Patents

Literature

31results about How to "Prolonged oxidation induction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

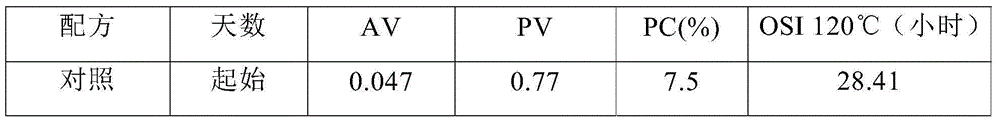

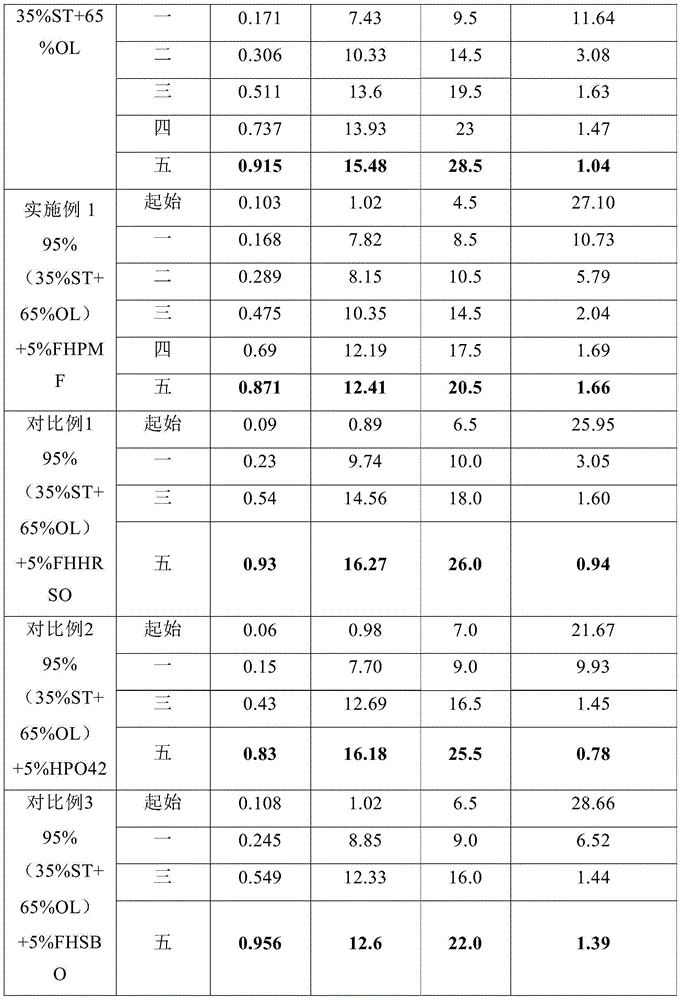

Grease composition for frying

The invention provides a grease composition for frying; the grease composition contains a fully hydrogenated palm oil intermediate fraction. The invention also relates to a preparation method of the grease composition for frying and a method of improving the frying performance of frying oil; the methods include the step of mixing the fully hydrogenated palm oil intermediate fraction and the frying oil. The invention also includes a use of the fully hydrogenated palm oil intermediate fraction in preparation of the grease composition for frying or improvement of the frying performance of the frying oil. The grease composition for frying does not have a health problem of trans-fatty acids, the frying stability is markedly improved, the oil absorption rate of fried products is significantly reduced, and color, luster, brittleness, flavor and greasy feeling are all improved.

Owner:嘉里特种油脂(上海)有限公司

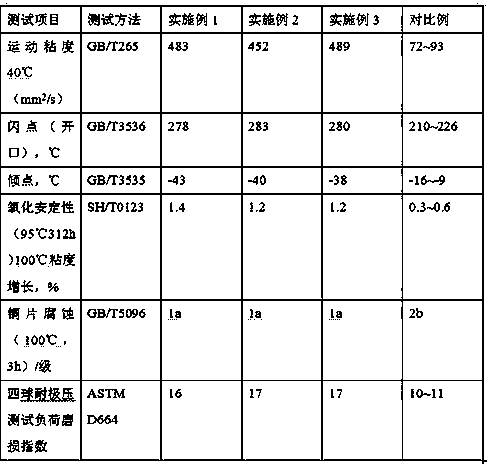

Non-sulphur and phosphorus antiwear and friction reducing multifunctional additive agent and preparation method

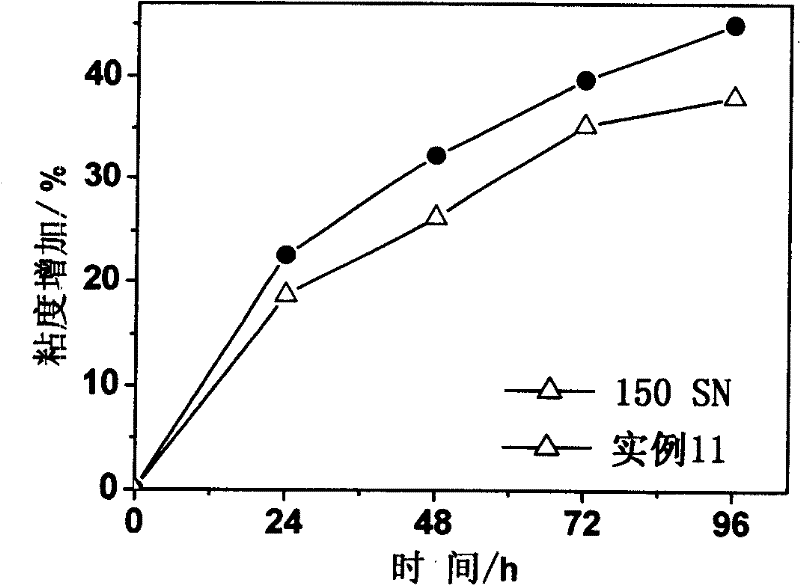

InactiveCN101381649ARaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesAntioxidantInternal combustion engine

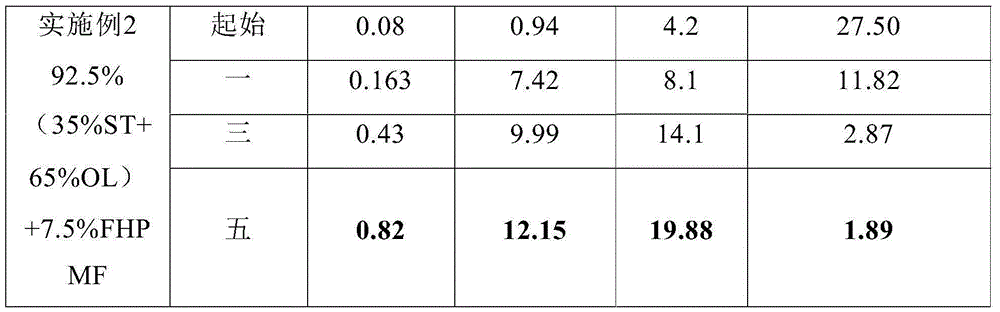

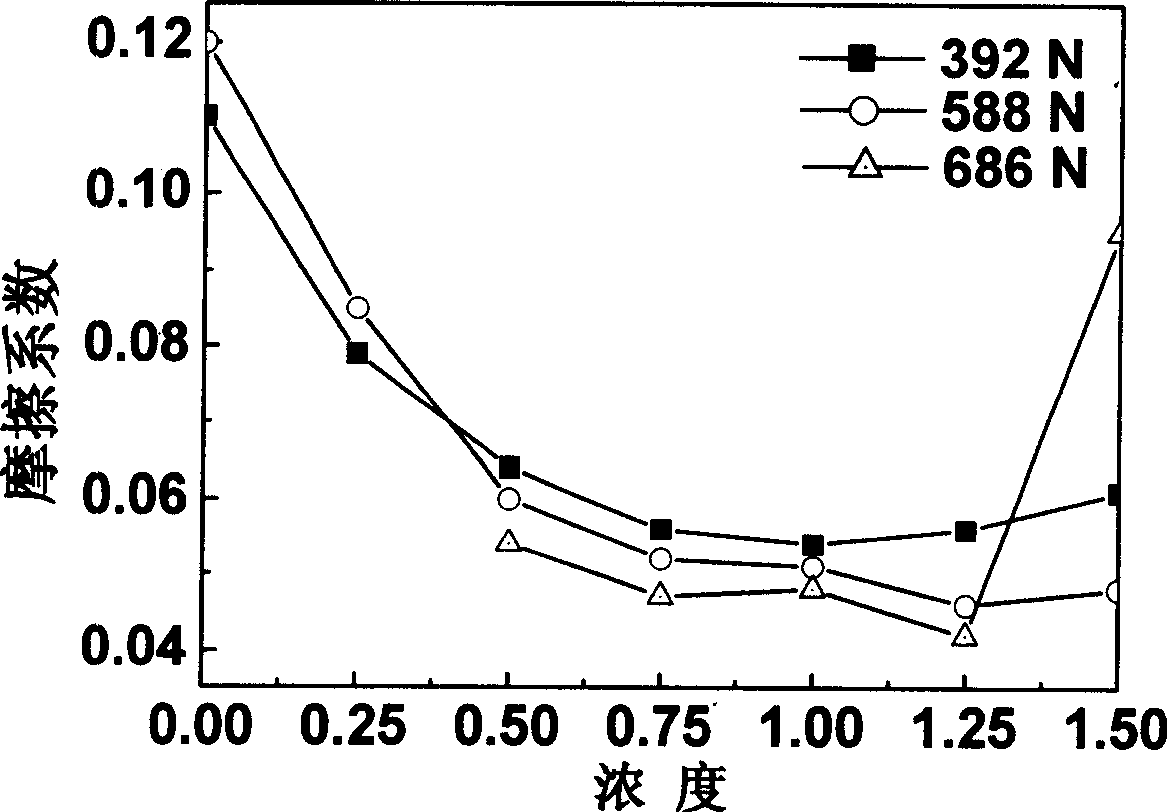

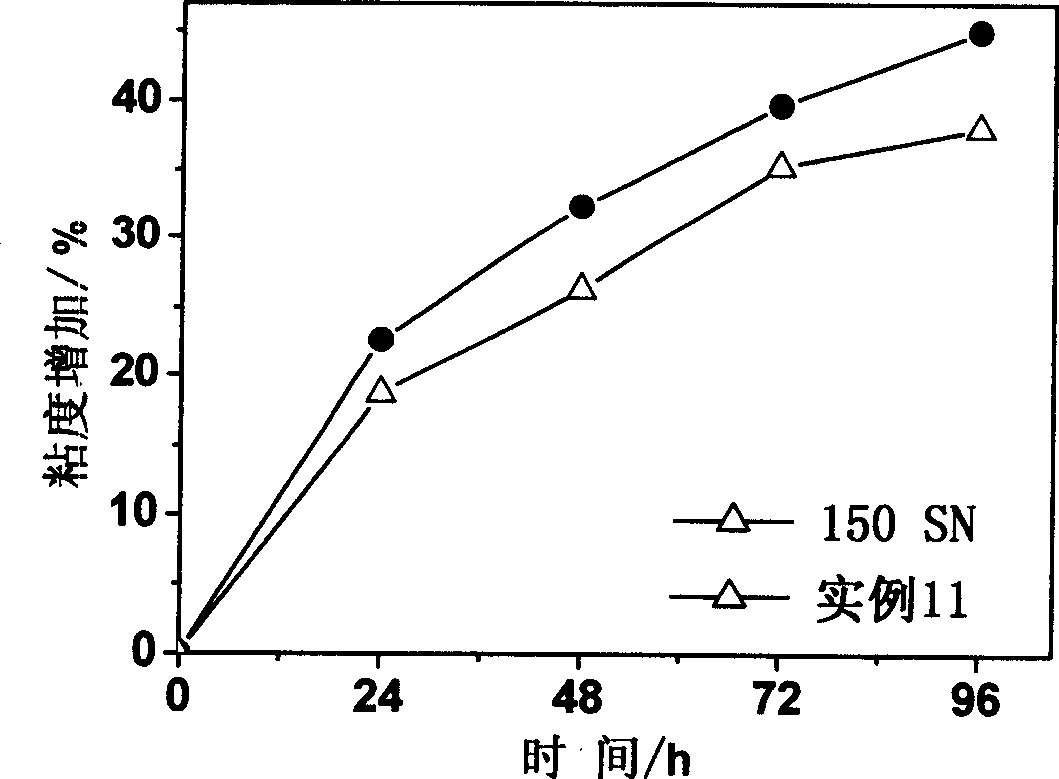

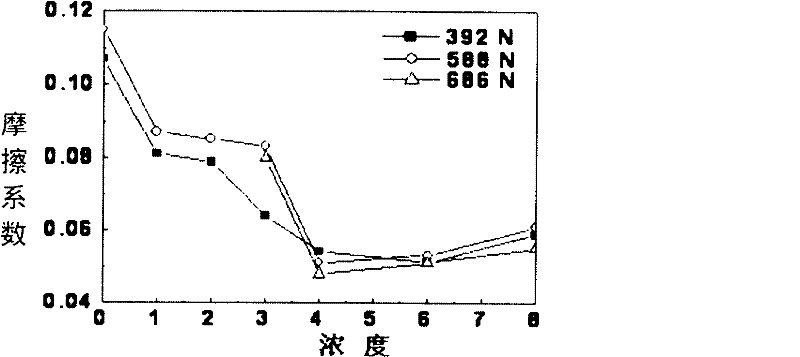

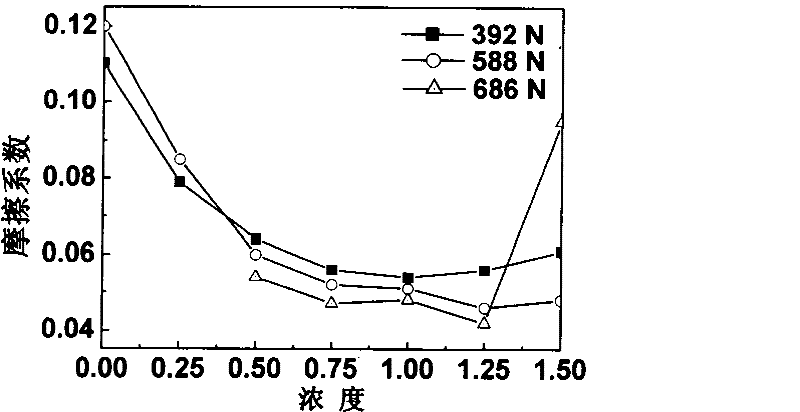

The invention belongs to the technical field of lubricating oil and discloses a non-sulfur non-phosphorus anti-wear and antifrictional multifunctional additive and a preparation method thereof. The compositions of the additive comprise a friction modifier, an antiwear agent, an antioxidant, a detergent dispersant, and an antirusting agent. Firstly, the friction modifier is synthesized, then the friction modifier, the antiwear agent, the detergent dispersant, the antioxidant, and the antirusting agent with the needed amount are orderly mixed according to the proportion, and the mixture is heated to between 50 and 70 DEG C under the stirring and then is stirred evenly. The additive can be widely applied to various lubricating oil products including lubricant base oil or lubricant oil finished products, such as internal combustion engine oil, gear oil and so on, and is added into lubricating oil of an internal combustion engine with 3 to 20 weight percentage during the use. The additive can greatly improve the abrasion resistance and the antifriction performance of oil products, can also apparently improve the initial oxidation temperature and the oxidation induction time of the oil products, effectively suppress the viscosity of the oil products from increasing, and ensure that the high-temperature antioxidation performance of the internal combustion engine oil is greatly improved.

