High-brightness black composite nylon material as well as preparation method and application thereof

A nylon and polyamide technology, applied in the field of high-gloss black composite nylon material and its preparation, can solve the problems of increased density of high-gloss black nylon, high price of transparent nylon material, influence of blackness, etc., to reduce the crystallinity, improve the Transparency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

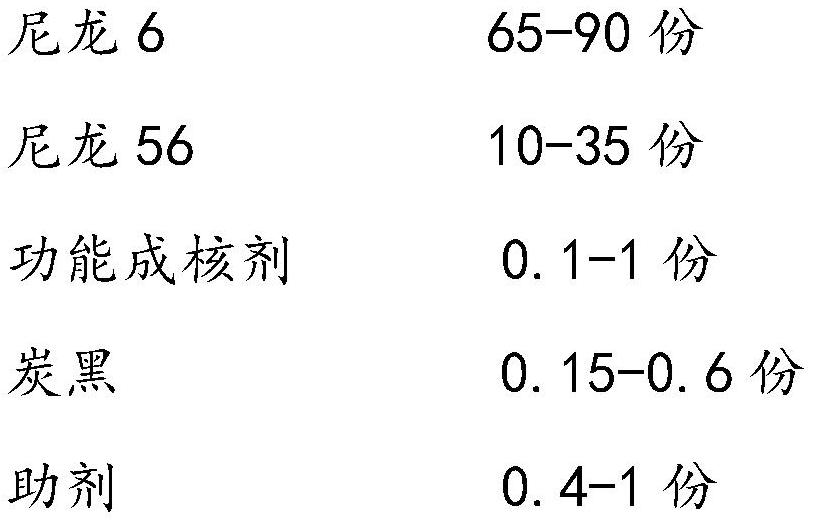

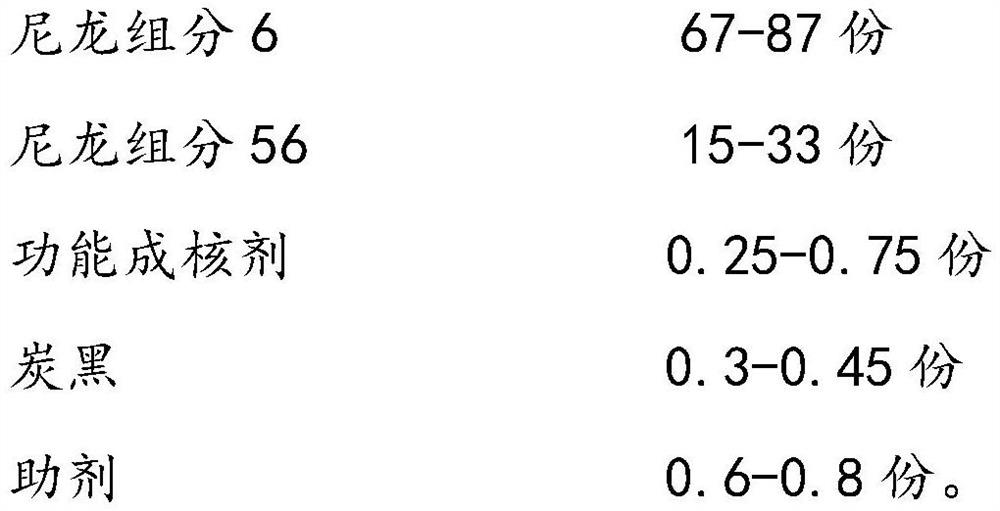

Method used

Image

Examples

Embodiment 11

[0072] The high-brightness black composite nylon material of Example 3 is used to make a sample plate, and the performance test is carried out. The results are: the blackness value is 24, the appearance has no pitting, and the linear wear resistance is 88%. It can be shown that the high-gloss black composite nylon material provided by the present invention can be suitable for preparing vehicle exterior parts with high requirements on appearance and wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com