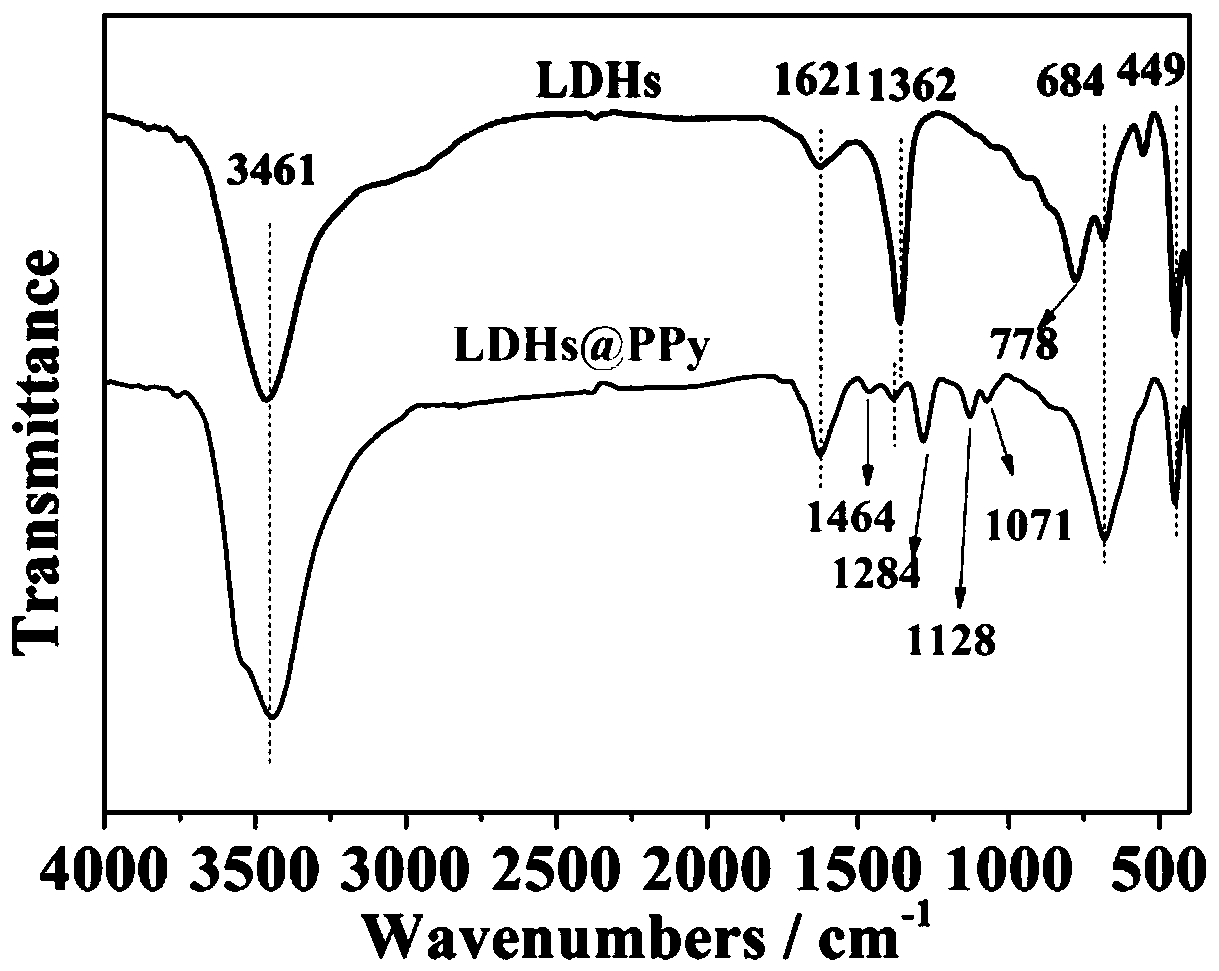

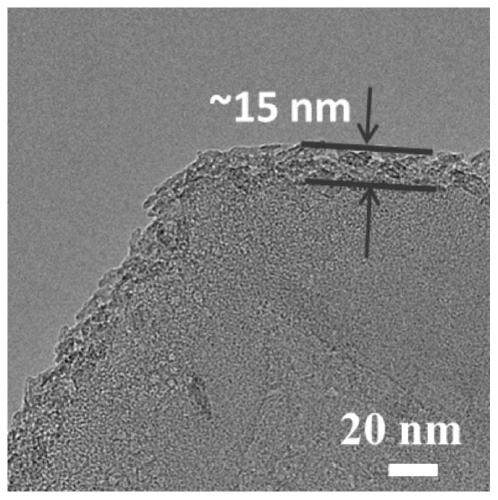

[0042] 1) Preparation of LDHs@PPy

[0043] Weigh 0.05g LDHs and disperse in 50mL deionized H 2 O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.22g FeCl 3 ·6H 2 O was dissolved in the LDHs dispersion, stirred ultrasonically for 5 min, followed by magnetic stirring, and adsorbed for 30 min. Then 1.0 g of Py was added to 50 mL of deionized H 2 In O, sonicate for 10 min until Py is completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred by magnetic force for 60 min, and the temperature was 25°C. The reaction liquid began to gradually turn black. After the reaction, three times of centrifugation and washing, lyophilization to obtain black LDHs@PPy powder.

[0044] 2) Preparation of LDHs@PPy / PCL composite film

[0045] Dissolve 0.01...

Embodiment 2

[0048] This embodiment provides a method for preparing a polypyrrole-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

[0049] 1) Preparation of LDHs@PPy

[0050] Weigh 0.05g LDHs and disperse in 50mL deionized H 2 O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.40g FeCl 3 ·6H 2 O was dissolved in the LDHs dispersion, stirred ultrasonically for 10 min, followed by magnetic stirring, and adsorbed for 40 min. Then 0.16 g of Py was added to 50 mL of deionized H 2 O, sonicate for 20 min until Py is completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred by magnetic force for 150 min, and the temperature was 20°C. The reaction liquid began to gradually turn black. After the reaction, the black LDHs@PPy powder was obtained by centrifuging and washing for 5 times, and freeze-drying.

[0051] 2) Preparation of LDHs@PPy / PCL composite film

[0052] Disso...

Embodiment 3

[0054] This embodiment provides a method for preparing a polypyrrole-polycaprolactone antibacterial nanocomposite film, which is prepared according to the following steps.

[0055] 1) Preparation of LDHs@PPy

[0056] Weigh 0.05g LDHs and disperse in 50mL deionized H 2 O, ultrasonic stirring for 30min to obtain 0.5g / L LDHs dispersion. Then weigh 0.08g FeCl 3 ·6H 2 O was dissolved in the LDHs dispersion, stirred ultrasonically for 5 min, followed by magnetic stirring, and adsorbed for 20 min. Then 0.80 g of Py was added to 50 mL of deionized H 2 O, magnetically stirred for 20 min until Py was completely dissolved. Finally, the Py aqueous solution was added to the LDHs dispersion, stirred ultrasonically for 50 minutes at a temperature of 30°C, and the reaction solution began to gradually turn black. After the reaction was completed, it was washed by centrifugation four times and freeze-dried to obtain black LDHs@PPy powder.

[0057] 2) Preparation of LDHs@PPy / PCL composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com