Method for improving catalytic property of methane aromatization catalyst

A technology for catalytic performance and catalyst, which is applied in the field of molecular sieve assembly catalyst, improves catalytic performance of methane aromatization reaction catalyst, and can solve the problems of limited, unsatisfactory, low conversion rate and the like of industrialized development of oxygen-free aromatization of methane, Achieve the effect of improving anti-coking ability, long catalyst life and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

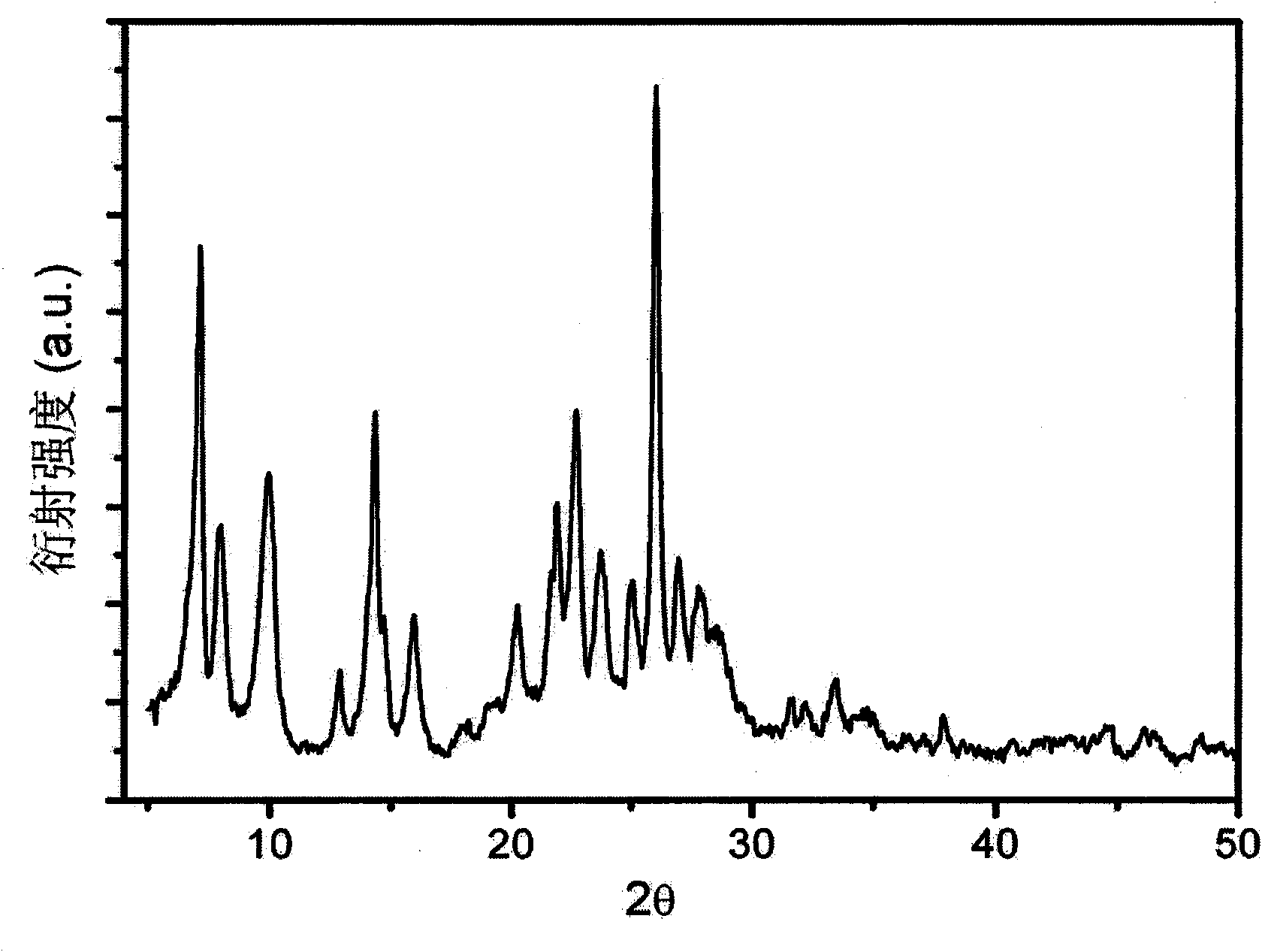

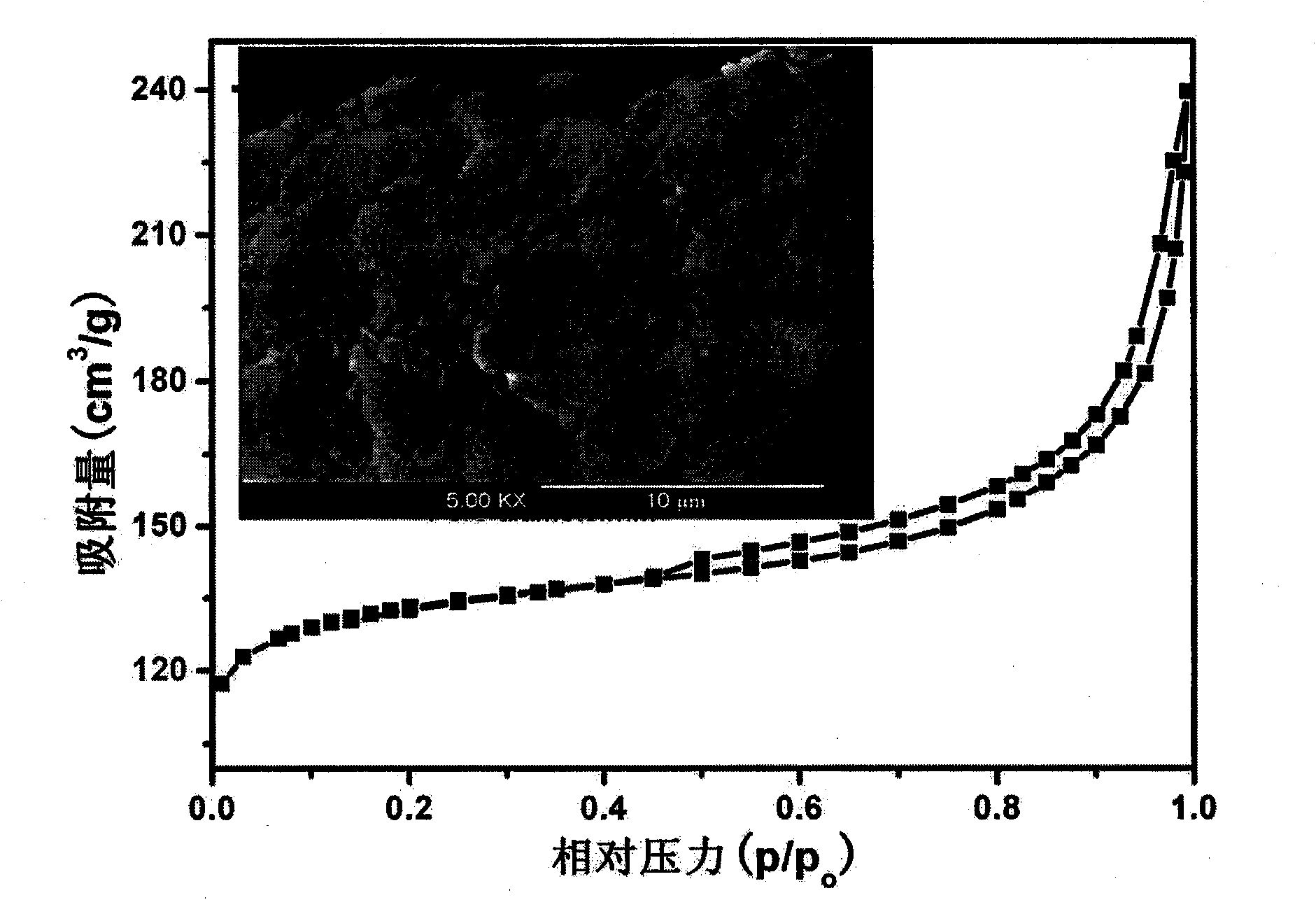

[0032] Preparation of MCM-22 hierarchical structure molecular sieve assembly: 0.25g NaOH, 1.6gNaAlO 2 Soluble in 95g H 2 Mix in O to form a solution evenly, then weigh 10.7g of hexamethyleneimine and add it to the solution and stir evenly. Finally, add 31.6g of silica sol within 1 hour and keep vigorously stirring overnight to obtain a system with a molar ratio of: SiO2 : Al 2 o 3 :Na 2 O:R:H 2 O=1:0.03:0.06:2:30, followed by static aging for 24 hours. The resulting mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner at 150°C for 7 days, and the product was quenched to room temperature, washed, dried, and calcined in a muffle furnace at 550°C for 8 hours. The organic template is removed to obtain the MCM-22 zeolite molecular sieve assembly with a hierarchical pore structure. The obtained product was characterized by X-ray diffraction, scanning electron microscope, nitrogen adsorption, etc., which proved that the product is dif...