Owner:天津市东宝润滑油脂有限公司

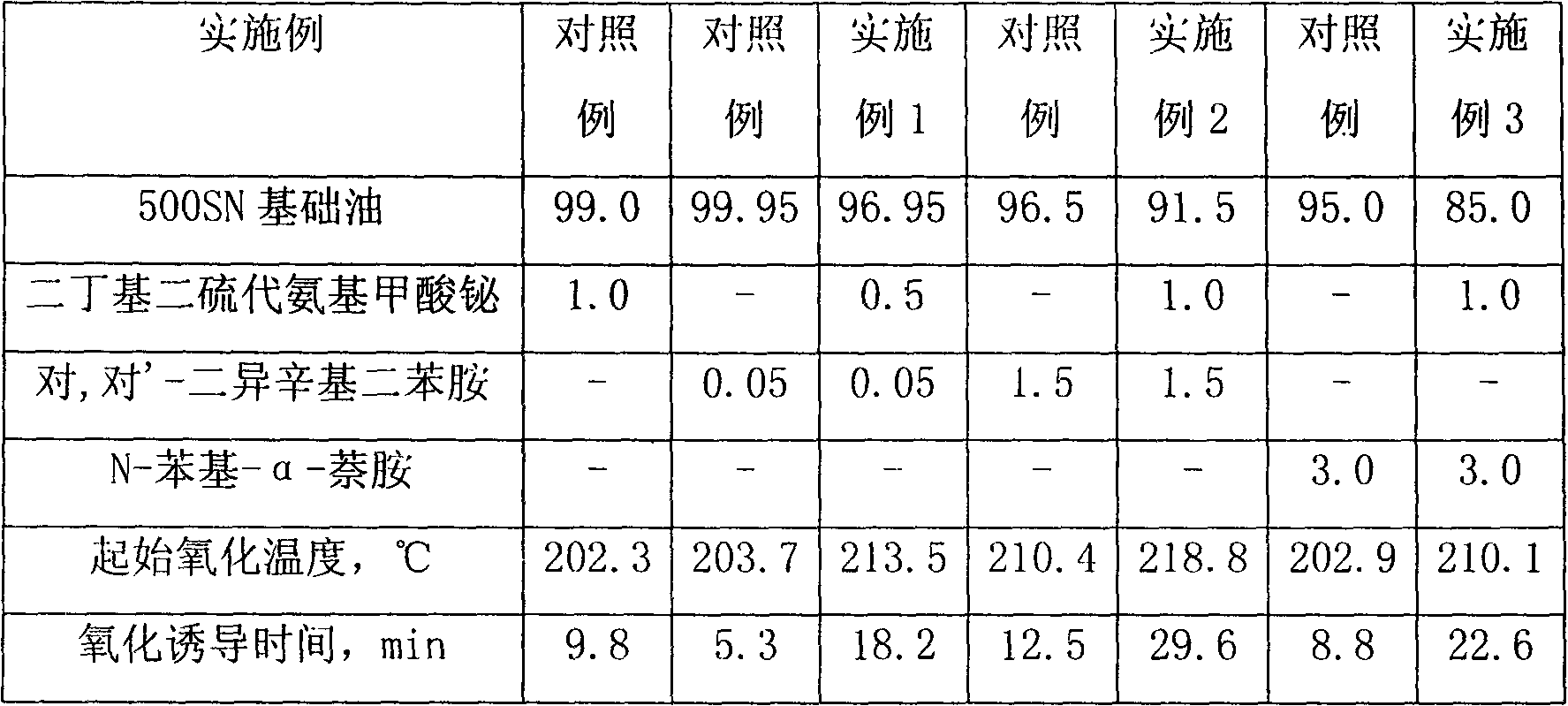

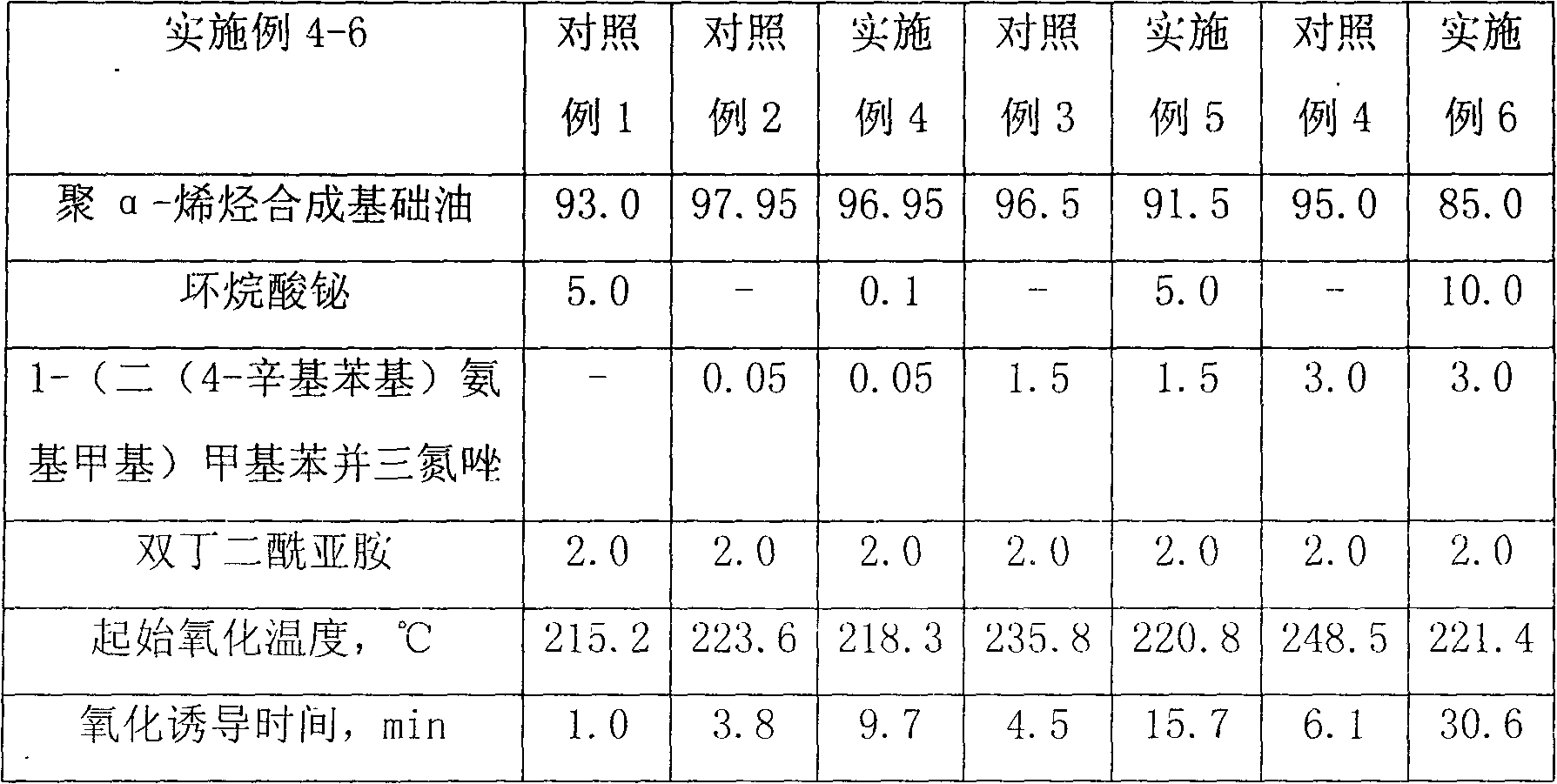

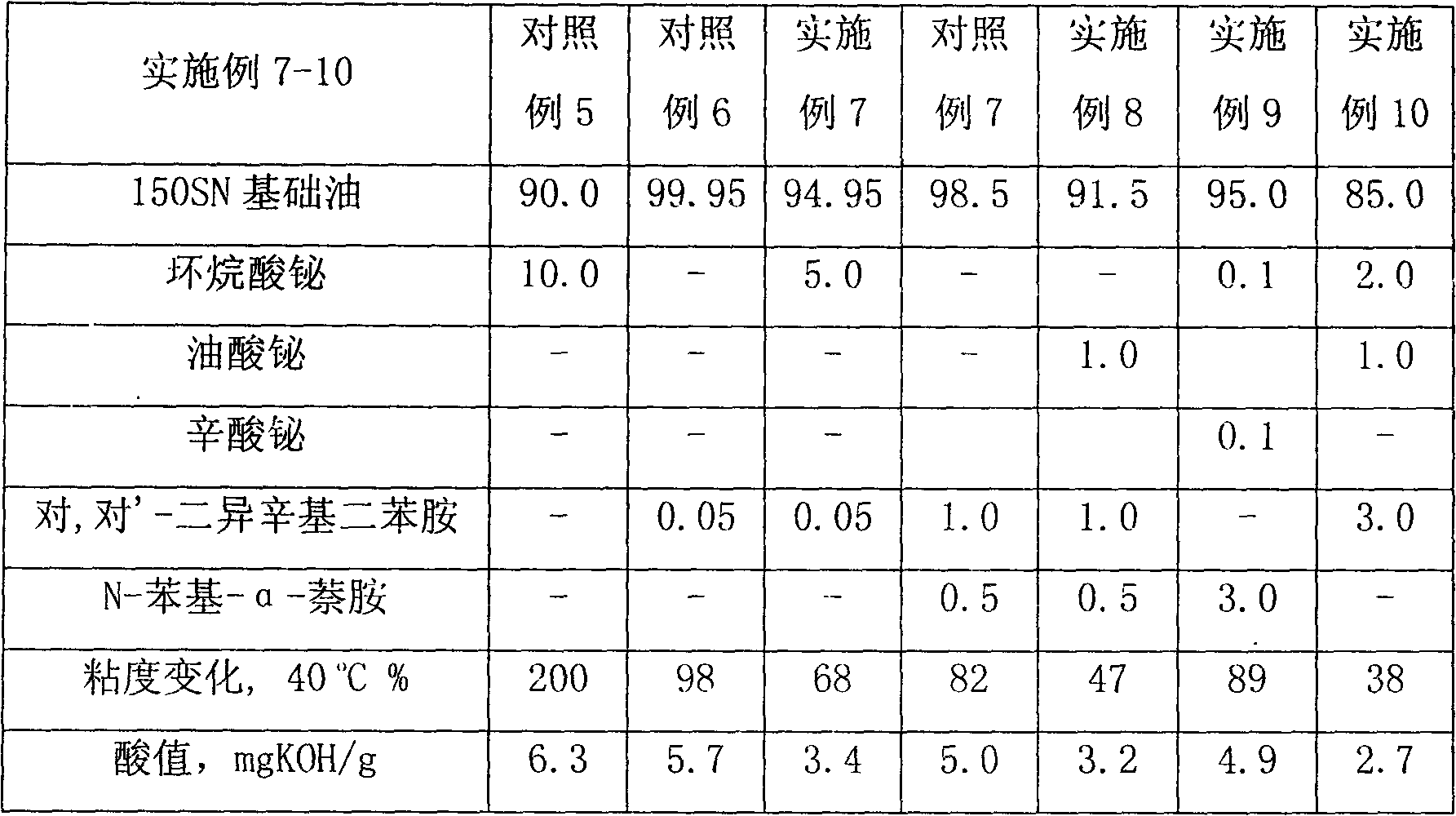

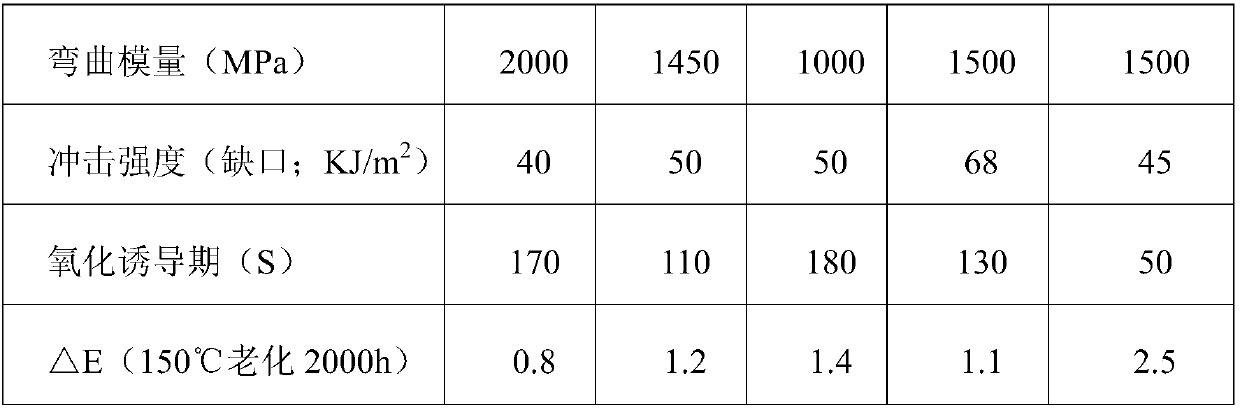

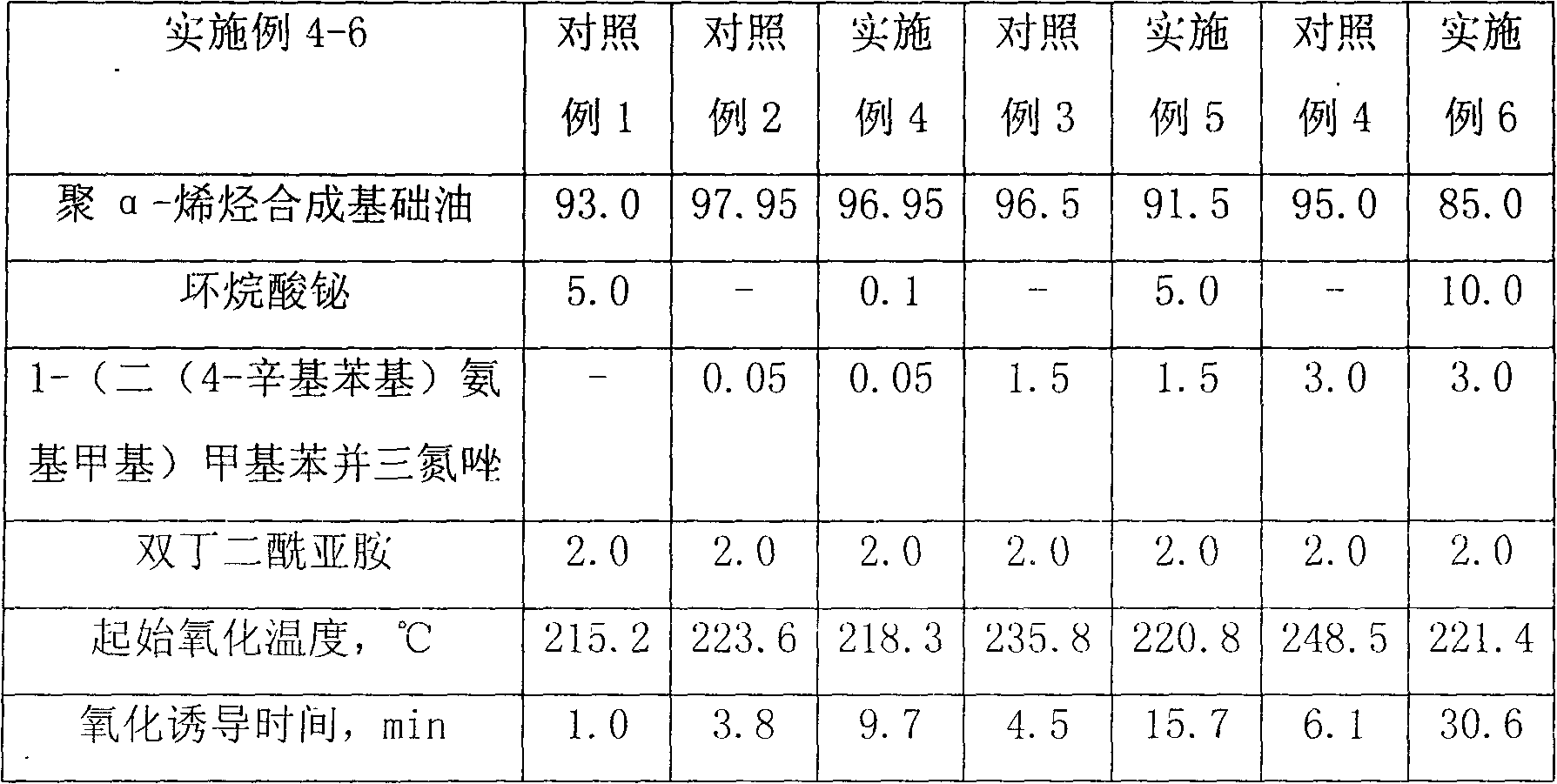

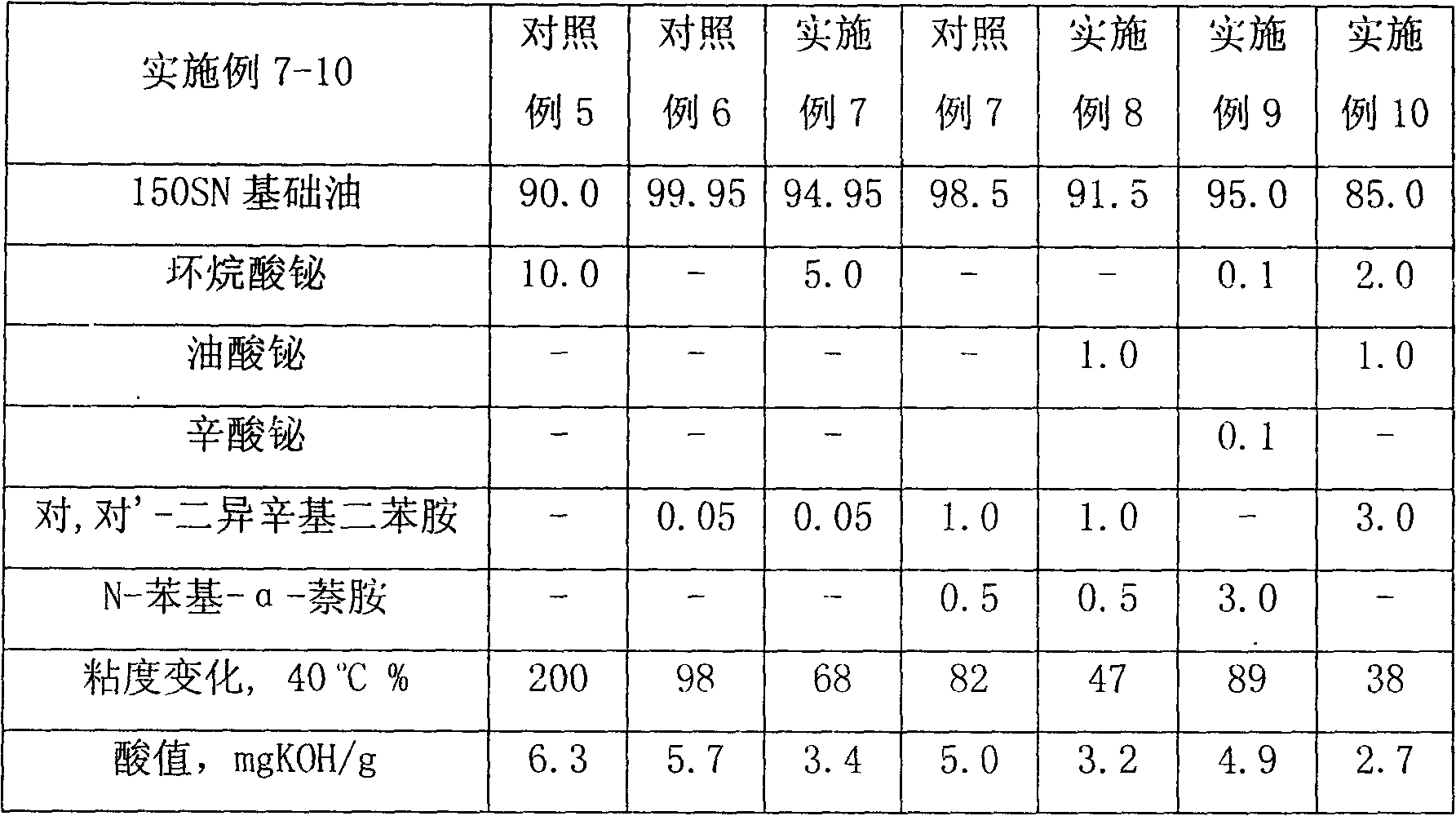

Antioxidant additive composite

InactiveCN102206532AGood high temperature oxidation resistanceRaise the initial oxidation temperatureAdditivesBismuth compoundInternal combustion engine

The invention discloses an antioxidant additive composite, belonging to the technical field of lubricating oil. The antioxidant additive composite consists of the following compounds in parts by weight: 0.1-1 part of bismuth compound and 0.05-3 parts of arylamine compound. After the antioxidant additive composite is added into lubricating oil, the initial oxidation temperature and oxidation induction time of the lubricating oil can be greatly increased, and the high-temperature antioxidant property of the lubricating oil can be greatly improved. The antioxidant additive composite can be widely applied to various lubricating oil products including basic lubricating oil or finished lubricating oil, such as internal combustion engine oil, gear oil and the like.

