Talcum powder-polyester composite material and preparation method thereof

A technology of polyester composite material and talc powder, which is applied in the field of talc powder-polyester composite material and its preparation, can solve the problems of poor dimensional stability, low crystallization rate, and low thermal deformation temperature of PET, so as to improve thermal performance and improve Crystallization performance, effect of improving surface affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

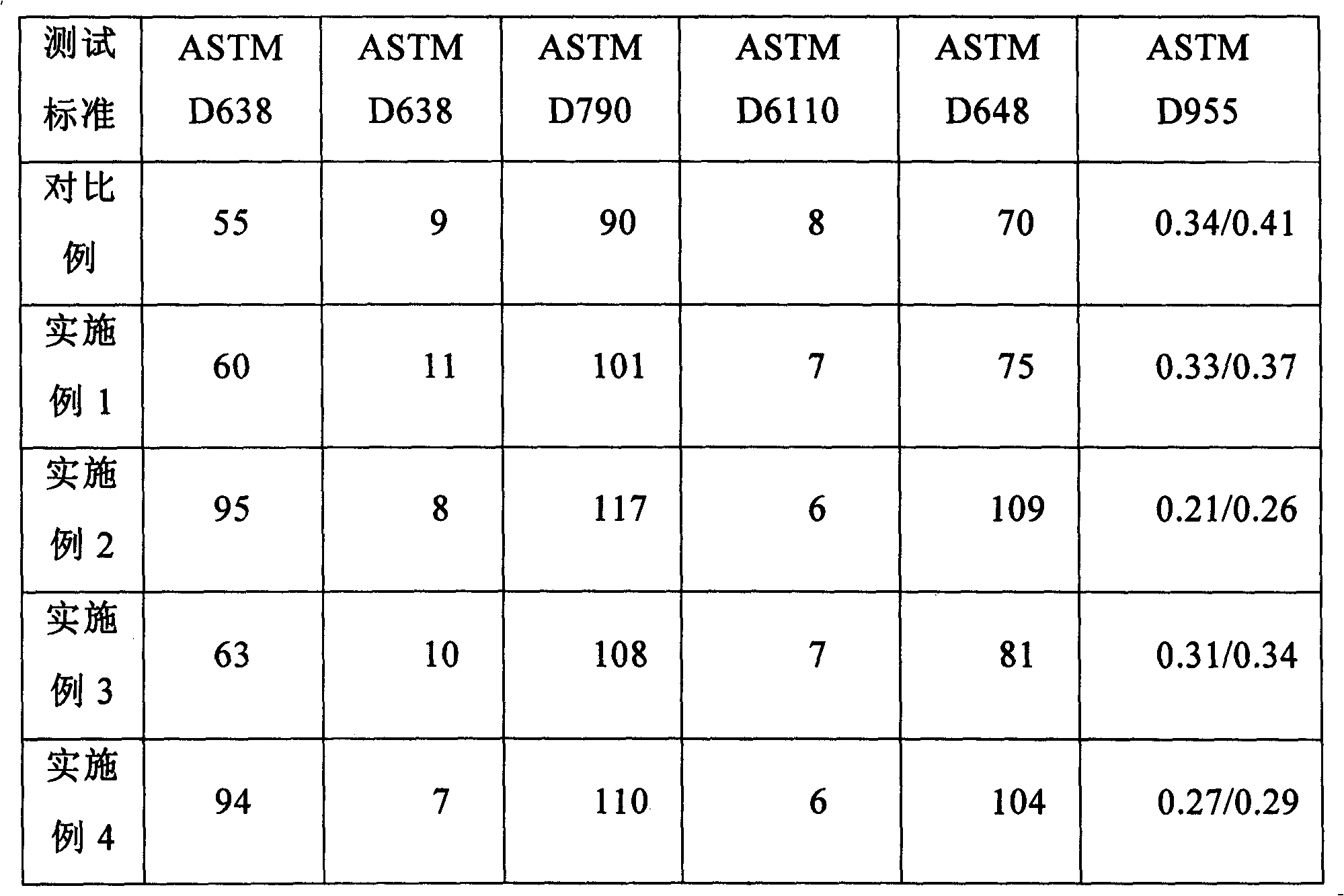

[0023] Take a solution prepared with 0.2g of coupling agent vinyltriethoxysilane, 5g of ethylene glycol, and 1g of water, adjust the pH value to 6 with oxalic acid, hydrolyze for 1 hour, and blend with 200g of talc powder passing through a 1250 mesh sieve for 5min. The talcum powder activated by the coupling agent is obtained for subsequent use. Take 41.9g of activated talcum powder, add PTA290g, EG129g, catalyst antimony acetate 0.13g, mix and stir. After pumping water until the water content is less than 1%, start to raise the temperature to 70°C to carry out the esterification reaction. After esterification at 220-240°C for 8 hours under normal pressure, add 0.01g of diisopropylamine as an additive, evacuate until the vacuum degree is below 80Pa, and polymerize at 240°C for 3 hours to obtain the desired PET / talc powder composites. The properties of the obtained composite materials are shown in Table 1.

Embodiment 2

[0025] Take 0.2g coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 5g ethylene glycol, 1g water configuration solution, adjust the pH value to 6 with oxalic acid, hydrolyze for 1 hour, and 200g of talcum powder with a particle size of 10000 mesh was blended for 5 minutes to obtain talcum powder activated by a coupling agent, which was set aside. Take 16g of activated talcum powder, add PTA290g, EG129g, catalyst antimony acetate 0.13g, mix and stir. After pumping water until the water content is less than 1%, start to raise the temperature to 90°C to carry out the esterification reaction. After esterification at 220-240°C for 8 hours under normal pressure, add 0.01g of diisopropylamine as an additive, vacuumize until the vacuum degree is below 80Pa, and polymerize at 250°C for 3 hours to obtain the required PET / talcum powder composite material. The properties of the obtained composite materials are shown in Table 1.

Embodiment 3

[0034] Take 1g coupling agent N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 10g ethylene glycol, 0.1g water configuration solution, adjust the pH value to 6 with hydrochloric acid, hydrolyze for 1 hour, and 30g of talcum powder with a particle size of 3000 mesh was blended for 5 minutes to obtain activated talcum powder activated by a coupling agent, which was set aside. Take 0.27g of activated talcum powder, add PTA210g, EG60g, catalyst antimony acetate 0.01g, mix and stir. After pumping water until the water content is less than 1%, start to raise the temperature to 80°C to carry out the esterification reaction. After esterification at 220°C for 6 hours under normal pressure, add 0.01g of diisopropylamine as an additive, vacuumize until the vacuum degree is below 80Pa, and polymerize at 260°C for 3 hours to obtain the required PET / talc powder compound Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com