Embodiment 2

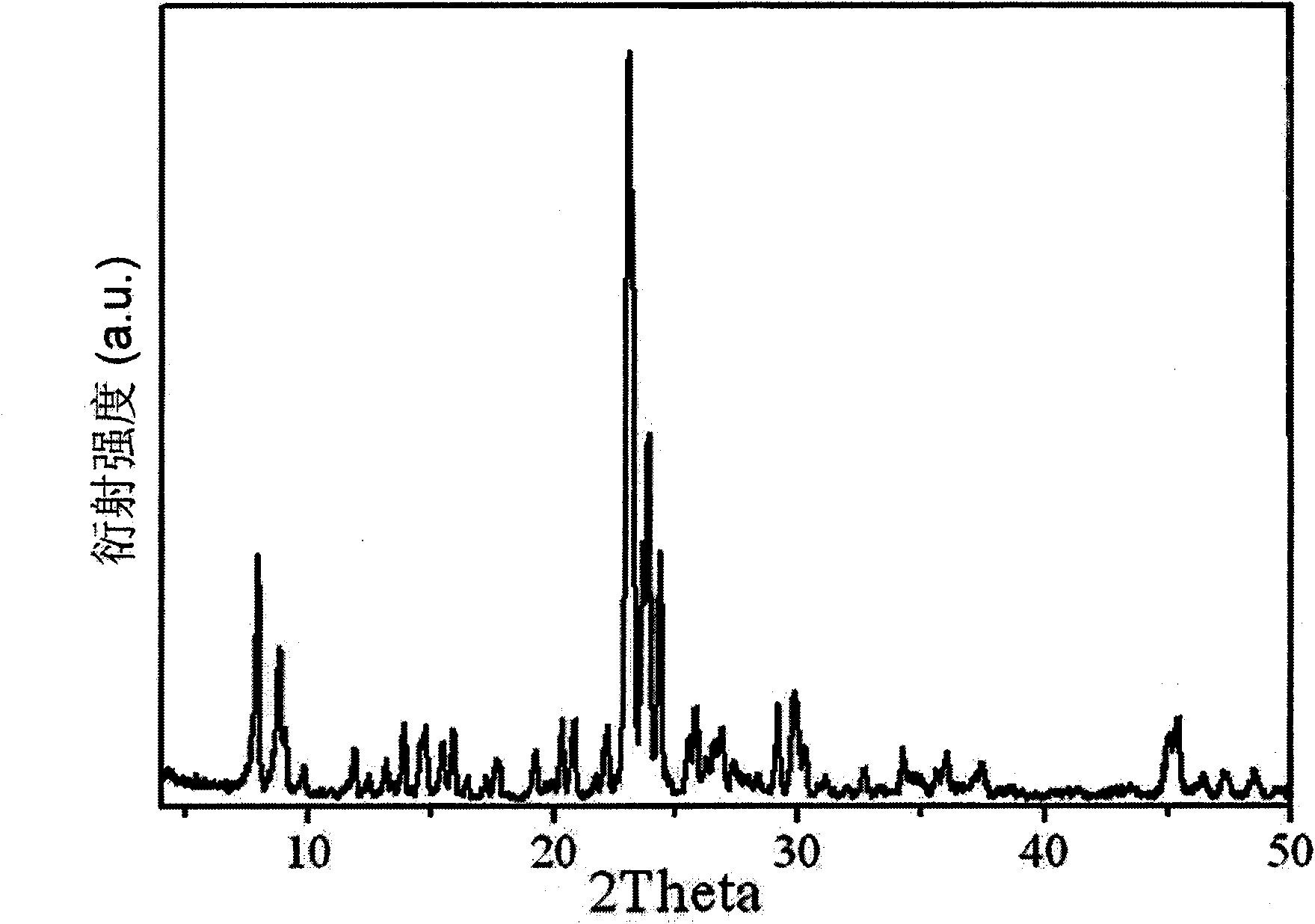

[0034] Preparation of ZSM-5 hierarchical molecular sieve assembly: 32.6g TPAOH was dissolved in 30gH at room temperature 2 Mix in O to form a solution evenly, then weigh 41.6g TEOS and slowly add the above solution dropwise, stir evenly to form solution A; another 32.6g TPAOH is dissolved in 30g H 2 Mix well in O to form a solution, then weigh 1.36g of AIP and slowly add the above solution dropwise, stir well to form solution B; after stirring for 24 hours, solutions A and B were mixed and stirred for 4 hours, and statically aged for 3 hours. The molar ratio of the obtained system is: SiO 2 : Al 2 o 3 :R:H 2 O=1:0.017:0.37:30. Then the resulting mixture was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and was statically crystallized at 100°C for 1 day, and then statically crystallized at 175°C for 1 day. After crystallization, it was quenched to room temperature and washed to obtain a complete Crystalline product. After drying, cal...

Embodiment 3

[0036] Preparation of Mo / HMCM-22 molecular sieve assembly catalyst with hierarchical pore structure: the Na-type MCM-22 molecular sieve assembly was exchanged 3 times with 1M ammonium nitrate solution at 80-100°C, washed 3 times with water, and then heated at 550°C Calcined in air atmosphere for 6 hours to obtain HMCM-22 for future use. Weigh 3 grams of HMCM-22, place it in 30 ml of 0.011 g / ml ammonium molybdate solution, stir and impregnate overnight. Dry at 100°C for 6 hours, and then bake in an air atmosphere at 500°C for 6 hours to obtain the product Mo / HMCM-22 assembly catalyst, which is crushed to 40 mesh and ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com