Owner:中国人民解放军徐州空军学院

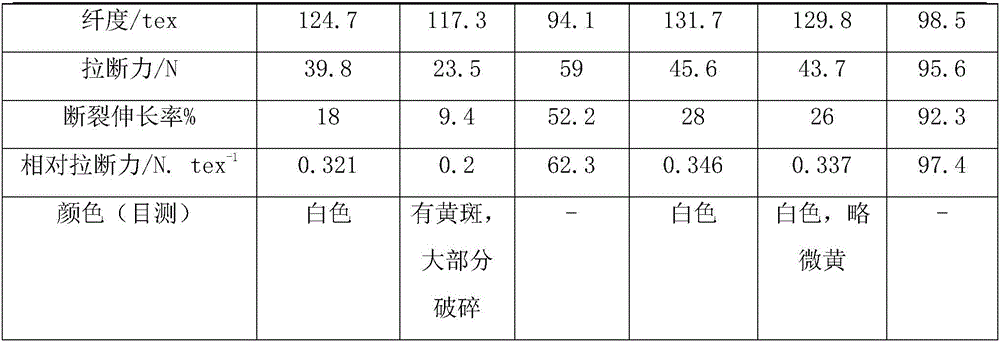

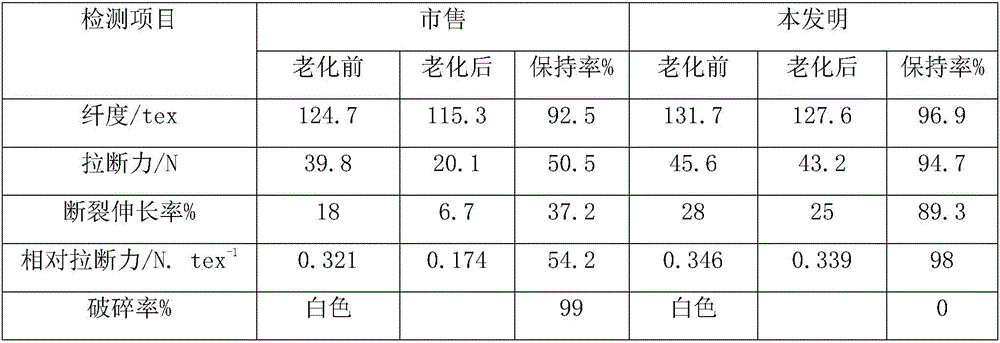

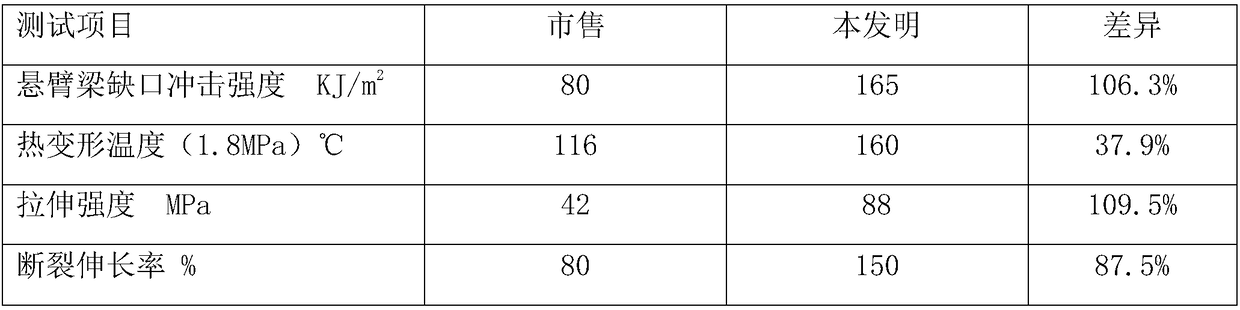

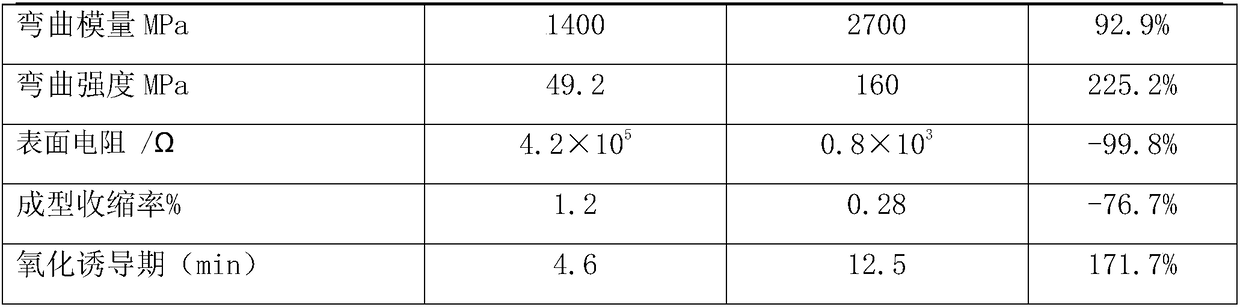

Easily-degradable anti-shrinkage polypropylene master batch and preparation method thereof

InactiveCN106674728AImprove high temperature resistanceImproves shrink resistanceFungiMicroorganism based processesPolypropyleneAntioxidant

The invention discloses an easily-degradable anti-shrinkage polypropylene master batch, wherein polypropylene serves as a base material, the types and the formula of the master batch are optimized, and a production process is improved. A complex antioxidant which contains a biologic antioxidant, modified nanocarbon which can obviously improve high temperature resistance, shrinkage resistance, relative tensile load, strength and toughness and elasticity modulus of the polypropylene master batch, calcium fruit fibers which can obviously improve shock resistance of the polypropylene master batch, are easily biodegradable and lower production cost, polyethylene / winter rye peptide complexes which can greatly improve low temperature resistance of the polypropylene master batch and bitter almond oil which can effectively improve lubricating property and oxidation resistance of the polypropylene master batch are scientifically compounded; the obtained compound has a synergistic effect with other processing aids; finally, the environment-friendly easily-degradable anti-shrinkage polypropylene master batch with good physical property is obtained.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

Extrusion grade polypropylene material with high heat resistance and method for preparing extrusion grade polypropylene material

InactiveCN109575434AImprove heat resistanceProlonged oxidation induction timePolymer scienceAntioxidant

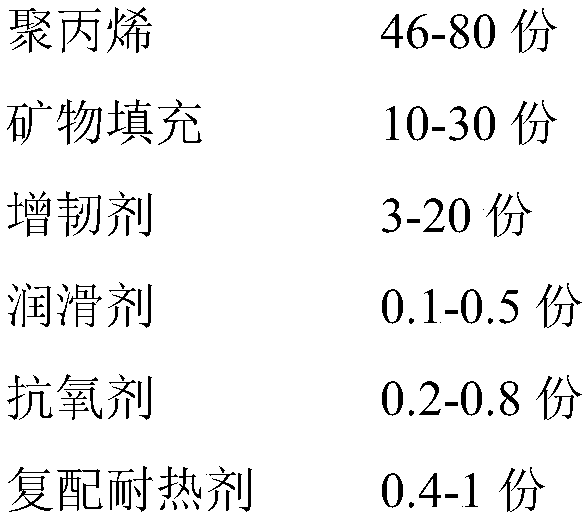

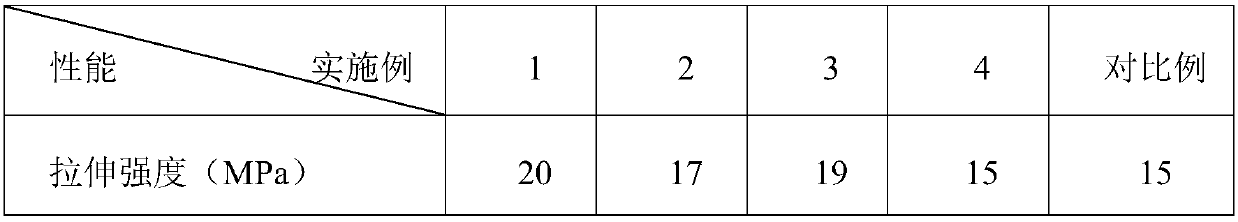

The invention discloses an extrusion grade polypropylene material with high heat resistance and a method for preparing the extrusion grade polypropylene material. The extrusion grade polypropylene material comprises polypropylene, mineral filling, toughening agents, lubricants, antioxidants, complex heat-resistant agents and light stability complex agents. The polypropylene, the mineral filling, the toughening agents, the lubricants, the antioxidants, the complex heat-resistant agents and the light stability complex agents are mixed, extruded and granulated to obtain the extrusion grade polypropylene material. The extrusion grade polypropylene material and the method have the advantages that the complex heat-resistant agents are used, and accordingly the extrusion grade polypropylene material is high in heat aging resistance and light aging resistance; the excellent mechanical properties of the extrusion grade polypropylene material can be guaranteed, and application of the extrusion grade polypropylene material in the aspect of liquid delivery and storage systems of chemical pipelines further can be expanded.

Owner:HEFEI GENIUS NEW MATERIALS

Antioxidant additive composite

InactiveCN102206532BGood high temperature oxidation resistanceRaise the initial oxidation temperatureAdditivesBismuth compoundInternal combustion engine

The invention discloses an antioxidant additive composite, belonging to the technical field of lubricating oil. The antioxidant additive composite consists of the following compounds in parts by weight: 0.1-1 part of bismuth compound and 0.05-3 parts of arylamine compound. After the antioxidant additive composite is added into lubricating oil, the initial oxidation temperature and oxidation induction time of the lubricating oil can be greatly increased, and the high-temperature antioxidant property of the lubricating oil can be greatly improved. The antioxidant additive composite can be widely applied to various lubricating oil products including basic lubricating oil or finished lubricating oil, such as internal combustion engine oil, gear oil and the like.

Owner:中国人民解放军徐州空军学院

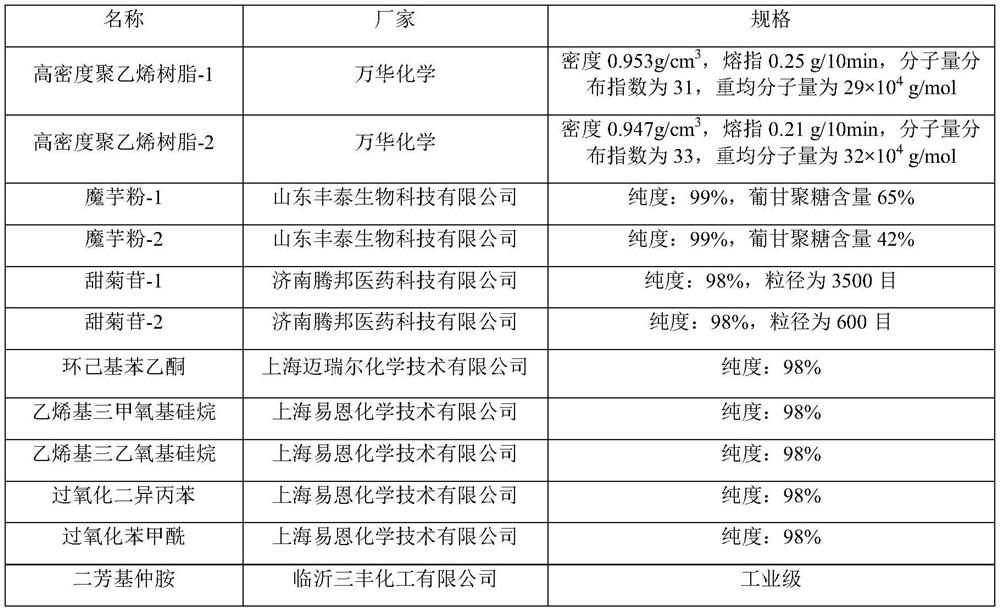

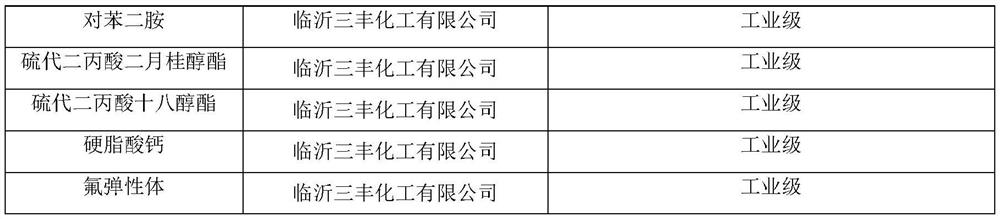

Special high-density polyethylene resin for pressure-resistant pipes and preparation method of special high-density polyethylene resin

The invention provides a special material high-density polyethylene resin for a pressure-resistant pipe and a preparation method of the special material high-density polyethylene resin. The special material high-density polyethylene resin for the pressure-resistant pipe is prepared from the following raw materials through reaction: high-density polyethylene resin, konjaku flour, stevioside, cyclohexyl acetophenone, a cross-linking agent, a cross-linking auxiliary agent, a main antioxidant, an auxiliary antioxidant, a halogen absorbent and a processing auxiliary agent. The special high-density polyethylene resin for the pressure-resistant pipe has high heat resistance, high strength, high modulus and high fracture toughness, and particularly, the pressure resistance necessary for the pipe is greatly improved, so that the pressure-resistant ductility such as slow crack growth resistance, environmental stress cracking resistance and the like of the pipe are improved, and the application field of the pipe is widened.

