Method for preparing anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe

A technology of composite pipes and manufacturing methods, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem of not greatly improved service life, pulverization and mechanical property damage, poor overall performance of wear-resistant materials, etc. problems, to achieve the effects of improving mechanical properties and aging resistance, reducing linear expansion coefficient, and prolonging oxidation induction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 200ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0035] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 100ml, nucleating agent DBS 12.5kg;

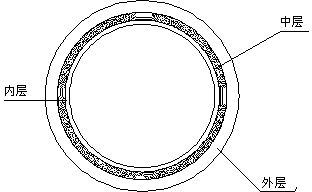

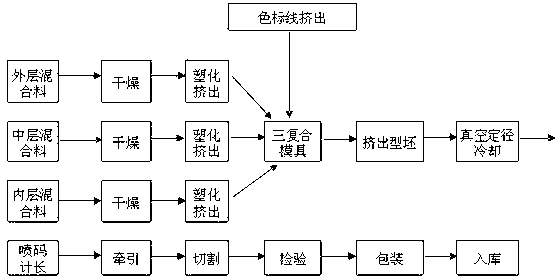

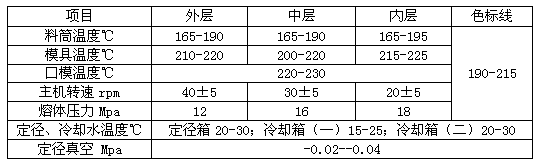

[0036] 3. Pipe preparation: The outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 4.5 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 2.5 parts of nucleating agent masterbatch, and 3 parts of white masterbatch ;The middle layer mixture is made of the following weight ratio raw materials: 100 parts of PP-R raw material, 2 parts of gray masterbatch, 4.5 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP - 100 parts of R, 2 parts of nano-silver ion composite titanium dioxide antibacterial mas...

Embodiment 2

[0041] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 200ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0042] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 100ml, nucleating agent DBS 12.5kg;

[0043] 3. Preparation of pipe material: The outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 5.5 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 4 parts of nucleating agent masterbatch, and 2 parts of white masterbatch ;The middle layer mixture is made of the following weight ratio raw materials: 100 parts of PP-R raw material, 3 parts of gray masterbatch, 4 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP - 100 parts of R, 2 parts of nano-silver ion composite titanium dioxide antibacte...

Embodiment 3

[0048] 1. Preparation of antioxidant and anti-ultraviolet agent masterbatch: 200kg of PP-R raw material, 300ml of white oil, 6kg of antioxidant 168, 4kg of antioxidant 1010, 5kg of anti-ultraviolet agent UV-531, and 4kg of UV-P ;

[0049] 2. Prepare nucleating agent masterbatch: PP-R raw material 200kg, white oil 200ml, nucleating agent DBS 12.5kg;

[0050] 3. Preparation of pipe material: the outer layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 5.4 parts of anti-oxidant and anti-ultraviolet agent masterbatch, 4 parts of nucleating agent masterbatch, and 3 parts of white masterbatch ;The middle layer mixture is made of the following raw materials in weight ratio: 100 parts of PP-R raw material, 3 parts of gray masterbatch, 4.5 parts of nucleating agent masterbatch; the inner layer mixture is made of the following weight ratio of raw materials: PP - 100 parts of R, 2 parts of nano-silver ion composite titanium dioxide anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com