High-toughness and high-heatproof glass fiber reinforced PBT (Polybutylece Terephthalate) composite material and preparation method thereof

A composite material, high heat-resistant technology, applied in the field of high heat-resistant glass fiber reinforced PBT composite material and its preparation, high toughness, can solve the problem of high cost, complex alloy material processing, material mechanical properties and thermal properties need to be further improved, etc. problem, to achieve the effect of improving thermal performance, improving toughness and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

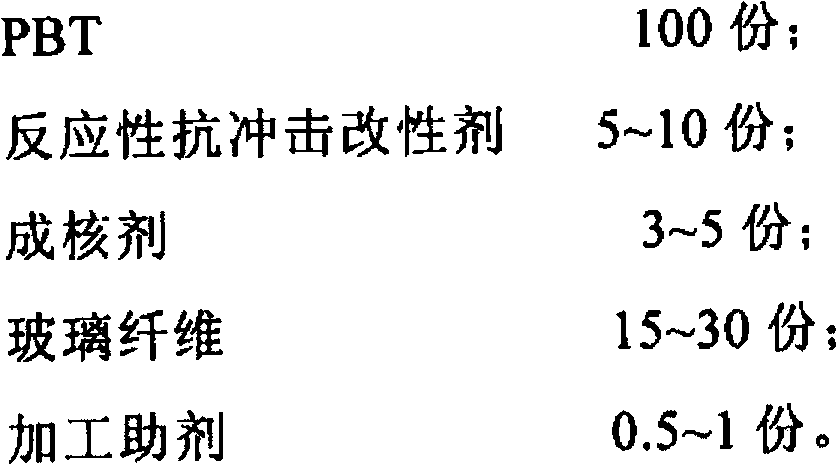

[0025] A high-toughness, high-heat-resistant glass fiber reinforced PBT composite material is made of the following components and raw materials in parts by weight:

[0026]

[0027] Among them, the intrinsic viscosity of PBT is 0.9 dL / g.

[0028] The reactive impact modifier is a composite of the toughening agent EPDM-g-GMA with reactive groups and the PBT tackifier pyromellitic dianhydride, and the composite weight ratio is 3:2. The introduction of the toughening agent EPDM-g-GMA with reactive groups increases the binding ability of EPDM-g-GMA to the matrix on the one hand, and improves the dispersion of EPDM-g-GMA in the matrix on the other hand. Pyrellitic dianhydride improves the toughness of the material from the molecular weight level, and the impact performance of the material is greatly improved through the combination of the two.

[0029] The nucleating agent is talc powder, and the molecular chain of PBT is flexible, so the low-temperature growth ability of the ...

Embodiment 2

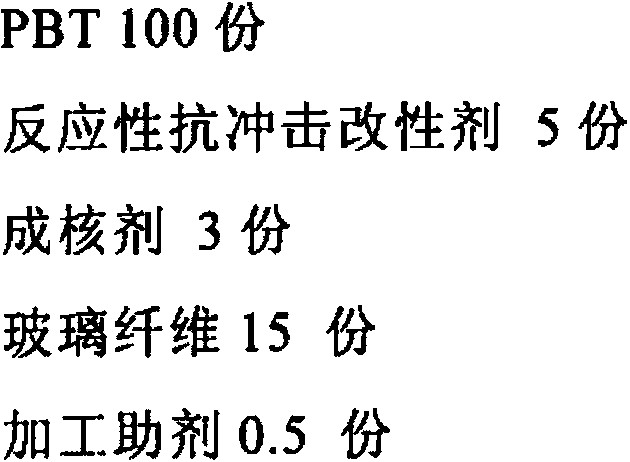

[0036] A high toughness, high heat-resistant glass fiber reinforced PBT composite material, the composite material is made of the following components and raw materials in parts by weight:

[0037]

[0038] The intrinsic viscosity of PBT is 1.05dL / g.

[0039] The reactive impact modifier is a compound of a toughening agent LLDPE-g-MAH with a reactive group and a PBT tackifier bisoxazoline-based benzene, and the composite weight ratio is 4:1. The introduction of the toughening agent LLDPE-g-MAH with reactive groups increases the binding ability of LLDPE-g-MAH and the matrix on the one hand, and improves the dispersion of LLDPE-g-MAH in the matrix on the other hand. Oxazoline-based benzene improves the toughness of the material from the molecular weight level, and the impact performance of the material is greatly improved through the combination of the two.

[0040] The nucleating agent is calcium carbonate, and the molecular chain of PBT is flexible, so the low-temperature ...

Embodiment 3

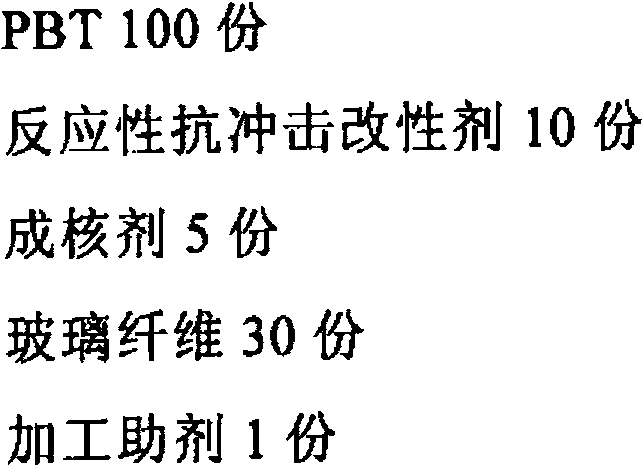

[0047] A high toughness, high heat-resistant glass fiber reinforced PBT composite material, the composite material is made of the following components and raw materials in parts by weight:

[0048]

[0049] The intrinsic viscosity of PBT is 1.0dL / g.

[0050] The reactive impact modifier is a composite of the toughening agent POE-g-MAH with reactive groups and the PBT tackifier pyromellitic dianhydride, and the composite weight ratio is 3:1. The introduction of POE-g-MAH, a toughening agent with reactive groups, increases the binding ability of POE-g-MAH to the matrix on the one hand, and improves the dispersion of POE-g-MAH in the matrix on the other hand. Pyrellitic dianhydride improves the toughness of the material from the molecular weight level, and the impact performance of the material is greatly improved through the combination of the two.

[0051] The nucleating agent is nano-montmorillonite, and the molecular chain of PBT is flexible, so the low-temperature growth a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com