Owner:WANHUA CHEM GRP CO LTD

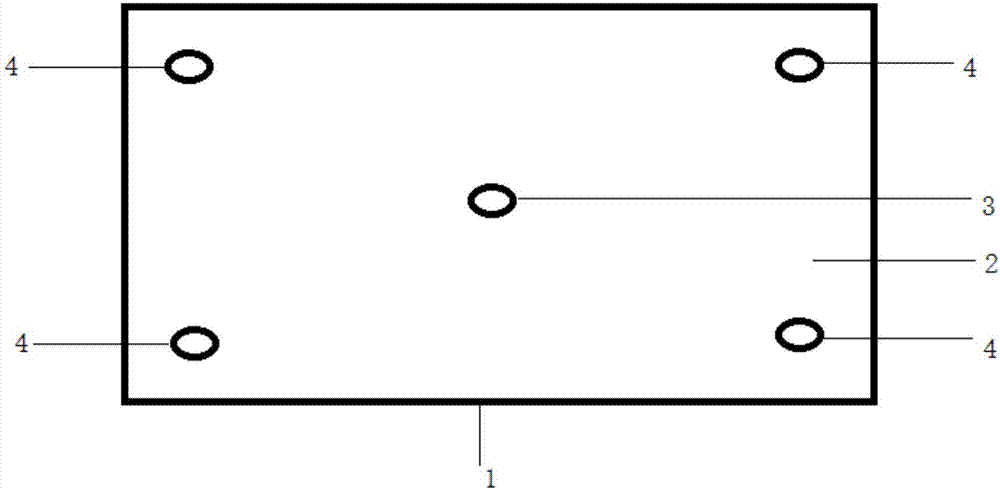

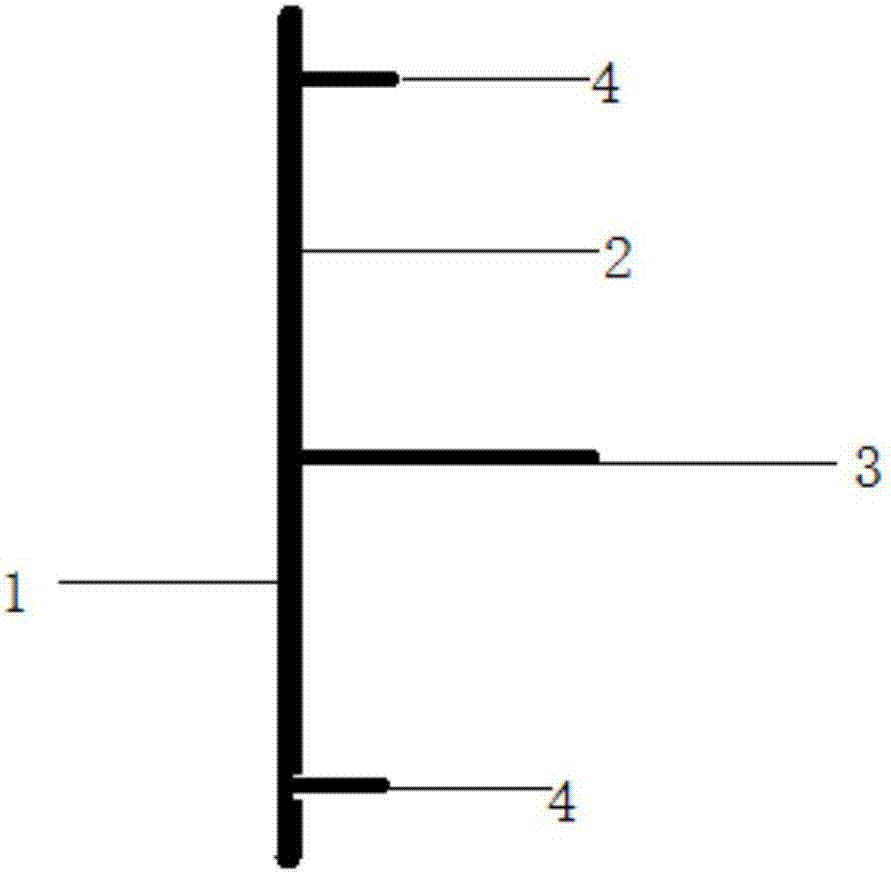

Method for producing plastic tray by utilizing hollow blow molding machine

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

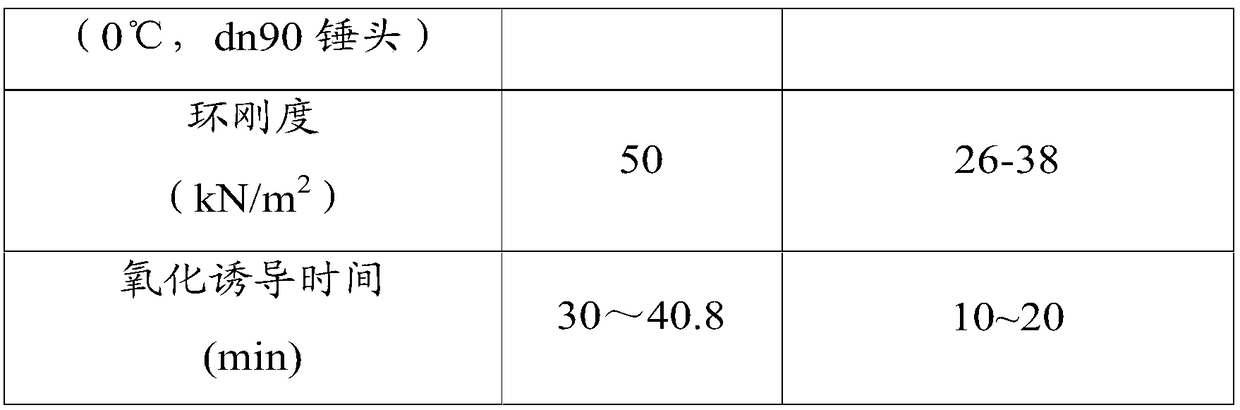

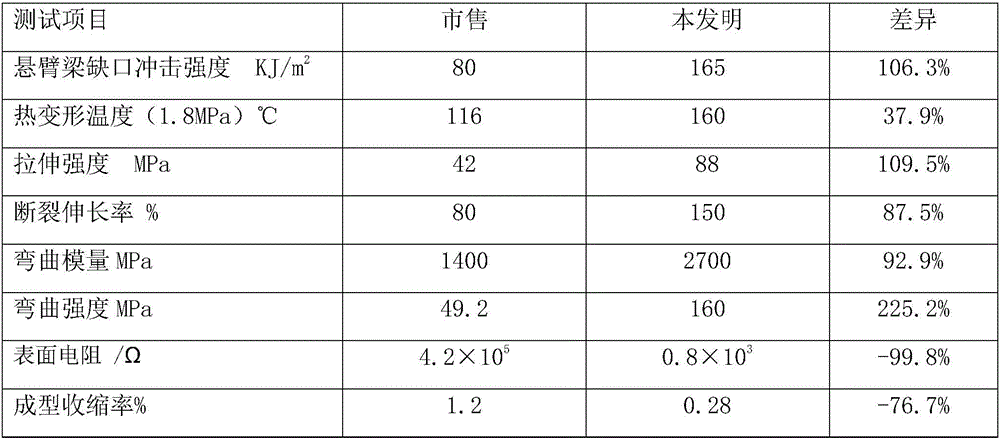

Anti-aging geocell material and preparation method thereof

The invention discloses an anti-aging geocell material. The high-density polyethylene material is prepared from the following raw materials in parts by weight: 70 to 85 parts of high-density polyethylene, 7 to 16 parts of ethylene-vinyl acetate copolymer, 2 to 6 parts of basalt fiber, 3 to 8 parts of nano zinc oxide, 0.2 to 1 part of ultraviolet absorbent, 0.3 to 1 part of antioxidant, 2 to 6 parts of interfacial compatibilizer and 0.3 to 1 part of processing aid. The ultraviolet absorbent is at least one of a hindered amine ultraviolet absorbent, benzotriazole UVP and dihydroxy benzophenone UV531; the antioxidant is a mixture of a hindered phenol main antioxidant and a phosphite ester auxiliary antioxidant, and the mass ratio of the hindered phenol main antioxidant to the phosphite esterauxiliary antioxidant is 1:(0.2-0.4). The aging-resistant geocell material disclosed by the invention is long in oxidation induction time and excellent in aging resistance; the tensile strength is high and the mechanical property is good. The geocell material is high in cantilever beam notch impact strength and good in impact resistance, is high in the bending modulus and has good comprehensive mechanical property.

Owner:哈尔滨金蜂巢工程材料开发有限公司

Method for molding low-temperature-resistant high-strength polyethylene pipe applied to water supply

InactiveCN108943654AHigh strengthImprove low temperature resistanceTubular articlesPolyolefinPolyvinyl chloride

The invention provides a method for molding a low-temperature-resistant high-strength polyethylene pipe applied to water supply. The method comprises the following steps: (1) preparing raw materials consisting of, by weight, 100 parts of polyethylene, 20 to 30 parts of polyolefin, 10 to 20 parts of CPVC resin, 1 to 5 parts of polyvinyl chloride resin, 1 to 3 parts of barium laurate, 1 to 2 parts of ACR-201, 5 to 10 parts of titanium dioxide, 1 to 3 parts of talcum powder and 1 to 2 parts of an anti-oxidant; (2) subjecting polyethylene, polyolefin, CPVC resin and polyvinyl chloride resin to vacuum-pumping; (3) adding polyethylene and polyolefin into a mixing pot at a low rotation speed, starting high-speed mixing, adding the CPVC resin polyvinyl chloride resin into the mixing pot at 70 DEGC, adding barium laurate at 80 DEG C, adding ACR-201, titanium dioxide and talcum powder at 110 DEG C; and (4) carrying out extruding via a conical twin-screw extruder so as to form a pipe, and afterextrusion, carrying out vacuum sizing and cooling so as to obtain the low-temperature-resistant high-strength polyethylene pipe. The method of the invention has the advantages of high extrusion speedand high production efficiency; and the prepared pipe is remarkably improved in strength, low temperature resistance and other performance.

Owner:胡建芳

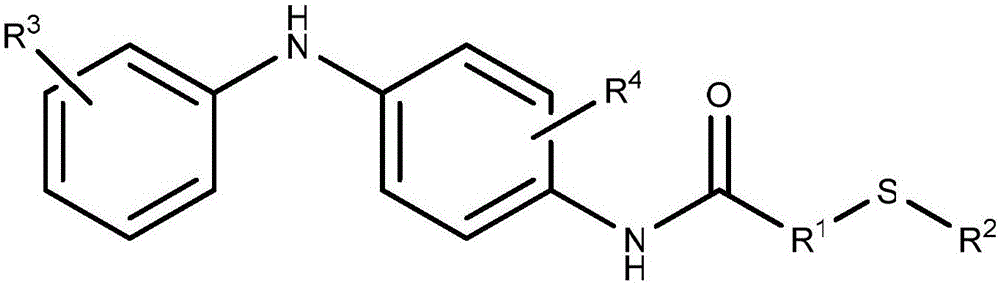

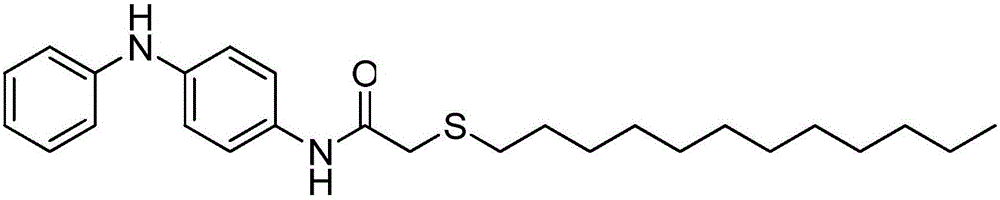

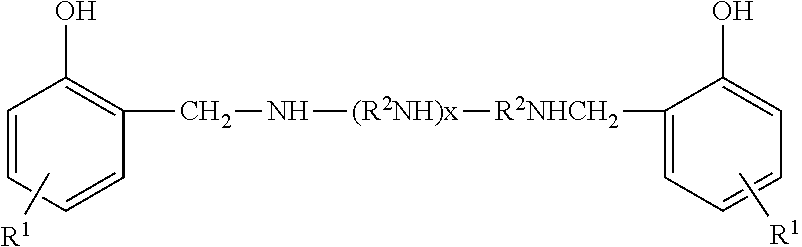

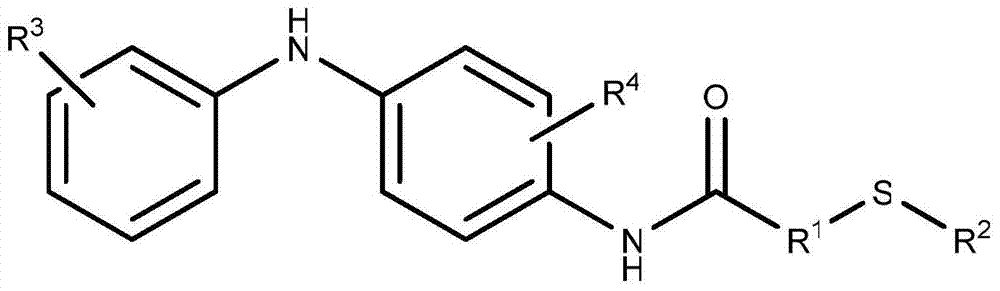

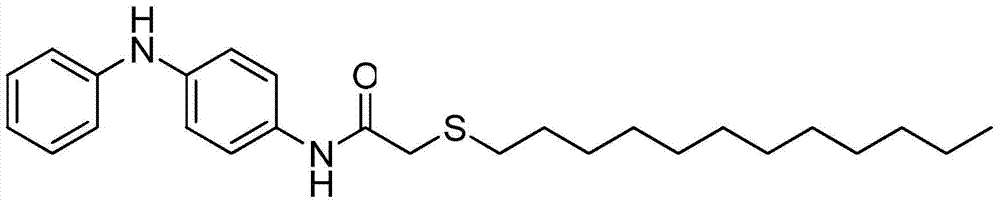

Anti-oxygen of N-(4-anilino phenyl)-acylamino sulfoether compound

ActiveCN104987304AEffective control of oxidative deteriorationDelay oxidative deteriorationOrganic chemistryAdditivesHydrogenMulti effect

The invention discloses anti-oxygen of an N-(4-anilino phenyl)-acylamino sulfoether compound. The anti-oxygen is characterized in that according to the requirement of ester oil applied under the wide temperature range condition (120 DEG C-230 DEG C), a N-(4-anilino phenyl)-acylamino sulfoether compound serves as efficient / multi-effect lubricating oil anti-oxygen, and the oxidation resistance of lubricating oil is improved. The structure of the type of compound is the N-(4-anilino phenyl)-acylamino sulfoether compound shown in the graph 1, R1 and R2 are selected from alkyl, and R3 and R4 are selected from hydrogen or alkyl. The service performance of the lubricating oil can be improved through the compound.

