Polypropylene modified master batch and low-residual solvent polypropylene flexible package thin film

A low solvent residue, polypropylene technology, applied in the field of packaging film, can solve the problems of excessive organic solvent residue value, easy solvent residue value, difficulty in organic solvent diffusion, etc., to reduce solubility, reduce free volume, and reduce amorphous The effect of the area ratio

Inactive Publication Date: 2013-03-13

BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Also as a printing substrate, polyethylene terephthalate (BOPET) film is much less absorbent to organic solvents than BOPP, that is to say, the solvent residue value of BOPP film after printing is particularly easy to exceed the standard

One of the reasons is that the crystallinity of BOPET is high, the diffusion of organic solvents in the film is difficult, and it is easy to be removed in the drying tunnel, while the crystallinity of BOPP is lower than that of BOPET, and the proportion of amorphous regions in the material is larger, causing organic solvents to be adsorbed , High solubility and high diffusion coefficient, the organic solvent can easily diffuse into the depth of the BOPP film, and it is difficult to desorb even in the drying tunnel, making the residual value of the organic solvent exceed the standard

In order to reduce the residue of organic solvents in polypropylene films, we disclo

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

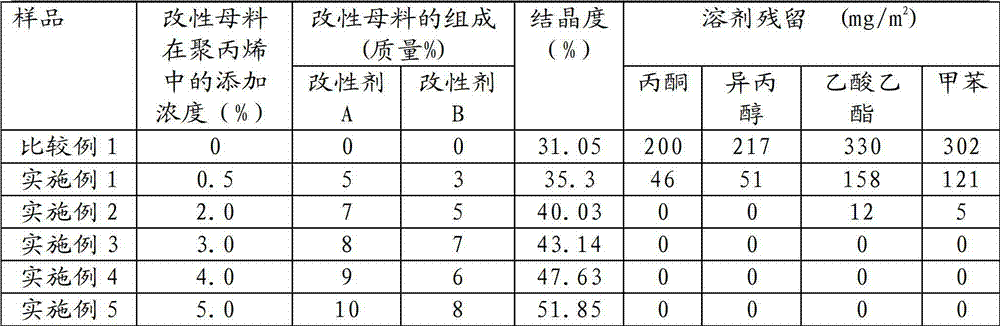

The invention provides a low-residual solvent polypropylene flexible package thin film and a preparation technology of the low-residual solvent polypropylene flexible package thin film, belonging to the technical field of package thin films. Polypropylene modified master batch comprises SiO2/EVA (ethylvinylacetate) auxiliaries, PP (propene polymer)-g-GMA (glycidyl methacrylate)/PS (poly styrene) and polypropylene. The preparation technology comprises the following steps of: mechanically mixing; and carrying out melt blending by a twin-screw extruder at 160-225 DEG C. The acrylic resin and the polypropylene modified master batch are jointly blown into the low-residual solvent polypropylene flexible package thin film. According to the thin film provided by the invention, the residual value of the weak-polarity solvent, i.e. the toluene, the ethyl acetate and the like, in printed BOPP (biaxially-oriented polypropylene) can be reduced, and the residual value to the high-polarity solvent, i.e. ketone, alcohol and the like, can be greatly reduced as well.

Description

technical field [0001] The invention provides a low-solvent residual polypropylene flexible packaging film and a processing masterbatch of polypropylene for food packaging; the crystallization performance of the polypropylene flexible packaging film prepared by using the polypropylene modified masterbatch provided by the invention is greatly improved, and the improved The absorptivity of common organic solvents such as toluene and ethyl acetate to the polypropylene film after printing is greatly reduced, and the residual value of the organic solvent of the printed polypropylene film is greatly reduced, which belongs to the technical field of packaging film. Background technique [0002] Polypropylene (PP) film is widely used in flexible packaging. Biaxially oriented polypropylene (BOPP) can be used as a printing film, while heat-sealable CPP is mainly used as a food contact layer. [0003] Also as a printing substrate, polyethylene terephthalate (BOPET) film is much less abs...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/08C08L51/06C08K3/36C08K5/098C08K5/134C08J3/22B65D65/00

Inventor 李东立许文才付亚波齐英群曹国荣刘全校

Owner BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com