A kind of preparation method of polylactic acid composite material and product

A composite material, polylactic acid technology, applied in coatings and other directions, can solve problems such as poor heat resistance and mechanical properties, complex product production steps, etc., to improve heat resistance and mechanical properties, improve molding quality and molding efficiency, The effect of easy molding and demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

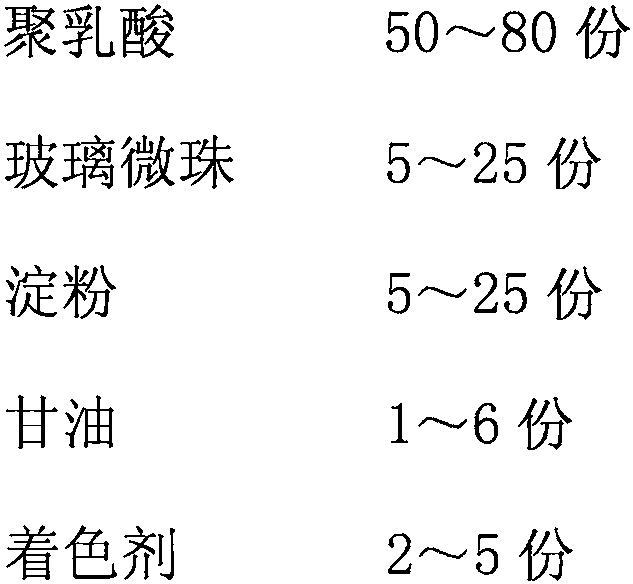

[0043] This embodiment provides a polylactic acid composite material, which includes the following components in parts by weight:

[0044]

[0045] Such as figure 1 As shown, the preparation method of the polylactic acid composite product provided in this embodiment includes the following steps:

[0046] S1. Add polylactic acid, starch, glass microspheres, glycerin, colorants and antioxidants into a stirred tank at a temperature of 80°C, and stir for 0.5h until they are evenly mixed. Then the temperature in the stirred tank was kept at 80° C., and the mixed product was dried in the stirred tank for 4 hours.

[0047] S2. Put the product obtained in step S1 into an extruder for extrusion and granulation. The temperature of the five temperature zones from the feed end to the discharge end of the extruder is 160°C, 180°C, 180°C, 180°C, and 180°C. The screw speed is 50r / min, and the feeding speed is 3r / min. Then the granules obtained by granulation were dried, the drying tem...

Embodiment 2

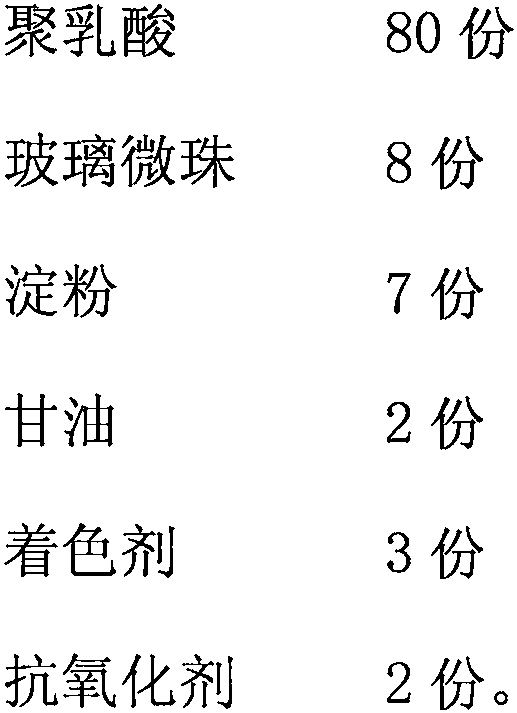

[0050] The difference between this embodiment and the first embodiment lies in that the parts by weight of the components in the polylactic acid composite material are different. Specifically, the polylactic acid composite material provided in this embodiment includes the following components in parts by weight:

[0051]

[0052] The preparation method of the polylactic acid composite product provided in this example is the same as that in Example 1, and the polylactic acid composite product is prepared.

Embodiment 3

[0054] Likewise, the difference between this embodiment and the first embodiment lies in that the parts by weight of the components in the polylactic acid composite material are different. Specifically, the polylactic acid composite material provided in this embodiment includes the following components in parts by weight:

[0055]

[0056] The preparation method of the polylactic acid composite product provided in this example is the same as that in Example 1, and the polylactic acid composite product is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com