Owner:梧州科润润滑科技有限公司

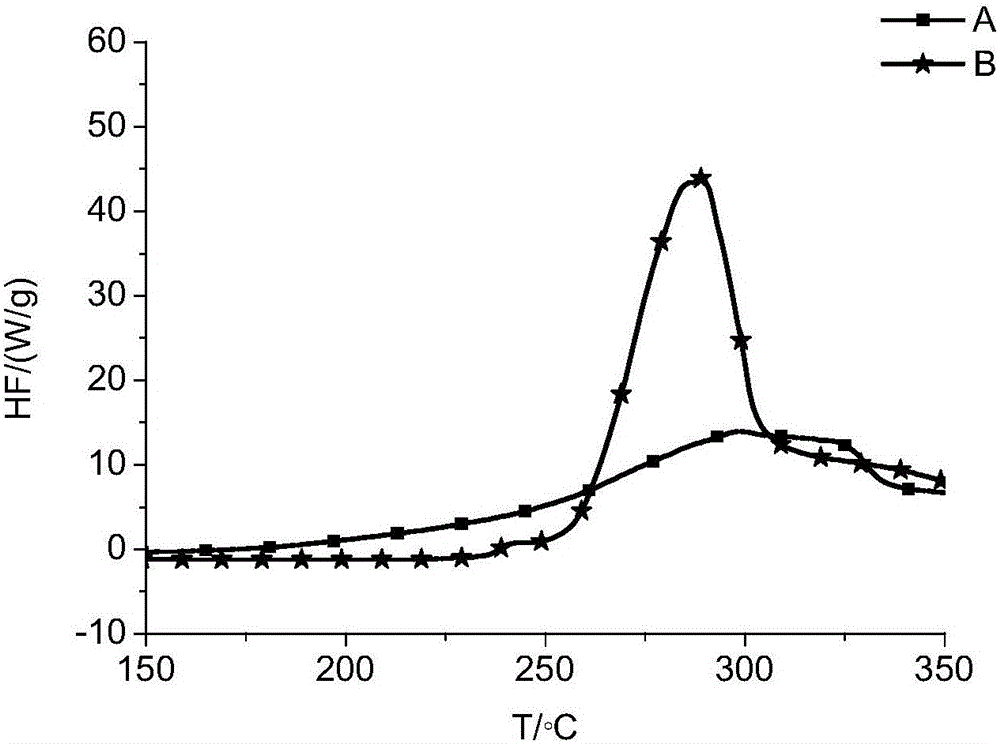

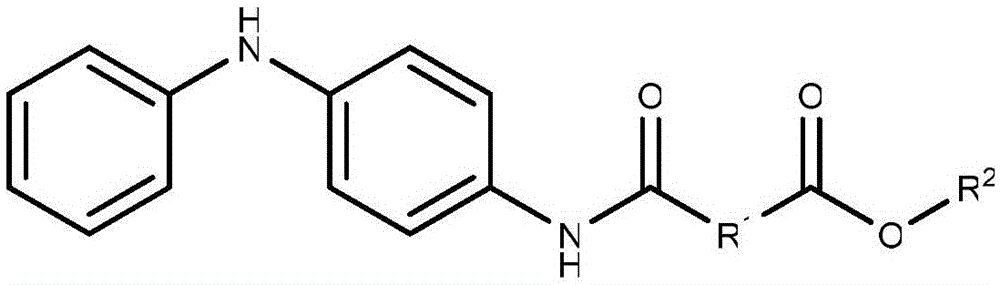

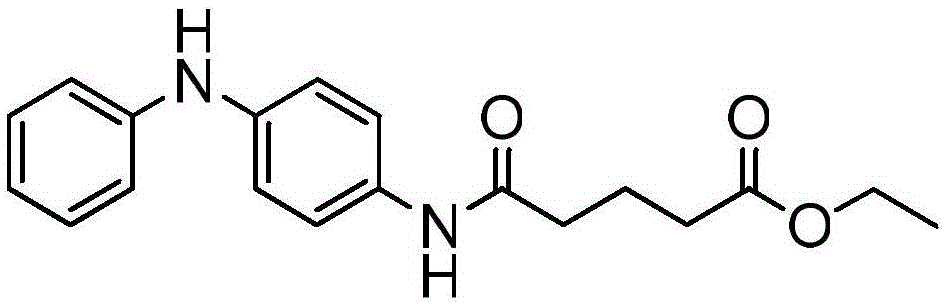

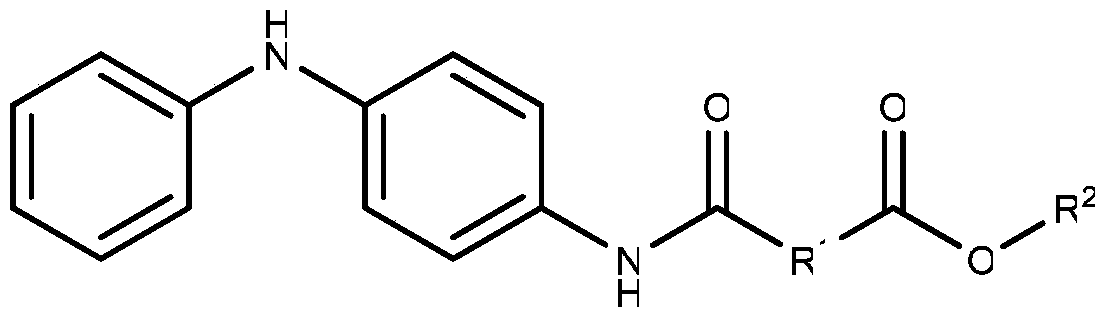

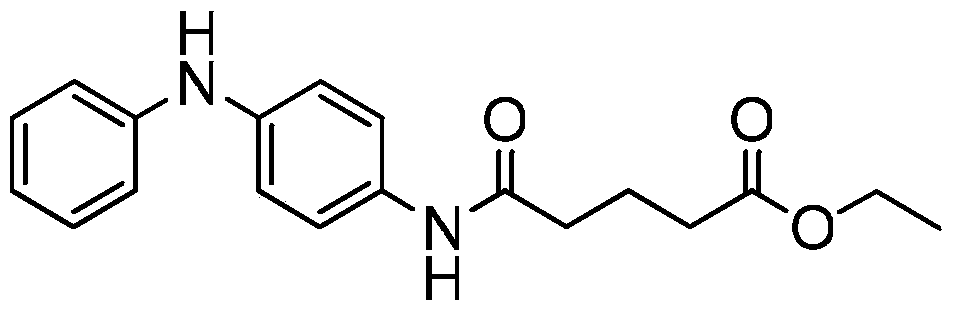

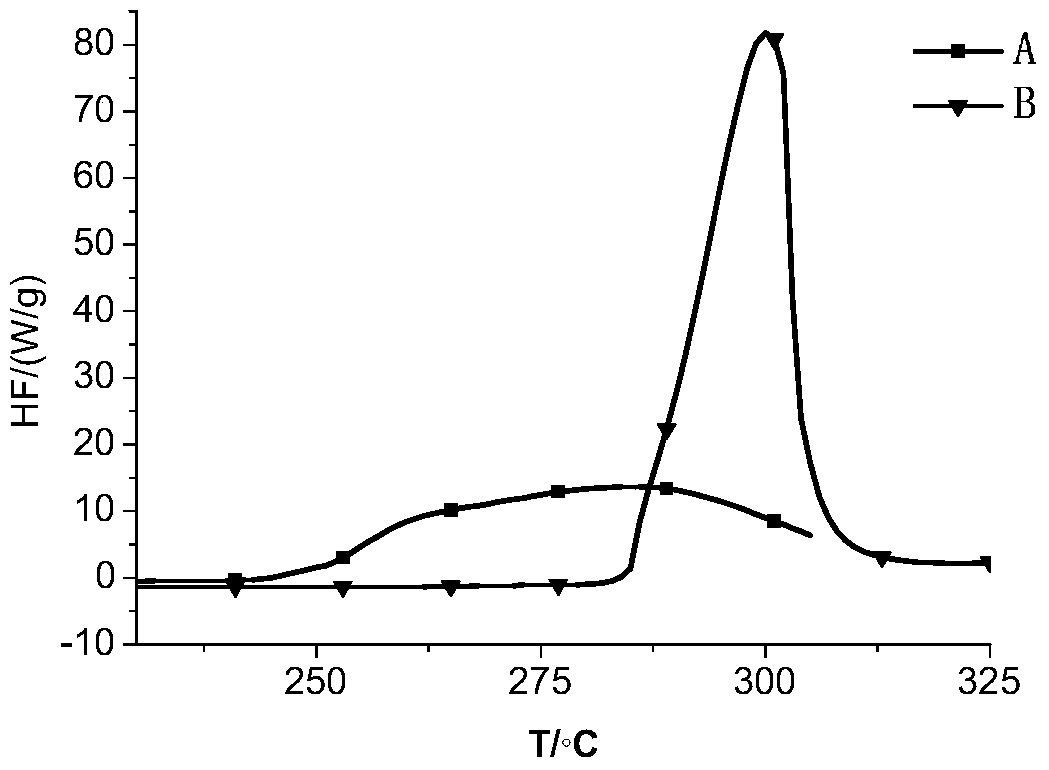

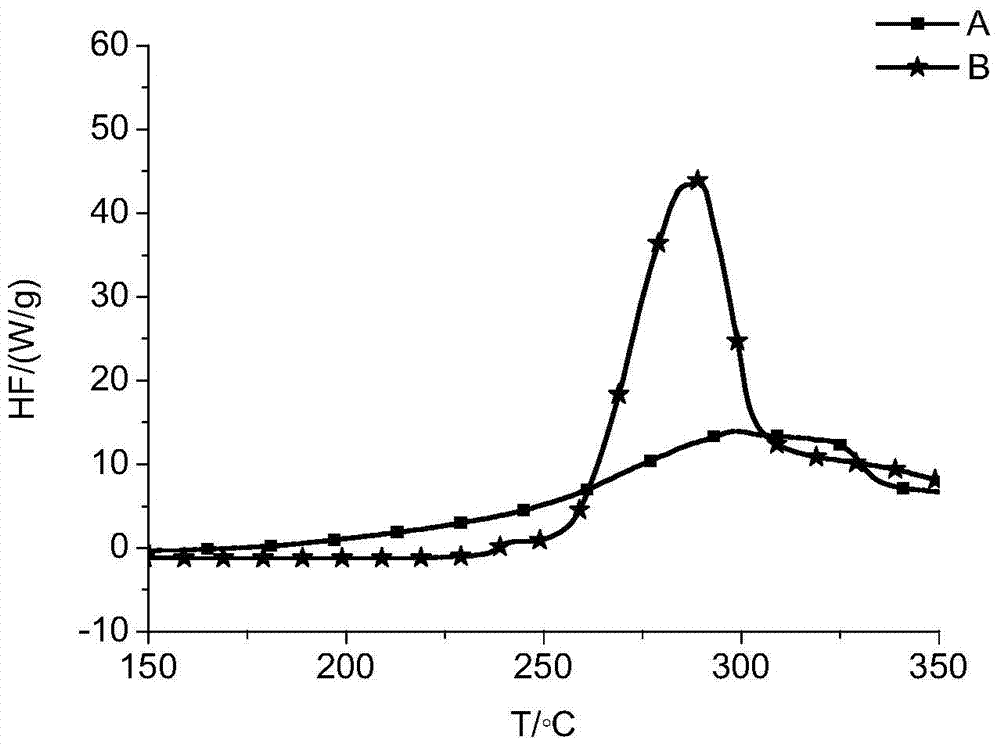

Antioxidant based on N-(4-anilinophenyl)-amide carboxylic acid ester

ActiveCN105018179ARaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesInduction timeChemistry

The present invention relates to an antioxidant based on N-(4-anilinophenyl)-amide carboxylic acid ester, wherein the antioxidant is characterized in that R1 is selected from alkyl, and R2 is selected from alkyl. According to the present invention, the antioxidant is added in the lubricating oil so as to be used, and can be used within a temperature of 230 DEG C; the initial oxidation temperature of the lubricating oil can be effectively improved with the antioxidant, the oxidation induction time of the lubricating oil can be effectively prolonged during the use process of the antioxidant as the lubricating oil anti-oxidation additive, the antioxidant can be effectively dissolve in the lubricating base oil, the use temperature is high, the maximum temperature is 230 DEG C, and the tribological properties of the lubricating oil are basically not affected; with the application of the antioxidant as the lubricating oil anti-oxidation additive in the lubricating base oil, the lubricating oil oxidation deterioration can be effectively controlled; and with the method of the present invention, the risk of the lubricating oil oxidation deterioration can be effectively reduced, and the service life of the lubricating oil can be prolonged.

Owner:梧州科润润滑科技有限公司

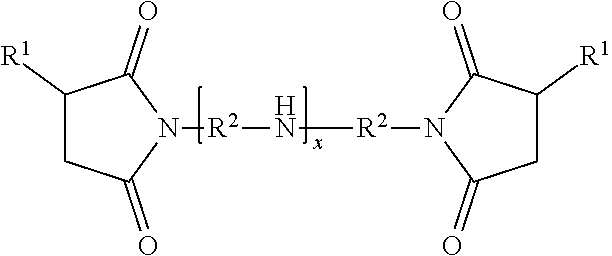

Reduced engine deposits from dispersant treated with copper

InactiveUS20160298052A1Reduce depositionProlonged oxidation induction timeAdditivesEngineeringCopper

The invention provides a lubricating composition containing an oil of lubricating viscosity and a dispersant treated with copper reagent. The invention further relates to methods of lubricating an internal combustion engine by supplying the described lubricating composition to the internal combustion engine. The invention further relates to the use of a dispersant treated with copper to reduce deposits on the inner surfaces of engine components.

Owner:THE LUBRIZOL CORP

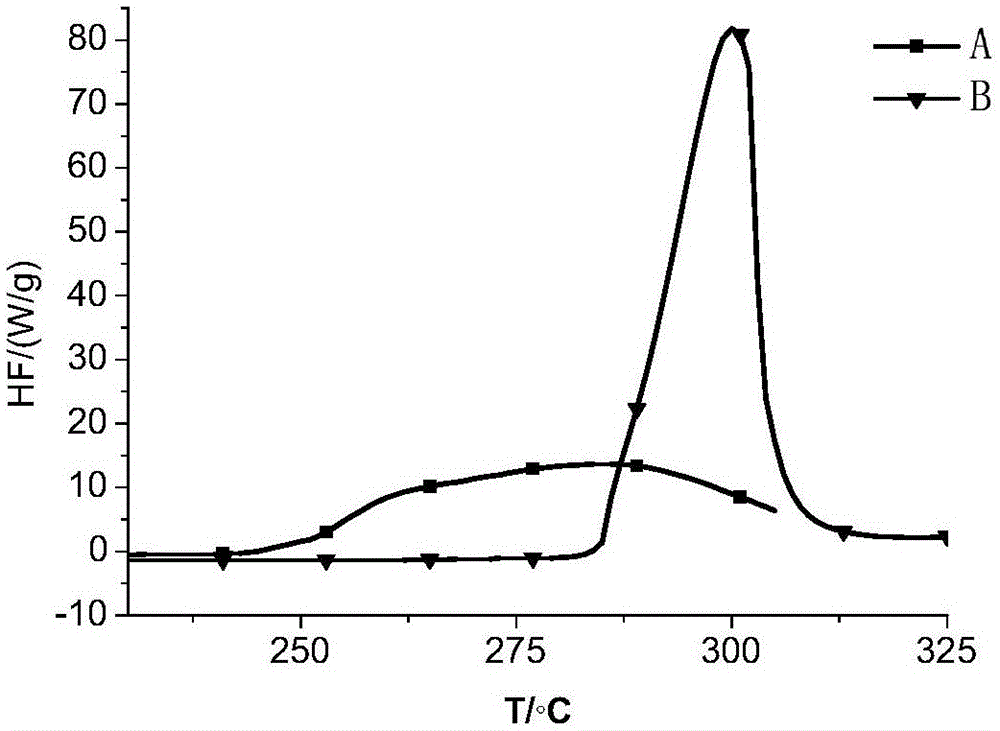

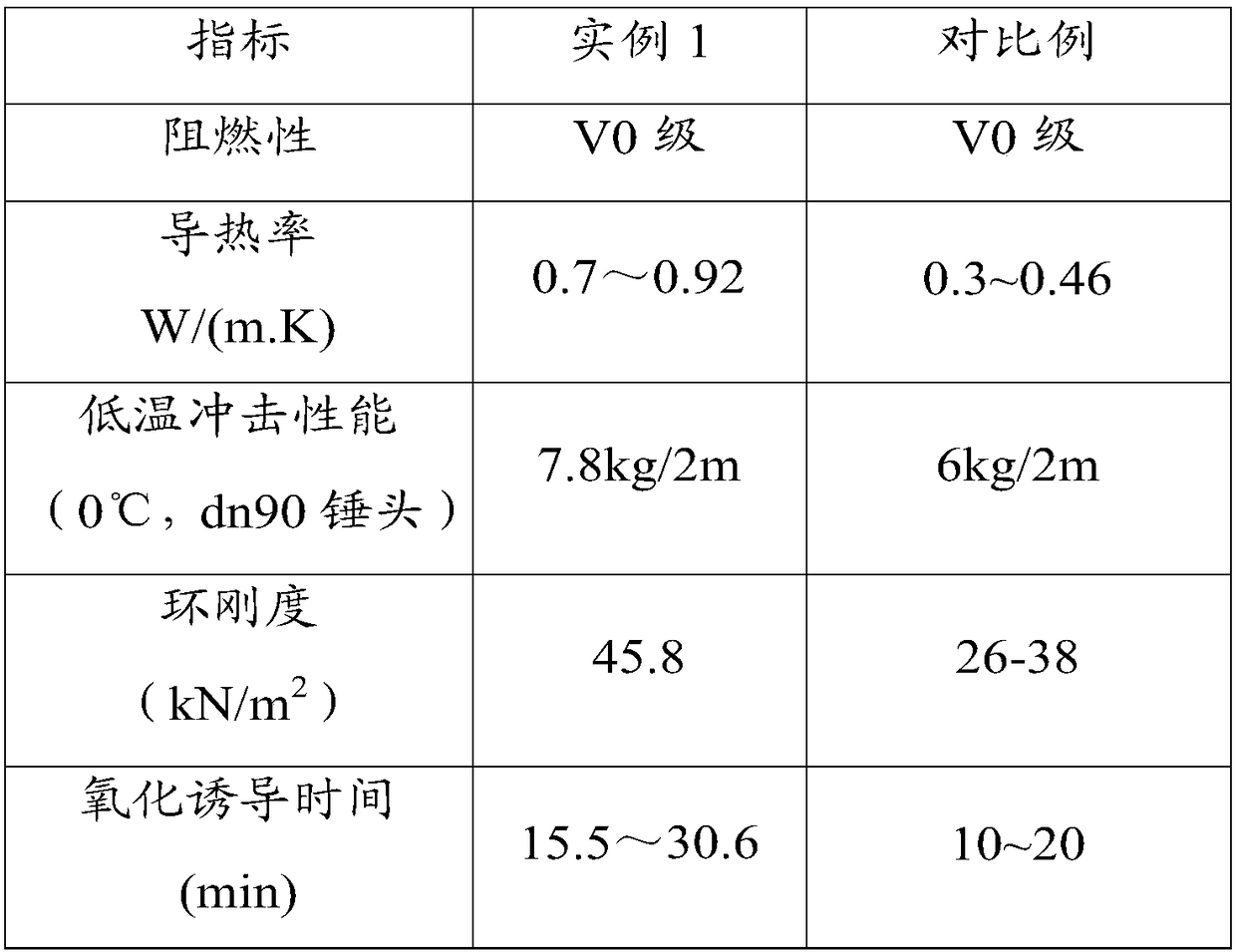

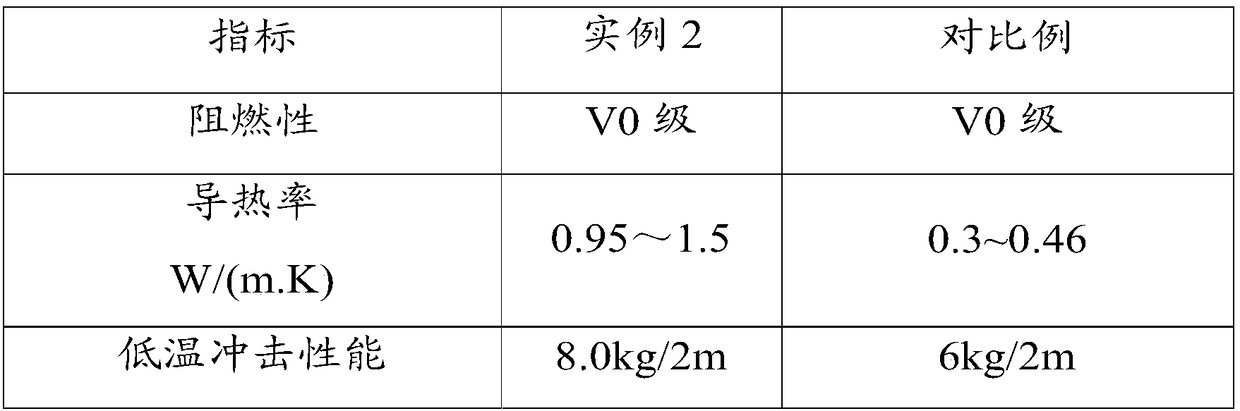

A flame retardant high heat dissipation modified polypropylene power pipe and its preparation method

ActiveCN105482262BImprove cooling effectImprove low temperature and impact resistanceHeat conductingAntioxidant

The invention provides a flame-retardant high-heat-dissipation modified polypropylene electric tubular product and a preparation method thereof and belongs to the field of electric equipment. The flame-retardant high-heat-dissipation modified polypropylene electric tubular product is mainly prepared from, by weight, 750-1000 parts of polypropylene, 5-200 parts of diamond powder, 5-100 parts of graphene, 5-80 parts of silver powder, 10-180 parts of aluminum nitride powder, 1-10 parts of oxidized polyethylene wax, 10-100 parts of an ethylene-propylene copolymer, 10-100 parts of an ethylene-vinyl acetate copolymer, 10-80 parts of ethylene-propylene-diene-terpolymer rubber, 50-150 parts of heat-resistant polyethylene, 5-30 parts of an antioxidant, 80-300 parts of a flame retardant, 10-100 parts of a rigid packing material, 5-30 parts of a coupling agent and 50-150 parts of chlorinated polypropylene. The electric tubular product can be prepared by using the materials through blending, granulation and extrusion molding and has excellent flame-retardant and heat-conducting performances.

