Natural fiber-reinforced polylactic acid resin composition and molded product made using the same

A technology of polylactic acid resin and natural fiber, which is applied in the field of natural fiber reinforced polylactic acid resin composition and its molded products, can solve the problem of insufficient bonding between natural fiber and polylactic acid, failure to provide performance, and biomass reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

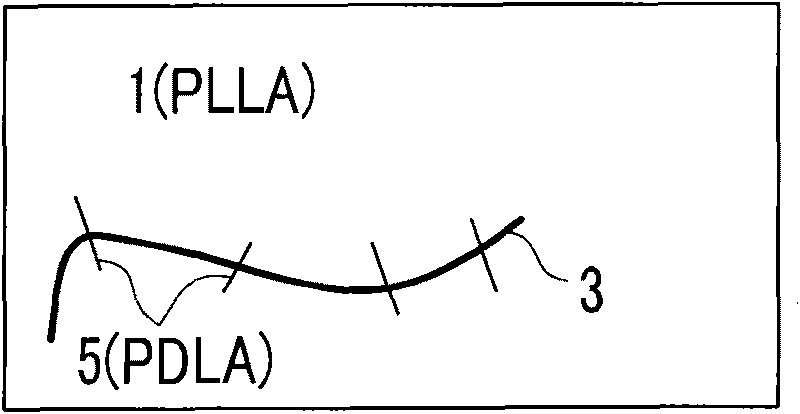

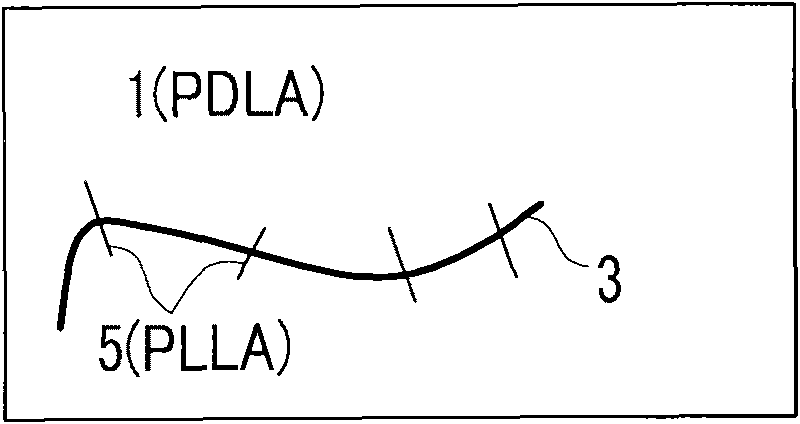

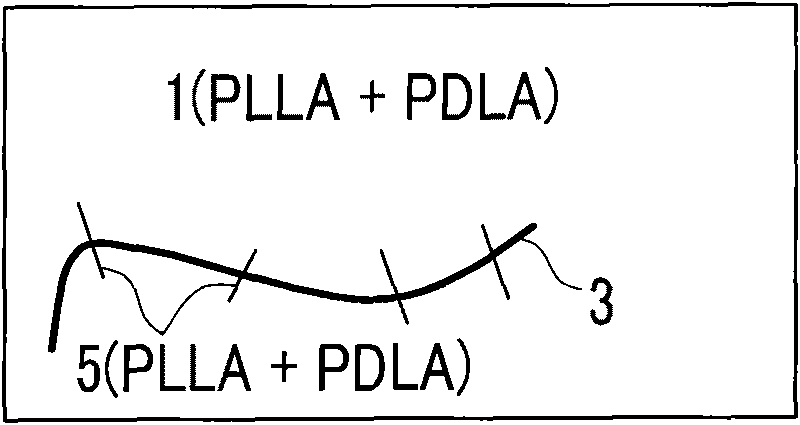

[0107] The natural fiber reinforced polylactic acid resin composition according to the embodiment includes the following components:

[0108] (1) Polylactic acid resin

[0109] 4032D produced by NatureWorks, Inc., USA was used as the L-polylactic acid resin. D,D-lactide manufactured by Purac Corporation was polymerized to provide a D-polylactic acid resin having a weight average molecular weight of 50000 g / mol.

[0110] (2) Natural fiber

[0111] It is produced from hemp and has a cellulose component content of 98% by weight, an average length of 5 mm, and an average diameter of 10 μm.

preparation example 1

[0114] The masterbatch is prepared by adding dried hemp to the reactor, followed by ring-opening polymerization of D,D-lactide monomer produced by Purac.

[0115] During ring-opening polymerization, hemp and D,D-lactide monomers were mixed in a batch mixing device at 180°C for 5 minutes and extruded with a twin-screw extruder attached to the mixing device to provide pellets. D,D-lactide monomer and hemp were used in a 1:1 weight ratio in the final dipped product.

[0116]At this time, the catalyst used for polymerization included stannous octoate and triphenylphosphine in the same molar ratio. In the impregnated product, D-polylactic acid resin obtained by adding D,D-lactide monomer in an amount of 500 mol based on 1 mol of the catalyst and natural fiber was present in a weight ratio of 1:1.

[0117] Vacuum drying was performed at 100°C to remove unreacted monomer from the mixture of polymer, monomer and natural fibers.

preparation example 2

[0119] The masterbatch was prepared by adding D-polylactic acid resin and natural fibers into a batch mixing device at a weight ratio of 1:1 and then melt mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com