A kind of high β crystal polypropene material and preparation method thereof

A technology of polypropylene material and β crystal form, which is applied in the field of high β crystal form polypropylene material and its preparation, can solve problems such as cracks, material damage, difficulty in obtaining, etc., achieve excellent mechanical properties, improve application fields, and increase crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

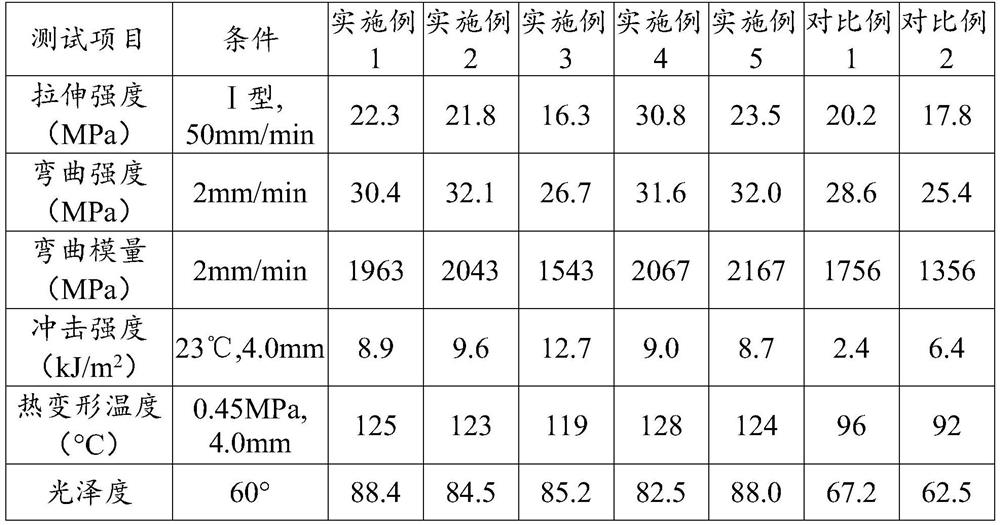

Examples

Embodiment 1

[0023] The preparation method of high β crystal polypropylene material:

[0024] (1) Accurately weigh 98.47kg of homopolypropylene, 0.03kg of N,N′-dicyclohexyl-1,5-diamino-2,6-naphthalene dicarboxamide, (3-aminopropyl)dimethyl Ethoxysilane 0.5kg, hindered phenolic antioxidant 10100.4kg, metal soap 0.6kg;

[0025] (2) Add polypropylene, β-type nucleating agent, (3-aminopropyl) dimethylethoxysilane, heat stabilizer, and processing aid to the high-mixer at 400-1000r / min, 23°C Down, stir 8min to obtain mixture;

[0026] (3) Put the mixture obtained in step (2) into a twin-screw extruder with an aspect ratio of 38:1 to melt, mix and disperse, extrude and granulate to obtain a high-β crystal polypropylene material.

Embodiment 2

[0028] The preparation method of high β crystal polypropylene material:

[0029] (1) Accurately weigh 98.46 kg of homopolypropylene, 0.04 kg of 2,6-phthalic acid cyclohexylamide, 0.8 kg of (3-aminopropyl) dimethylethoxysilane, and 10760.1 kg of hindered phenolic antioxidant kg, phosphite antioxidant Irgafos 1680.1kg, thioester antioxidant DSTDP 0.1kg, amide lubricant erucamide 0.4kg;

[0030] (2) Add polypropylene, β-type nucleating agent, (3-aminopropyl) dimethylethoxysilane, heat stabilizer, and processing aids into the high mixer at 400-1000r / min, 40°C Down, stir 7min to obtain mixture;

[0031] (3) Put the mixture obtained in step (2) into a twin-screw extruder with an aspect ratio of 38:1 to melt, mix and disperse, extrude and granulate to obtain a high-β crystal polypropylene material.

Embodiment 3

[0033] The preparation method of high β crystal polypropylene material:

[0034] (1) Accurately weigh 98.07kg of polypropylene copolymer, 50.03kg of TMB-50.03kg, 0.6kg of (3-aminopropyl) dimethylethoxysilane, 3300.2kg of hindered phenolic antioxidant, and phosphite antioxidant Irgafos P-EPQ 0.3kg, metal soap lubricant calcium stearate 0.8kg;

[0035] (2) Add polypropylene, β-type nucleating agent, (3-aminopropyl) dimethylethoxysilane, heat stabilizer, and processing aid to the high-mixer at 400-1000r / min, 35°C Down, stir 6min to obtain mixture;

[0036] (3) Put the mixture obtained in step (2) into a twin-screw extruder with an aspect ratio of 42:1 to melt, mix and disperse, extrude and granulate to obtain a high-β crystal polypropylene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com