Owner:康泰塑胶科技股份有限公司

Polypropylene composite material with strong dimensional stability and preparation method of polypropylene composite material

InactiveCN106674729AProlonged oxidation induction timeTo expand the applicationMicroorganism based processesFermentationProcedure AgentsAntioxidant

The invention discloses a polypropylene composite material with strong dimensional stability and belongs to the technical field of polypropylene materials. Polypropylene is used as a basic material, raw material kinds and a formula of a composite material are optimized, and a production process is improved; a calcium fruit fiber, modified nano carbon, a polyethylene / winter rye peptide complex, bitter almond oil and a composite antioxidant are scientifically compounded and are synergized with other assistants, thus finally obtaining the polypropylene composite material with good physical properties and the strong dimensional stability, wherein by means of the calcium fruit fiber, the impact resistance of the polypropylene composite material can be remarkably improved, and the production cost is reduced; the calcium fruit fiber is easily biodegraded; according to the modified nano carbon, high temperature resistance, shrinkage resistance, relative tensile load, strength, toughness and elasticity modulus of the polypropylene composite material can be remarkably improved; according to the polyethylene / winter rye peptide complex, the low temperature resistance of the polypropylene composite material can be greatly improved; according to the bitter almond oil and the composite antioxidant, the lubricating property and the antioxidant property of the polypropylene composite material can be effectively improved.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

Preparation method of PVC pipe with high weather resistance

InactiveCN108948564AGood weather resistanceProlonged oxidation induction timeTubular articlesWeather resistanceParaffin oils

A preparation method of a PVC pipe with high weather resistance comprises the following steps: (1) the PVC pipe with the high weather resistance comprises the following components: 100 parts of SG-3 type PVC, 20-30 parts of toluene isocyanate, 1-5 parts of iron oxide powder, 2-3 parts of a heat transfer agent, 3-6 parts of a heat absorbent, 2-7 parts of paraffin, 1-3 parts of a low-lead compound stabilizer and 2-6 parts of erucyl amide; weighing the components, sequentially feeding all the components into a material mixing machine, uniformly mixing at 80-100 DEG C to obtain a mixture; (2) extruding and forming the mixture by using a screw extruder; (3) cooling and shaping the pipe through a vacuum cooling sizing method after the pipe is extruded. According to the method disclosed by the invention, by improving the formula of the pipe, the inner wall and the outer wall of the pipe produced by the SG-3 type PVC raw material are smooth and smooth, and on the premise that the original mechanical strength is kept, so that the problem that the weather resistance is poor in the using process of the pipeline is solved, the production efficiency and the product percent of pass are obviouslyimproved, and the manufacturing cost of products is greatly reduced.

Owner:胡建芳

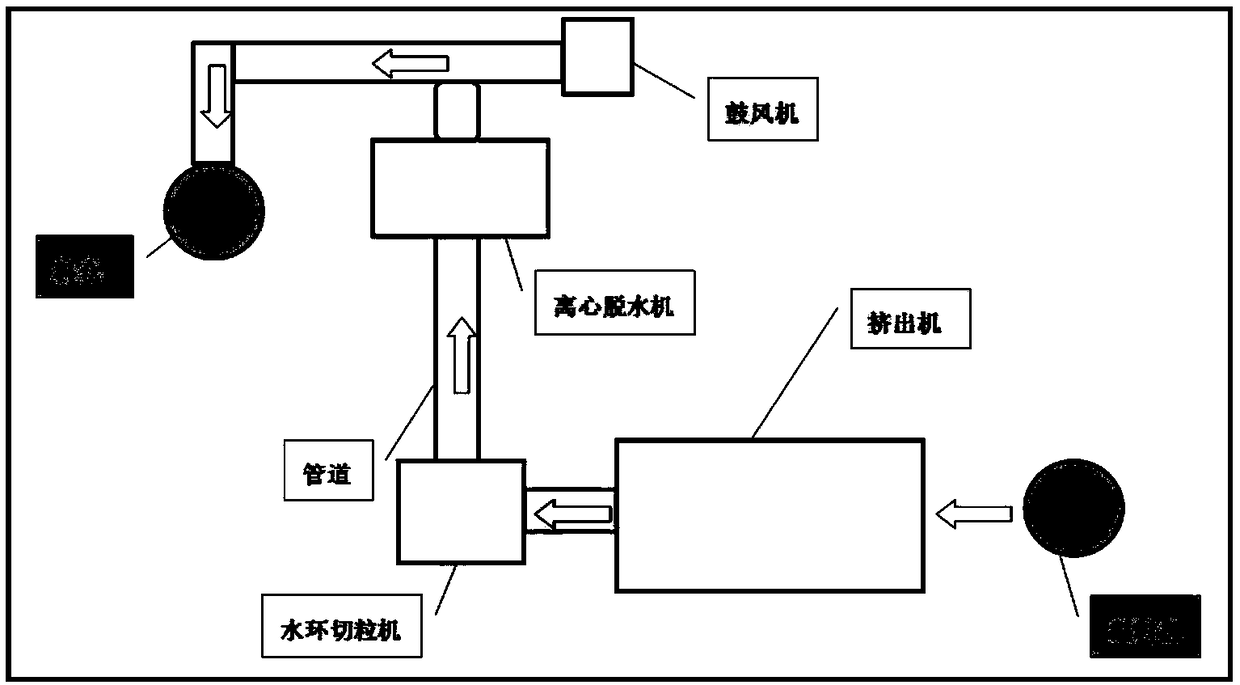

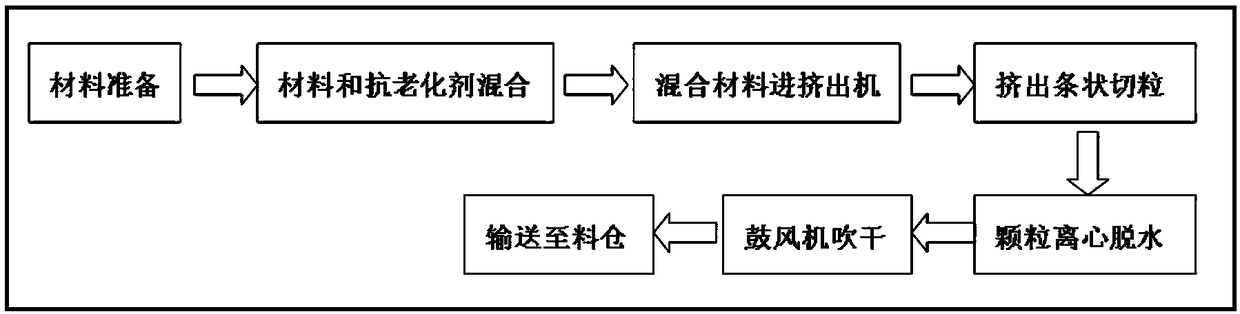

Production system for anti-aging linear low density polyethylene resin

InactiveCN109228252AImprove anti-agingImprove aging resistanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a production system for anti-aging linear low density polyethylene resin. The production system comprises a material mixer, an extruder, a water-ring pelletizing machine and acentrifugal dehydrator which are sequentially connected by a pipeline; a blower is connected with a stock bin by a first pipeline; the output end of the centrifugal dehydrator is connected with the first pipeline. The production system disclosed by the invention has the beneficial effects that other properties of linear low density polyethylene resin are not changed and anti-aging performance is enhanced, so that oxydation induced time (200 DEG C) of the linear low density polyethylene resin can reach 100 minutes or above, the phenomena of cracking, deformation and the like of injection molding products within 15 years can be avoided and stable performance of the injection molding products can be ensured.

Owner:GUANGDONG MINGHUA MACHINERY

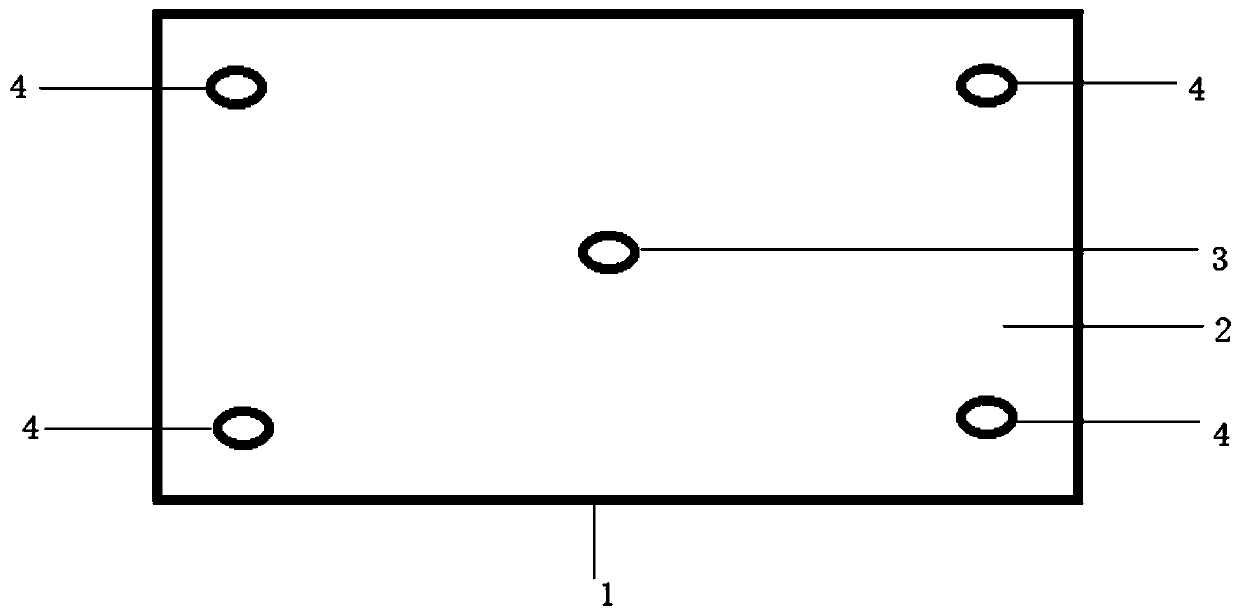

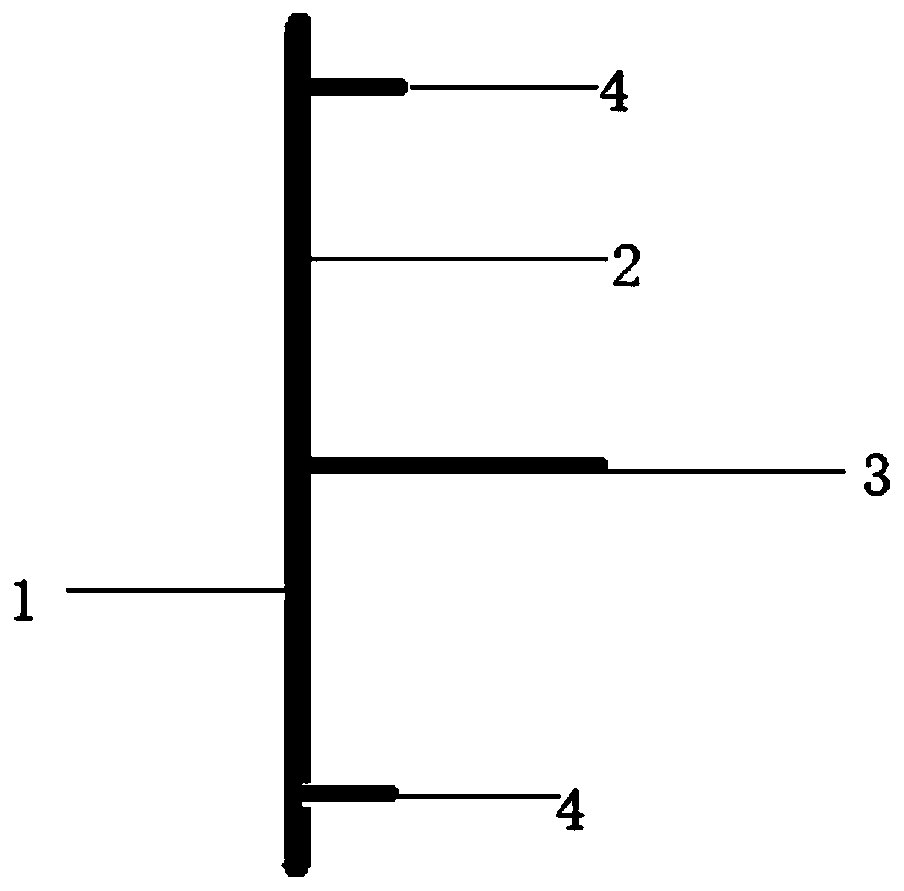

A method for producing plastic trays using a hollow blow molding machine

ActiveCN106926439BSmall toleranceStrong impact resistanceDomestic articlesBlow moldingMechanical engineering

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

Multifunctional lubricating oil and preparation method thereof

InactiveCN113717774AReduce consumptionImprove pass rateLubricant compositionElastomerChitosan nanoparticles

The invention discloses multifunctional lubricating oil which is characterized by being prepared from the following components as raw materials in parts by weight: 1-3 parts of cyano ethyoxyl phosphine sulfate polyquaternium, 0.3-0.6 part of 6-(dibutylamino)-1, 3, 5-triazole-2, 4-dithiol, 0.5-1.2 parts of lipophilic graphene nanosheets, 0.3-0.6 part of tea polyphenol chitosan nanoparticles, 0.3-0.5 part of a dispersing agent, 0.4-0.6 part of N, N-bis (2-ethoxyl)-2-aminoethanesulfonic acid, 0.1-0.2 part of thermoplastic elastomer TPEE and 60-70 parts of base oil. The invention also provides a preparation method of the multifunctional lubricating oil. The multifunctional lubricating oil is good in comprehensive performance and performance stability, excellent in anti-oxidation stability, excellent in extreme pressure performance, wear resistance and lubricating performance and diversified in function.

Owner:泗县唯澳生物技术开发有限公司

Antioxidants based on n-(4-anilinophenyl)-amidocarboxylates

ActiveCN105018179BRaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesAntioxidantCarboxylic acid

The present invention relates to an antioxidant based on N-(4-anilinophenyl)-amide carboxylic acid ester, wherein the antioxidant is characterized in that R1 is selected from alkyl, and R2 is selected from alkyl. According to the present invention, the antioxidant is added in the lubricating oil so as to be used, and can be used within a temperature of 230 DEG C; the initial oxidation temperature of the lubricating oil can be effectively improved with the antioxidant, the oxidation induction time of the lubricating oil can be effectively prolonged during the use process of the antioxidant as the lubricating oil anti-oxidation additive, the antioxidant can be effectively dissolve in the lubricating base oil, the use temperature is high, the maximum temperature is 230 DEG C, and the tribological properties of the lubricating oil are basically not affected; with the application of the antioxidant as the lubricating oil anti-oxidation additive in the lubricating base oil, the lubricating oil oxidation deterioration can be effectively controlled; and with the method of the present invention, the risk of the lubricating oil oxidation deterioration can be effectively reduced, and the service life of the lubricating oil can be prolonged.

