A heat-resistant and impact-resistant polylactic acid composite material and its preparation method and application

A composite material, polylactic acid technology, applied in the field of heat-resistant and shock-resistant polylactic acid composite material and its preparation, heat-resistant and shock-resistant PLA/PBAT/nano calcium carbonate composite material and its preparation field, can solve the lack of pertinence, trichloride The problems of high toxicity of methane and high surface energy can achieve the effect of good fracture strain rate and impact toughness, excellent mechanical properties and impact resistance, good flexibility and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another aspect of the embodiment of the present invention also provides the preparation method of the aforementioned heat-resistant and impact-resistant polylactic acid composite material, which includes: polylactic acid, polybutylene terephthalate / adipate, compatibilizer, active The nano-calcium carbonate and the antioxidant are banburyed, and then the obtained mixed material is fed into a twin-screw extruder for melt blending to obtain a heat-resistant and impact-resistant polylactic acid composite material.

[0030] In some more specific embodiments, the preparation method specifically includes:

[0031] Mix polylactic acid, polybutylene terephthalate / adipate, compatibilizer, active nano-calcium carbonate and antioxidant at a speed of 30-70rpm and a temperature of 130-180°C for 10 minutes. obtain the mixture;

[0032] And, the mixed material is added to a twin-screw extruder, and melted and blended under the conditions of a host speed of 100-200rpm and a temperature...

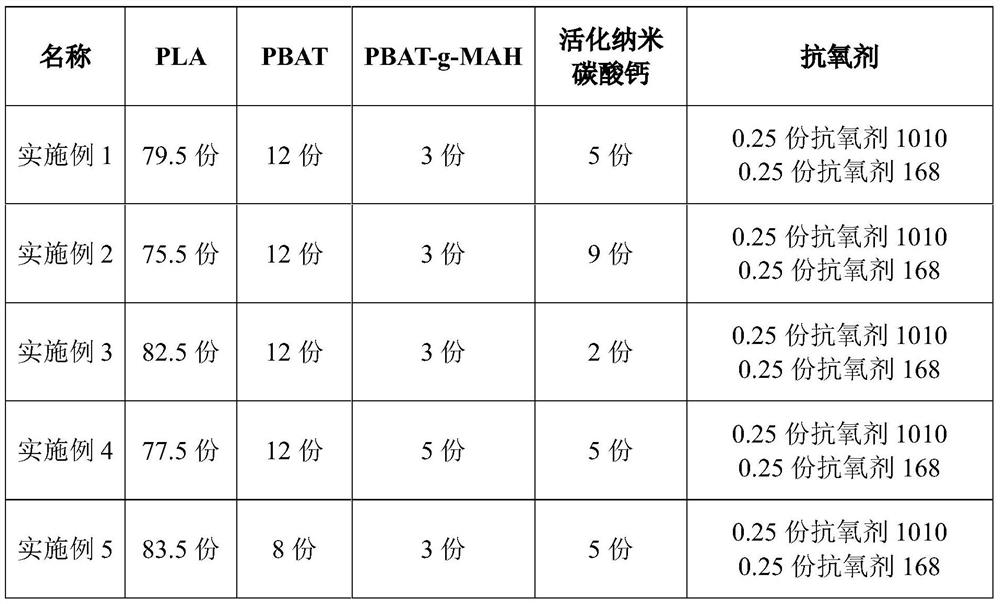

Embodiment 1

[0083] (1) Dry PLA, PBAT, PBAT-g-MAH, and activated nano-calcium carbonate at 75°C for 4 hours;

[0084] (2) Mix 79.5 parts of dried PLA, 12 parts of PBAT, 12 parts of PBAT-g-MAH, 12 parts of activated nano-calcium carbonate, and antioxidant with an internal mixer for 10 minutes, with a speed of 50 rpm and a temperature setting of 160 °C;

[0085](3) Lead the colloid obtained from banburying into the hopper of the twin-screw extruder, force feed it, and send it to the twin-screw for melt blending and extrusion. The extrusion temperature is set at 130°C-165°C, and the speed of the main machine is 100rpm -200rpm;

[0086] (4) pulling strips, cooling, pelletizing;

[0087] (5) Use an oven to dry the particles at a temperature of 80°C and a drying time of 4 hours. The injection molding sample test is (heat-resistant and impact-resistant polylactic acid composite material). The specific dosage of each component in the composite material is shown in Table 1. The composite material ...

Embodiment 2

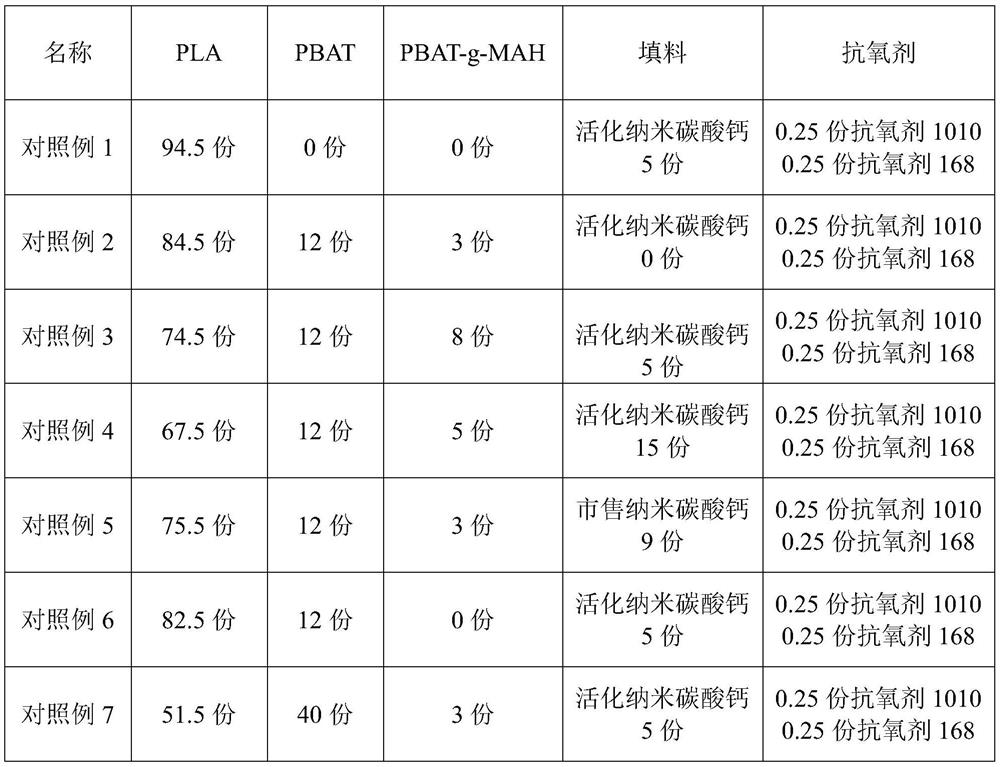

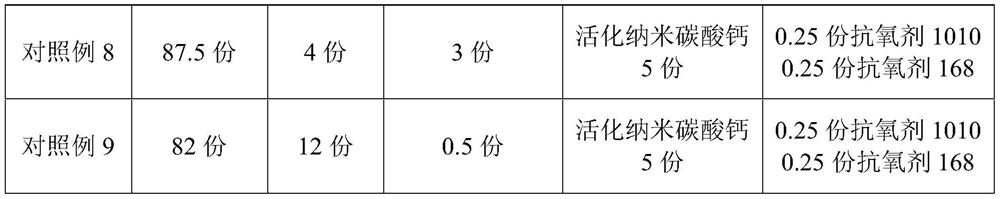

[0089] The method is the same as in Example 1, except that the amounts of PLA, PBAT, PBAT-g-MAH, activated nano-calcium carbonate, and antioxidants are different. The specific amounts are shown in Table 1, and the test properties of the composite materials are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com