Owner:梧州科润润滑科技有限公司

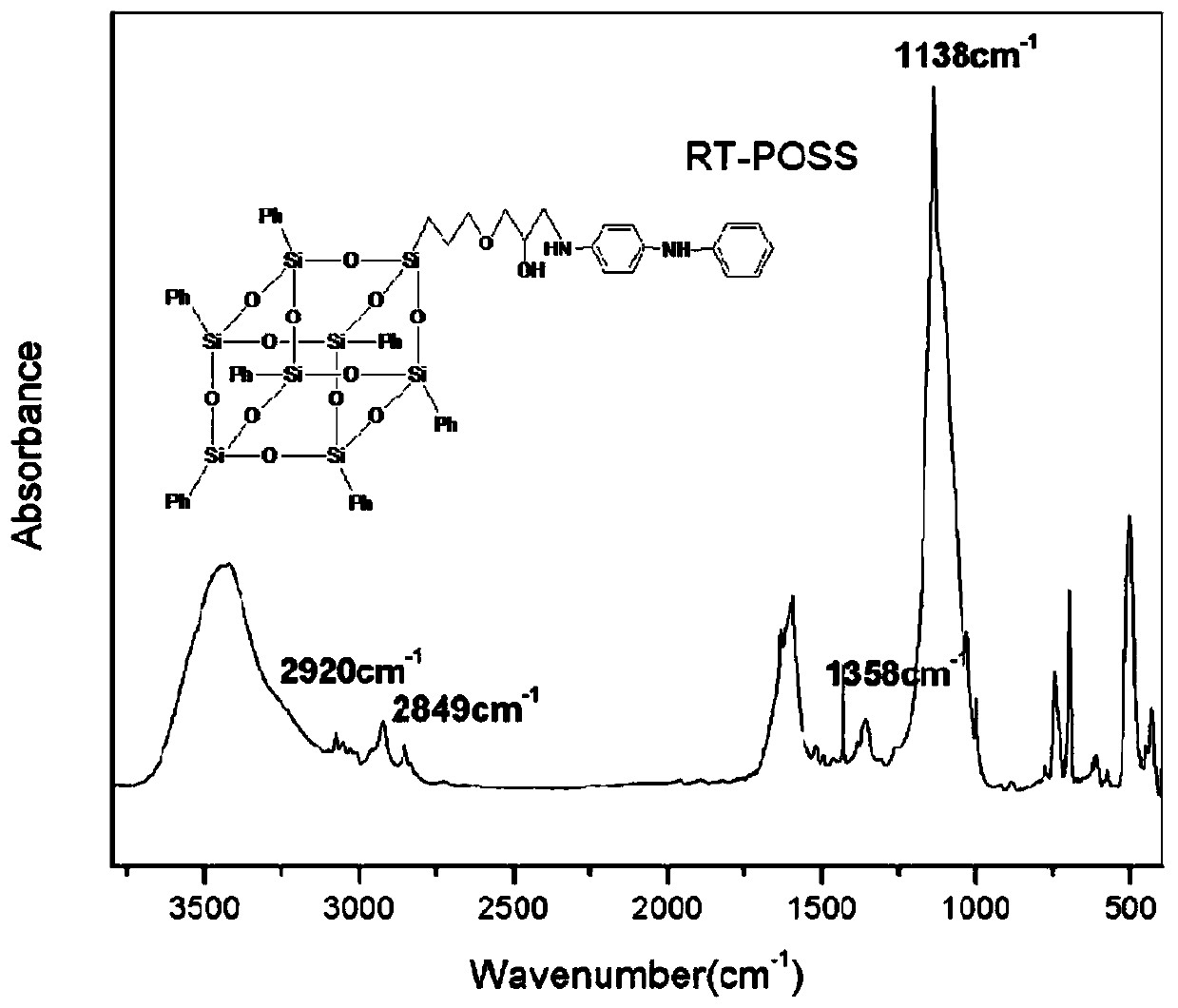

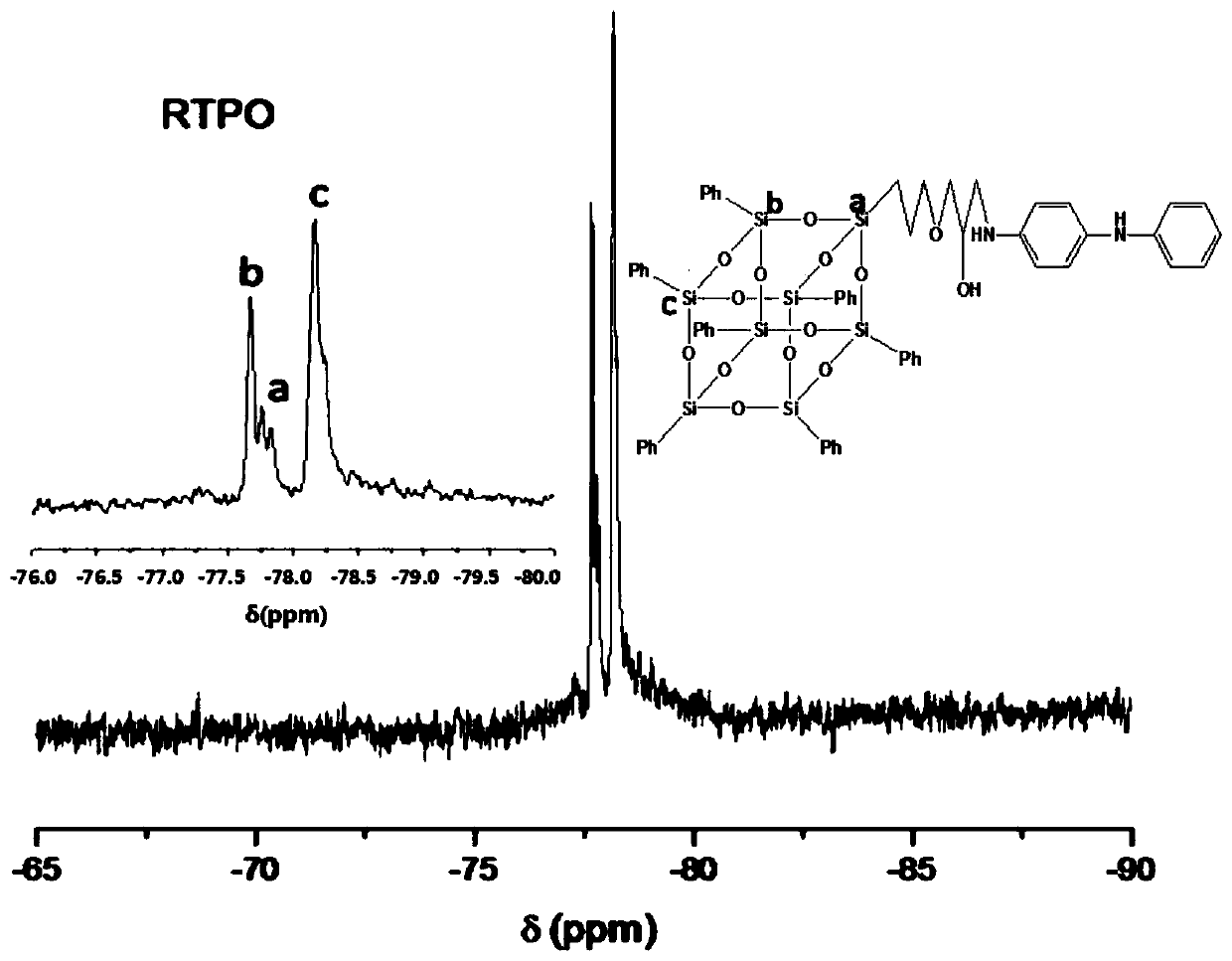

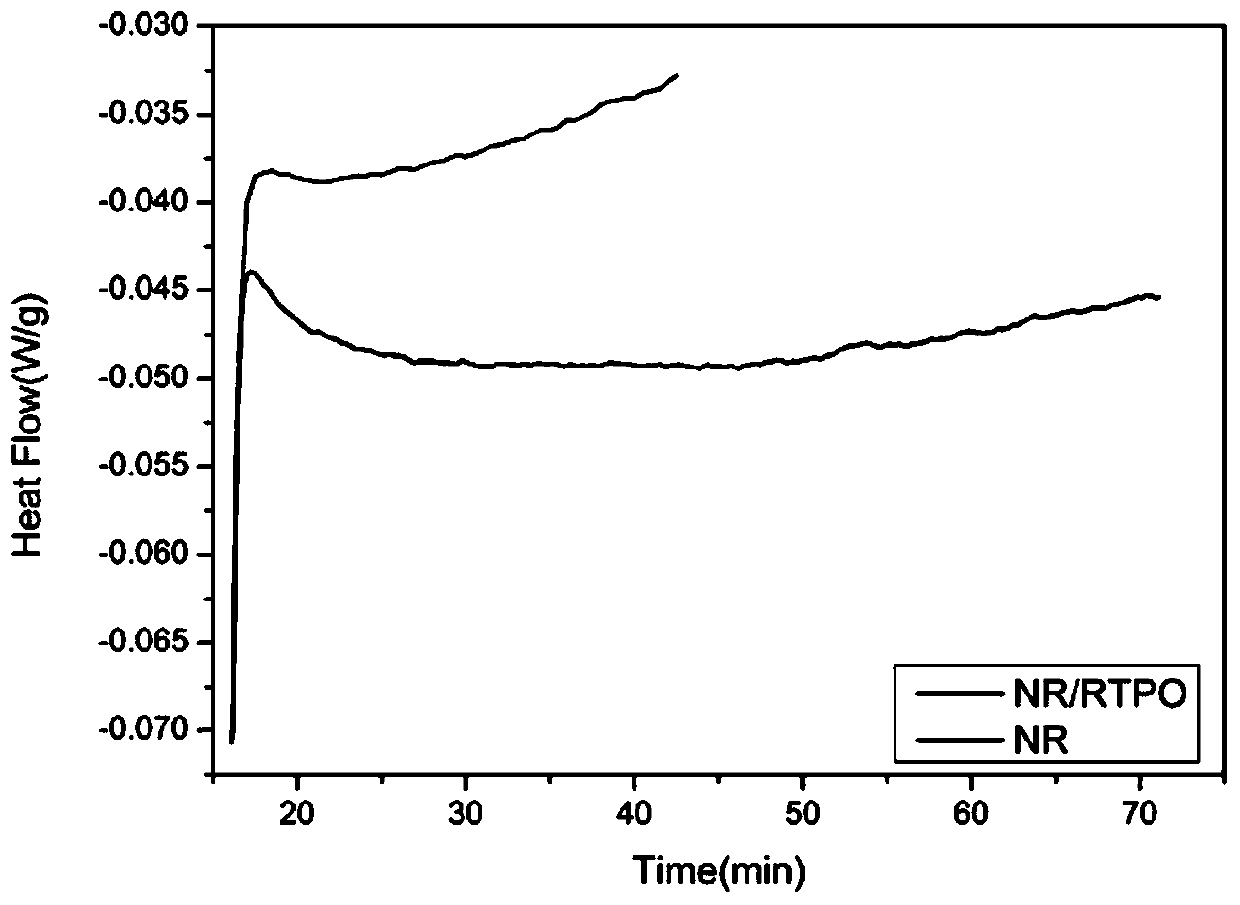

Non-migratory poss grafted antioxidant and preparation method thereof

ActiveCN107641325BImprove migration resistanceProlonged oxidation induction timeElastomerPolymer science

The invention provides a non-migrating POSS (polyhedral oligomeric silsesquioxane) grated anti-ageing agent and a preparation method thereof; active amino groups in an amine anti-ageing agent are allowed to react with active groups in single-active functional group POSS, the amine anti-ageing agent is chemically grafted to POSS molecules, and the POSS grafted anti-ageing agent is obtained. The novel anti-ageing agent of higher anti-oxidant property and higher anti-migrating property is provided for the ageing protection for rubber and other rubber elastomers, and anti-ageing efficiency is improved without affecting structural properties of rubber and other rubber elastomers.

Owner:SICHUAN UNIV

Method for preparing gear oil

InactiveCN108441291AImprove Oxidation StabilityHigh degree of branchingLubricant compositionOxygenOleic Acid Triglyceride

The invention discloses a method for preparing gear oil, and belongs to the technical field of lubricating oil. According to the preparation method, easily biodegradable long-chain fatty acid oleic acid and organism forming components of amino acids are used as raw materials for preparing an amino acid type biodegradation promoter with a structure similar to a natural amino acid lipid body, the thermal stability is good, and the amino acid type biodegradation promoter cannot decompose or degenerate; on the other hand, a synthesized additive can improve the anti-rust property of gears, and theadditive covers the metal surfaces of the gears, so that oxygen, moisture or other corrosive substances in the air can be isolated to a certain extent. The invention solves the problems that existingcommon gear oil is not prominent in the abrasion-resistant effect of gears, gear oil has a good effect is added with fluorides which can pollute the environment, the base oil of gear oil has poor oxidation stability and poor low-temperature fluidity, the oil easily deteriorates, and the gear oil is corroded and abraded.

Owner:蒋春霞

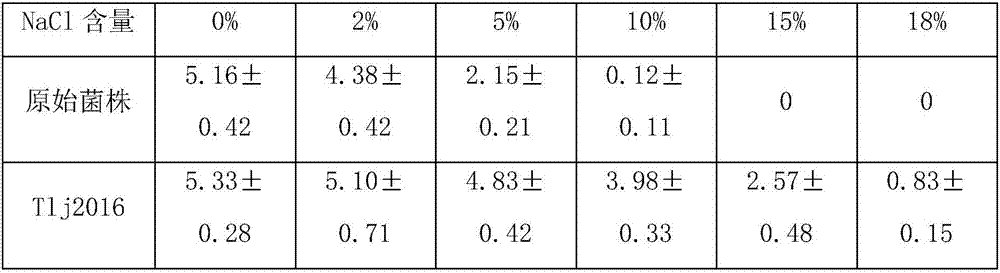

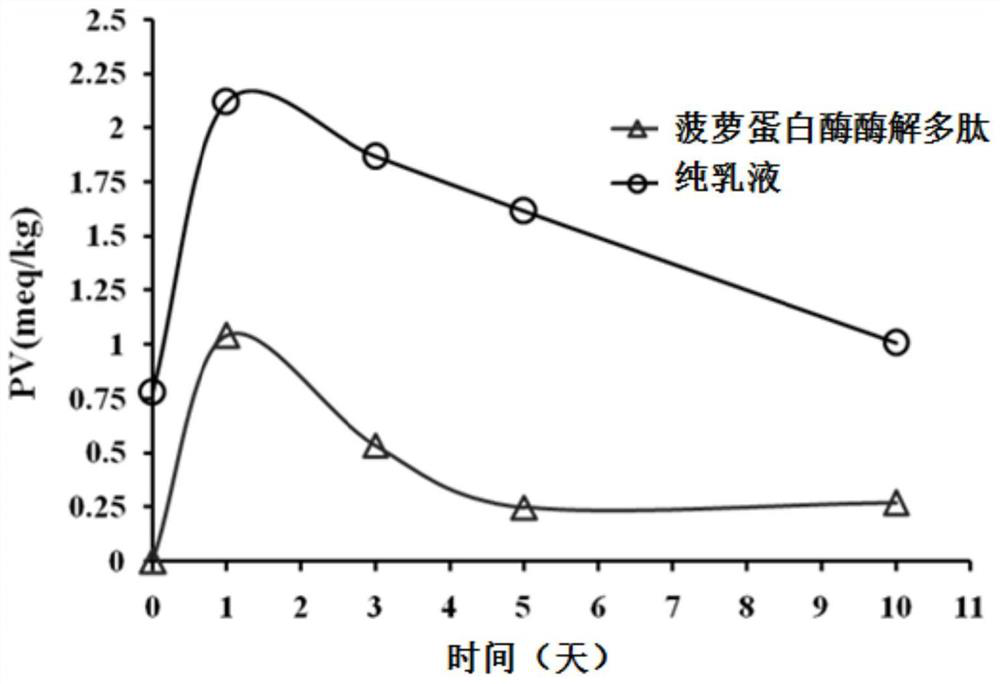

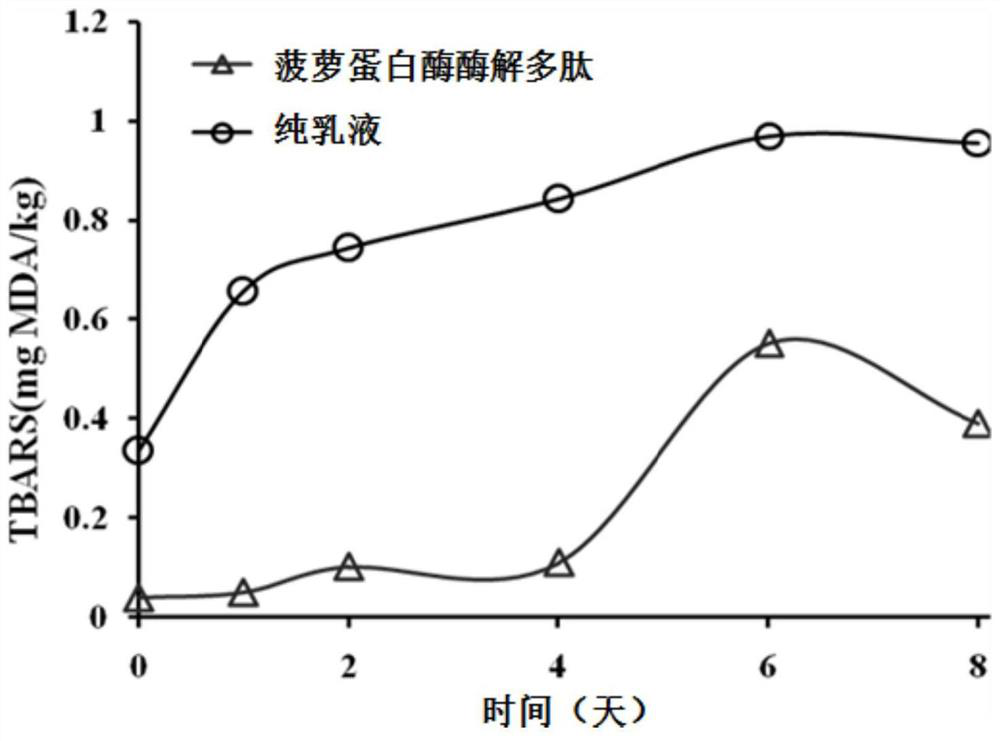

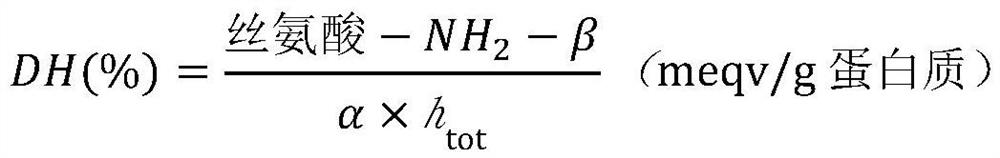

A kind of active peptide with anti-oil oxidation function and its preparation method and application

ActiveCN109797183BInhibit peroxidationProlonged oxidation induction timeHydrolasesFatty substance preservation using additivesBiotechnologyOil processing

The invention discloses an active peptide with anti-oil oxidation function, its preparation method and application, and belongs to the technical field of plant-derived bioactive peptides. The present invention selects the by-product of oil plant processing, that is, the oil plant after oil extraction, as a raw material, and through the steps of protein extraction, infrared pretreatment, proteolysis, freeze-drying, extraction of lipophilic part, vacuum concentration and drying, etc., a DPPH free radical scavenging compound is prepared. , metal ion chelation, inhibit lipid peroxidation, prolong the oxidation induction time of vegetable oil, enhance the stability of emulsion and other functional properties of anti-lipid oxidation peptide, can be used as a natural antioxidant in the storage and preservation of oil and other oil-containing foods, It solves the problem of product deterioration and harmful products caused by oil oxidation, and prolongs the shelf life of food; the method of the invention has great practical and social significance for curbing oil oxidation, ensuring food safety, and promoting technological progress.

Owner:JIANGNAN UNIV

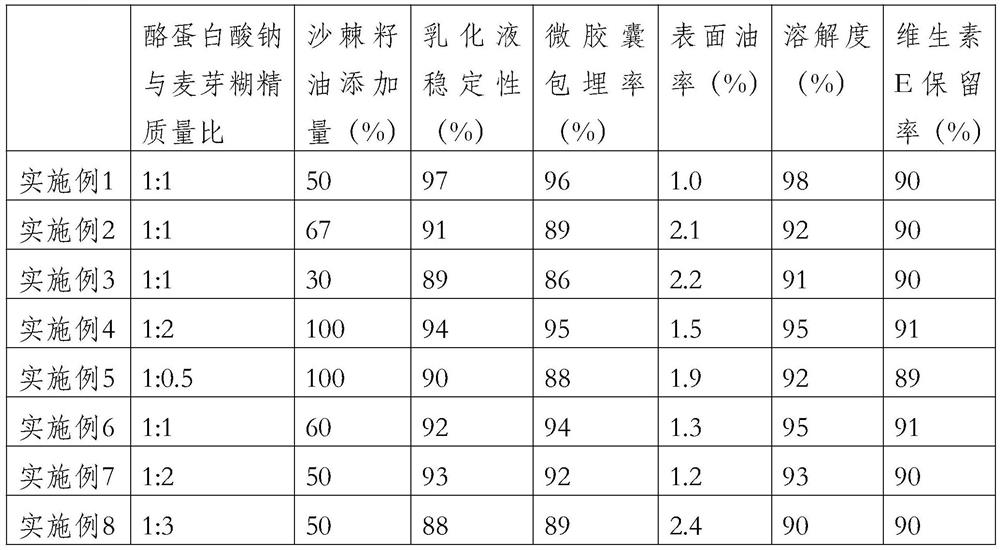

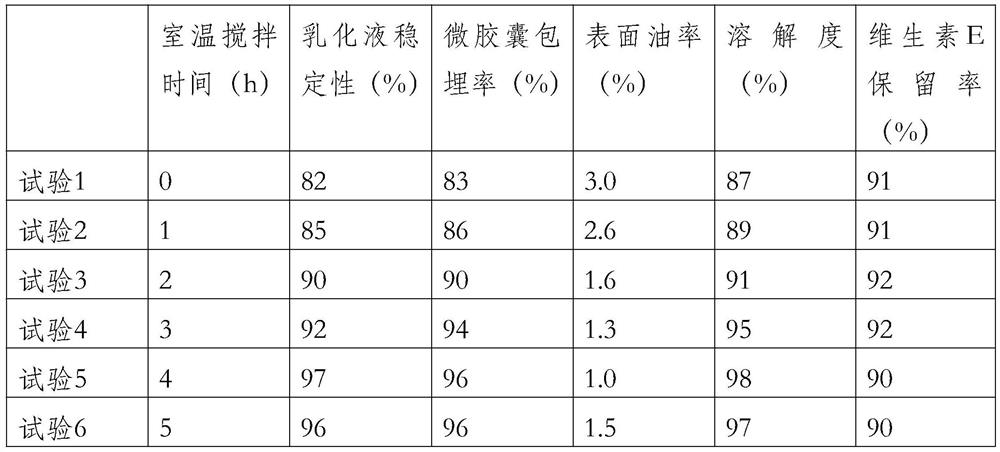

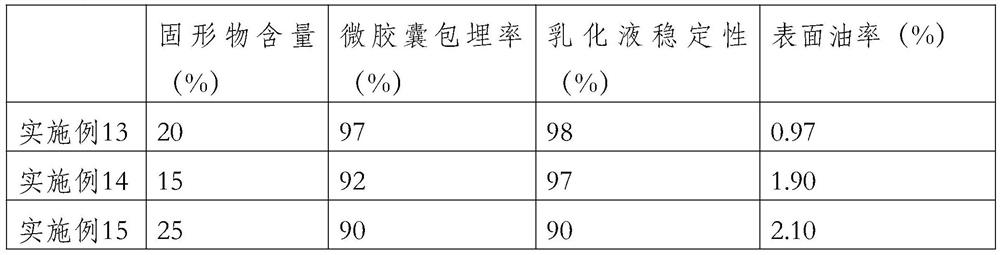

A preparation method and product of seabuckthorn seed oil microcapsules and its application in seabuckthorn chewable tablets

ActiveCN109700030BSimple ingredientsSimple processConfectionerySweetmeatsSpray driedNutrients substances

The invention discloses a preparation method and product of seabuckthorn seed oil microcapsules and its application in seabuckthorn chewable tablets. material to obtain a wall material solution; after dissolving the wall material solution in a water bath at 50-60°C for 30 minutes, stirring at room temperature for 2-4 hours to fully dissolve, adding seabuckthorn seed oil, and shearing at a speed of 20000r / min for 5- 8 minutes to obtain seabuckthorn seed oil primary emulsion; homogenize the seabuckthorn seed oil primary emulsion twice under a pressure of 30-40 MPa to obtain seabuckthorn seed oil microcapsule emulsion, then spray dry to obtain the seabuckthorn seed oil Microcapsules. The invention provides a preparation method and product of seabuckthorn seed oil microcapsules with uniform particle size distribution, good solubility, high embedding rate, less loss of nutrients and good oxidation stability and its application in seabuckthorn chewable tablets.

Owner:JIANGNAN UNIV

Polypropylene composite with good dimensional stability and preparation method thereof

InactiveCN108570183AProlonged oxidation induction timeTo expand the applicationFungiMicroorganism based processesProcedure AgentsPolymer science

The invention discloses polypropylene composite with good dimensional stability and belongs to the technical field of polypropylene materials. Polypropylene is used as a base material; the types and formulas for the raw materials of the composite are optimized; a production technique is improved; scientific formulating is performed on: Prunus humilis that helps significantly improve impact resistance of the polypropylene composite, provides good biodegradability and reduces production cost; modified nano carbon that may significantly improve high temperature resistance, shrinking resistance, relative tension load, strength, toughness and elastic modulus in the polypropylene composite; polyethylene / winter rye peptide composite that may greatly improve low temperature resistance of the polypropylene composite; bitter almond oil and a composite antioxidant which may effectively improve lubricating performance of the polypropylene composite and oxidation resistance thereof. The above materials cooperate with other processing aids to finally produce the polypropylene composite that has good physical properties and good dimensional stability.

Owner:NINGXIA YANCHI WEST CHANGXIANG AGRI BIOTECH

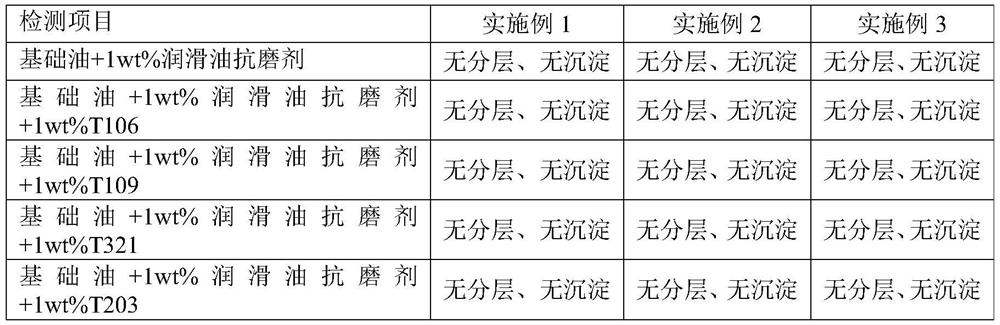

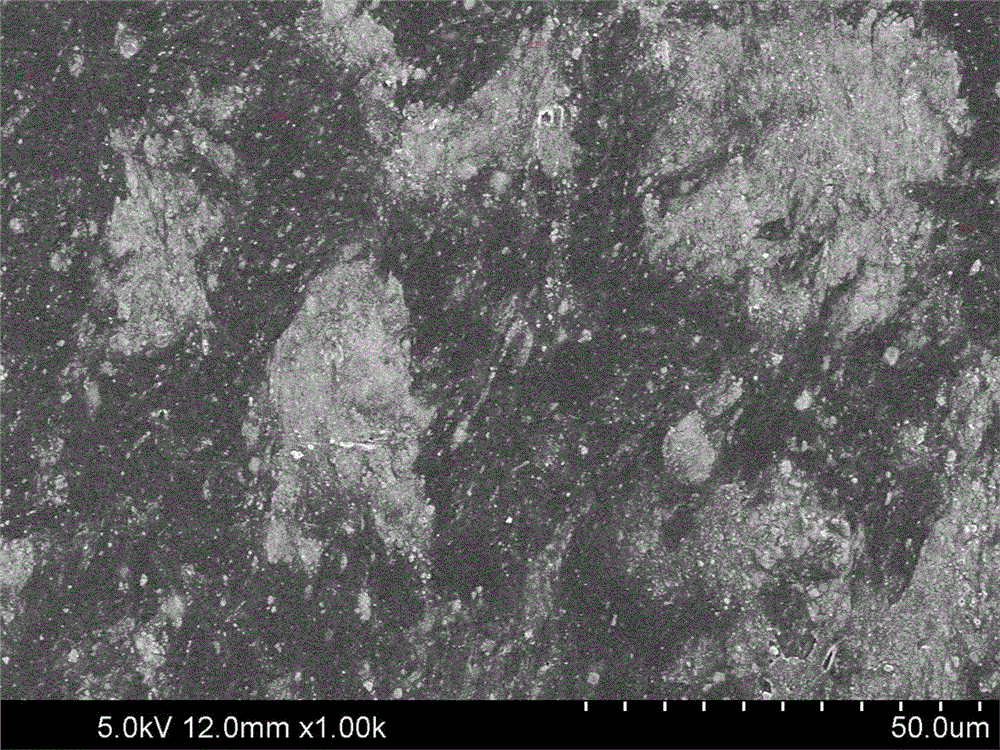

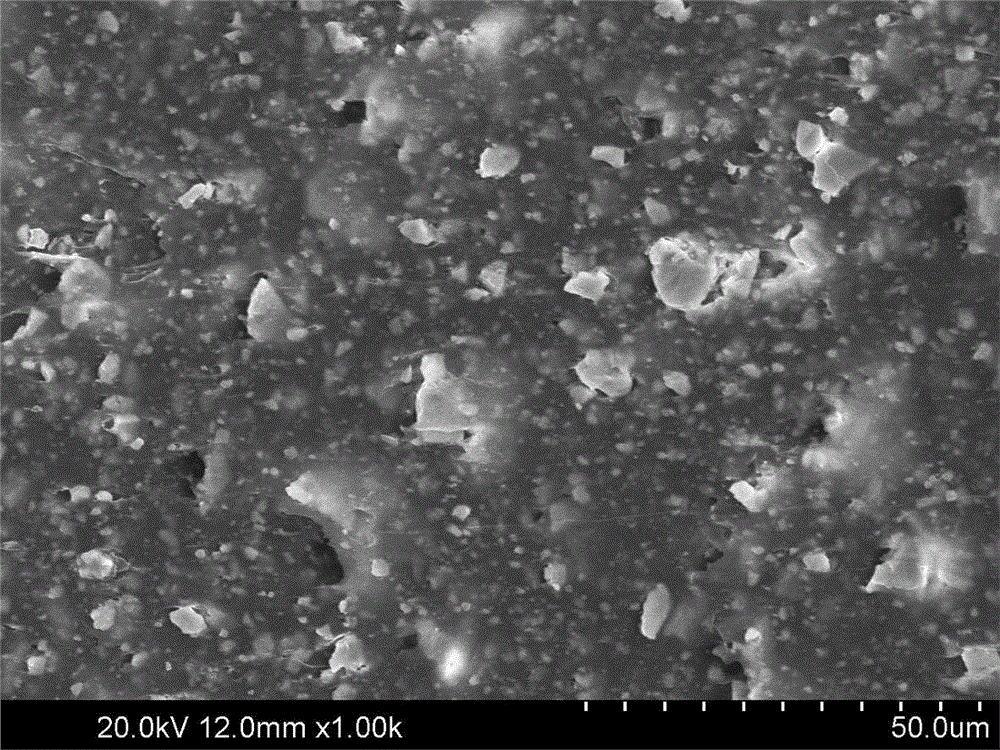

Preparation method of lubricating oil anti-wear agent

ActiveCN110982582BCompatibility is goodHigh viscosityLubricant compositionXylyleneTrithiocarbonic acid

The invention belongs to the technical field of lubricating compositions characterized by reaction product additives with unknown or incompletely determined structures, and specifically relates to a preparation method of lubricating oil anti-wear agents, which includes the following steps: A. Using n-butyl acrylate as raw material; Azobisisobutyronitrile is used as the initiator, s, s'-bis (α,α'-methyl-α"-acetic acid) trithiocarbonate is used as the chain transfer agent, and the polymerization reaction is carried out in the presence of a solvent, and then the pressure is reduced Distill the solvent to obtain polymer A; B. Use cationic resin as a catalyst and esterify polymer A with ethanolamine to obtain polymer A containing -NH. 2 Polymer B of the group; C. Polymer B and molybdenum trioxide are heated to 127-135°C in the presence of N,N-dimethylformamide and xylene, refluxed for 4-5 hours, and then cooled to 60 -80°C, add hydrazine hydrate and continue stirring for 2-3 hours until the reaction substrate turns blue-green or dark green. Distillate the xylene under reduced pressure and filter. The lubricating oil anti-wear agent prepared by the method of the present invention has good raw material compatibility stability.

Owner:重庆昆崧科技有限公司

A kind of polyethylene sound-absorbing composite material for building drainage pipeline and preparation method thereof

The invention relates to a noise-reducing polyethylene composite material for a drainage pipeline of a building and a preparation method thereof, belonging to the technical field of inorganic powder modified high-molecular polymers. The material comprises the following raw materials in parts by weight: 30-50 parts of polyethylene, 0.01-0.02 part of a peroxide initiator, 0.5-1 part of vinyl unsaturated silane, 50-60 parts of barium sulfate, 1-3 parts of a dispersant, 3-5 parts of titanium dioxide, 0.2-0.5 part of an antioxidant and 1-3 parts of carbon black. The material provided by the invention effectively solves the problem that existing drainage pipeline of the building is noisy and poor in high temperature resistance and chemical corrosion resistance. Raw materials are input to a high speed mixer to be mixed firstly, and then pelleted through a twin-screw extruder to obtain the composite material. The composite material provided by the invention has the advantages of mute-resistant effect, chemical corrosion resistance, heat resistance and shock resistance of a common tubular product, simple processing process, low cost and suitability of preparing the drainage pipeline of the building.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

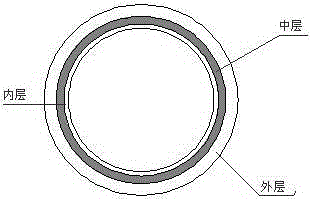

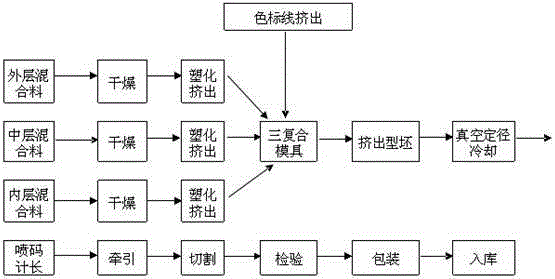

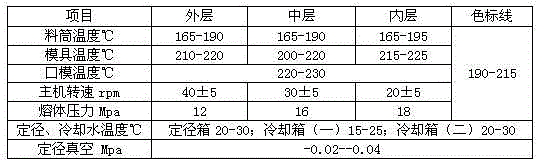

A method for manufacturing a three-resistance light-blocking composite pipe

ActiveCN103225716BImprove mechanical propertiesImprove aging resistanceRigid pipesInternal pressureHeat deflection temperature

The invention discloses a method for preparing an anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe, relates to a technology for preparing the anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe, and belongs to the technical field of novel material and process. The method is characterized in that the anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe is formed by co-extrusion of three layers, wherein the thickness ratio of an inner layer to a middle layer and the thickness ratio of the middle layer to an outer layer are 0.618. The method has the beneficial effects that the anti-microbial performance of the pipe is improved; the anti-oxygen capacity and anti-ultraviolet capacity of the pipe are improved; by changing the crystallinity of a material and the size of a spherical crystal, the heat distortion temperature of the pipe is improved, and the coefficient of linear expansion is reduced; the impact strength, particularly low-temperature impact strength, of the pipe is improved; and the internal pressure resistance strength and hardness of the pipe are improved.

Owner:甘肃顾地塑胶有限公司 +1

Non-sulphur and phosphorus antiwear and friction reducing multifunctional additive agent and preparation method

InactiveCN101381649BRaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesAntioxidantInternal combustion engine

The invention belongs to the technical field of lubricating oil and discloses a non-sulfur non-phosphorus anti-wear and antifrictional multifunctional additive and a preparation method thereof. The compositions of the additive comprise a friction modifier, an antiwear agent, an antioxidant, a detergent dispersant, and an antirusting agent. Firstly, the friction modifier is synthesized, then the friction modifier, the antiwear agent, the detergent dispersant, the antioxidant, and the antirusting agent with the needed amount are orderly mixed according to the proportion, and the mixture is heated to between 50 and 70 DEG C under the stirring and then is stirred evenly. The additive can be widely applied to various lubricating oil products including lubricant base oil or lubricant oil finished products, such as internal combustion engine oil, gear oil and so on, and is added into lubricating oil of an internal combustion engine with 3 to 20 weight percentage during the use. The additive can greatly improve the abrasion resistance and the antifriction performance of oil products, can also apparently improve the initial oxidation temperature and the oxidation induction time of the oil products, effectively suppress the viscosity of the oil products from increasing, and ensure that the high-temperature antioxidation performance of the internal combustion engine oil is greatly improved.

Owner:天津市东宝润滑油脂有限公司

Antioxidant of n‑(4‑anilinophenyl)‑amidosulfide compounds

ActiveCN104987304BEffective control of oxidative deteriorationDelay oxidative deteriorationOrganic chemistryAdditivesHydrogenOxygen

The invention discloses anti-oxygen of an N-(4-anilino phenyl)-acylamino sulfoether compound. The anti-oxygen is characterized in that according to the requirement of ester oil applied under the wide temperature range condition (120 DEG C-230 DEG C), a N-(4-anilino phenyl)-acylamino sulfoether compound serves as efficient / multi-effect lubricating oil anti-oxygen, and the oxidation resistance of lubricating oil is improved. The structure of the type of compound is the N-(4-anilino phenyl)-acylamino sulfoether compound shown in the graph 1, R1 and R2 are selected from alkyl, and R3 and R4 are selected from hydrogen or alkyl. The service performance of the lubricating oil can be improved through the compound.

Owner:梧州科润润滑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com